Reservoir deepwater sediment cleaning method

A cleaning method and sediment technology, which is applied in construction, mechanically driven excavators/dredgers, earth movers/shovels, etc., can solve the high requirements for equipment to adapt to changes in water depth and the uneven thickness of the gravel layer. , Device positioning is difficult to fix, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

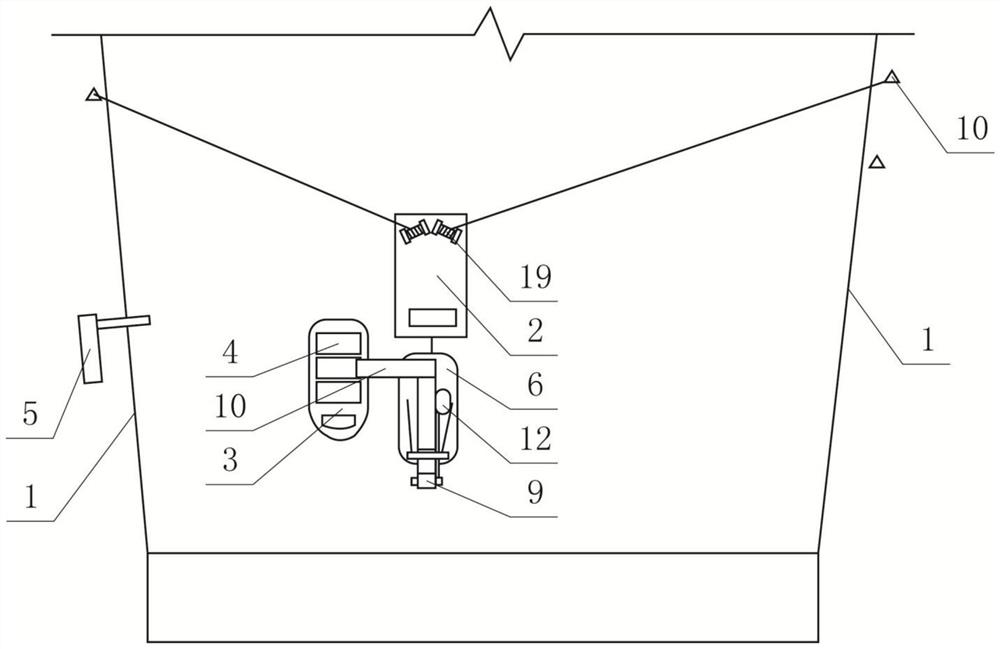

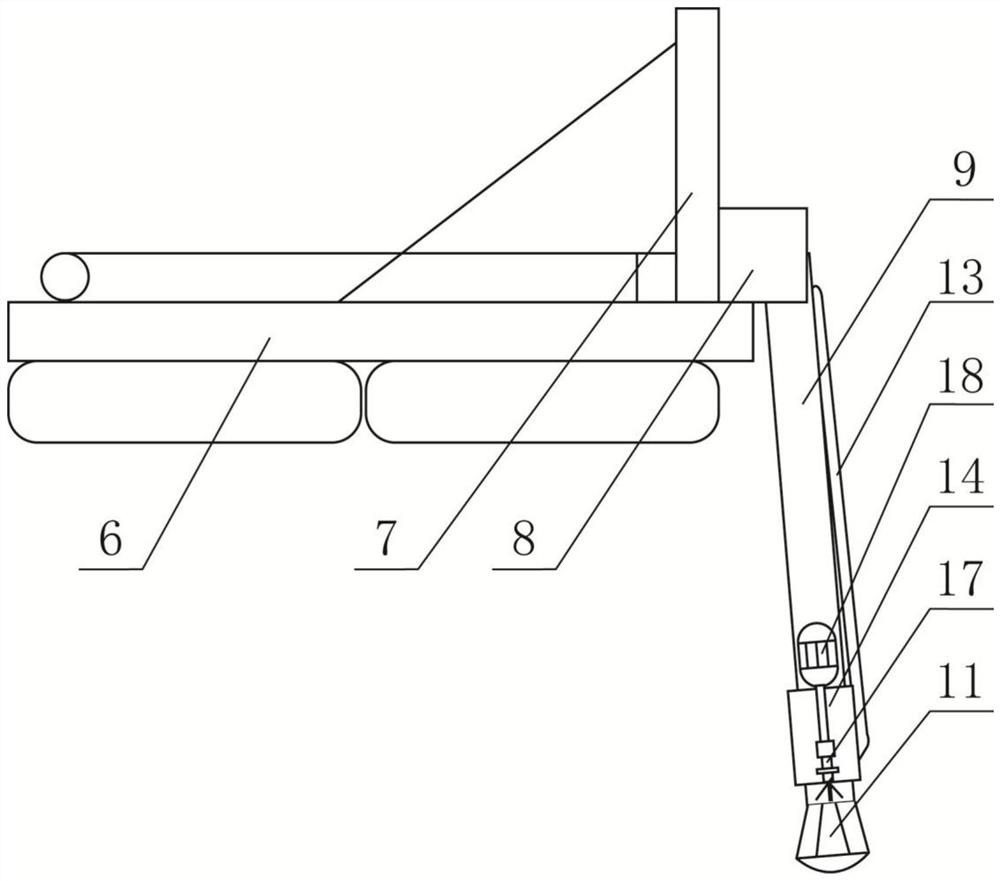

[0028] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

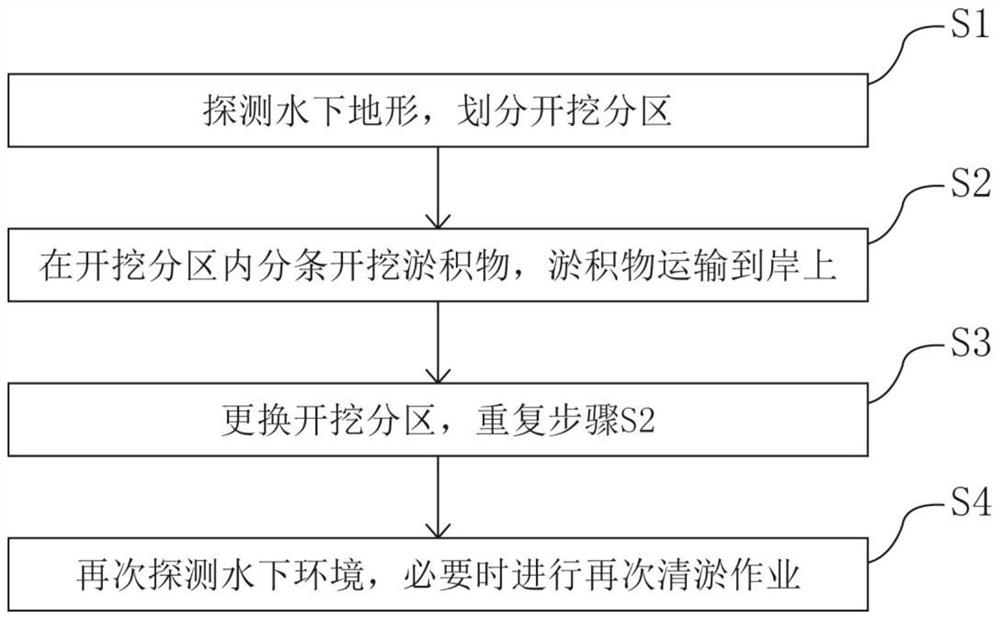

[0029] Embodiments of the present invention provide a method for cleaning reservoir deep water silt, such as figure 1 shown, including the following steps:

[0030] S1: Detect underwater terrain: (1) Measuring instruments: use HY1600 single-beam depth sounder to measure water depth, and use GPS (RTK1+1) for plane positioning and elevation measurement; (2) Surveying line layout: sedimentation measurement: along the clearing area Grid-like layout, the cross-section and measuring point spacing are both 1.0m; (3) Surveying ship: arrange the measuring instruments on the traffic ship, and follow the route determined by the surveying plan; (4) Specific implementation: divers (hand-held cameras) launch into the water Finally, carry out c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com