Cylindrical wind generator with multi-stage impeller set

A technology of wind power generator and impeller group, which is applied in the direction of wind power generator, wind power motor, wind power motor combination and other directions consistent with the wind direction, and can solve the problems of low annual utilization hours, increased swing of fuselage tower, self-height, weight, Volume increase and other issues, to achieve the effect of reducing natural erosion or the probability of blades being struck by lightning, reducing mechanical failure rate, and reducing the cost of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

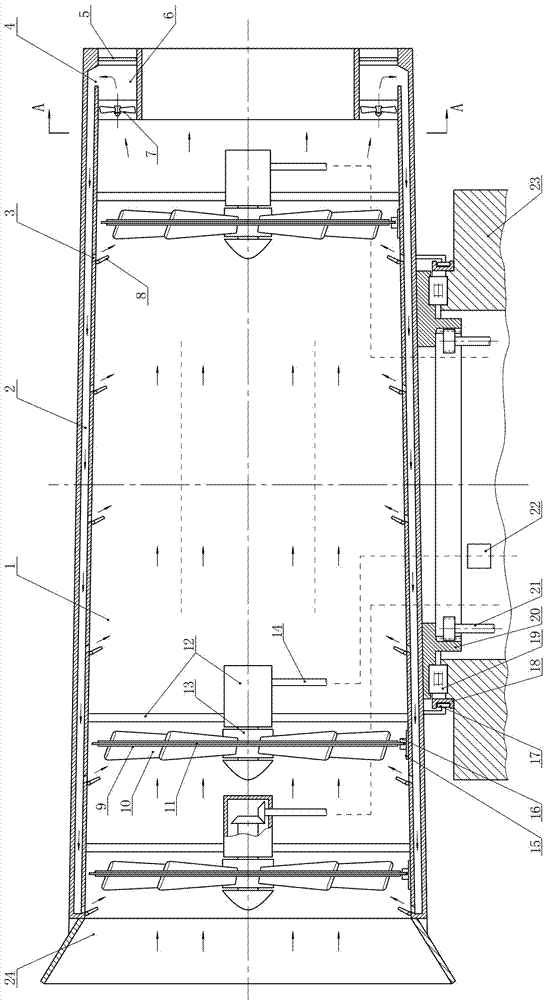

[0028] From Figure 1 ~ Figure 3 It can be seen that the technical solution of the present invention includes the base and the generator set arranged inside the base; the present invention also includes the air duct 1, the shaft frame 12, the impeller group, the return air duct 2, the braking device, and the yaw mechanism;

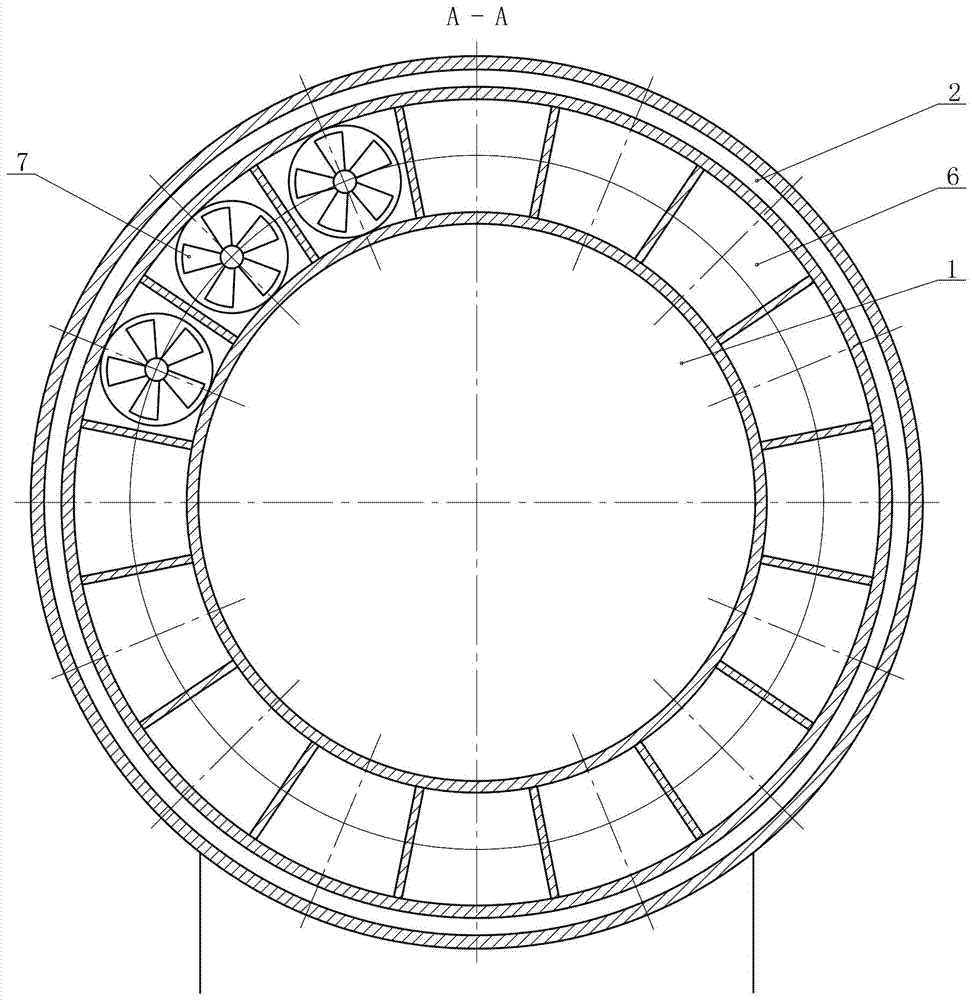

[0029] The air cylinder 1 is assembled on the top of the base 23 through a yaw mechanism; the yaw mechanism includes an arc-shaped guide rail 18, a guide hook wheel 17, a thrust bearing group 19, and a ring gear 20; the lower part of the air cylinder 1 is equipped with a guide hook wheel 17 and the ring gear 20; the arc-shaped guide rail 18 is fixed on the top of the base 23; the base 23 and the lower part of the blower 1 are slidably matched through the thrust bearing group 19, and the guide hook wheel 17 is clamped in the arc-shaped guide rail 18 and rolls with the guide rail Cooperate to prevent the fan cylinder from tilting; the ring gear 20 is connect...

Embodiment 2

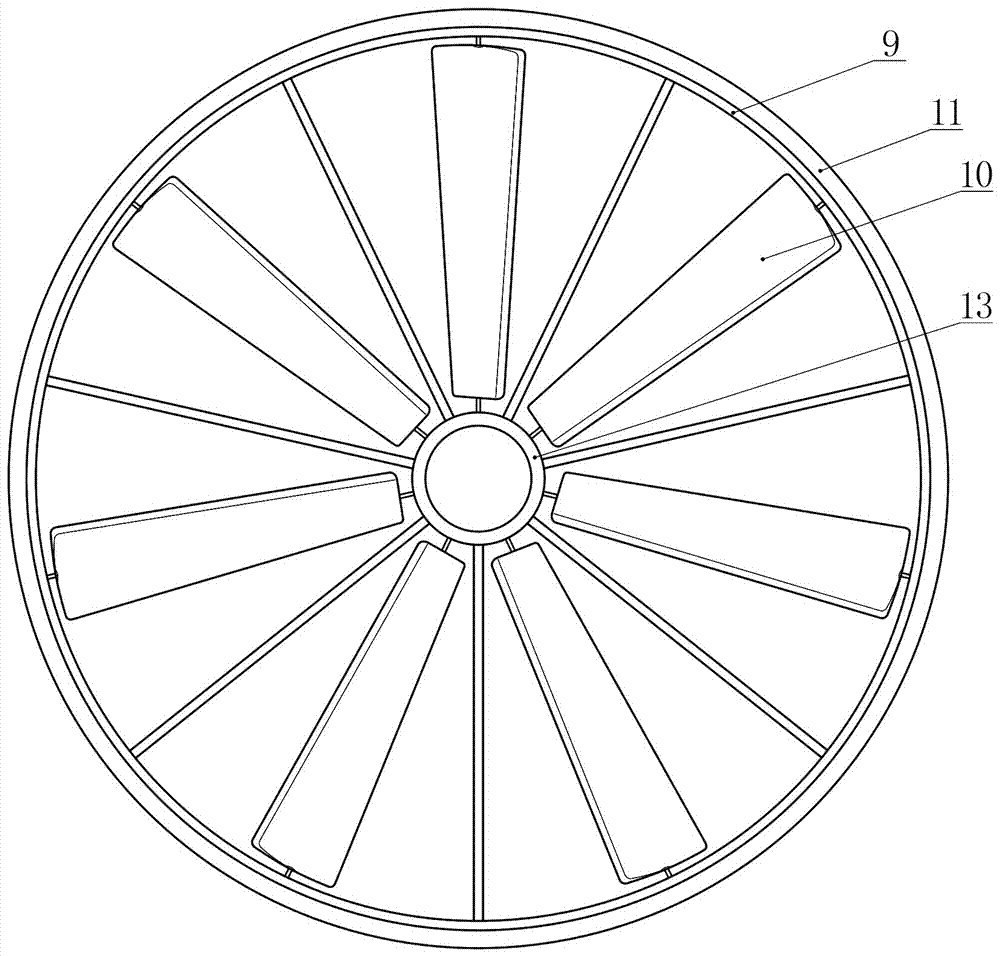

[0036] From Figure 4 It can be seen that the difference between this embodiment and Embodiment 1 is that a limit device is installed on the rear side of the annular frame 9 of each impeller group, and the limit device includes a limit roller 25 and an annular slideway fixed on the inner wall of the air duct 26. The limit roller 25 is rollingly matched with the annular slideway 26. It can prevent the annular frame 9 and the blade body from receding deformation due to the stress of the impeller. According to the material and operating conditions of the whole machine, the connection mode between the brake caliper 16 and the air duct can also be fixedly connected.

[0037] Figure 5 As shown, in this embodiment, the booster fan 7 is installed at the inlet of the return air duct at the side of the air collection duct to ensure the air circulation of the air collection duct 6 when the exhaust door 5 is fully opened.

[0038] Other technical features of this embodiment are the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com