Wind power generation device utilizing wind energy of factory equipment and using method of wind power generation device

A technology for wind power generation equipment and factory equipment, which is applied to wind power generation, wind turbines, and wind turbine combinations, etc., can solve the problems of inability to make full use of factory equipment, inconvenient replacement of fan blades, and easy damage to wind power generation equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

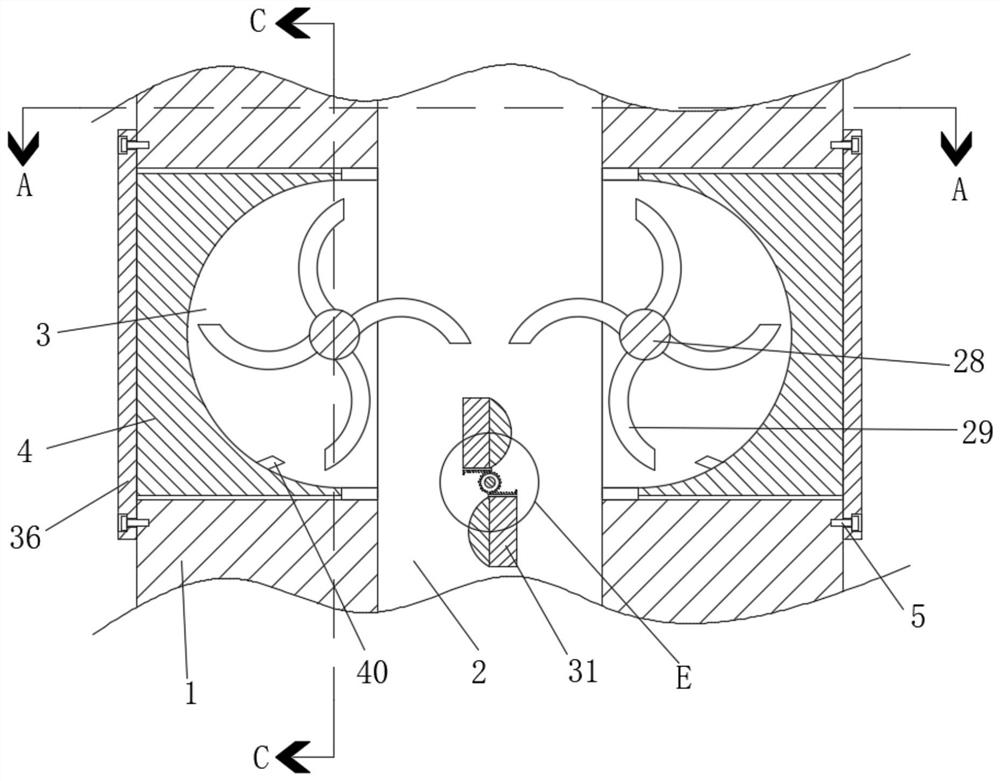

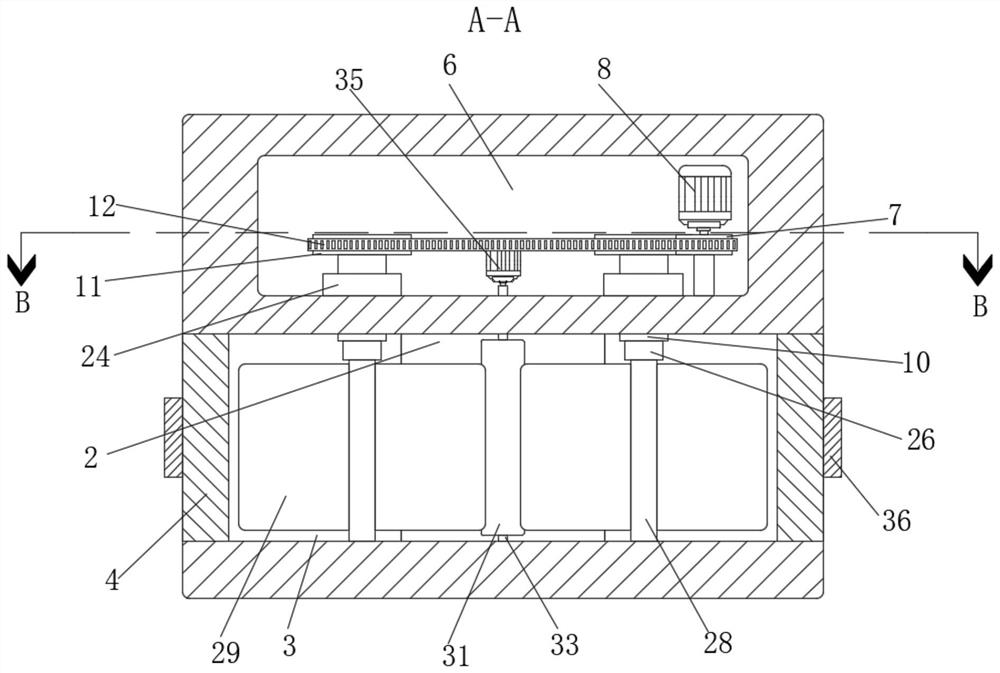

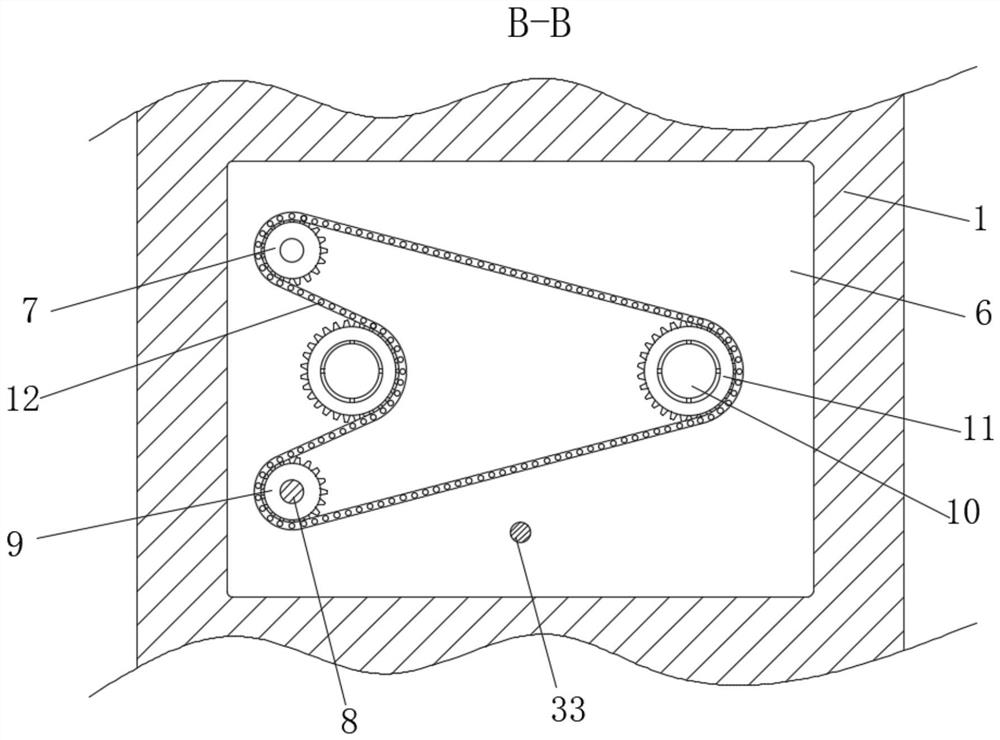

[0043] Such as Figure 1-7 The shown a kind of wind power generation device that utilizes the wind energy of factory equipment includes an exhaust pipe 1, and an air vent 2 is arranged in the exhaust pipe 1, and two symmetrical sliding grooves 3 are arranged in the exhaust pipe 1, and two The sliding grooves 3 are all in communication with the air vent 2, and the sliding groove 3 is slidingly connected with an arc-shaped plate 4, and the side of the arc-shaped plate 4 away from the air vent 2 is fixedly connected with a connecting plate 36, and a plurality of bolts are arranged in the connecting plate 36 5, and one end of a plurality of bolts 5 close to the vent 2 is threadedly connected with the exhaust pipe 1, and the exhaust pipe 1 is provided with a placement slot 6, and the inner wall of the placement slot 6 near the vent 2 rotates through and connects two The rotating shaft 10 is relatively symmetrical, and the end of the rotating shaft 10 close to the vent 2 extends int...

Embodiment 2

[0056] This embodiment is a further improvement of the previous embodiment, such as Figure 1-8As shown, a wind power generation device utilizing wind energy of factory equipment includes an exhaust duct 1, an air vent 2 is arranged in the exhaust duct 1, two symmetrical sliding grooves 3 are arranged in the exhaust duct 1, and two The sliding grooves 3 are all in communication with the air vent 2, and the sliding groove 3 is slidingly connected with an arc-shaped plate 4, and the side of the arc-shaped plate 4 away from the air vent 2 is fixedly connected with a connecting plate 36, and a plurality of bolts are arranged in the connecting plate 36 5, and one end of a plurality of bolts 5 close to the vent 2 is threadedly connected with the exhaust pipe 1, and the exhaust pipe 1 is provided with a placement slot 6, and the inner wall of the placement slot 6 near the vent 2 rotates through and connects two The rotating shaft 10 is relatively symmetrical, and the end of the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com