Machining method for magnetic steel precision part

A processing method and precision parts technology, which is applied in the field of parts processing and magnetic steel precision parts processing, and can solve the problems of magnetic steel parts processing such as chipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

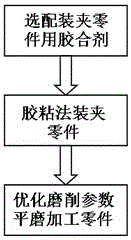

Image

Examples

Embodiment

[0016] The specific processing method is as follows:

[0017] a) Optional glue for clamping parts, the ingredients and weight percentage of the glue are: 27% succinic acid, 24% adipic acid, 26% 1,3-propylene glycol, 22% 1,4-butanediol %, catalyst 0.5%, crosslinking agent 0.5%. The preparation process of the adhesive is as follows: first, 27% of succinic acid, 24% of adipic acid, 26% of 1,3-propanediol and 22% of 1,4-butanediol are added to the organic In a nitrogen-protected reactor, the adhesive prepolymer is prepared after the temperature rise reaction, and then 0.5% glycerol crosslinking agent and 0.5% C-94 catalyst are added to the prepolymer, and then the temperature rises after the reaction The output is dried and ready to serve. The adhesive is firm in bonding, convenient in bonding and removal, biodegradable, and will not pollute the environment.

[0018] b) Clamping parts by gluing method, first fill the magnetic steel parts with weak magnetism to make them have we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com