A system for reducing slag accumulation and steady flow in zinc pot rolls

A zinc pot roll and slag accumulation technology, applied in coating, metal material coating process, hot dip plating process and other directions, can solve the problems of accelerating the growth of the alloy layer on the surface of the submerged roll, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The system for reducing slag accumulation and steady flow of zinc pot rolls according to the present invention will be further described below according to specific embodiments and accompanying drawings, but this description does not constitute an improper limitation to the technical solution of the present invention.

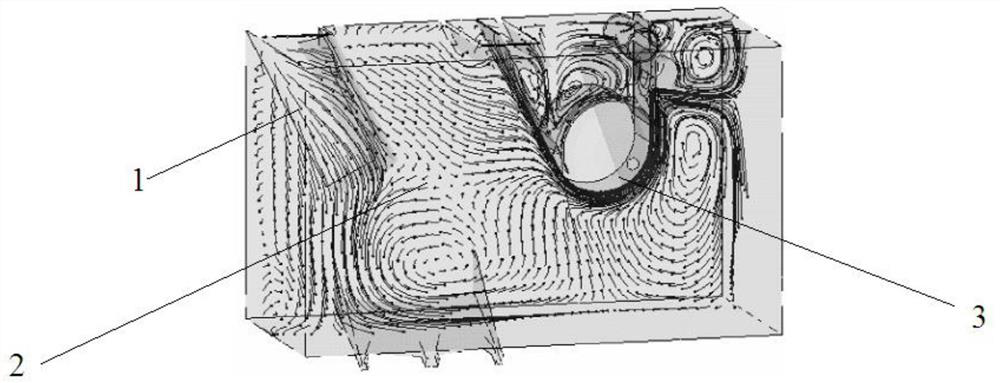

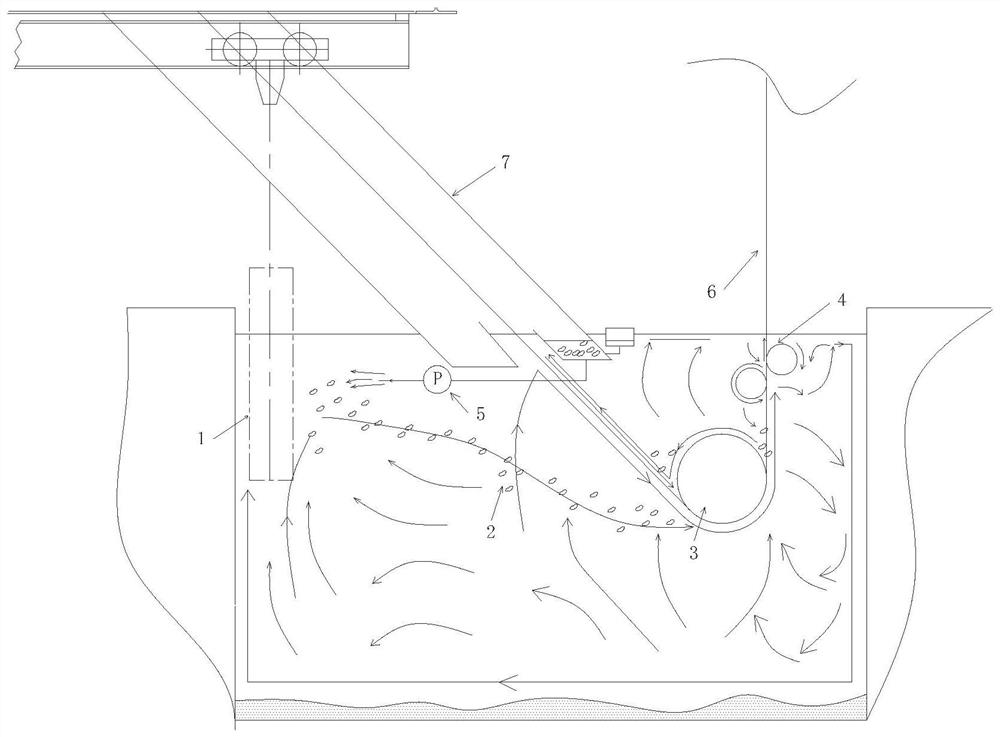

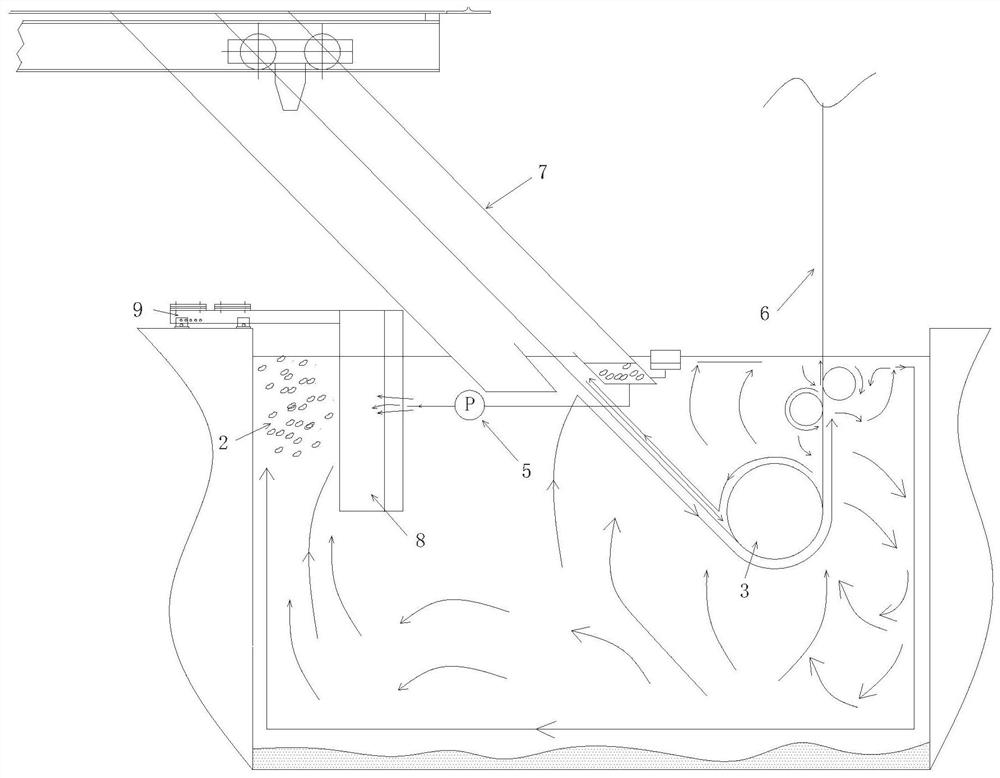

[0039] figure 2 It shows the zinc slag flow field of the zinc liquid in the zinc pot when the separator is just put in the system for reducing the slag accumulated in the zinc pot roll and stabilizing the flow in one embodiment of the system according to the present invention. image 3 It shows the zinc slag flow field of the zinc liquid in the zinc pot after the separator is placed in the system for reducing the slag accumulation and steady flow of the zinc pot rolls in one embodiment according to the present invention. to combine figure 2 and image 3 The working principle of the system for reducing zinc pot slag accumulation and steady flow descri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com