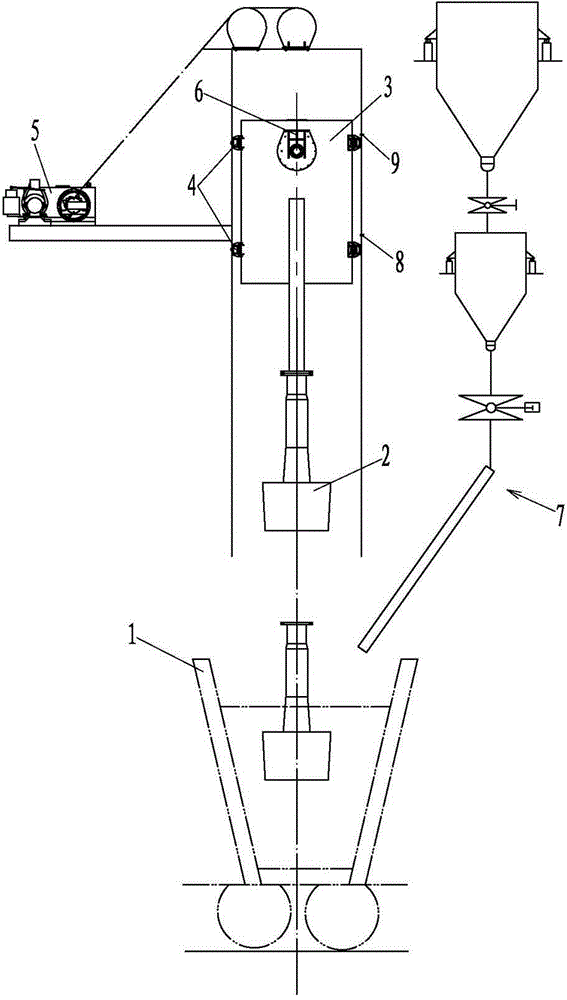

Intelligent control method of kr desulfurization lifting trolley system

A technology of intelligent control and trolley, which is applied in the direction of improving process efficiency, can solve the problems of accelerating the corrosion of the mixing head, prolonging the production cycle, and the difficulty of forming a stirring vortex, achieving the effect of shortening the production cycle and ensuring continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

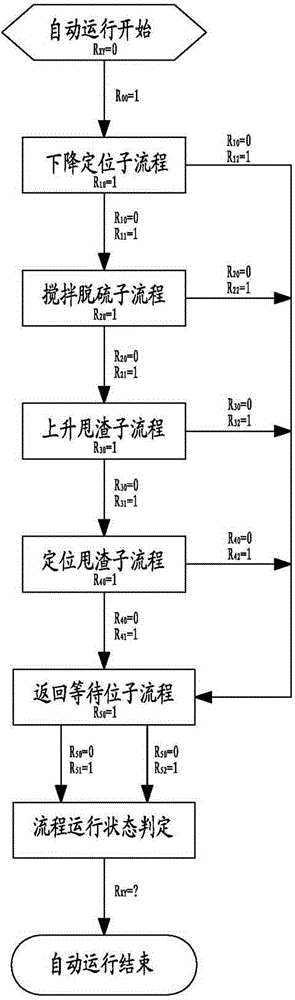

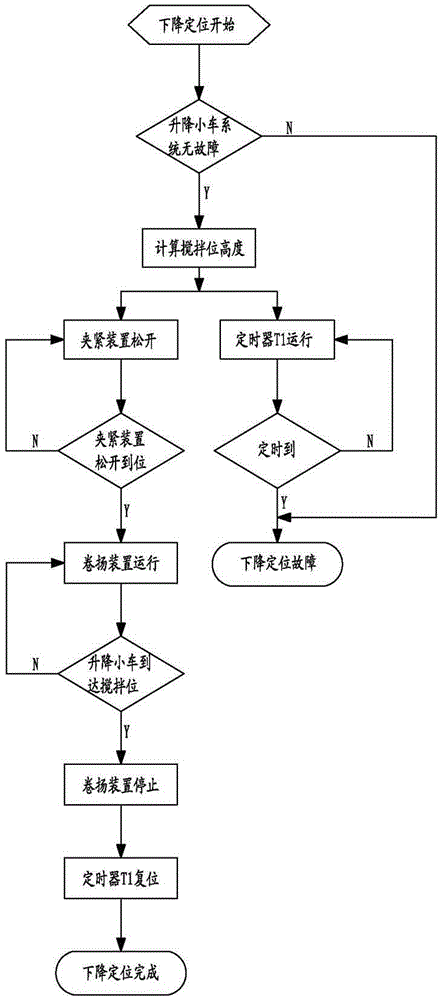

[0027] figure 2 As shown, the intelligent control method of the KR desulfurization lifting trolley system of the present invention, the steps are: first use the KR desulfurization control system to divide the entire working process of the lifting trolley system into five steps from front to back, namely: descending positioning sub-process, stirring Desulfurization sub-process, rising slag removal sub-process, positioning slag removal sub-process and return to standby position process.

[0028] (1) First allocate the register R of the KR desulfurization control system XY (where X=0, 1, 2, 3, 4, 5; Y=0, 1, 2) to store the entire control process and the running status of each sub-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com