Modified plastic particle for graphite pencil lead of plastic pencil

A technology of plastic granules and pencils, which is applied in the direction of pencil leads, applications, household appliances, etc., can solve the problems of not being better solved, easy to drop slag, writing comfort, plastic pencil leads are easy to break, etc., so that it is not easy to break, Solve the problem of easy breakage and slag, and improve the comfort of writing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

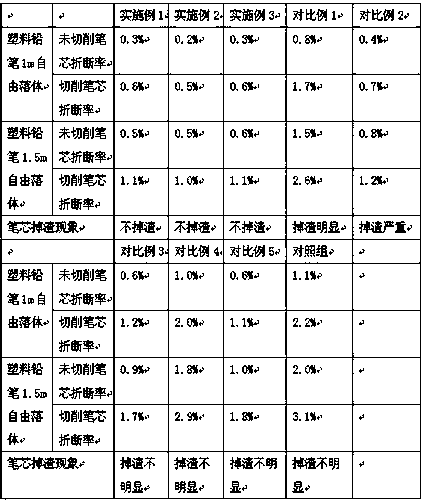

Examples

Embodiment 1

[0020] A modified plastic granule for plastic pencil graphite refill, the specific preparation method is as follows:

[0021] 1) Place the polymer plastic particles in a supercritical fluid carbon dioxide reactor for infiltration and swelling treatment. After the polymer plastic particles reach saturation, ultrasonic technology is assisted to ultrasonically treat the polymer plastic particles in the reactor. After the end, the supercritical fluid carbon dioxide in the reactor is released, the polymer plastic particles are taken out, and placed in a hot water bath for foaming treatment to obtain micro-foamed polymer plastic particles;

[0022] 2) Put the mixed solution of absolute ethanol and deionized water into a water bath, heat to 55°C, add aluminum sec-butoxide, stir at a speed of 500r / min until the solution is colorless and transparent, cool to room temperature and add A mixture of absolute ethanol and nitric acid, after stirring evenly, add acetone and aniline, and conti...

Embodiment 2

[0030] A modified plastic granule for plastic pencil graphite refill, the specific preparation method is as follows:

[0031] 1) Place the polymer plastic particles in a supercritical fluid carbon dioxide reactor for infiltration and swelling treatment. After the polymer plastic particles reach saturation, ultrasonic technology is assisted to ultrasonically treat the polymer plastic particles in the reactor. After the end, the supercritical fluid carbon dioxide in the reactor is released, the polymer plastic particles are taken out, and placed in a hot water bath for foaming treatment to obtain micro-foamed polymer plastic particles;

[0032] 2) Put the mixed solution of absolute ethanol and deionized water into a water bath, heat to 60°C, add aluminum sec-butoxide, stir at a speed of 650r / min until the solution is colorless and transparent, cool to room temperature and add A mixture of absolute ethanol and nitric acid, after stirring evenly, add acetone and aniline, continue ...

Embodiment 3

[0040] A modified plastic granule for plastic pencil graphite refill, the specific preparation method is as follows:

[0041] 1) Place the polymer plastic particles in a supercritical fluid carbon dioxide reactor for infiltration and swelling treatment. After the polymer plastic particles reach saturation, ultrasonic technology is assisted to ultrasonically treat the polymer plastic particles in the reactor. After the end, the supercritical fluid carbon dioxide in the reactor is released, the polymer plastic particles are taken out, and placed in a hot water bath for foaming treatment to obtain micro-foamed polymer plastic particles;

[0042] 2) Put the mixed solution of absolute ethanol and deionized water into a water bath, heat to 65°C, add aluminum sec-butoxide, stir at a speed of 800r / min until the solution is colorless and transparent, cool to room temperature and add A mixture of absolute ethanol and nitric acid, after stirring evenly, add acetone and aniline, continue ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com