Low-carbon free-cutting sulfur narrow strip steel and production method thereof

A production method and easy-cutting technology, applied in the field of strip steel production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

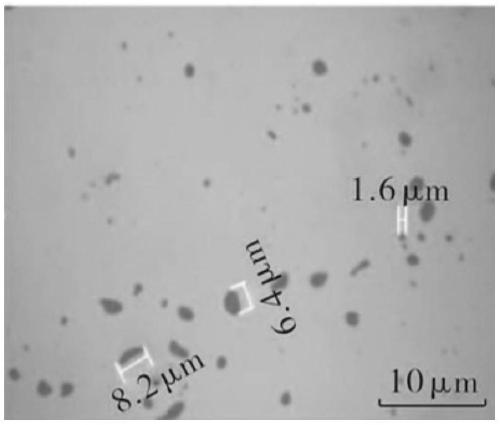

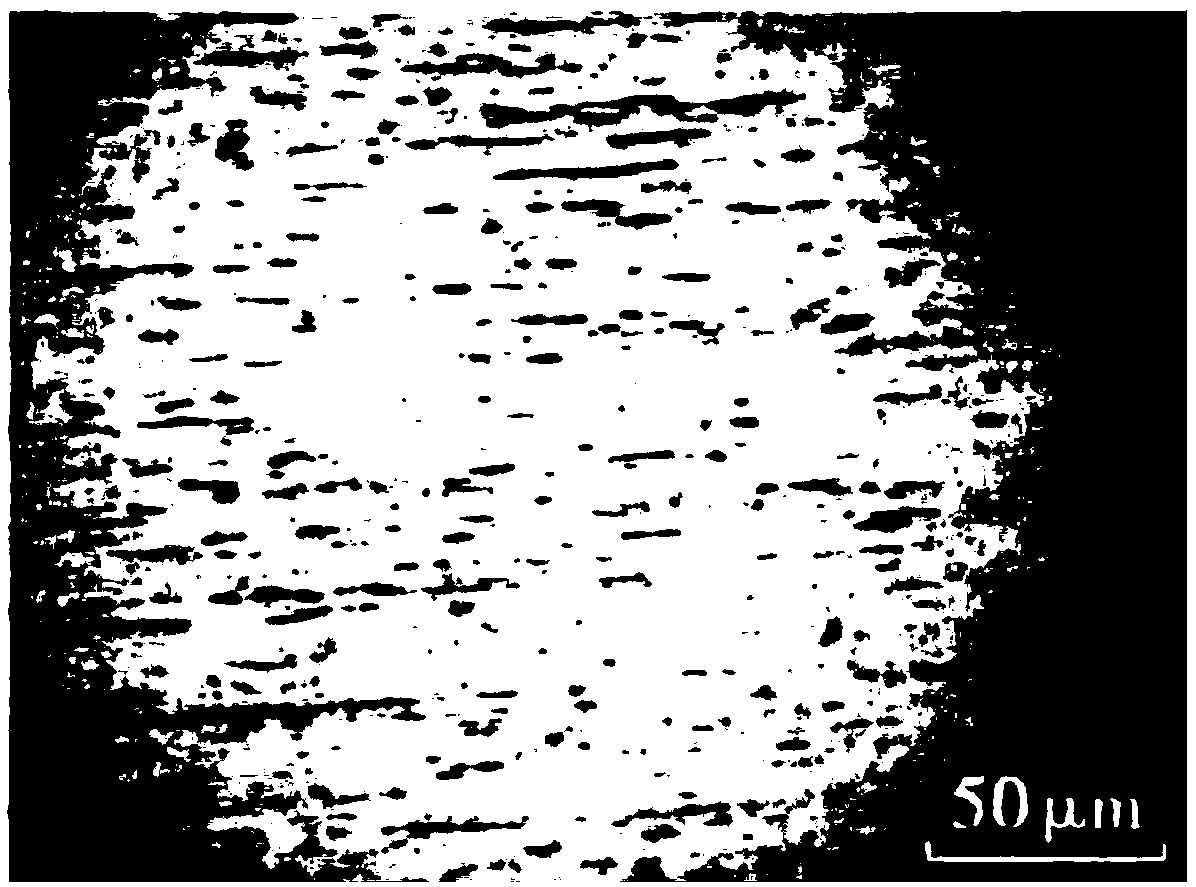

Embodiment 1

[0104] A 50t electric furnace smelting-LF refining-continuous casting-620mm narrow strip line process is used to produce low-carbon sulfur-based free-cutting narrow strip steel. The amount of molten iron in the furnace raw materials is 40 tons, and the amount of scrap steel is 10 tons. 100kg of sulfur-iron alloy Add steel scraps into the electric furnace. The electric furnace smelting process mainly carries out decarburization and temperature rise. The end point of the electric furnace smelting is 0.04% C content, P content 0.03%, tapping temperature 1690°C, when the electric furnace tapping reaches 1 / 5, add 2kg / per ton of steel silicon calcium barium for deoxidation, followed by alloying by adding low-carbon ferromanganese and phosphorus ferromanganese along with the steel flow. Immediately after the alloy is finished, add 300kg lightly burned dolomite and 400kg wollastonite along with the steel flow. Control the content of electric furnace slag flowing into the ladle to be ...

Embodiment 2

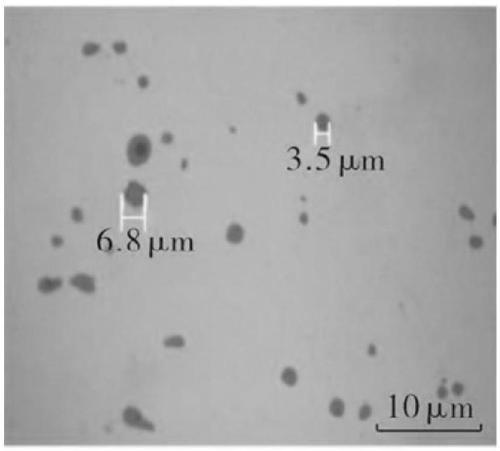

[0116] A 50t electric furnace smelting-LF refining-continuous casting-620mm narrow strip line process is used to produce low-carbon sulfur-based free-cutting narrow strip steel. The amount of molten iron in the furnace raw materials is 35 tons, and the amount of scrap steel is 15 tons. 80kg of sulfur iron Add steel scraps into the electric furnace. The electric furnace smelting process mainly carries out decarburization and temperature rise. The end point of the electric furnace smelting is 0.05% C content, P content 0.025%, the tapping temperature is 1700°C, and when the electric furnace tapping reaches 1 / 5, add 1.5kg with the steel flow Deoxidize with silicon calcium barium per ton of steel, then add low-carbon ferromanganese and ferrophosphorus for alloying with the steel flow, the addition of low-carbon ferromanganese is 14kg / ton of steel, and the addition of phosphorus ferromanganese is 0.8kg / ton of steel, Manganese is controlled according to the middle upper limit and pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com