Dry drilling slag salvaging operation device and use method thereof

The technology of a slag catcher and a transfer device is applied in the directions of drill pipe, drill pipe, earthwork drilling, etc. to achieve the effect of reliable working performance and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050]In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

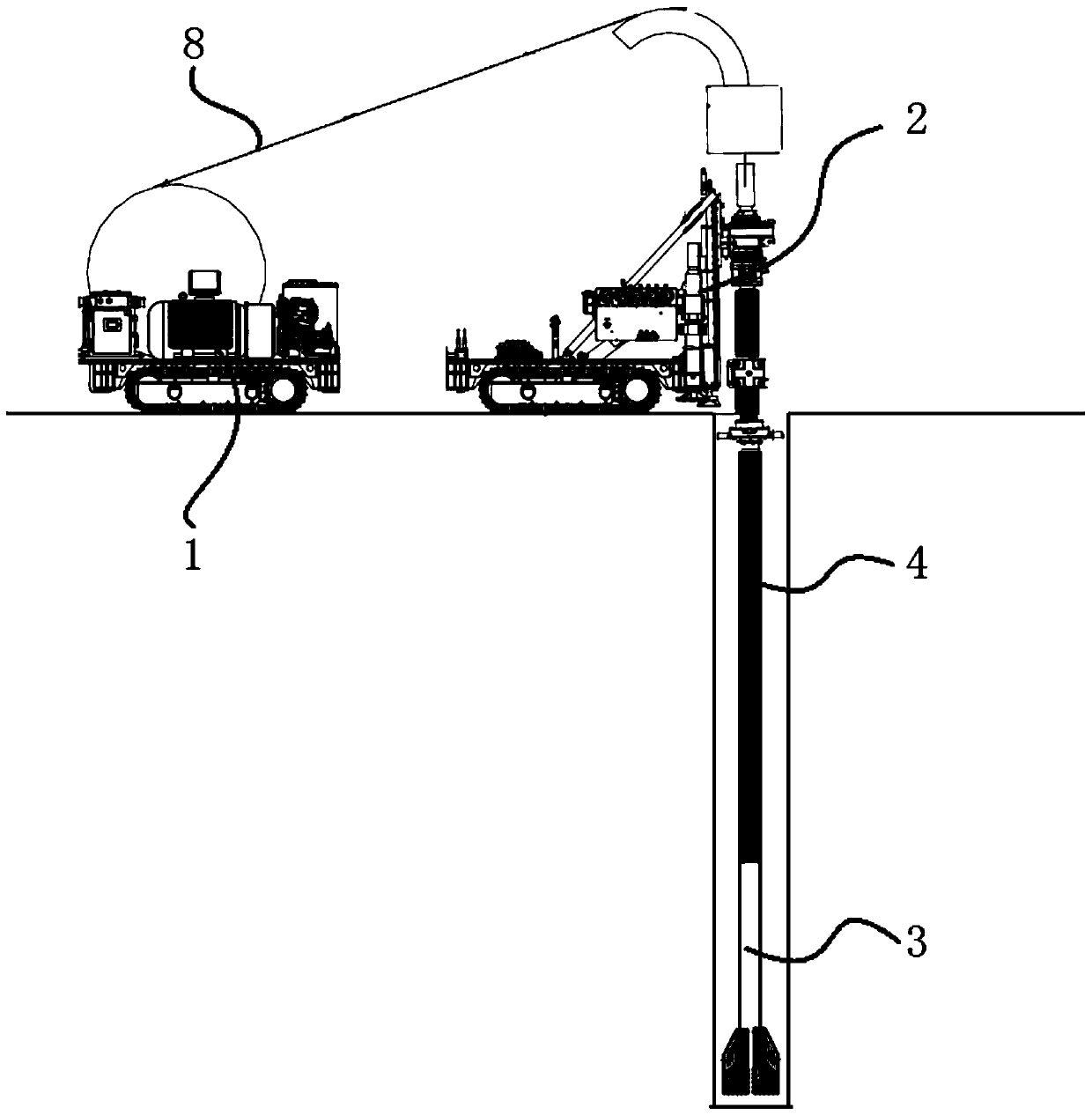

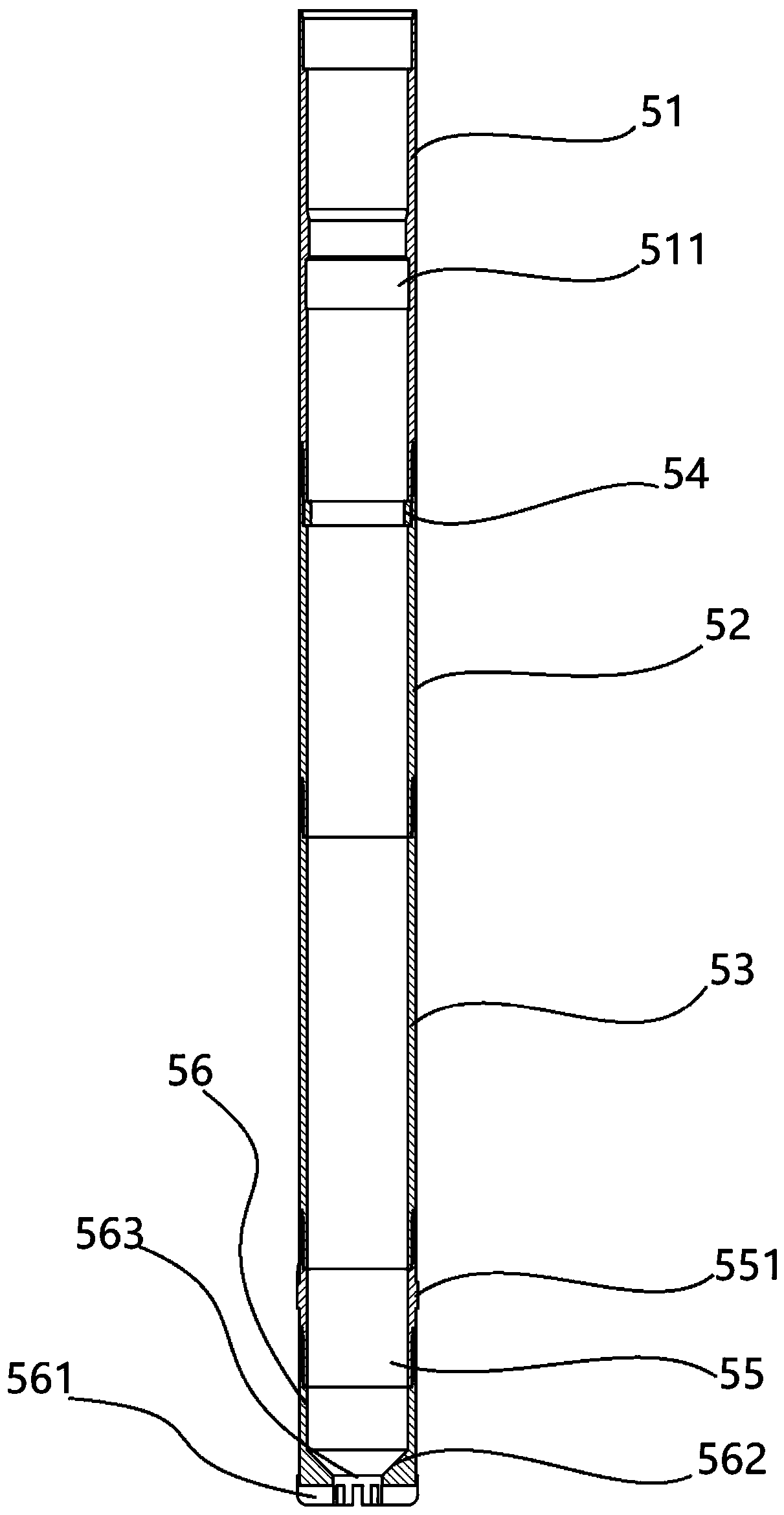

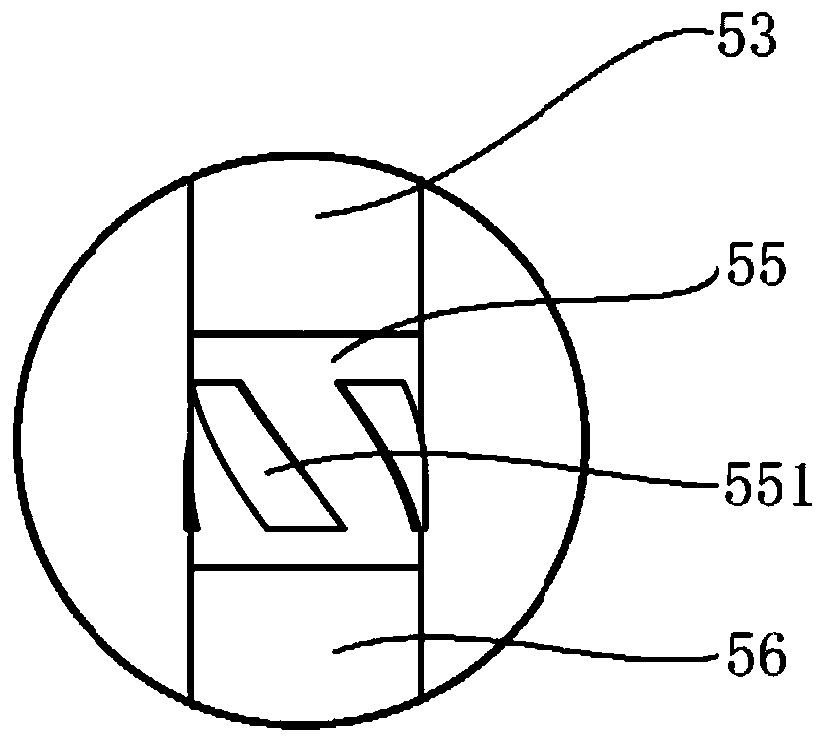

[0051] Such as Figure 1-14 As shown, the present invention discloses a dry drilling slag removal operation device, which includes continuous conduit operation equipment and a slag removal device 3;

[0052] The continuous conduit operation equipment includes a reel device 1 and a transfer device 2. The reel device 1 and the transfer device 2 are both equipped with a mobile base 1301, and the mobile base 1301 is equipped with a crawler belt 1302.

[0053] The reel device 1 is used to accommodate the continuous conduit 8. The reel device 1 includes a reel 1101 and a reel holder 1102. The reel 1101 is arranged on the reel holder 1102. The reel holder 1102 is provided with a pipe arrangement assembly 1103. The pipe arrangement assembly 1103 includes a support 1104 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com