Reluctance Adjustment Method of Generator

An adjustment method and generator technology, applied in magnetic circuits, electromechanical devices, electrical components, etc., can solve the problems of unstable clean power generation energy, impeding rotor rotation, and exhaustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

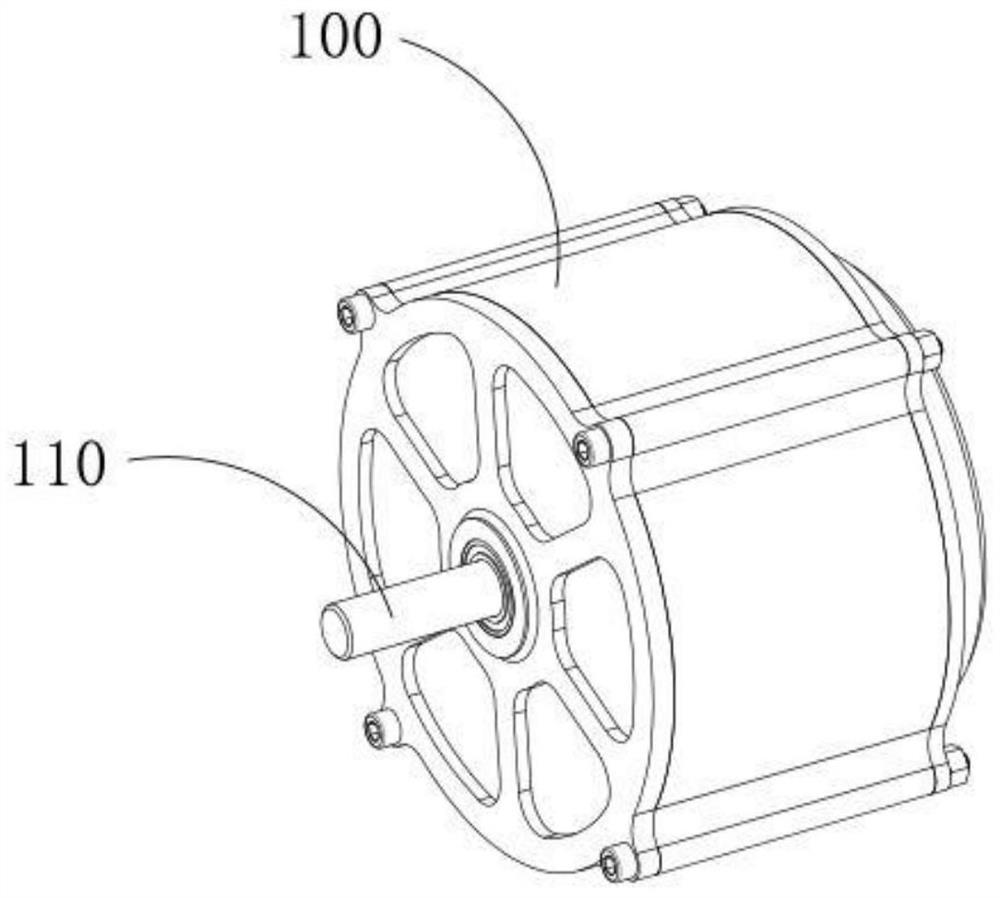

[0042] A reluctance adjustment method for a generator, the steps of which are:

[0043] (1) The natural energy weakening stage;

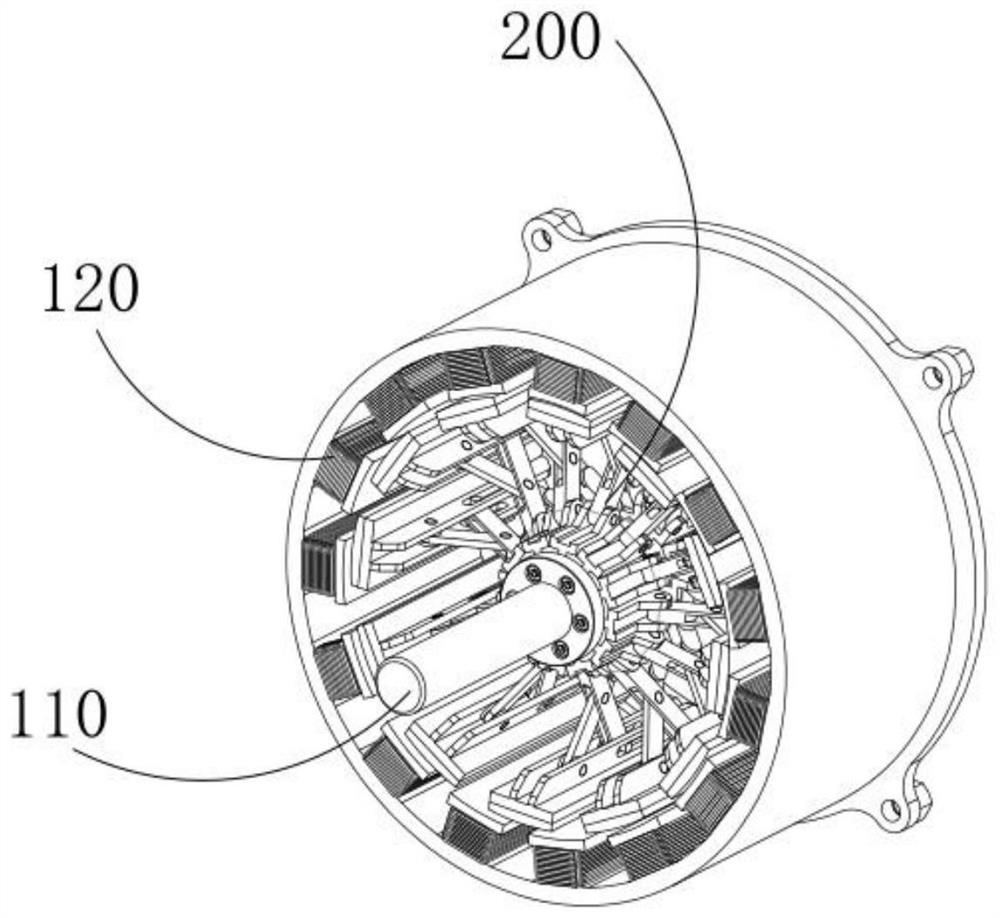

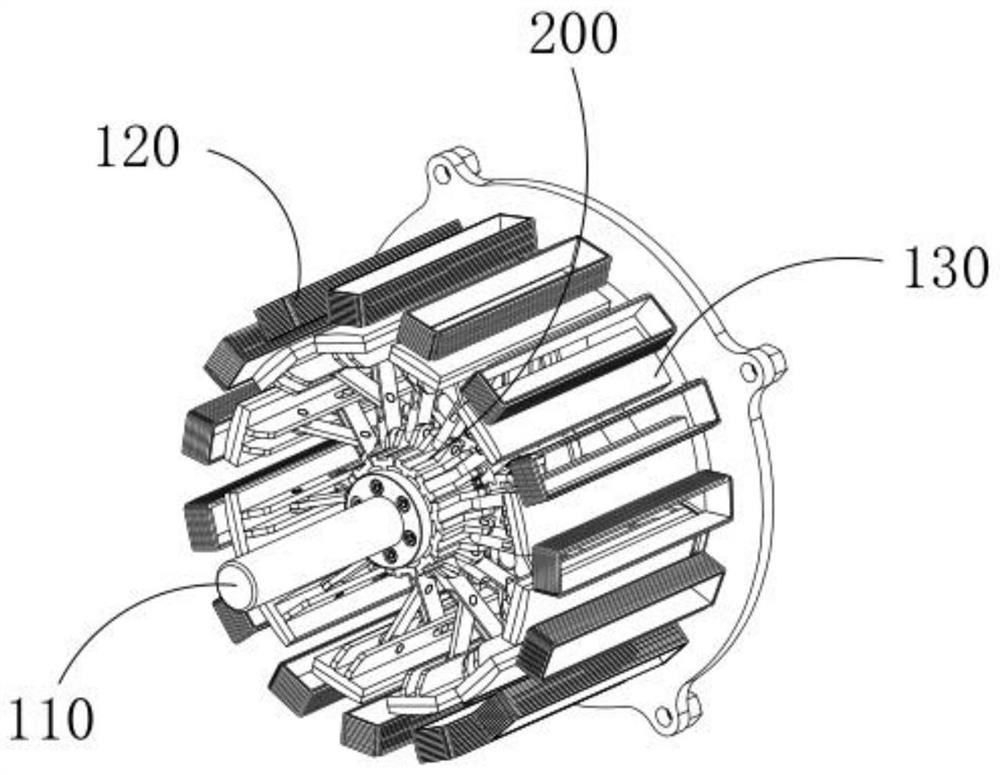

[0044] S1: When the external natural energy weakens, the rotation speed of the rotating shaft 110 of the motor body 100 decreases, and the internal components of the centrifugal drive mechanism 300 change;

[0045] The centrifugal drive mechanism 300 includes a centrifugal member 310 and a driving member 320. The centrifugal member 310 includes a fixed block 311 and a roller 313. The fixed block 311 is a cylindrical structure and the fixed block 311 is coaxially fixed on the outside of the rotating shaft 110. The fixed block 311 The outer surface of the centrifugal piece is provided with three groups along the circumferential direction of the rotating shaft 110. The centrifugal piece includes a guide block and a roller 313. The guide block is fixed on the fixed block 311 and the extension direction of the guide block is in line with the fixed block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com