Patents

Literature

38results about How to "Does not affect runnability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

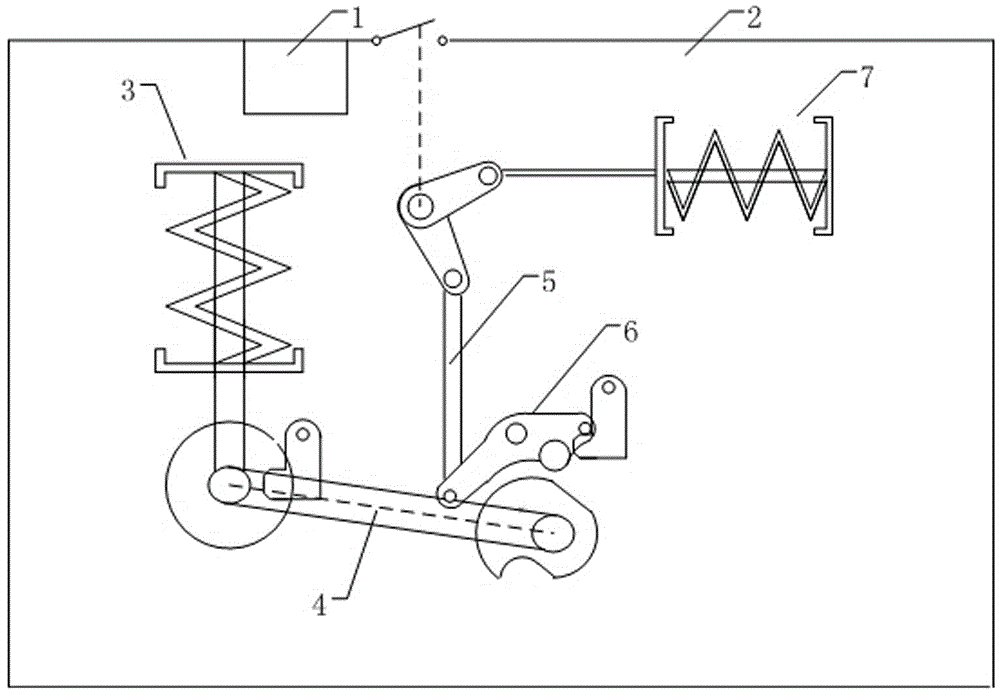

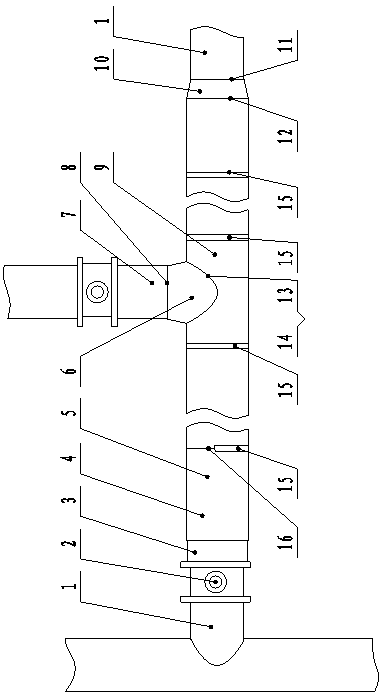

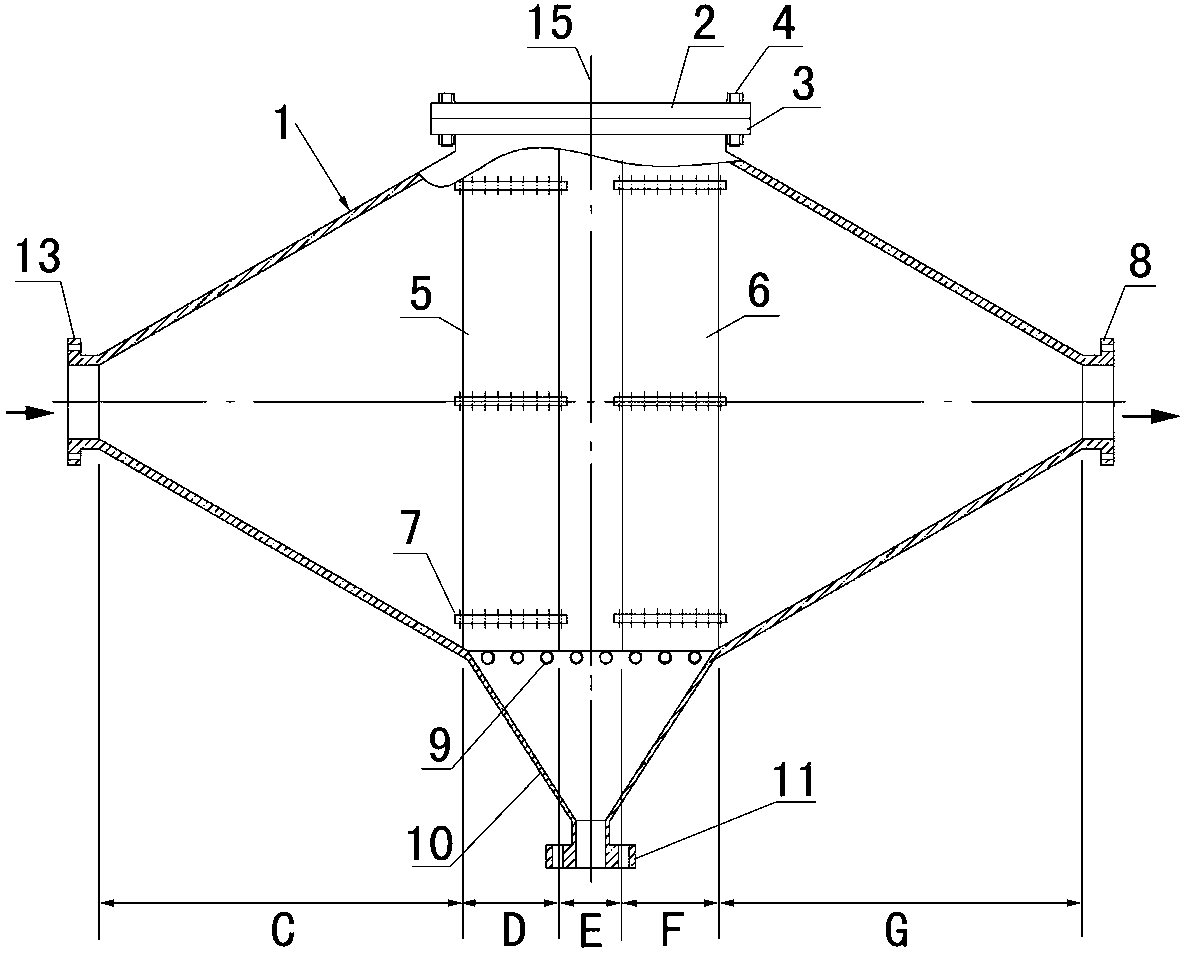

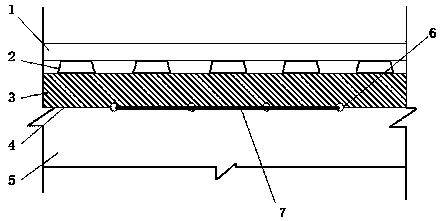

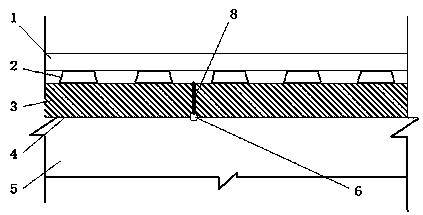

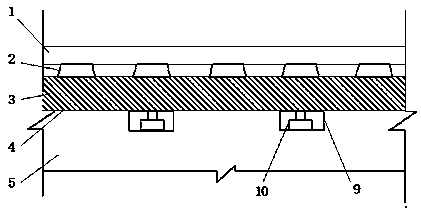

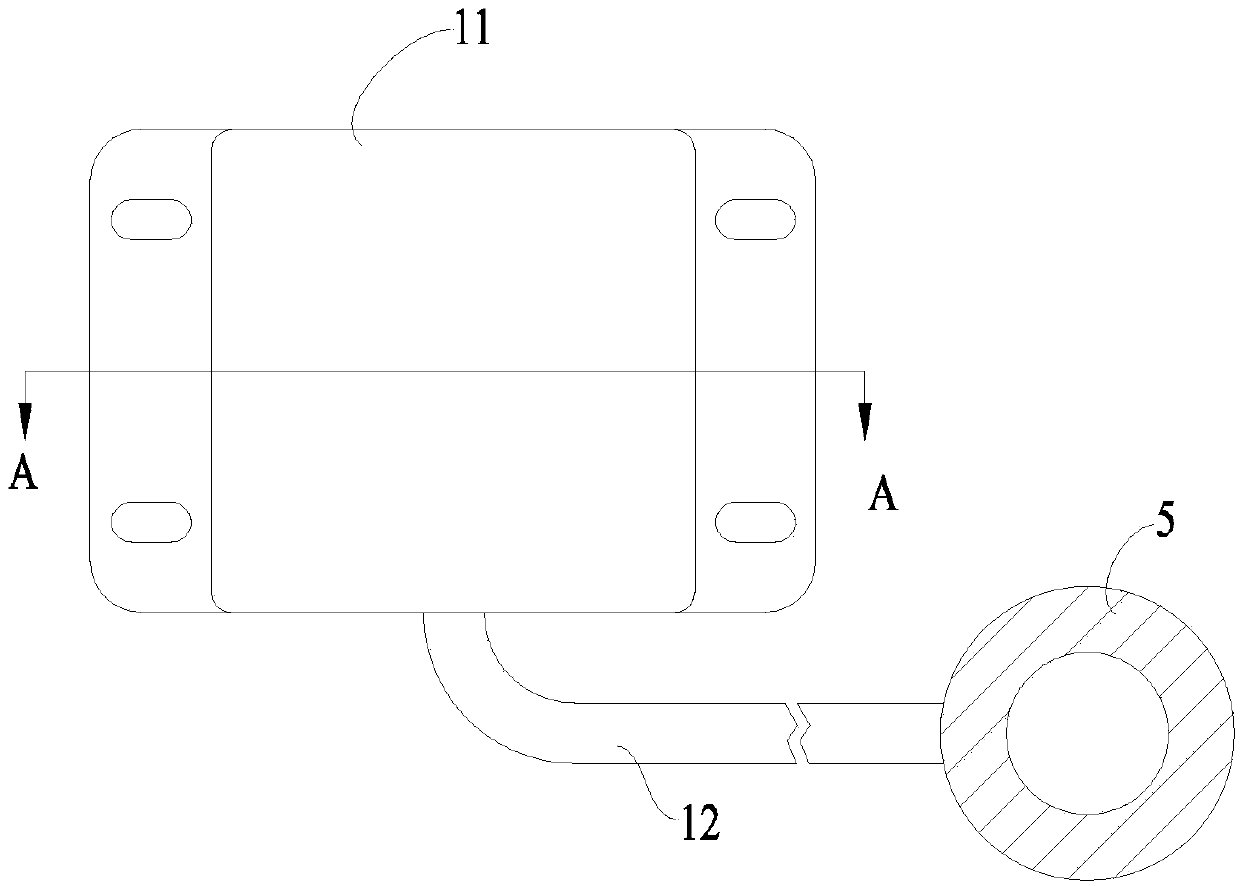

Method for collecting mechanical characteristic parameters of breaker based on high-speed camera

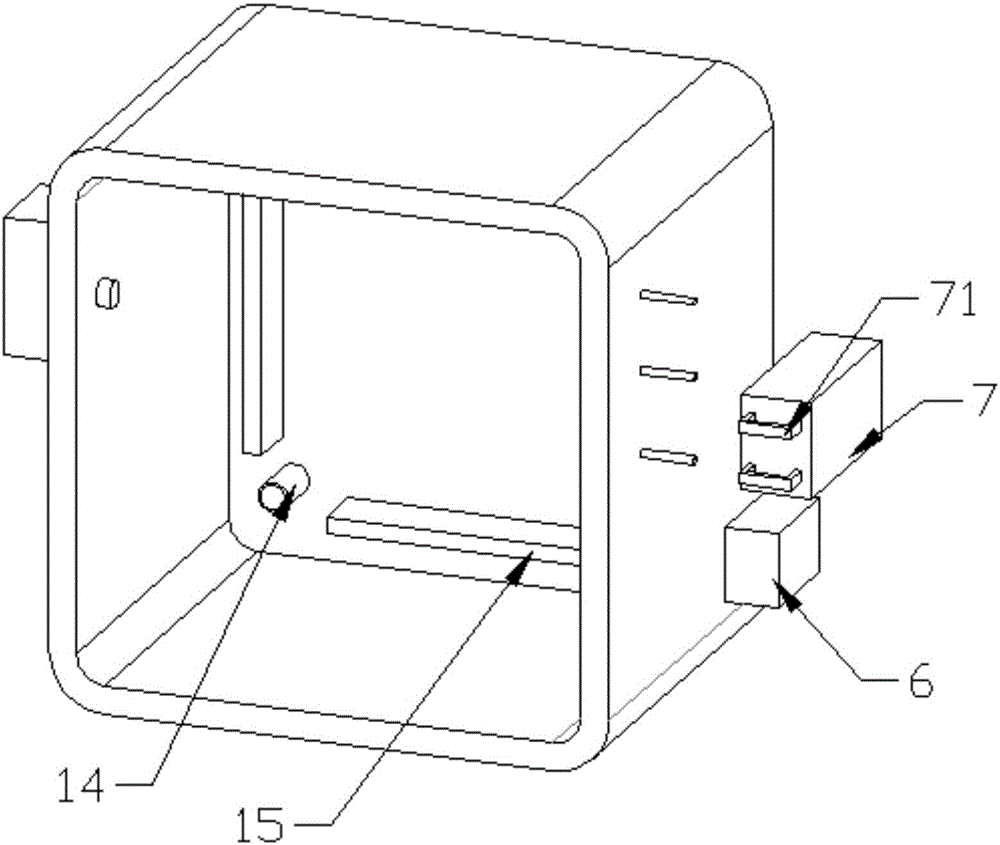

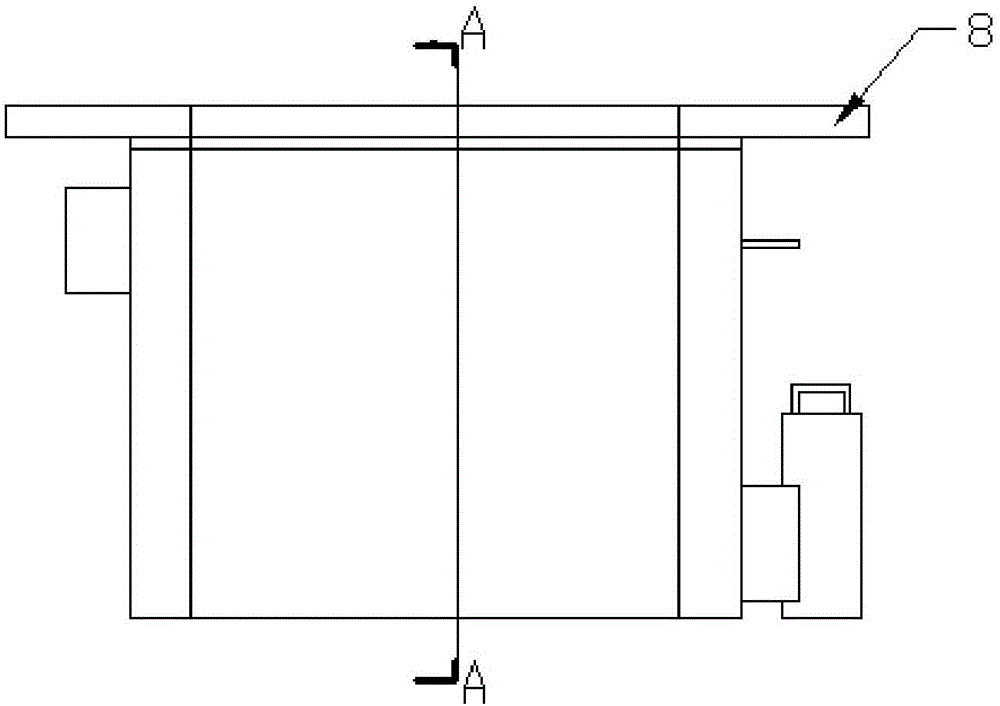

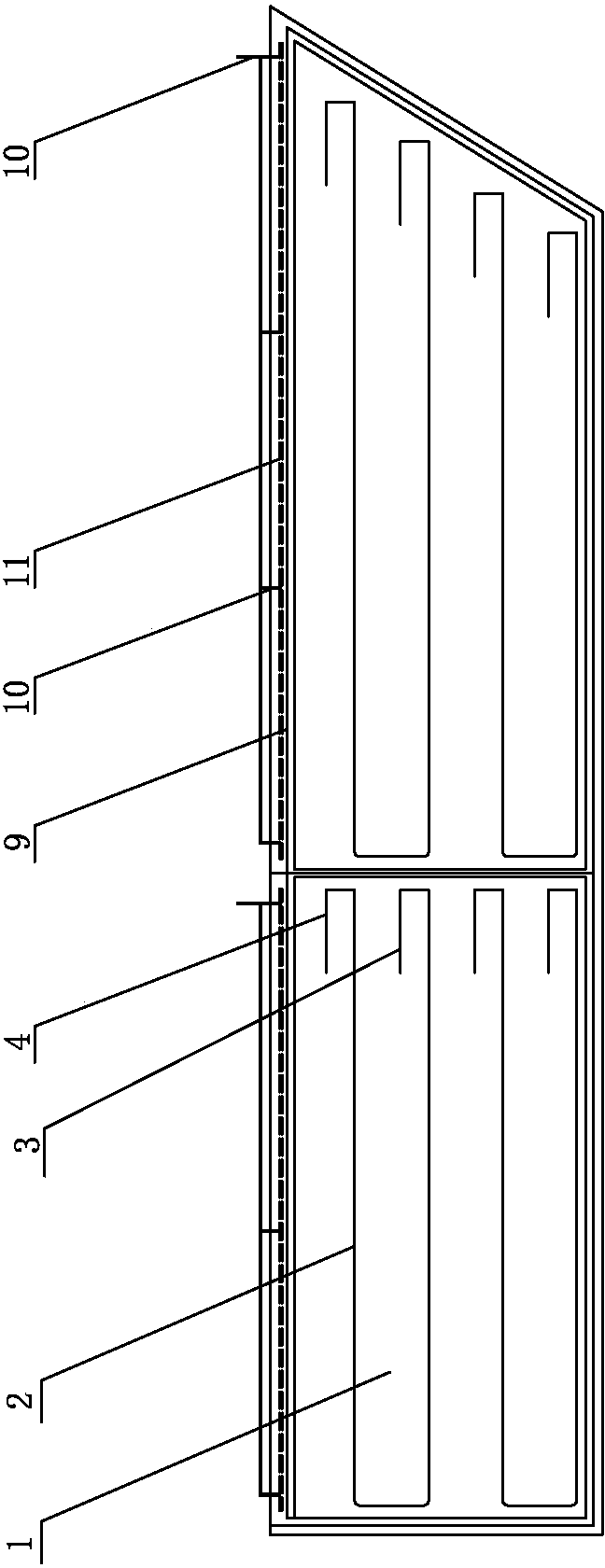

InactiveCN104062111ADoes not affect operabilityDoes not affect runnabilityMachine part testingStereo cameraAcoustic wave

A method for collecting the mechanical characteristic parameters of a breaker based on a high-speed camera comprises the following steps that (A) the high-speed camera (1) is used for capturing the image information of an operation mechanism (2) during moving in the closing and opening process of the breaker, wherein the operation mechanism (2) comprises a switching-on spring (3), a spindle (4), a metal connecting rod (5), a main connecting lever (6) and a switching-off spring (7); (B) the collected image information is input into an industrial personnel computer, images are analyzed and processed, and all the mechanical characteristic parameter values of the breaker are calculated; (C) conventional electric signals and vibration signals are fused in the mechanical characteristic parameter values obtained by processing of the images, and sound wave signals are combined for conducting analysis to obtain comprehensive and reliable mechanical characteristic parameter values. The parameter test precision and the speed calculated by the method are both greatly improved, a non-contact type measuring method is achieved, and the problem that sensor clamps for mounting different breakers are not universal on the site is solved.

Owner:YUN NAN ELECTRIC TEST & RES INST GRP CO LTD ELECTRIC INST +1

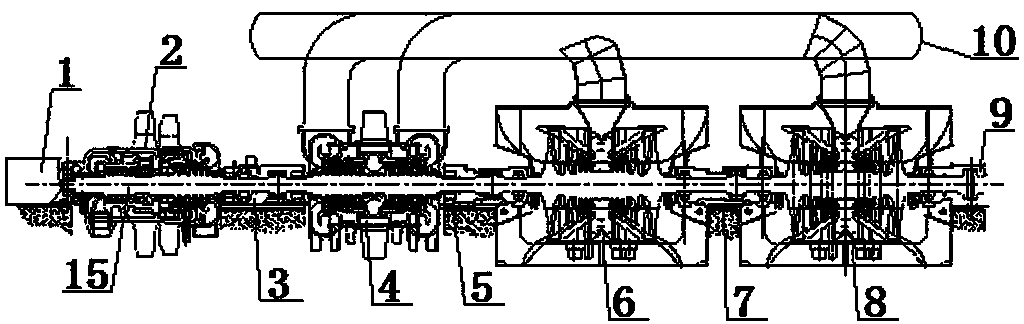

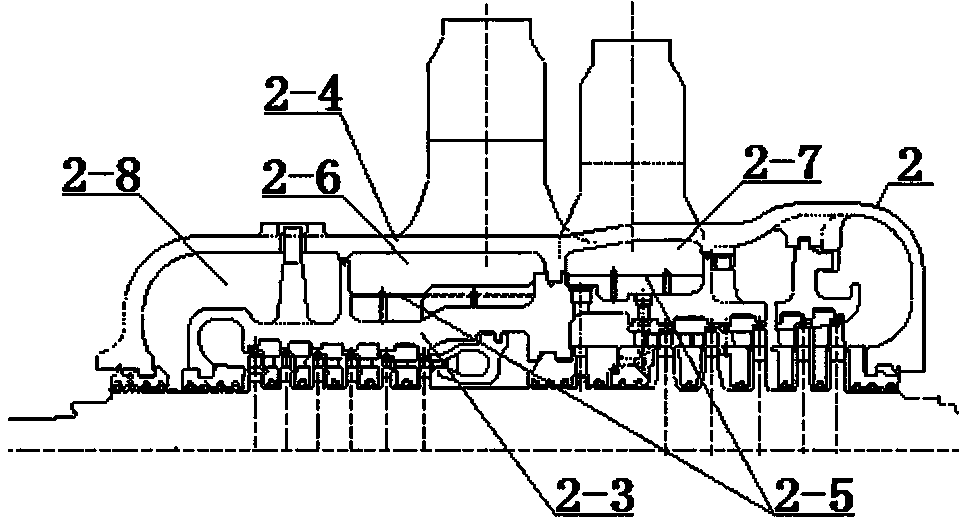

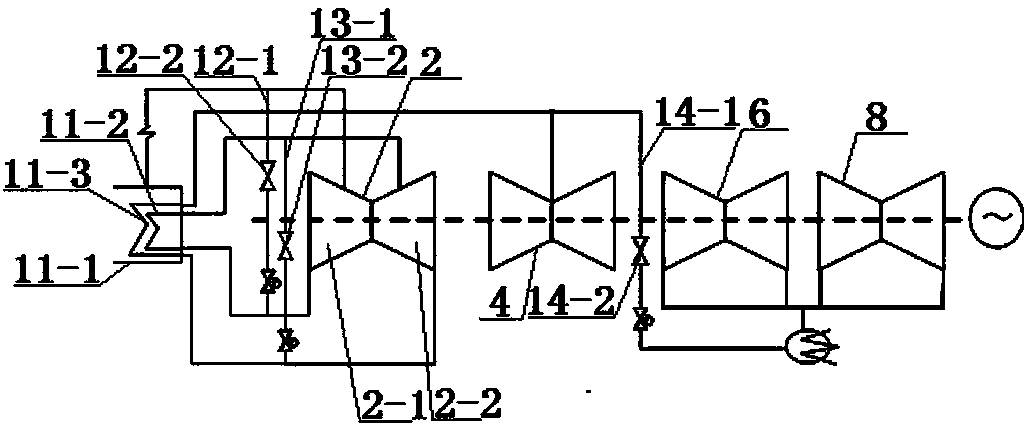

Ultra-supercritical secondary re-heating steam turbine set

InactiveCN103670550ADoes not affect safety and reliabilityDoes not affect runnabilityEngine componentsSteam engine plantsUltra high pressureEngineering

The invention discloses an ultra-supercritical secondary re-heating steam turbine set. The ultra-supercritical secondary re-heating steam turbine set comprises a first bearing box, an ultra high pressure-high pressure cylinder, a second bearing box, a medium-pressure cylinder, a third bearing box, a first low-pressure cylinder, a fourth bearing box, a second low-pressure cylinder and a turning gear box which are assembled on a rotor in sequence. The capacity of the steam turbine set is 1000-1300MW, the ultra high pressure-high pressure cylinder is of a cylinder combined structure, the pressure of a steam inlet of an ultra high pressure part is 30-35MPa, the temperature is 600 DEG C, the pressure of a primary re-heating steam inlet of a high pressure part is 10MPa, the temperature is 610-630 DEG C, the medium-pressure cylinder, the first low-pressure cylinder and the second low-pressure cylinder are respectively of a double-flow-division structure, the medium-pressure cylinder provides steam for the first low-pressure cylinder and the second low-pressure cylinder respectively through communication pipes, the pressure of a secondary re-heating steam inlet of the medium-pressure cylinder is 2.8MPa, and the temperature is 610-630 DEG C. The ultra-supercritical secondary re-heating steam turbine set has the advantages of being large in capacity, high in parameter, small in occupied space, low in investment cost, stable and reliable in operation and obvious in economical benefit, saving energy, reducing consumption and the like.

Owner:DONGFANG TURBINE CO LTD

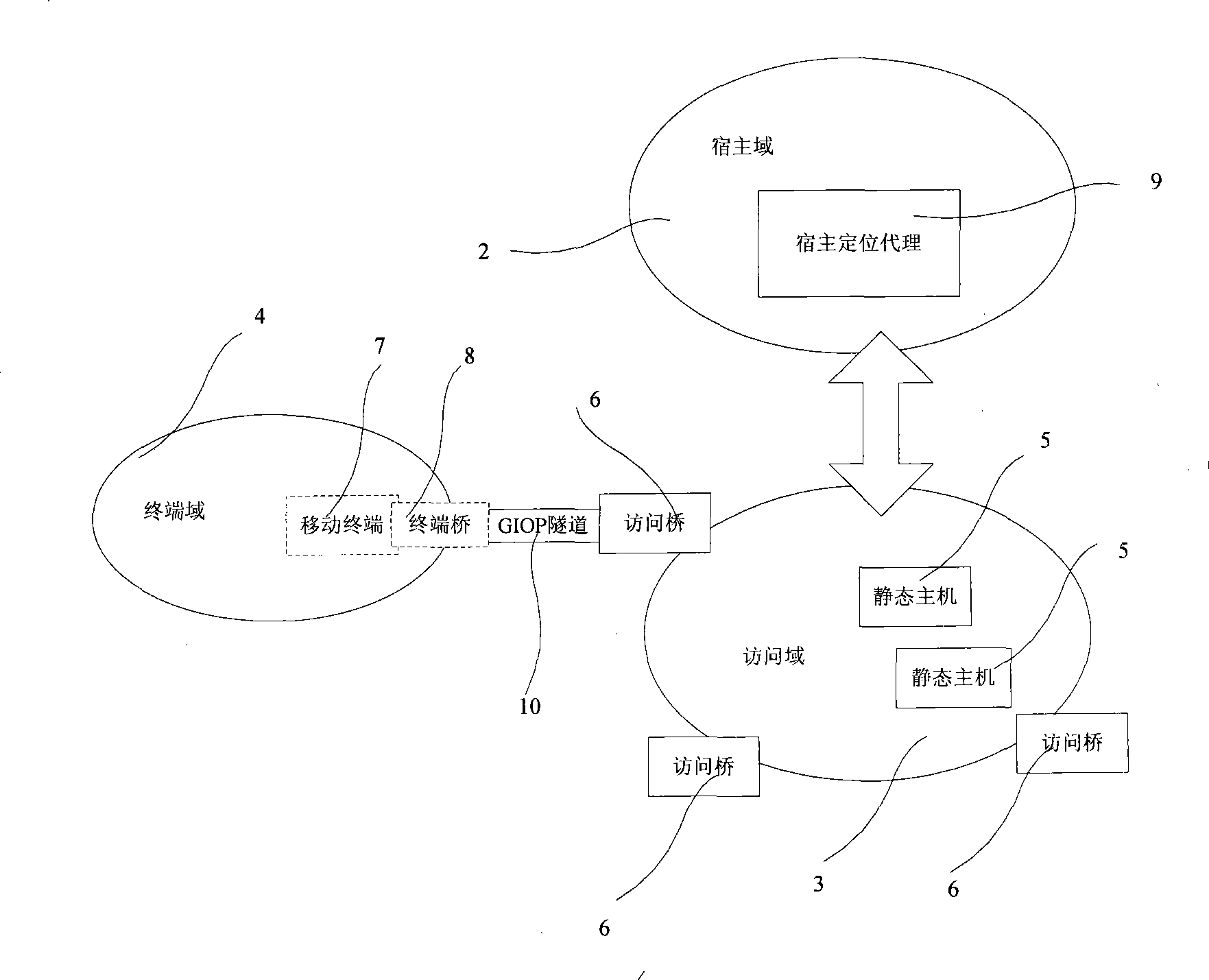

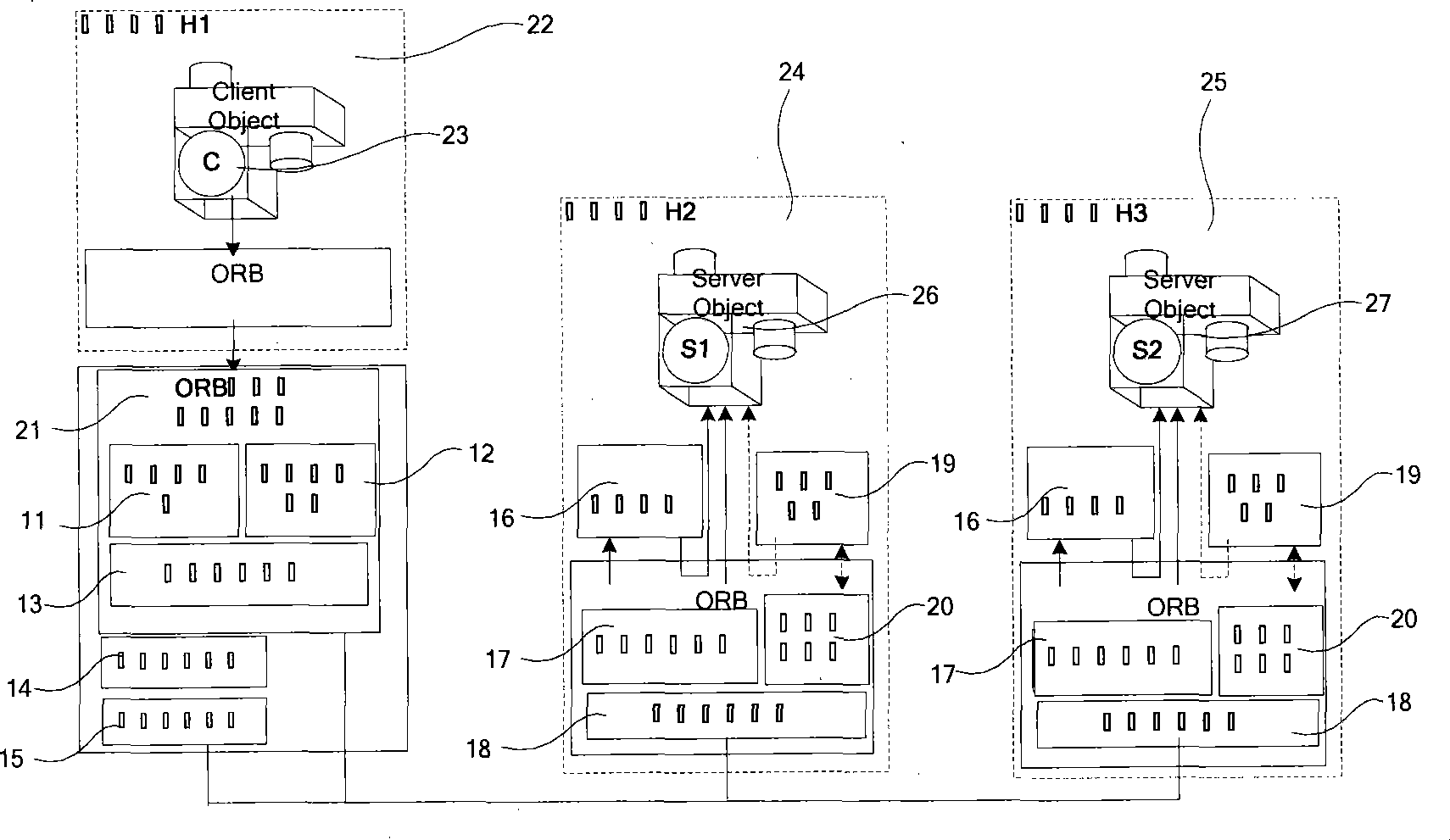

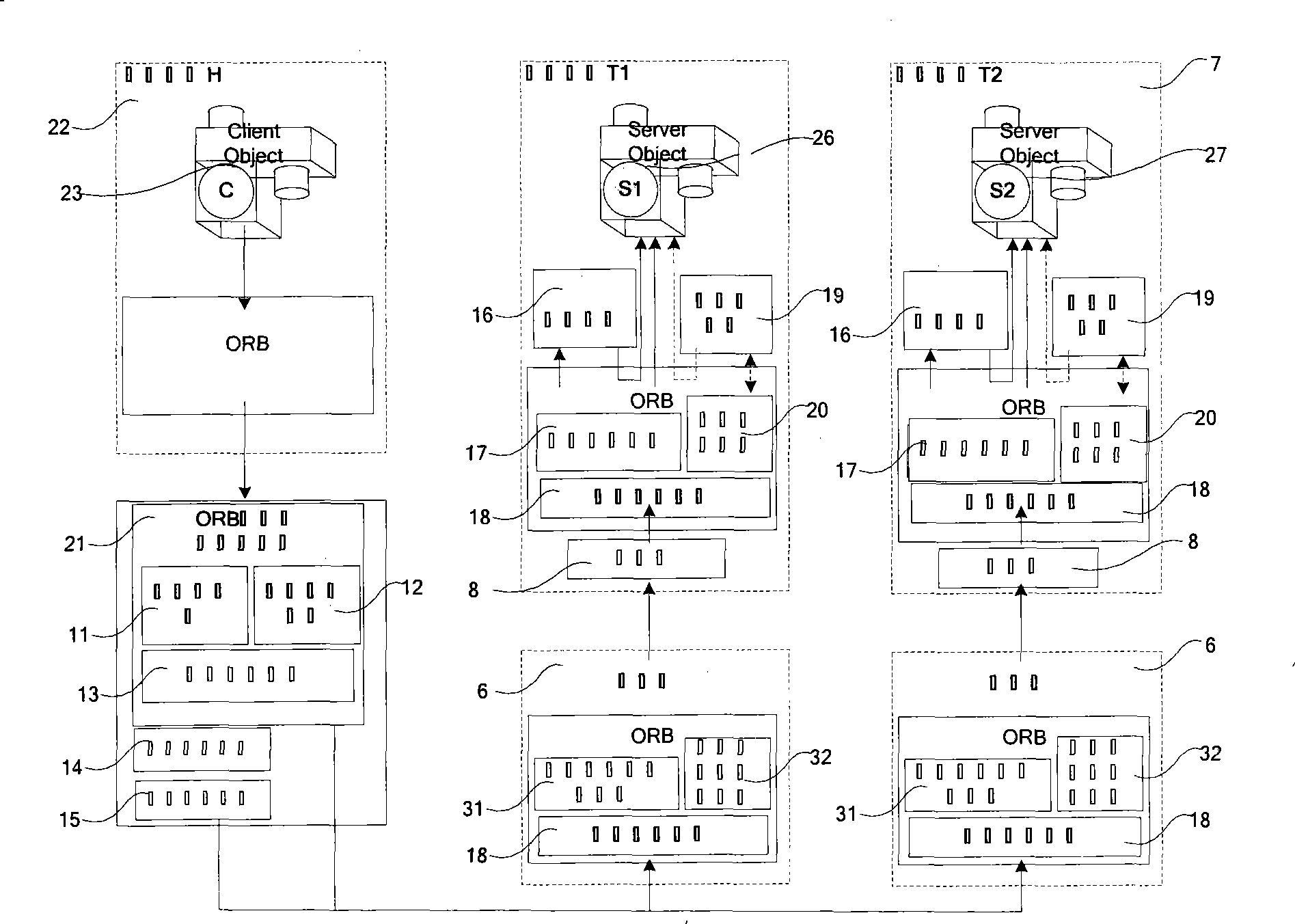

Error tolerance method in wireless public object request proxy construction application

InactiveCN101459690AAchieve recoveryDoes not affect runnabilityNetworks interconnectionStructure of Management InformationError tolerance

The invention provides a method for tolerating faults, which is applied in a wireless public object request agent structure. The method comprises: realizing the creation of a mobile terminal object duplicate under the assistance of an accessing bridge object request agent layer, utilizing an accessing bridge log recording mechanism 31of the accessing bridge object request agent layer to record and store mobile terminal object state detecting points and mobile terminal object message events, realizing the detection of mobile terminal object failures under the assistance of the accessing bridge object request agent layer, realizing the deletion of mobile terminal failure objects under the assistance of the accessing bridge object request agent layer, and realizing the recovery of the mobile terminal failure objects under the assistance of the accessing bridge object request agent layer. The method fully utilizes a CORBA error tolerant basic facility and a mechanism in an existing CORBA 3.0.3 criterion, enlarges an ORB layer of the accessing bridge in the wireless CORBA, and can be jointed with the existing CORBA 3.0.3 criterion and a wireless CORBA 1.2 criterion without slots to satisfy the demands of applying the wireless public object request agent structure on the aspects of reliable and real time performance.

Owner:HARBIN ENG UNIV

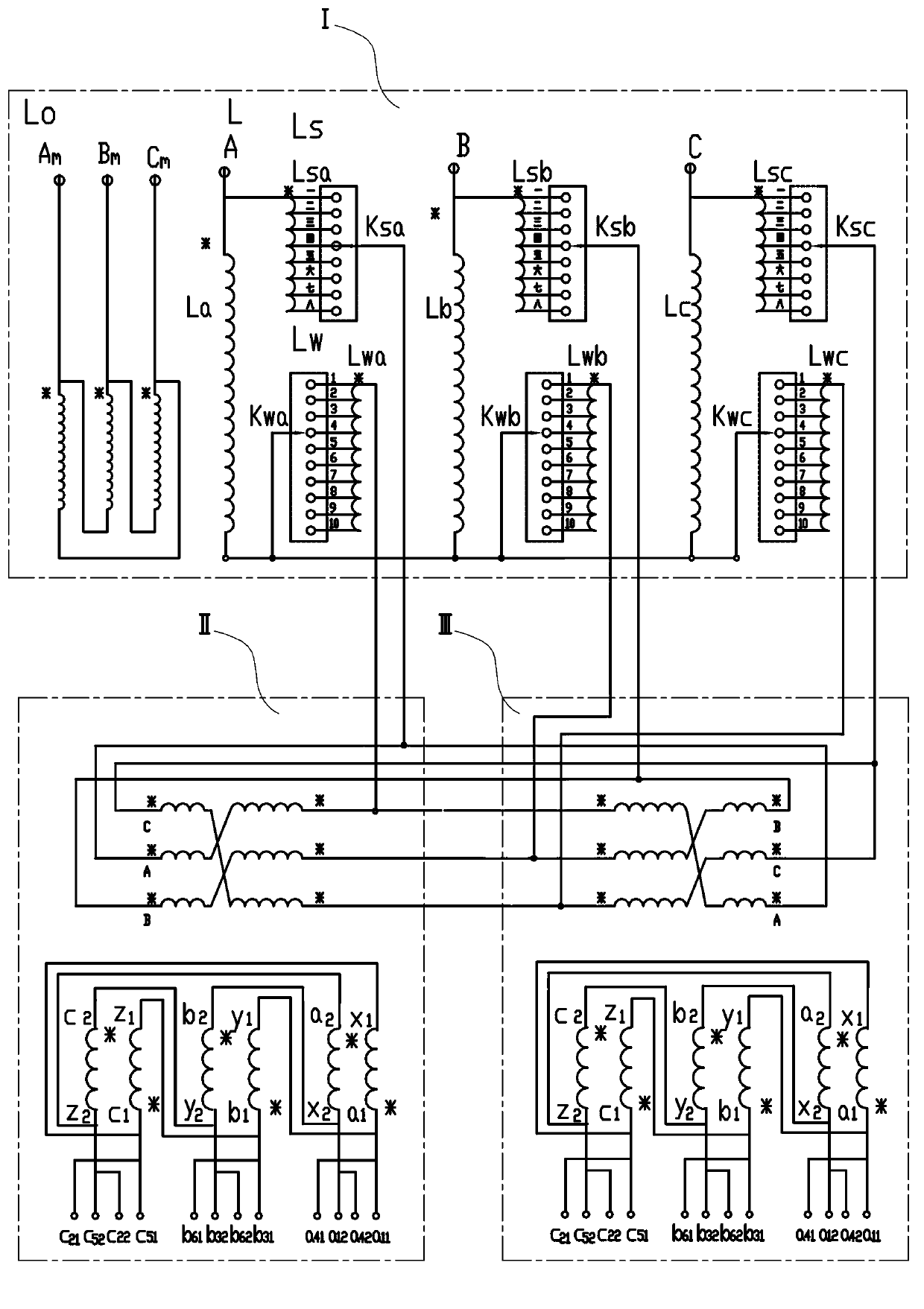

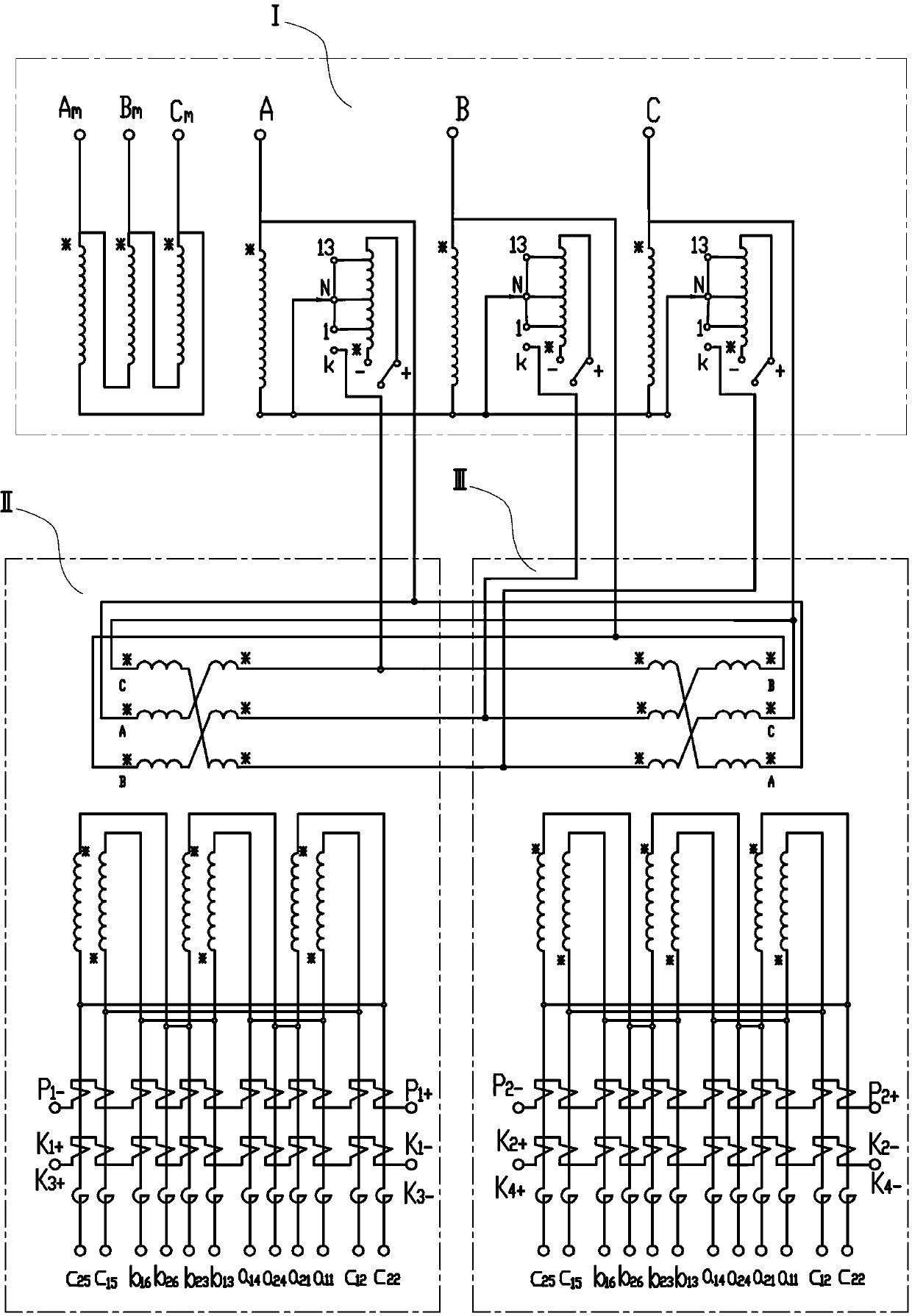

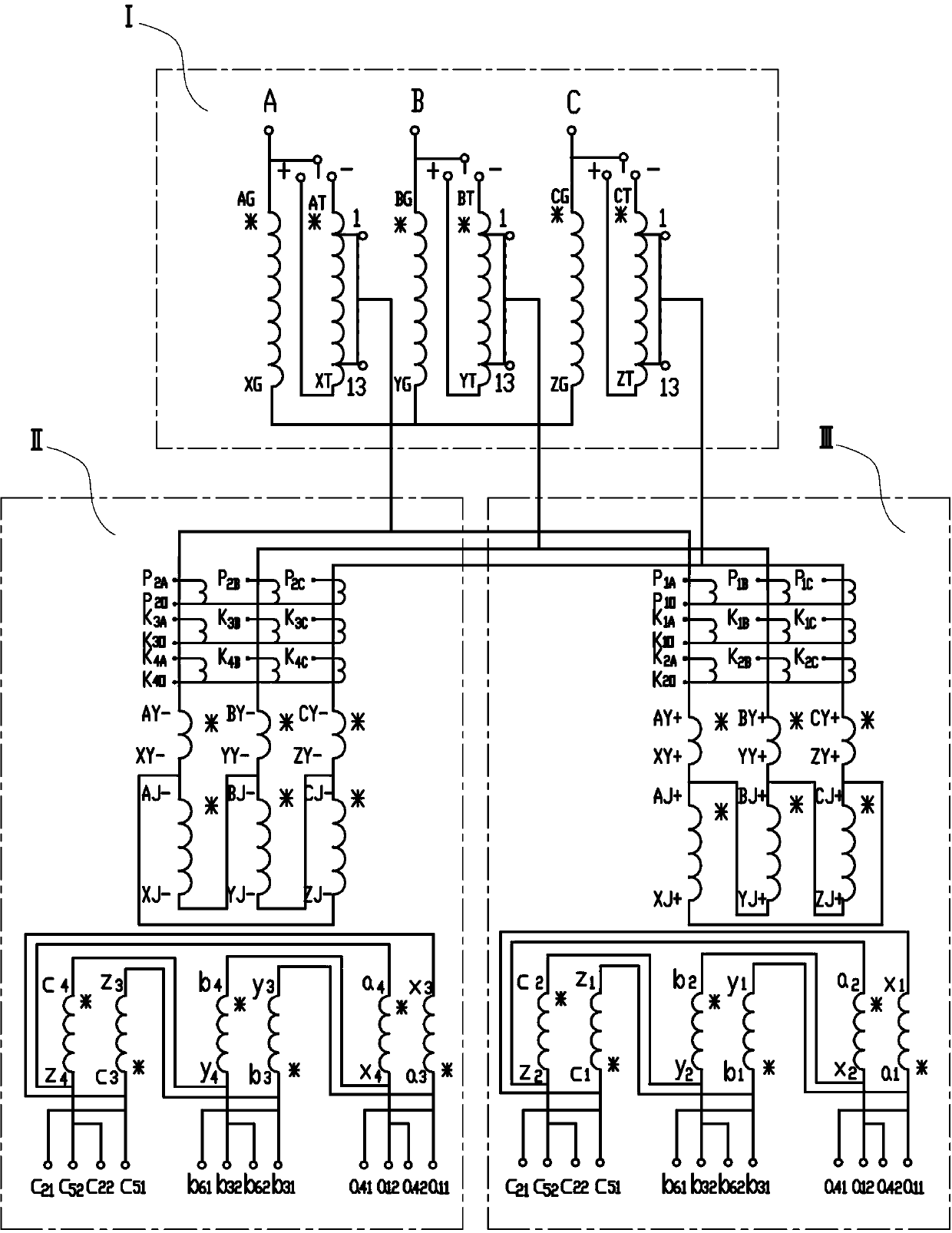

Novel on-load-tap-changing combined rectifier auto-transformer with independent ends

InactiveCN103023347ALow voltage output voltage smoothingImprove efficiencyAc-dc conversion without reversalTransformers/inductances coils/windings/connectionsManufacturing cost reductionLow voltage

A novel on-load-tap-changing combined rectifier auto-transformer with independent ends comprises a regulating transformer and two rectifier transformers. Phases of the regulating transformer are the same in structure. The regulating transformer comprises a high-tension coil, a front-end auto-regulating winding, a tail-end auto-regulating winding, a front-end on-load tap changer and a tail-end on-load tap changer. The front-end auto-regulating winding and the rear-end auto-regulating winding are combined ad connected to the front end of the high-tension coil of the regulating transformer and are connected with the same in parallel. The front-end and rear-end auto-regulating windings supply variable voltage to high-tension coils of the rectifier transformers through tap changing so as to achieve rough voltage regulating. The tail-end auto-regulating winding and the tail-end on-load tap changer are combined and connected to the tail ends of the high-tension coils of the rectifier transformers so as to achieve fine voltage regulating. The rough tap changer and the fine tap changer are fully isolated, regulating range is wide, regulating is multilevel, output of low voltage is smooth, operating performance is stable, harmonic wave generated by rectification can be reduced, power factor and production efficiency of rectifier systems are increased, and manufacturing cost is lowered.

Owner:GUANGXI LIUZHOU SPECIAL TRANSFORMER

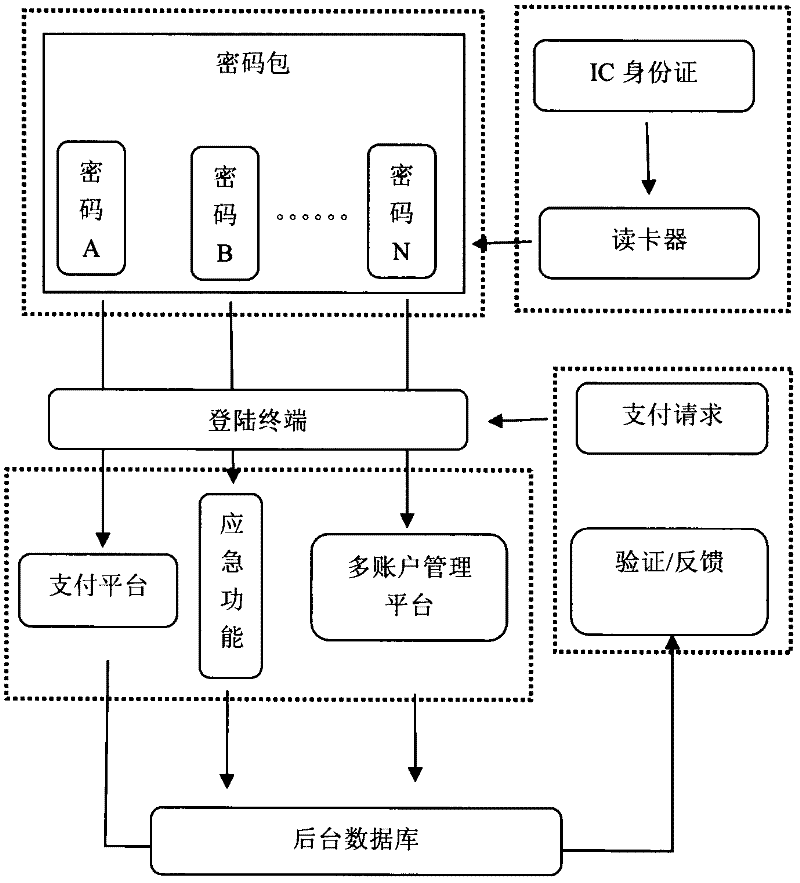

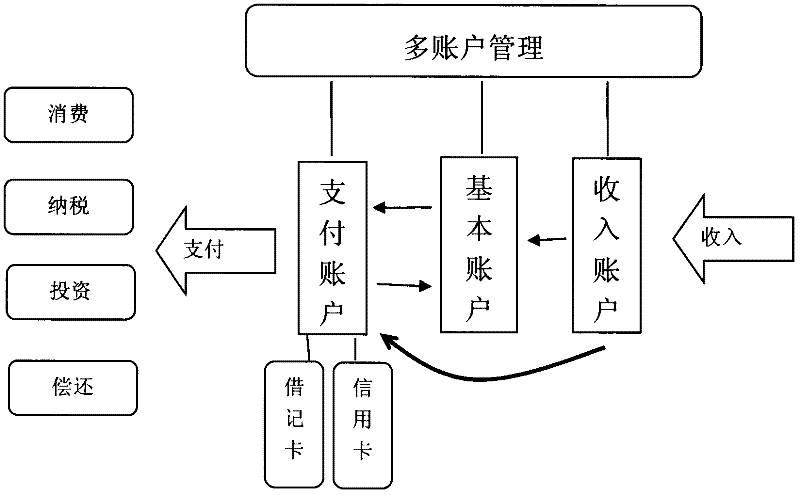

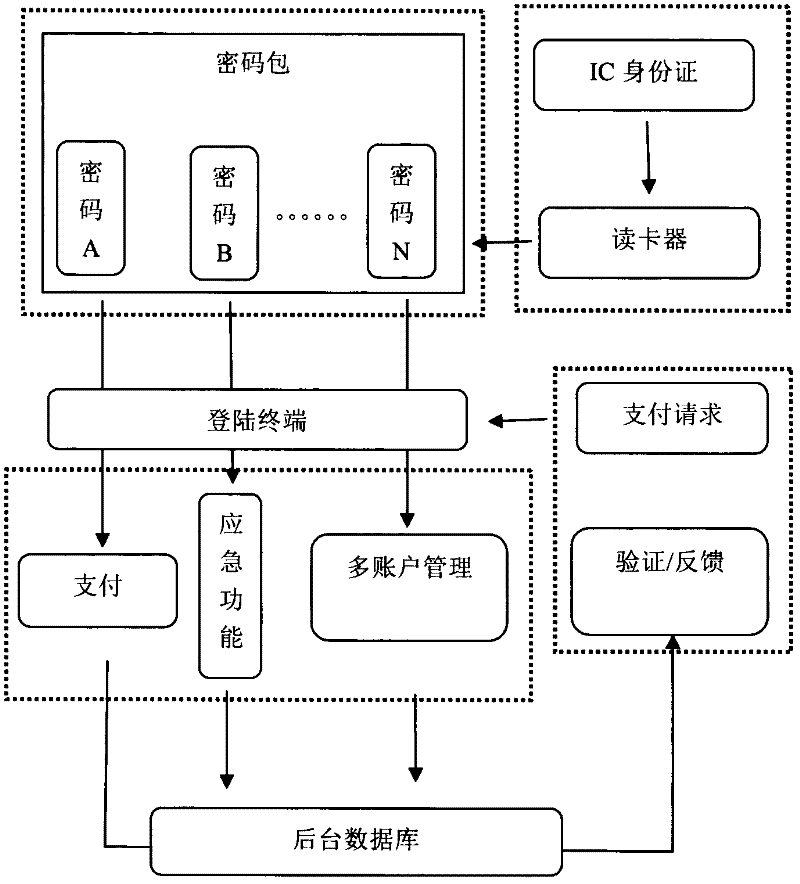

Multi-account management system based on IC (identification card) and identification password combined login

The invention relates to a multi-account management system based on IC (identification card) and identification password combined login. An identification module is connected with a login terminal which is in connection with an executive module, and the executive module is connected with a background data base. Safety is guaranteed by cooperative logins of IC identification, user password packets, card reading equipment, login equipment and the like. One or a plurality of groups of keys in the IC and the password packets are used for identification of users, all purposes can be achieved by one card, different functions, accounts and trading platforms are accessible when different passwords are identified according to unique identification information, and the limit that binding relation between identification cards and accounts or debit cards is set first in similar public technical schemes is broken through. Components of the system are functionally defined and divided, which establishes foundation for long-time availability of overall system establishment and insusceptibility of system integrity and operation to functional upgrading. An identification function and an identification module can be integrally managed by a public security system.

Owner:卢清伟

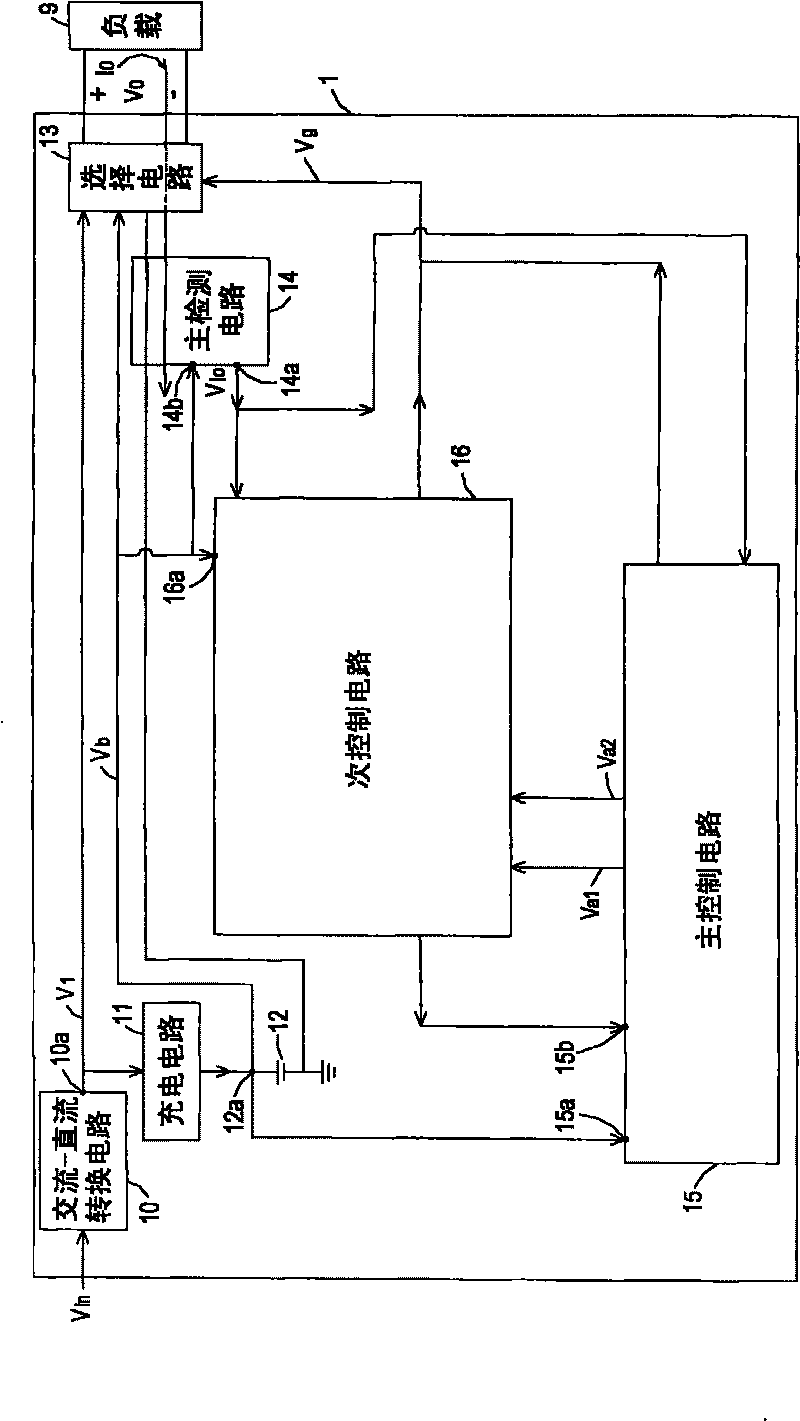

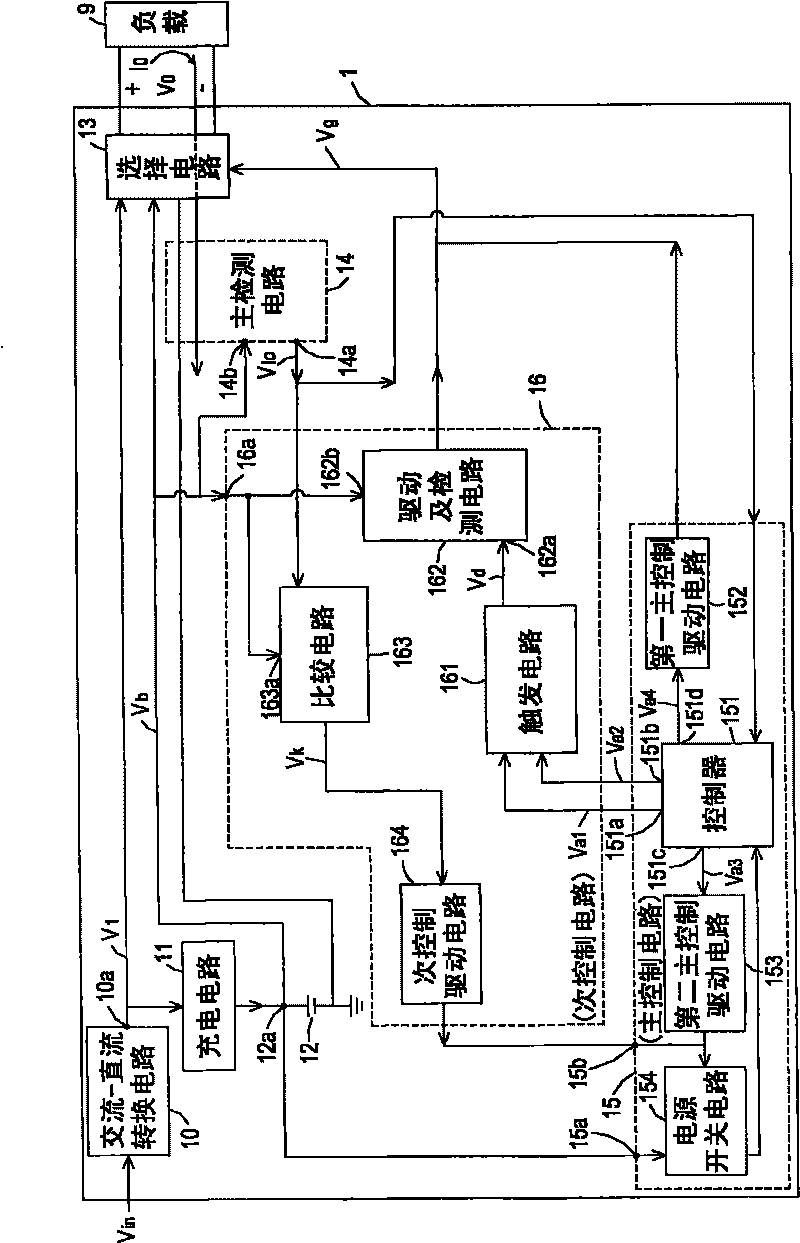

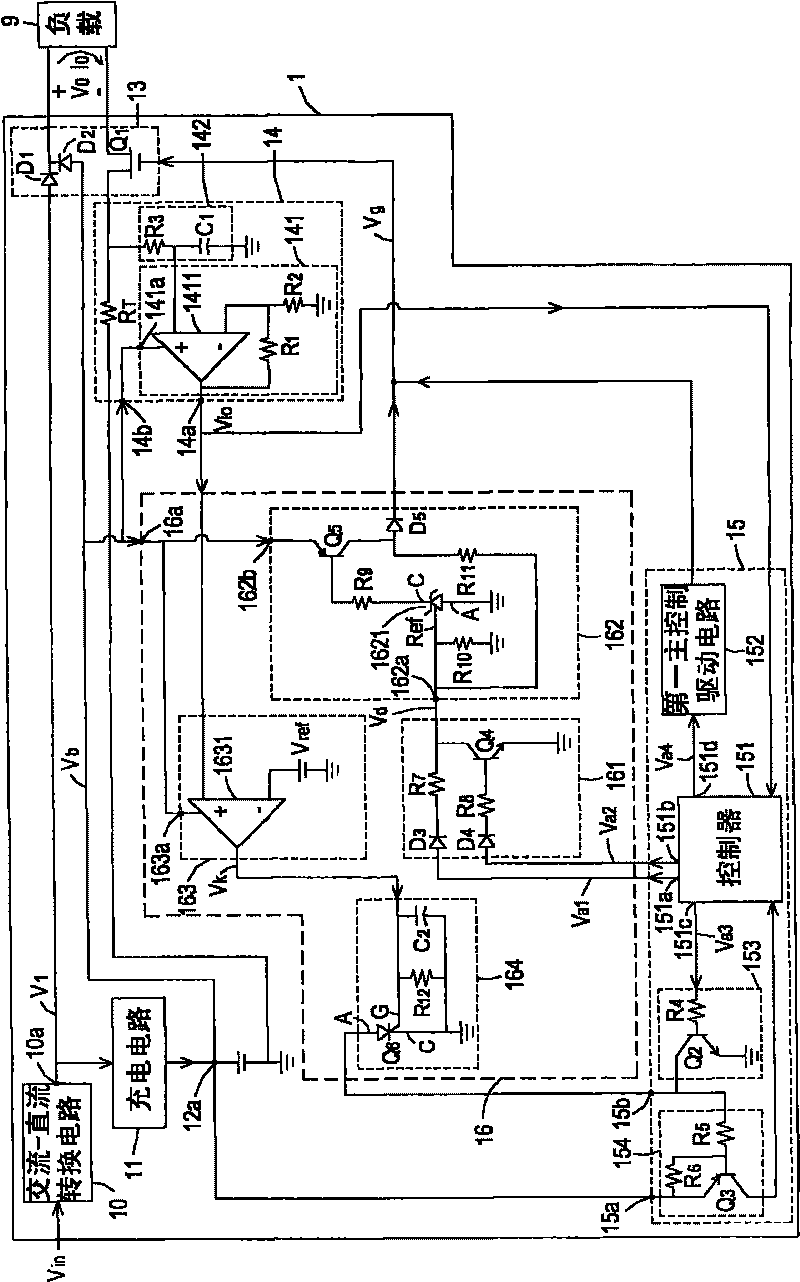

UPS (uninterrupted power supply) device with low power consumption

InactiveCN101752881AImprove efficiencyDoes not affect runnabilityBatteries circuit arrangementsSecondary cells charging/dischargingEngineeringControl circuit

The invention relates to a UPS (uninterrupted power supply) device with low power consumption, which comprises an energy storage unit, an AC-DC conversion circuit, a charging circuit, a selective circuit, a main detecting circuit, a main control circuit and a minor control circuit. As the running of the UPS device is controlled by the main control circuit or the minor control circuit, the UPS device can start and stop the running of the man control circuit or the minor control circuit in good time according to running information (for example, output current) of the UPS device so as to increase the overall efficiency of the UPS device and prolong the power supplying time; moreover, the UPS device can also stop a relatively high-drain controller in good time without affecting the running and power supplying of the UPS device.

Owner:DELTA ELECTRONICS INC

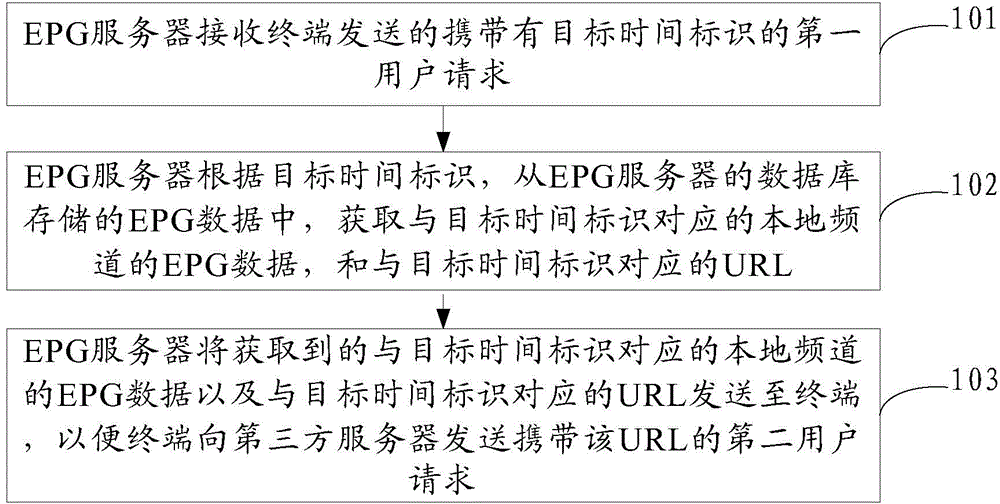

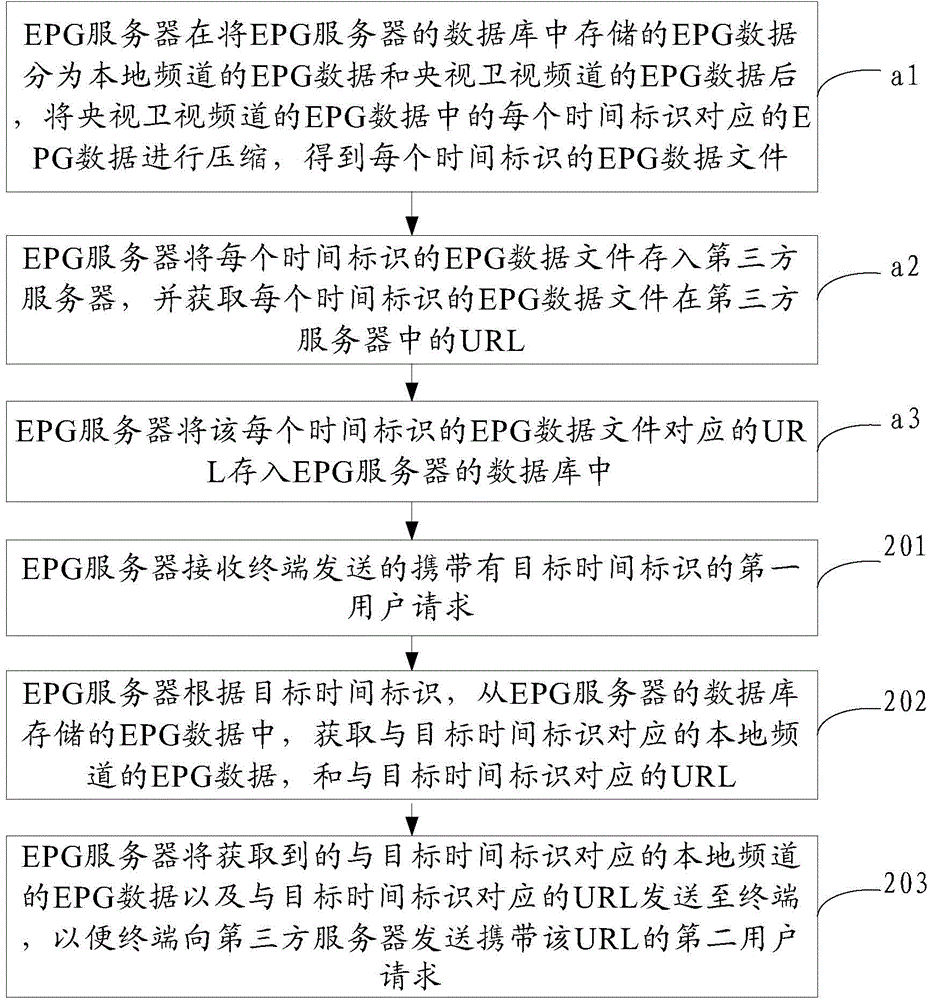

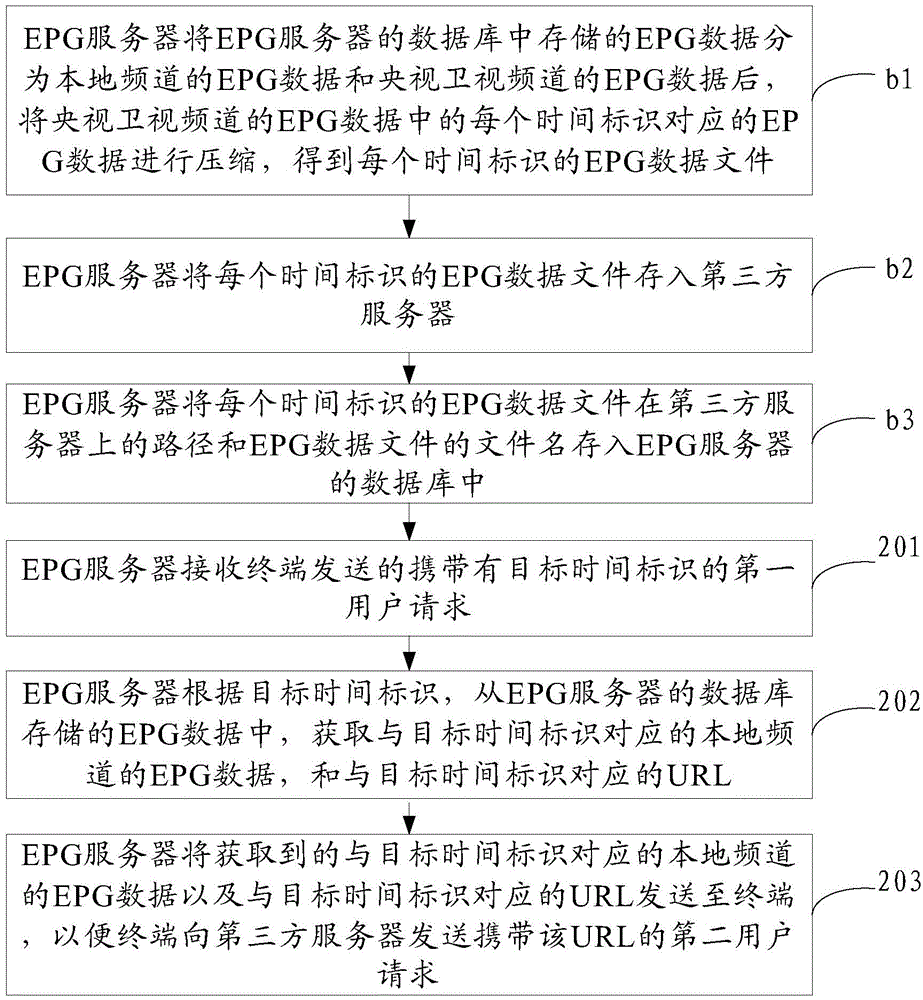

EPG data processing method, EPG server and EPG data processing system

ActiveCN104702980ATroubleshoot things that don't workAvoid non-functioning situationsSelective content distributionData processing systemComputer network

The invention discloses an EPG data processing method, an EPG server and an EPG data processing system and relates to the field of digital televisions. The EPG data processing method, EPG server and EPG data processing system solve the problem of the prior art that the EPG server cannot run normally due to the fact that a lot of outlet bandwidth of the EPG server is occupied when the EPG server sends EPG data to each smart television. The EPG data processing method includes that the EPG server acquires the EPG data of a local channel corresponding to a target time sign and the corresponding URL from the EPG data stored in a database of the EPG server according to the target time sign in the first user request sent by a terminal, and sends the EPG data of the local channel corresponding to the target time sign and the corresponding URL to the terminal to facilitate the terminal to send a second user request with the URL to a third server so as to indicate the third server to obtain the EPG data of a China Central Television satellite television channel corresponding to the URL according to the URL corresponding to the target time sign and send the EPG data to the terminal.

Owner:JUHAOKAN TECH CO LTD

Coking ammonium sulphate front part gas pipeline pressure welding method

ActiveCN103406676AAvoid safety hazardsReduce daily intensive care costsWelding apparatusCoke burnerEngineering

The invention relates to a coking ammonium sulphate front part gas pipeline pressure welding method. The method includes the following steps of step 1, enabling oxygen contents of a negative pressure operation area to be not more than 2%, step 2, enabling intensity of pressure of an air blower to be 14.5-15.5KPa, step 3, carrying out mother solution water seal separation and enabling the liquid level of mother solution to be not lower than 2.5m, step 4, plugging leak points, specifically, welding a V-shaped roll plate to prepare semi-circular arc-shaped roll plates, combining the two arc-shaped roll plates into a pair, welding the arc-shaped roll plates into a circular steel barrel to cover a gas pipeline, cutting the arc-shaped roll plates on connection portions of branch pipes and the gas pipeline into arc-shaped ports, and leading in nitrogen, step 5, manufacturing an arc-shaped-mouth horn barrel and a circular-mouth horn barrel and cutting the two horn barrels into symmetrical two halves respectively, and step 6, welding the horn barrels, specifically, welding the circular-mouth horn barrel with the arc-shaped roll plates, and welding the arc-shaped-mouth horn barrel with the arc-shaped ports and the gas pipeline. According to the welding method, the gas pipeline can be welded under the condition that a coke oven and a gas purification device operate normally.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

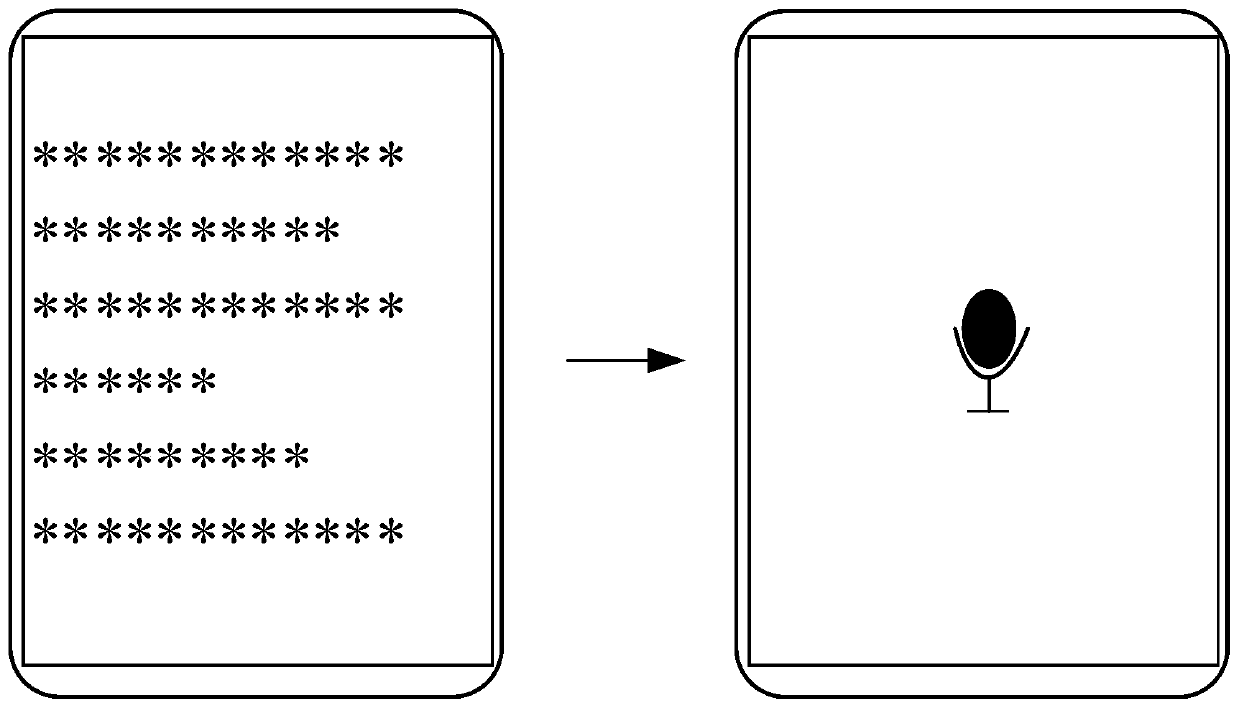

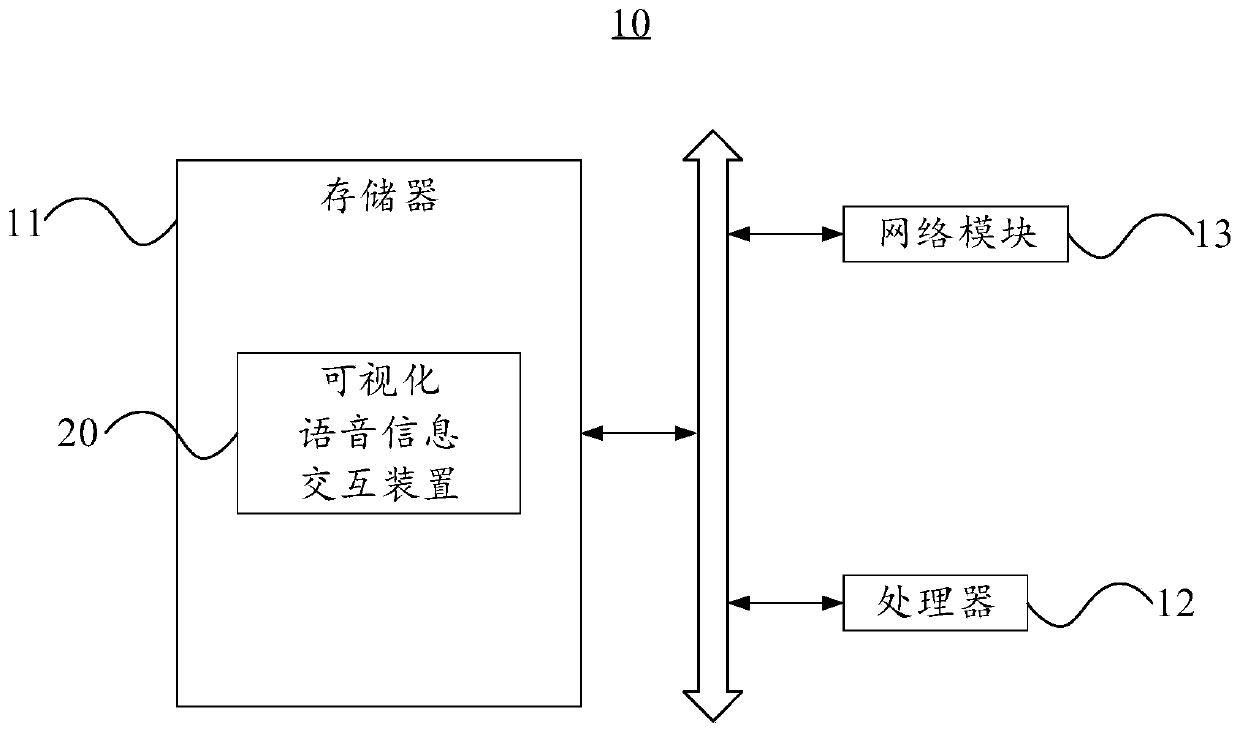

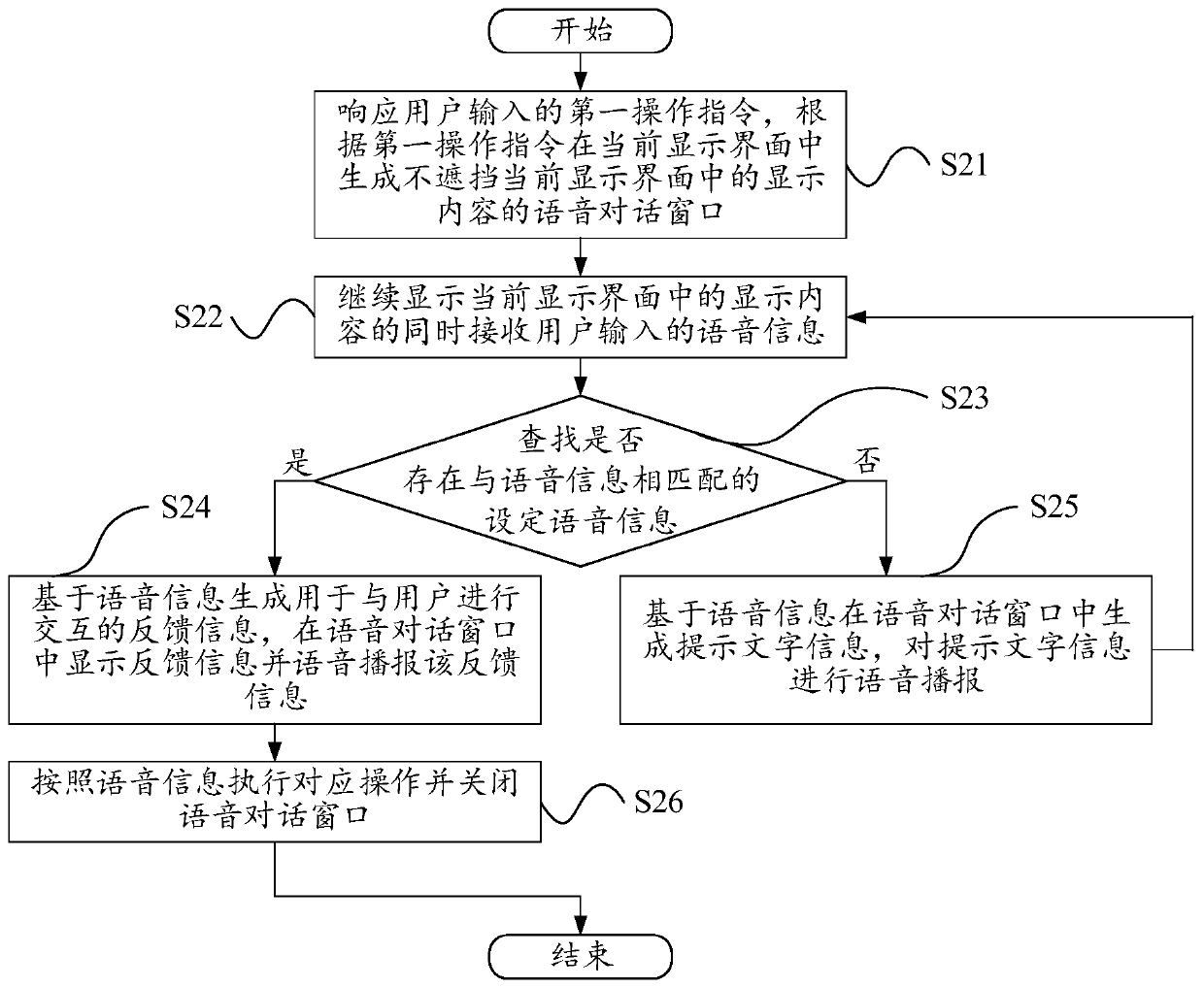

Visual voice information interaction method and device

InactiveCN109979460APerformance is not affectedDoes not affect runnabilitySemantic analysisSpeech recognitionInformation processingUser input

The embodiment of the invention relates to the technical field of information processing, and in particular relates to a visual voice information interaction method and a visual voice information interaction device. According to the method, a voice dialog box generated according to a first operation instruction input by a user can not shelter most of the displayed content in a current display interface, therefore, the use and operation of the displayed content in the current display interface can not be influenced, before the corresponding operation is carried out according to the voivce information input by the user, feedback information for carrying out interaction with the user can be generated based on the voice information, the feedback information is displayed in the voice dialog boxand voice broadcasting of the feedback information is carried out, and therefore, the interaction of the intelligent terminal can be improved.

Owner:上海白泽网络科技有限公司

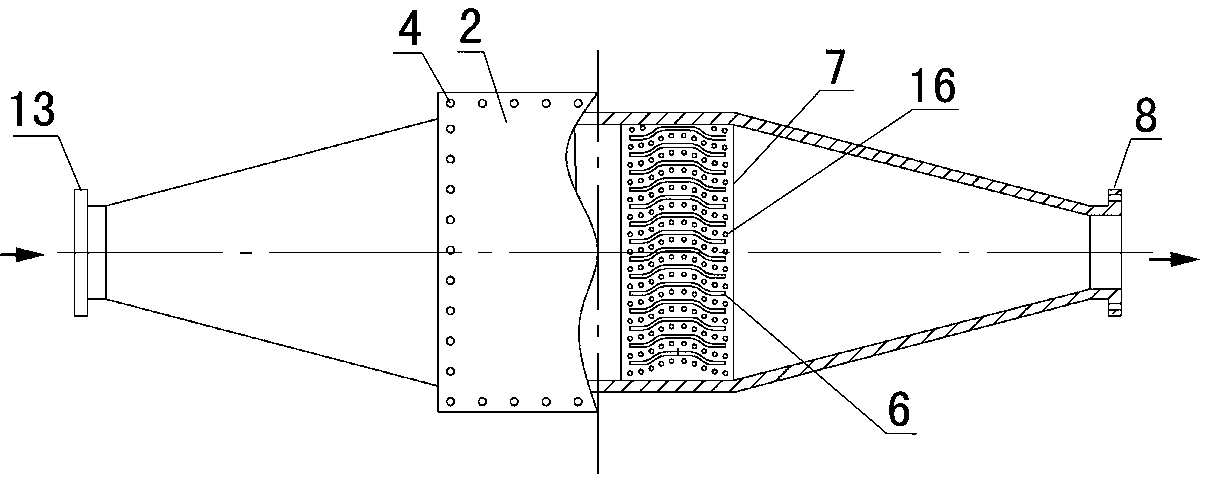

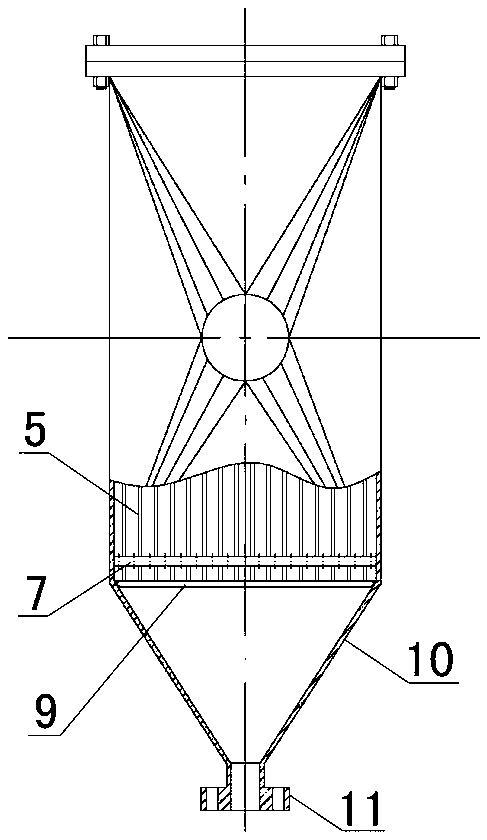

Flue gas desulphurization water ring vacuum pump outlet gas-liquid separation device

ActiveCN103055609AEasy to separateEfficient separationDispersed particle separationFlue gasEngineering

A flue gas desulphurization water ring vacuum pump outlet gas-liquid separation device comprises a housing, one side of the housing is provided with an inlet, the inlet is provided with an inlet flange, the other side of the housing is provided with an outlet, and the outlet is provided with an outlet flange; the housing is sequentially divided into a diffusion section, a large internal diameter section and a conflux section from the inlet to the outlet, the internal diameter of the diffusion segment gradually increases from the inlet to the outlet, and the internal diameter of the conflux gradually decreases from the inlet to the outlet; and the bottom of the large internal diameter section is a funnel-shaped liquid collection room, the top liquid inlet of the liquid collection room is provided with a baffle plate bracket, and the baffle plate bracket supports a baffle plate. The device is a two-phase fluid separation device combining baffling separation with settling separation, can effectively separate and collect fine droplets in the two-phase fluid at the outlet of a vacuum pump, can prevent the secondary entrainment of the collected droplets by a gas, and effectively treats the environmental pollution.

Owner:BEIJING GUODIAN LONGYUAN ENVIRONMENTAL ENG

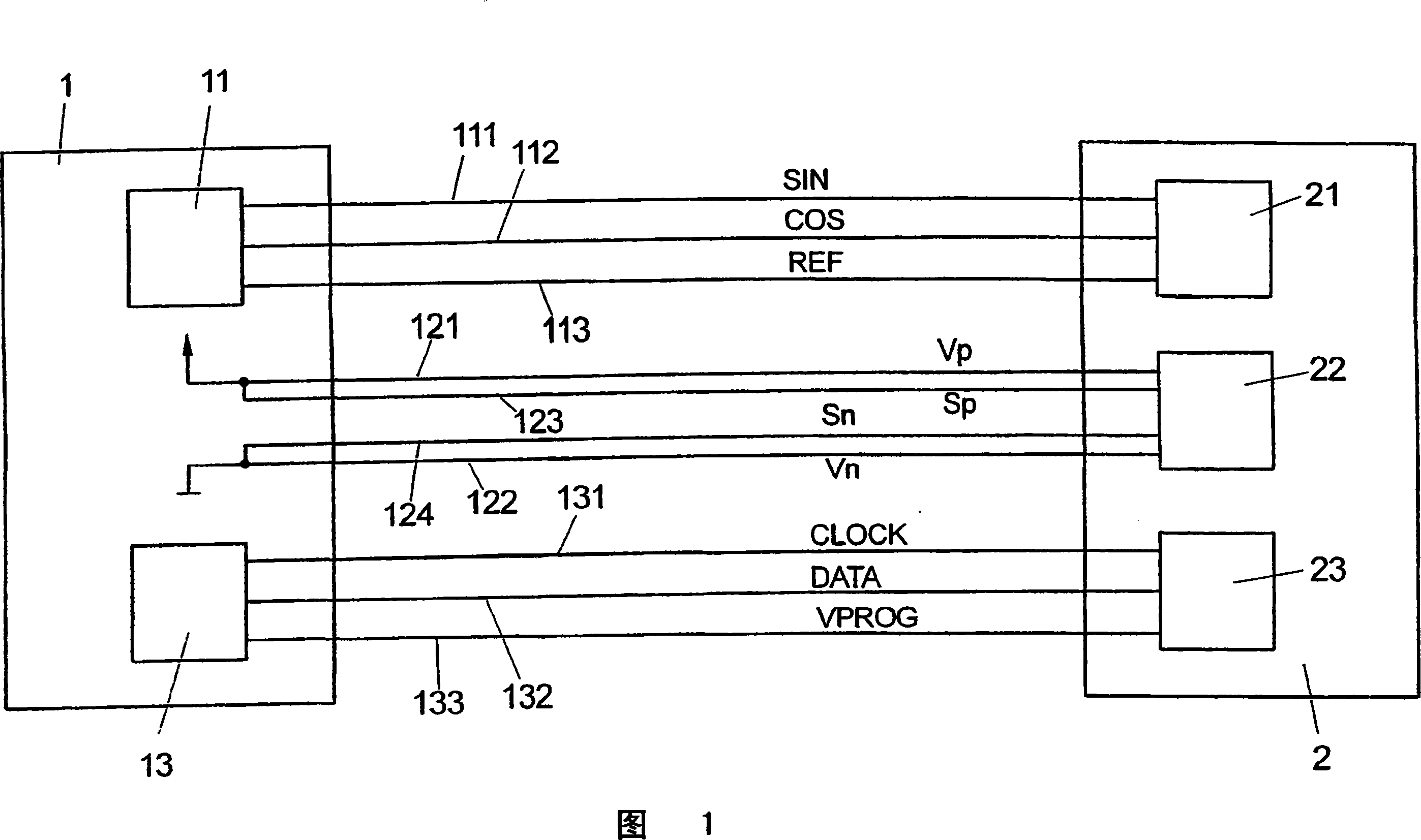

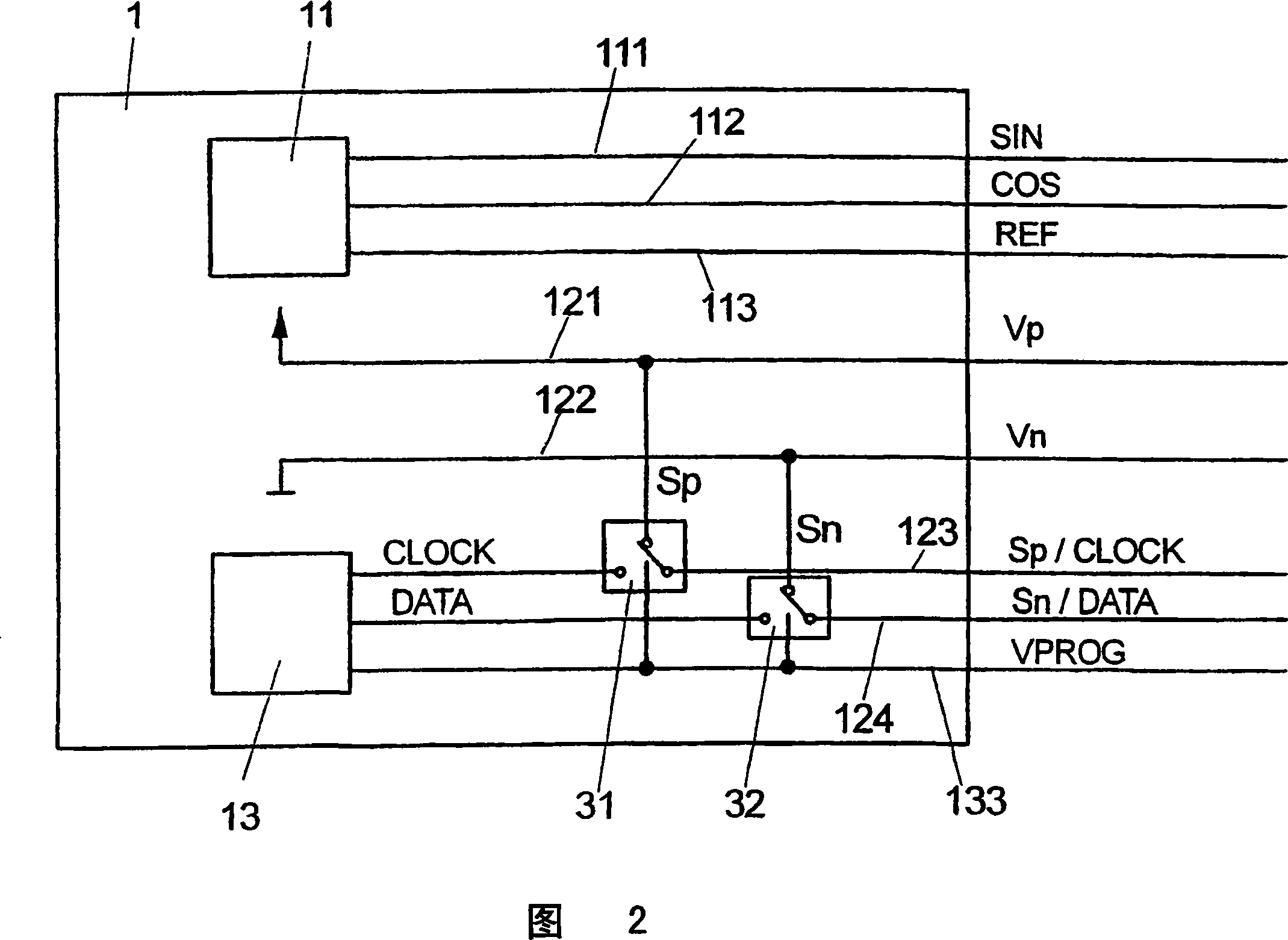

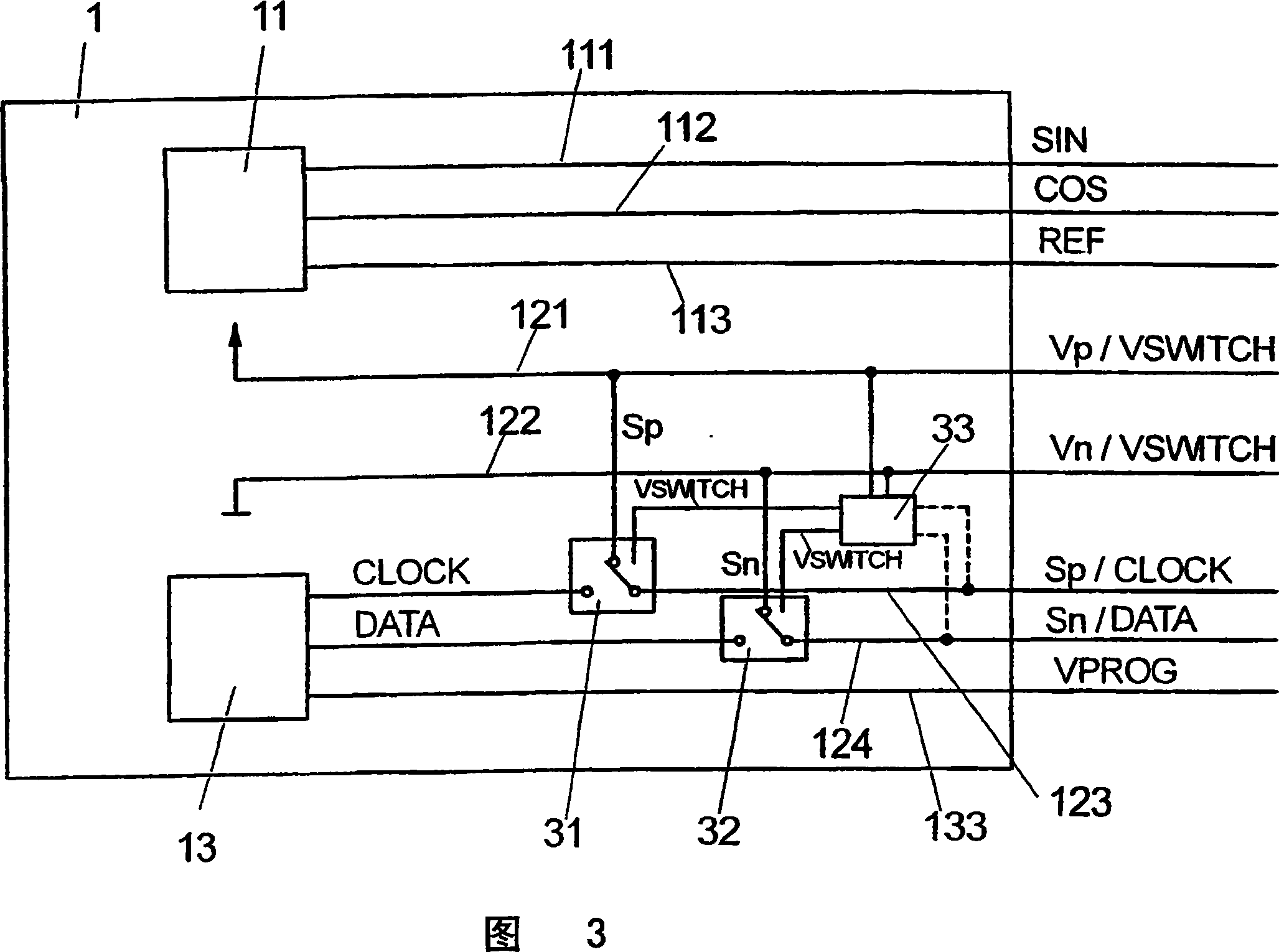

Measuring system with at least one sensor line

InactiveCN101055669ADoes not affect runnabilityDoes not affect functionElectric signal transmission systemsAltering/correcting law of variationSensor planeEngineering

The invention relates to measuring system for measuring at least a measurement value, having at least a sensor line. The sensor line is set to be sensitive line for measuring the state of the measuring system and transmitting the sensor signal indicating the state to the control unit connected to the measuring system. The measuring system has switch unit which switches at least a sensor line of the measuring system. The switching status is dependent on receiving sensor signals so that a data line is provided for transmission of the sensor signals of different data signal.

Owner:DR JOHANNES HEIDENHAIN GMBH

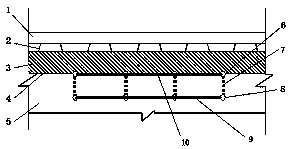

Ballastless track arch-up improving method based on rope saw cutting

InactiveCN109440553ADoes not affect runnabilityDoes not affect operationsRailway track constructionFilling materialsEngineering

A ballastless track arch-up improving method based on rope saw cutting includes the following steps of firstly, determining the falling amount of an arch-up section of a ballastless track, and conducting steel bar embedding and anchoring on the positions, at the two ends of the arch-up section, of the ballastless track; secondly, drilling rope saw operation holes in the side face of the ballastless track; thirdly, cutting off concrete of a supporting part of the ballastless track, providing a falling space for the ballastless track, and limiting the cut ballastless track; fourthly, fine adjusting the ballastless track to fall by a design value, fully filling the lower gap or interlayer gap of the ballastless track with a filling material, and recovering the route stability; fifthly, conducting steel bar embedding and anchoring on an improvement area of the ballastless track, fine adjusting a fastener system and recovering the route smoothness. By means of the method, the existing structure of the ballastless track cannot be changed, the geometrical state of the ballastless track is stable in the improvement process, the train driving safety is not affected, and the method can be implemented in the skylight maintaining time and is suitable for the arch-up improvement of the ballastless track with a high-quality lower concrete force-bearing structure.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

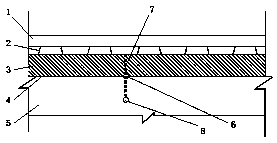

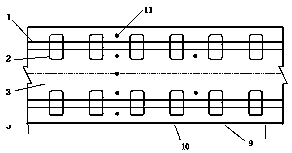

Sedimentation improving method for ballastless track based on rope saw cutting

InactiveCN109355986ADoes not affect runnabilityDoes not affect operationsRailway track constructionFilling materialsEngineering

The invention discloses a sedimentation improving method for a ballastless track based on rope saw cutting. The method comprises the following steps that (1) the sedimentation volume of the part, in asedimentation section, of the ballastless track is determined, and the two ends of the sedimentation section of the ballastless track are subjected to bar planting and anchoring; (2) a rope saw operation hole is drilled in the side surface of the ballastless track; (3) a rope saw is adopted for cutting concrete of the ballastless track, bonding constraint of the ballastless track is removed, andthe ballastless track after cutting is limited; (4) a jacking device placing groove is formed in concrete below a horizontal cutting seam; (5) after a jacking system is adopted for jacking the ballastless track to a design value, gaps of the lower portion of the ballastless track after jacking are filled with a filling material to be full, and the line stability recovers; (6) the ballastless trackin the improving area is subjected to bar planting and anchoring, the fastener system is accurately adjusted, and the line smoothness recovers. The method is simple, quick, safe and reliable, in theimproving process, the geometrical state of the ballastless track is stable, the running safety of trains cannot be influenced, and the improving can be conducted in the period of maintaining skylights and is suitable for quick jacking of the ballastless track.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

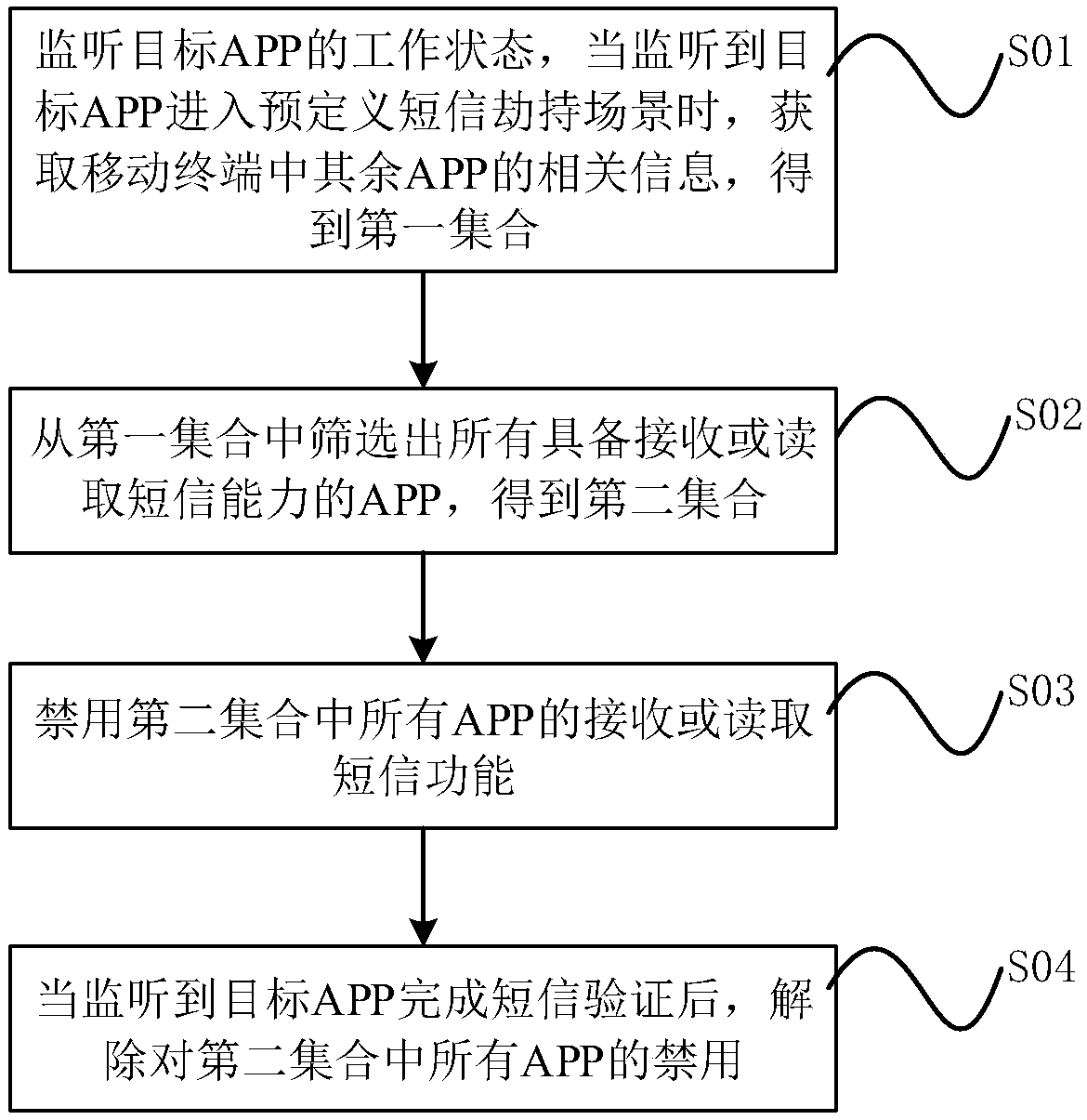

Short-message hijack prevention method applied to mobile terminal and device

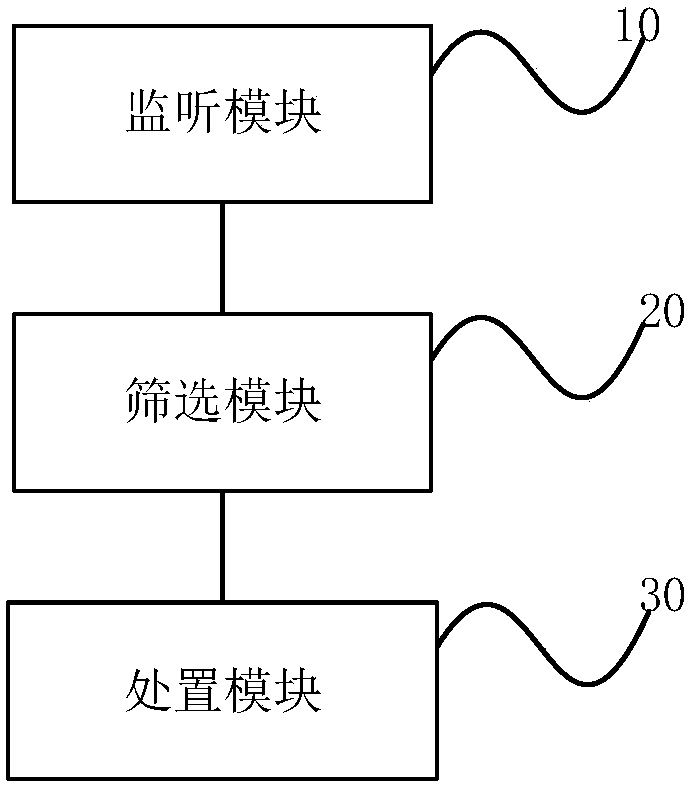

InactiveCN108229151AAvoid hijackingEnsure safetyPlatform integrity maintainanceComputer hardwareMobile end

The invention discloses a short-message hijack prevention method applied to a mobile terminal. According to the method, potential environmental threat to a user in a predefined short-message hijack scene is found by monitoring the whole working state of a target APP, the security of a current use environment is ensured by forbidding corresponding functions of APPs possibly hijacking a target short-message, and the purpose of preventing the short-message from being hijacked is achieved. The method only needs to be deployed on the mobile terminal, is high in universality and suitable for varioususe scenes requiring short-message hijack prevention, does not influence a normal running process and use of a system and also has the advantages of being convenient to operate, low in cost and the like.

Owner:WUHAN ANTIY MOBILE SECURITY

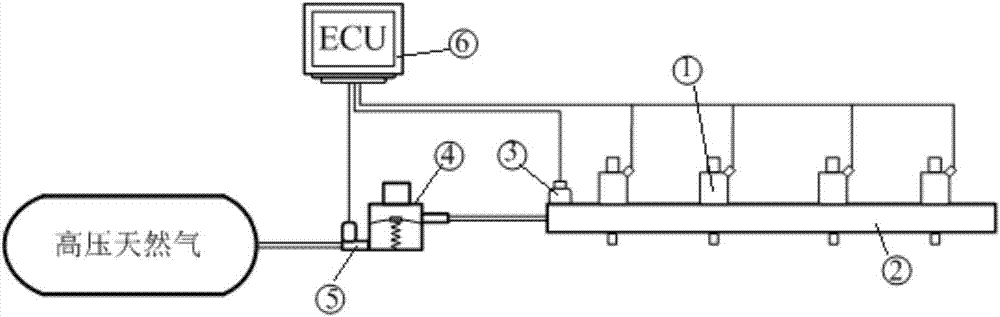

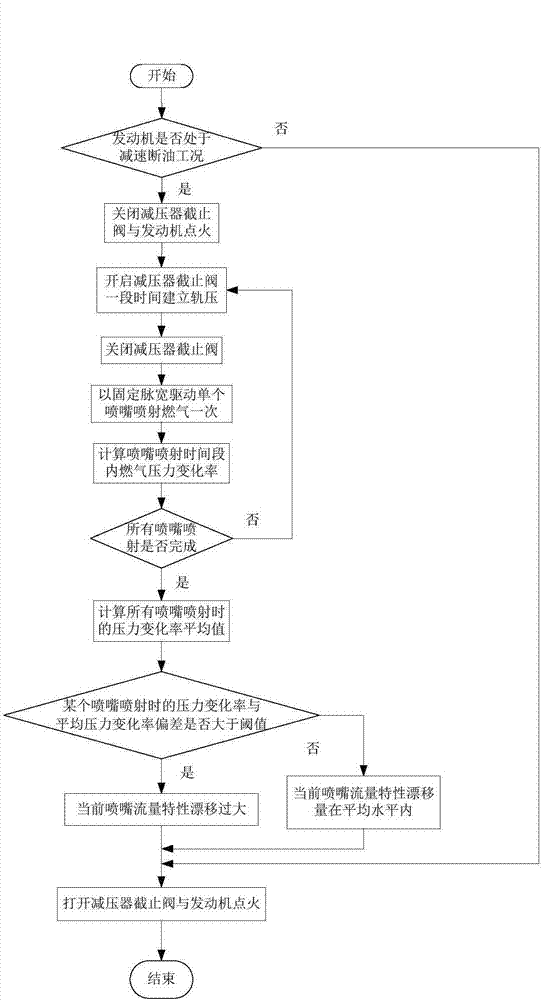

On-line detection method for flow characteristic drift amount of fuel gas nozzle

ActiveCN107218139AGuaranteed gas supplyGuaranteed demandInternal combustion piston enginesEngine controllersSpray nozzleProcess engineering

The invention discloses an on-line detection method for the flow characteristic drift amount of a fuel gas nozzle. According to the on-line detection method for the flow characteristic drift amount of the fuel gas nozzle, on the premise that parts and the cost are not increased, a warn that the flow characteristic drift amount of the fuel gas nozzle is too large is given for a user of a natural gas engine so that the safety of the using process of the engine can be ensured; the flow characteristic drift amount of the fuel gas nozzle is detected so that the user of the engine can be assisted to eliminate the fault causes; the user of the engine can be timely reminded to check and replace parts of a fuel gas supply system so that the controllability of fuel gas supply can be ensured, and the use safety of fuel gas can be ensured; and meanwhile, the detection method is executed in the engine deceleration and fuel cut-off processes so that normal operation and use of the engine cannot be influenced. The detection method has the advantages of being simple and effective.

Owner:CHINA FIRST AUTOMOBILE

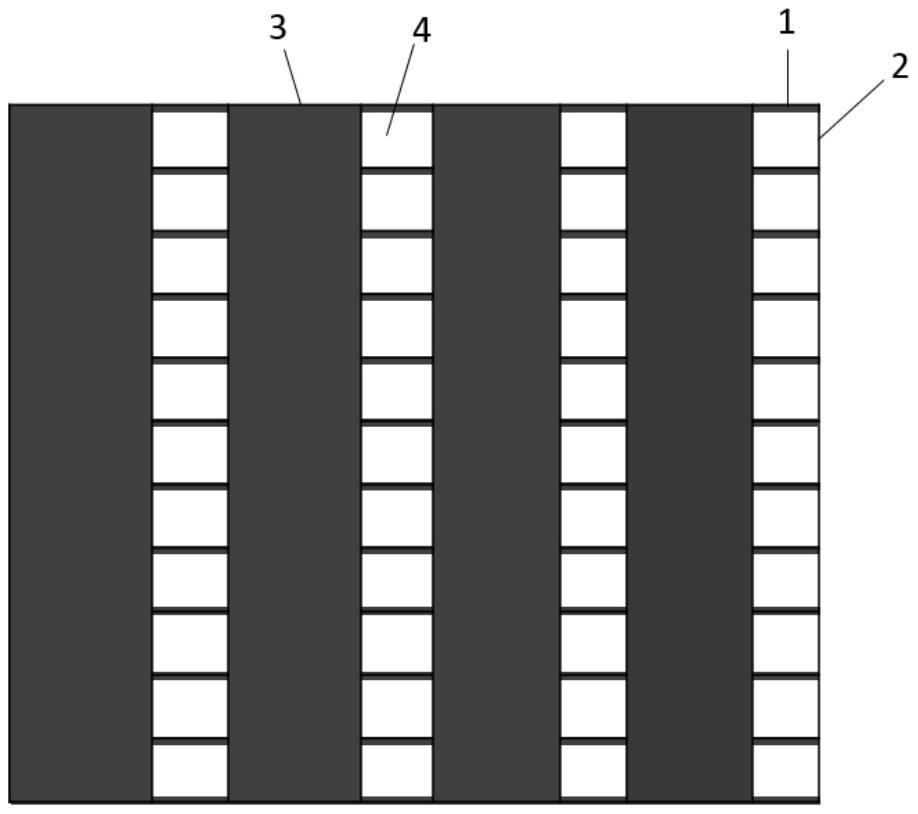

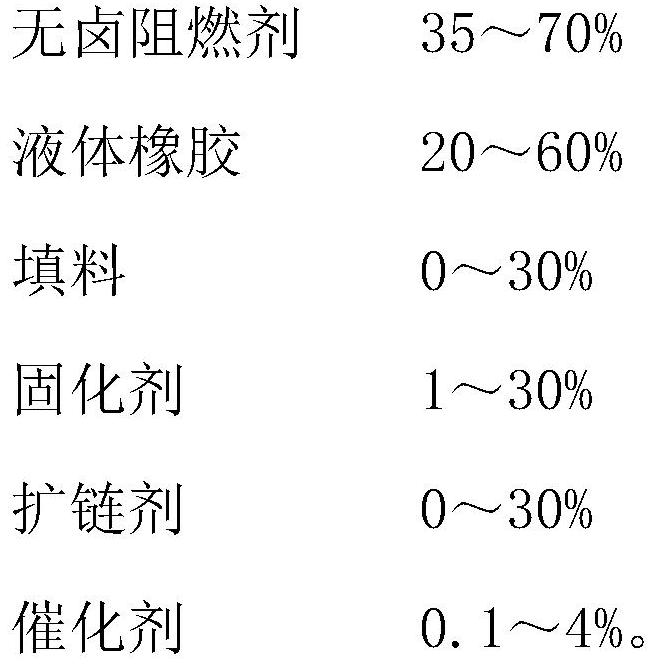

Novel explosion-proof flame-retardant belting material for cable

The invention provides a novel explosion-proof flame-retardant belting material for a cable, which comprises the following components in percentage by mass: 70-97% of a flame-retardant rubber materialand 3-30% of a framework material, and the framework material is a flame-retardant fiber mesh material with the strength of more than 25g / denier. The flame-retardant rubber material comprises a halogen-free flame retardant, liquid rubber, a filler, a chain extender and a catalyst. The framework material is controlled to be designed to be a flame-retardant fiber mesh type, good ventilation performance is achieved, air circulation is facilitated, heat generated by the cable in the operation process can be dissipated to the external environment in time, the temperature of the cable is reduced, and the service life of the cable is prolonged. By controlling the mass percentage of the halogen-free flame retardant in the flame-retardant rubber material to be 35-70%, the explosion-proof flame-retardant belting material can be instantly expanded and foamed under the action of open fire, thereby playing a good role in fire prevention and heat insulation on the internal cable and effectively protecting the cable from being damaged by fire accidents.

Owner:蔡晨灿

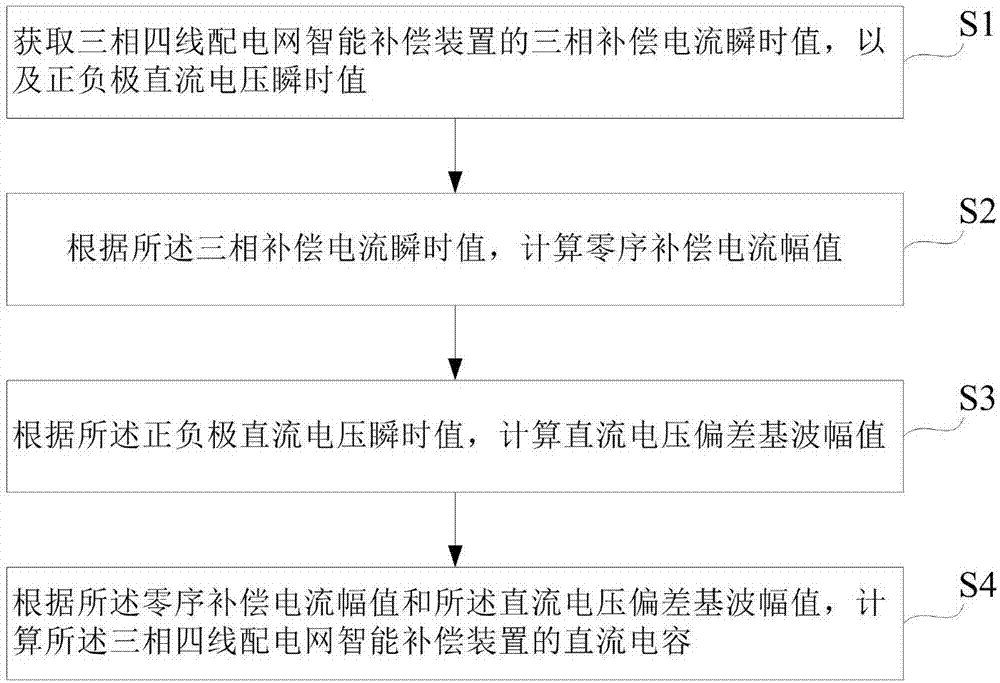

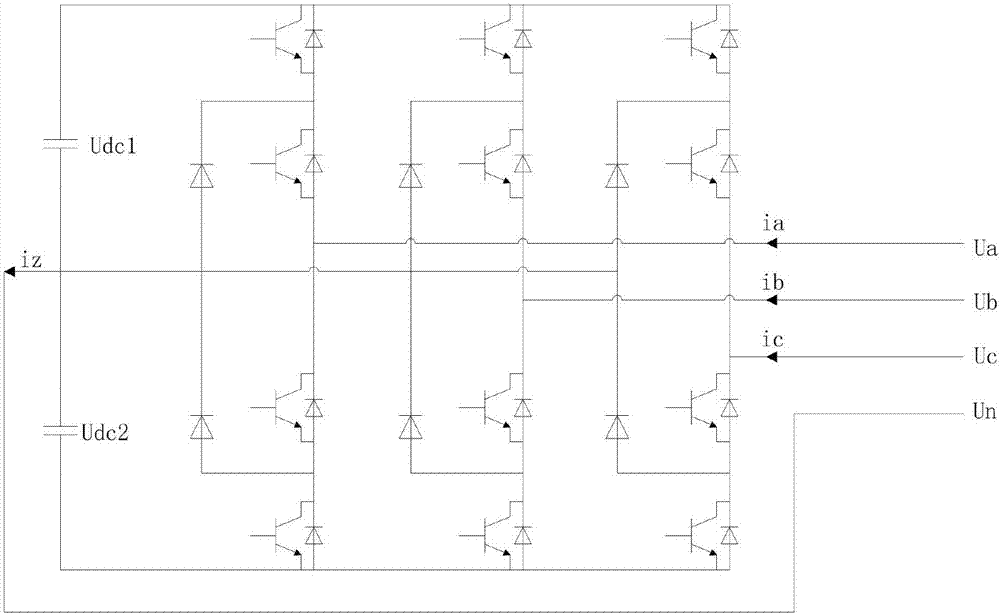

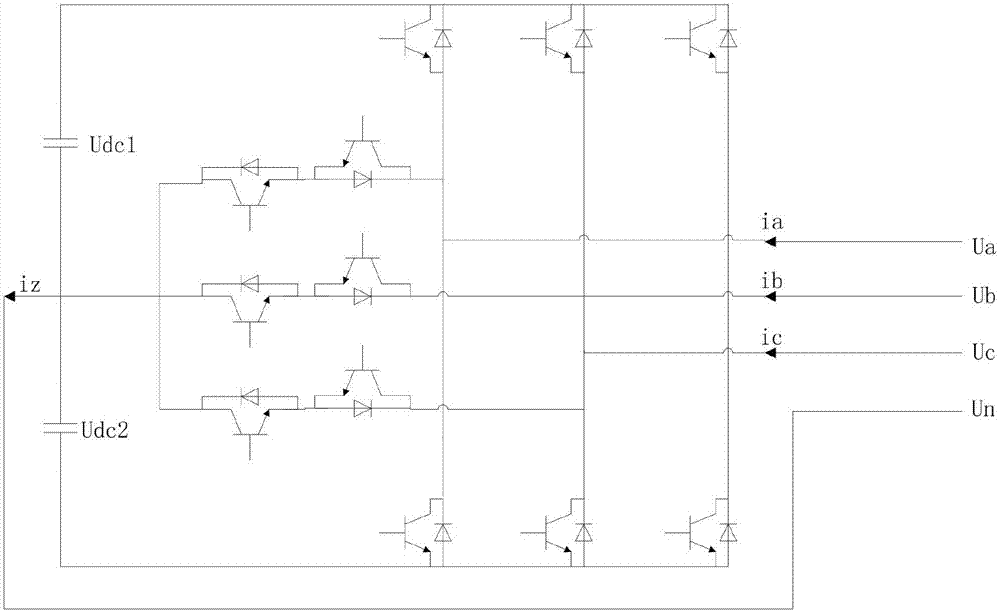

Direct current capacitance detection method, apparatus and system for three-phase four-wire power distribution network compensation equipment

ActiveCN107147138ADoes not affect runnabilityDoes not affect the compensation effectCapacitance measurementsPolyphase network asymmetry elimination/reductionCapacitancePower flow

Embodiments of the invention disclose a direct current capacitance detection method, apparatus and system for three-phase four-wire power distribution network compensation equipment. By means of obtaining a three-phase compensation current instantaneous value and positive electrode and negative electrode direct current voltage instantaneous values of the three-phase four-wire power distribution network compensation equipment, a zero-sequence compensation current amplitude and a direct current voltage deviation fundamental wave amplitude are calculated so as to calculate the direct current capacitance of the three-phase four-wire power distribution network compensation equipment. According to the method, operation stop of the three-phase four-wire power distribution network compensation equipment is not needed; and instead, the direct current capacitance value can be detected in the normal operation process of the three-phase four-wire power distribution network compensation equipment, and the direct current capacitance value of the three-phase four-wire power distribution network compensation equipment can be continuously monitored.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

Sliding pendulum pneumatic machine

The invention provides a sliding pendulum pneumatic machine which comprises a stator, a rotor and a cover plate, wherein the stator is a circular-ring table; the outer circle and inner circle of the circular-ring table are not concentric; an air inlet and an air exhaust opening are symmetrically formed in the circular-ring table; an arc air expansion cavity trench which is 3 / 4-4 / 5 of the inner circumference is formed in the inner wall of the circular-ring table; the axis of the rotor is concentric with the inner circle of the circular-ring table; the rotor is fixed in an inner circular hole of the stator through two end cover plates. The sliding pendulum pneumatic machine has the effects that 1, the efficiency of the sliding pendulum pneumatic machine is higher than that of the conventional screw expansion power machine and that of the steam turbine; 2, the sliding pendulum pneumatic machine is convenient for processing, the requirement on the precision is low, and the sliding pendulum pneumatic machine is easy to popularize and use; 3, the recycling rate of an afterheat source can be increased, and the device is beneficial to a path of substainable development of the society.

Owner:新余市银龙机电科技有限公司

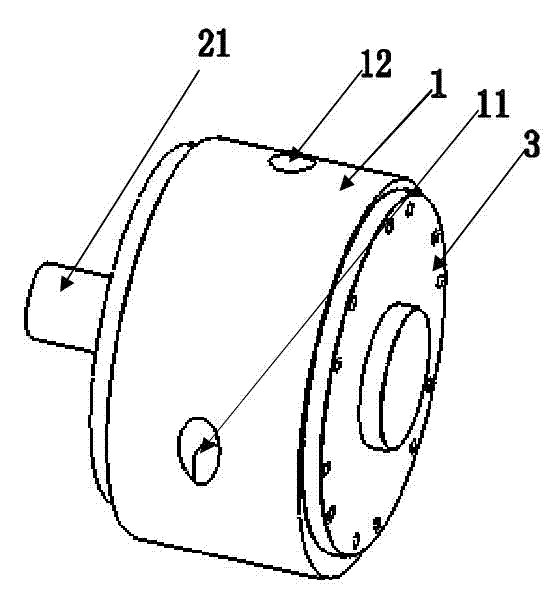

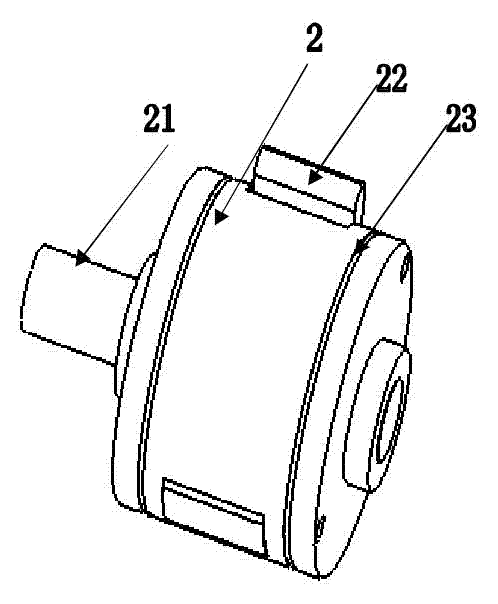

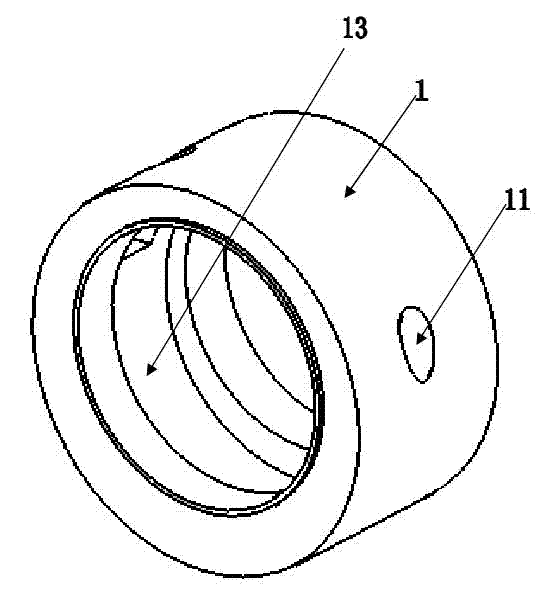

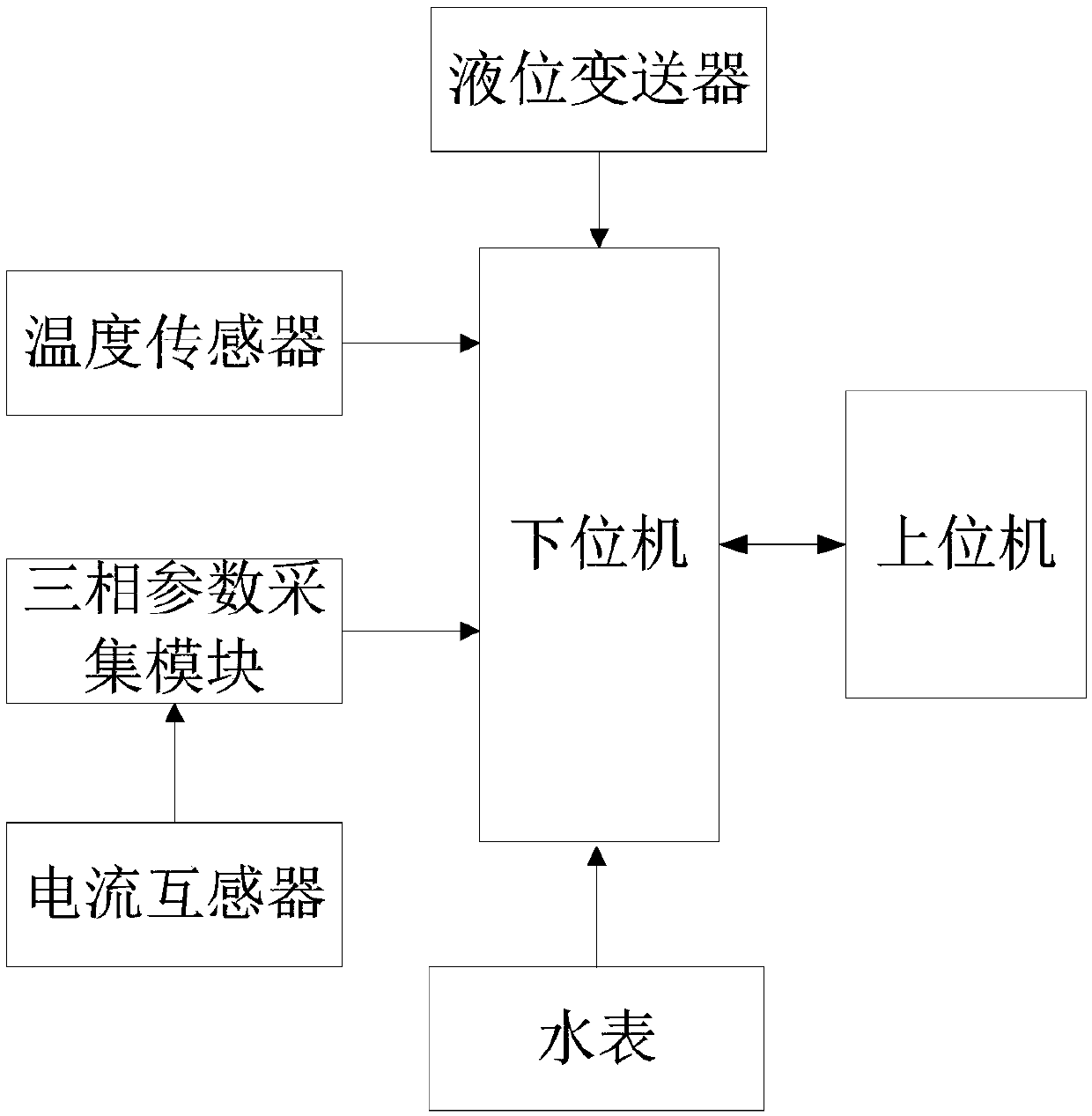

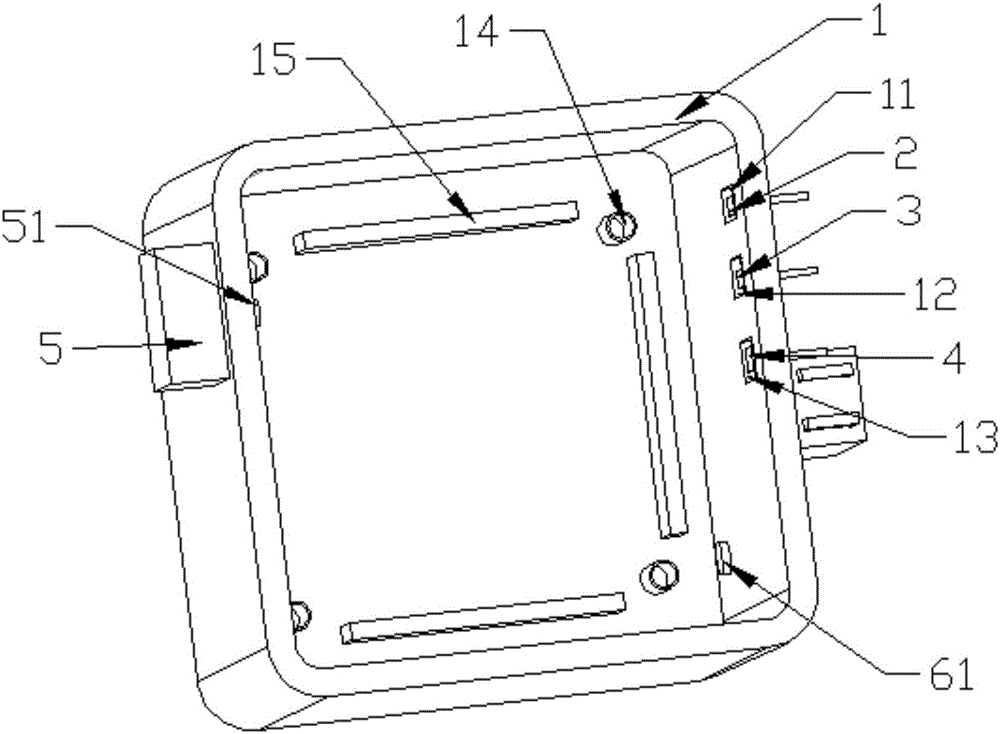

Submersible electric pump control system and method

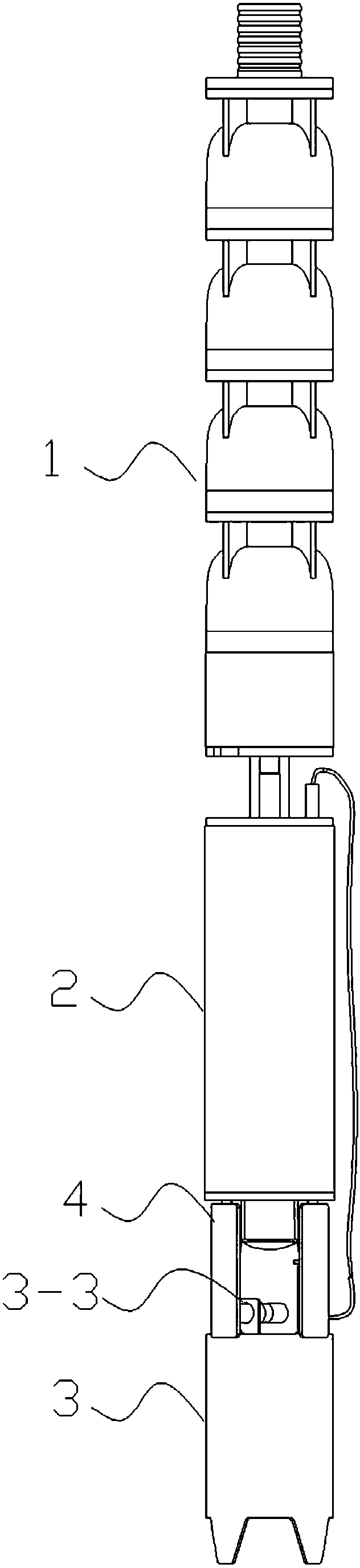

PendingCN107762895ADoes not affect assemblyDoes not affect runnabilityPump controlStructural associationControl systemPower parameter

The invention discloses a submersible electric pump control system and method. The submersible electric pump control system comprises a motor, a pump body arranged at the output end of the motor, a control mechanism arranged at the base end of the motor, and an upper computer arranged above the liquid level; the control mechanism comprises a water-proof sealed shell, a lower computer arranged in acavity of the water-proof sealed shell, a three-phase electric parameter collecting module and an power line carrier module and further comprises a liquid level transmitter arranged outside the water-proof sealed shell, a current transformer and a temperature sensor, and the current transformer and the temperature sensor are arranged in a shell of the motor. The control method comprises the stepsthat the liquid level transmitter, the temperature sensor and the three-phase electric parameter collecting module collect working parameters of a submersible electric pump and transmits the workingparameters to the lower computer; and the lower computer controls the power line carrier module to conduct data modulation loading on the collected working parameters, and the working parameters are uploaded to the upper computer in an power line carrier communication mode in real time. Through the submersible electric pump control system and method achieve online monitoring of the submersible electric pump.

Owner:河北省机械科学研究设计院有限公司

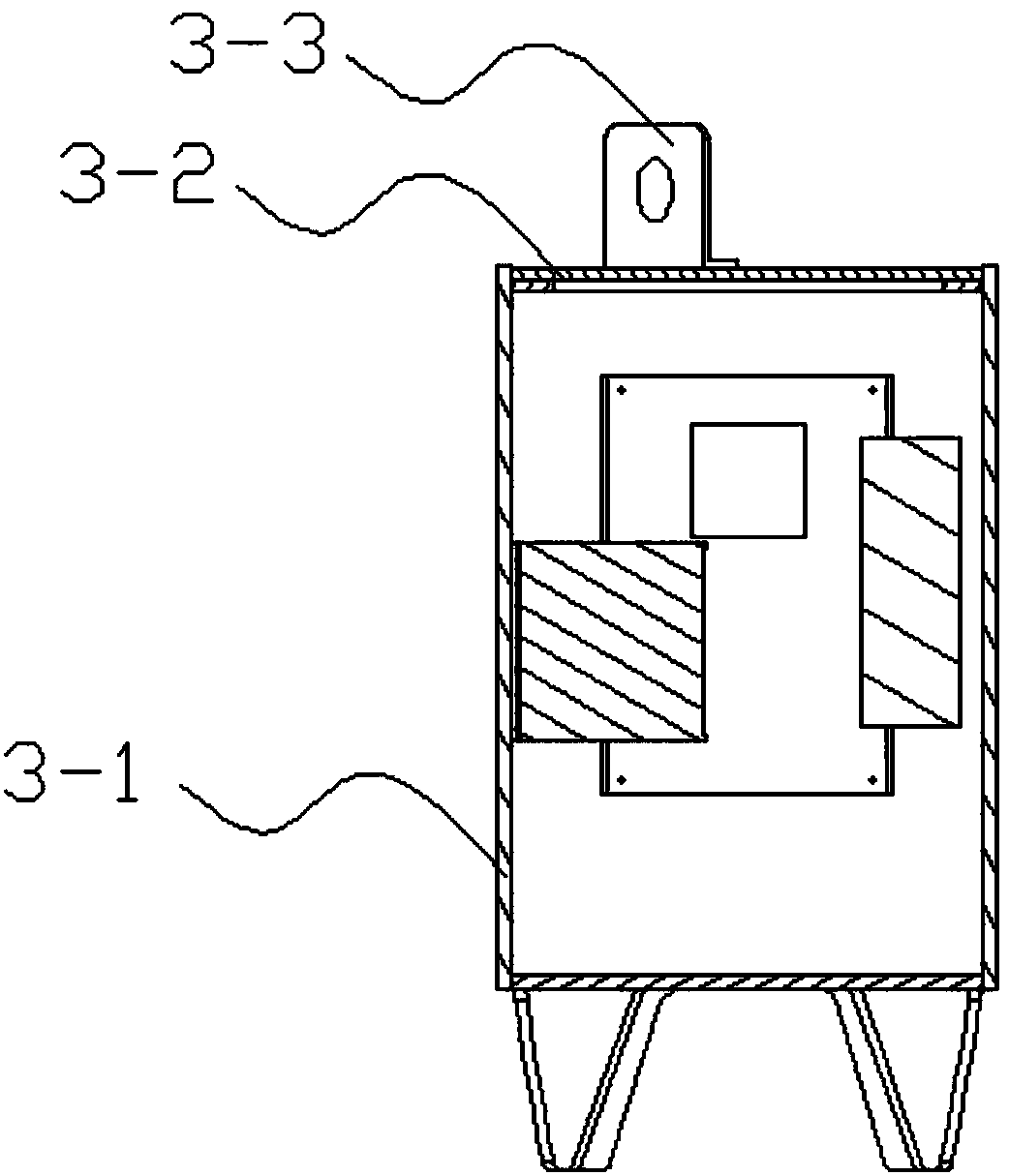

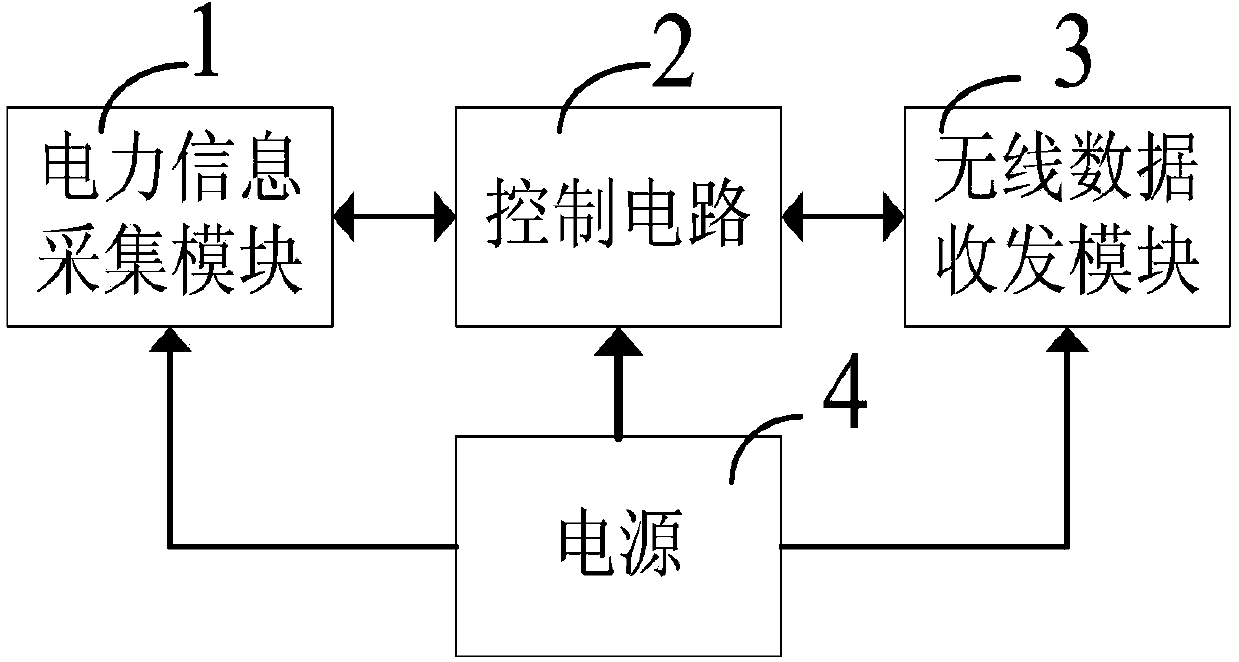

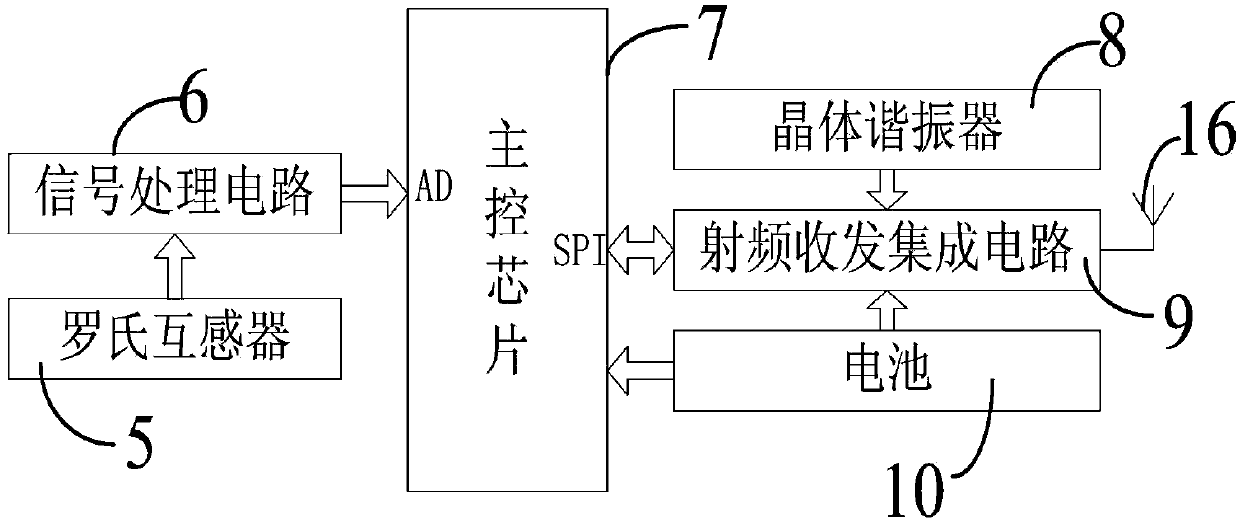

Wireless and intelligent trip

ActiveCN103995196AAccurate measurementEffective understandingElectrical testingPower gridWireless data

The invention relates to a wireless and intelligent trip which comprises an electric power information collecting module for obtaining power grid operation information. The electric power information collecting module is connected with the input end of a control circuit, and the control circuit is connected with a wireless data receiving-transmitting module; a power grid setting protection value is set in the control circuit in advance, and electric power operation information is obtained by the control circuit according to collected information transmitted by the electric power information collecting module and are stored; the electric power operation information is compared with the power grid setting protection value through the control circuit, when the electric power operation information is not matched with the power grid setting protection value, the control circuit transmits early-alarming information through the wireless data receiving-transmitting module in a wireless mode, and the sampling frequency of the control circuit on the electric power operation information of the electric power information collecting module is increased. The wireless and intelligent trip is compact in structure, can conduct electric power information detection analysis, fault early warning and relative data wireless receiving and transmitting, and guarantees that a power grid safely and reliably operate.

Owner:STATE GRID CORP OF CHINA +3

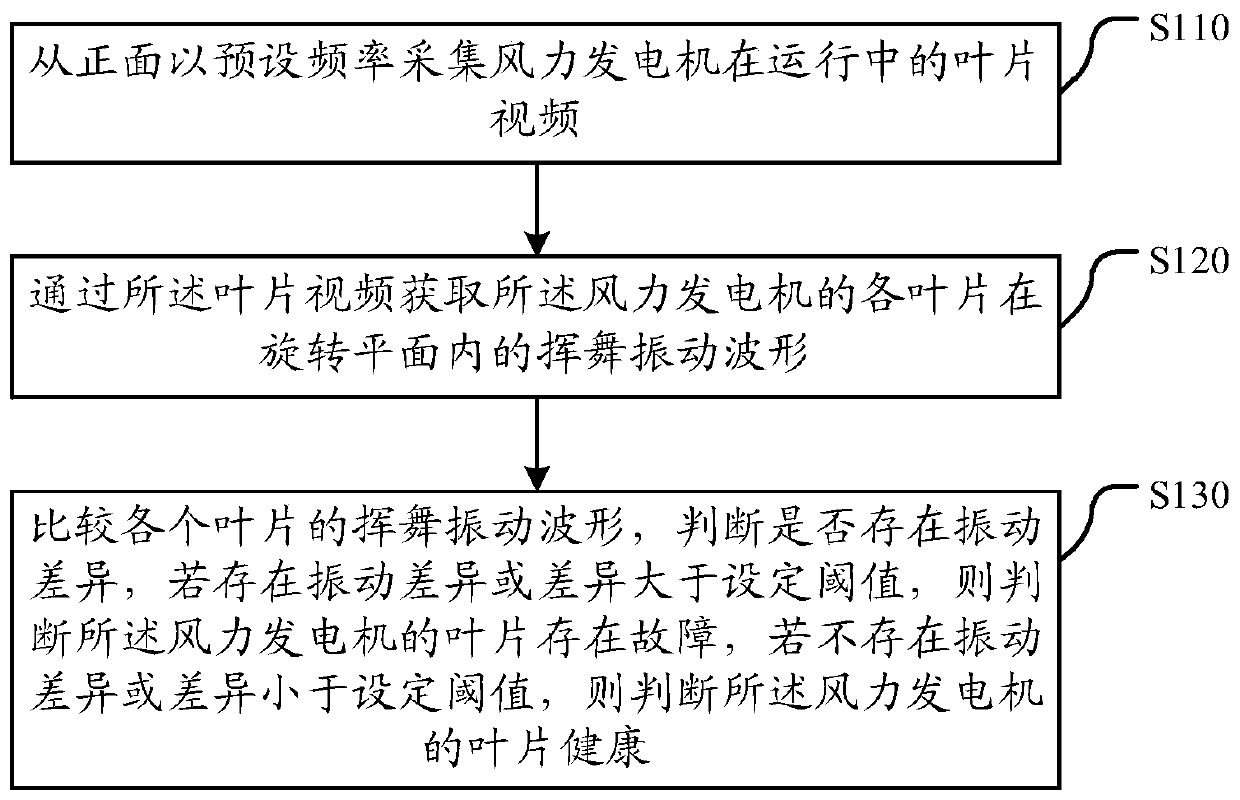

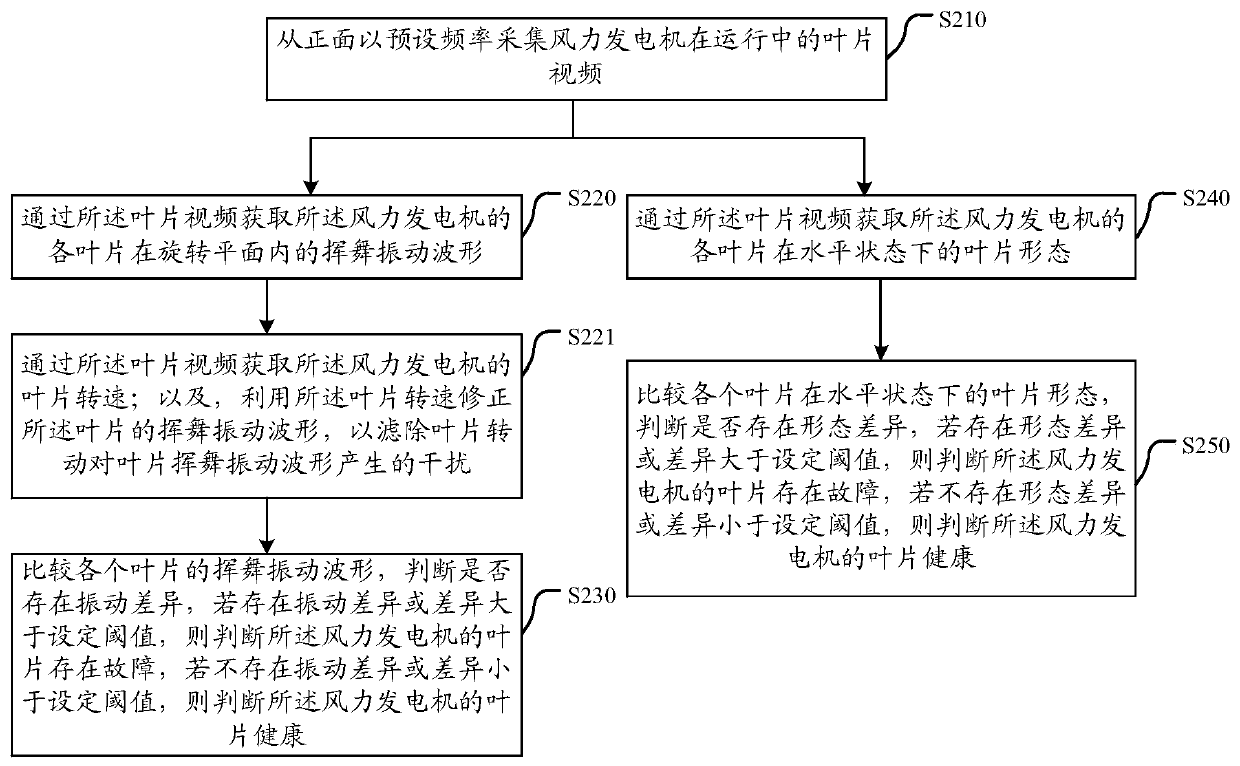

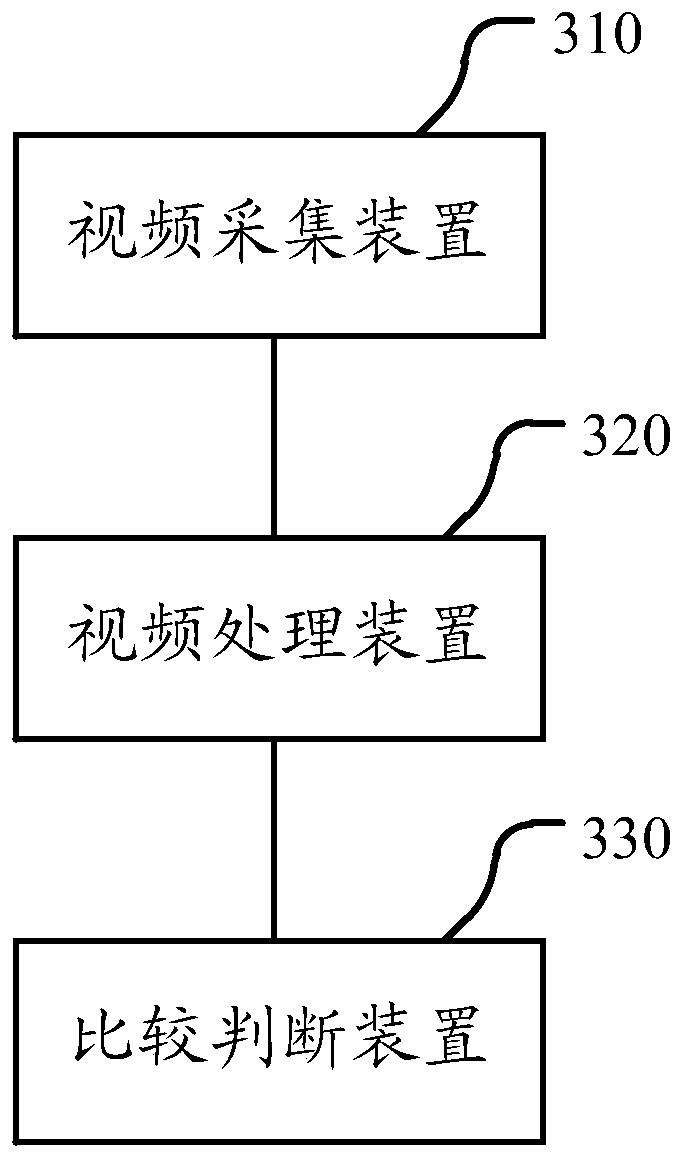

Fault detection method and system for wind driven generator

ActiveCN110486236ADoes not affect the structureDoes not affect runnabilityMachines/enginesWind motor monitoringWind drivenEngineering

The invention discloses fault detection method and system for a wind driven generator. The method comprises the following steps that a blade video of the wind driven generator in operation is collected from the front side at a preset frequency; the wave vibration waveform of each blade of the wind driven generator in the rotating plane is obtained through the blade video; and the wave vibration waveforms of all blades are compared, whether vibration difference exists or not is judged, if the vibration difference exists, whether the blades of the wind driven generator have faults is judged, andif the vibration difference does not exist, whether the blade of the wind driven generator is in good condition is judged. According to the method, the wave vibration waveform of each blade in the rotating plane is obtained through the collection of the blade front side video of the wind power generator in operation, and whether the wind power generator has a fault or not is judged through single-machine blade comparison; the non-contact type measurement is achieved, the structure and operation of the wind driven generator are not influenced, the cost is lower, the application is simple, andthe detection can cover all the blades, being sufficient and comprehensive.

Owner:北京汉能华科技股份有限公司

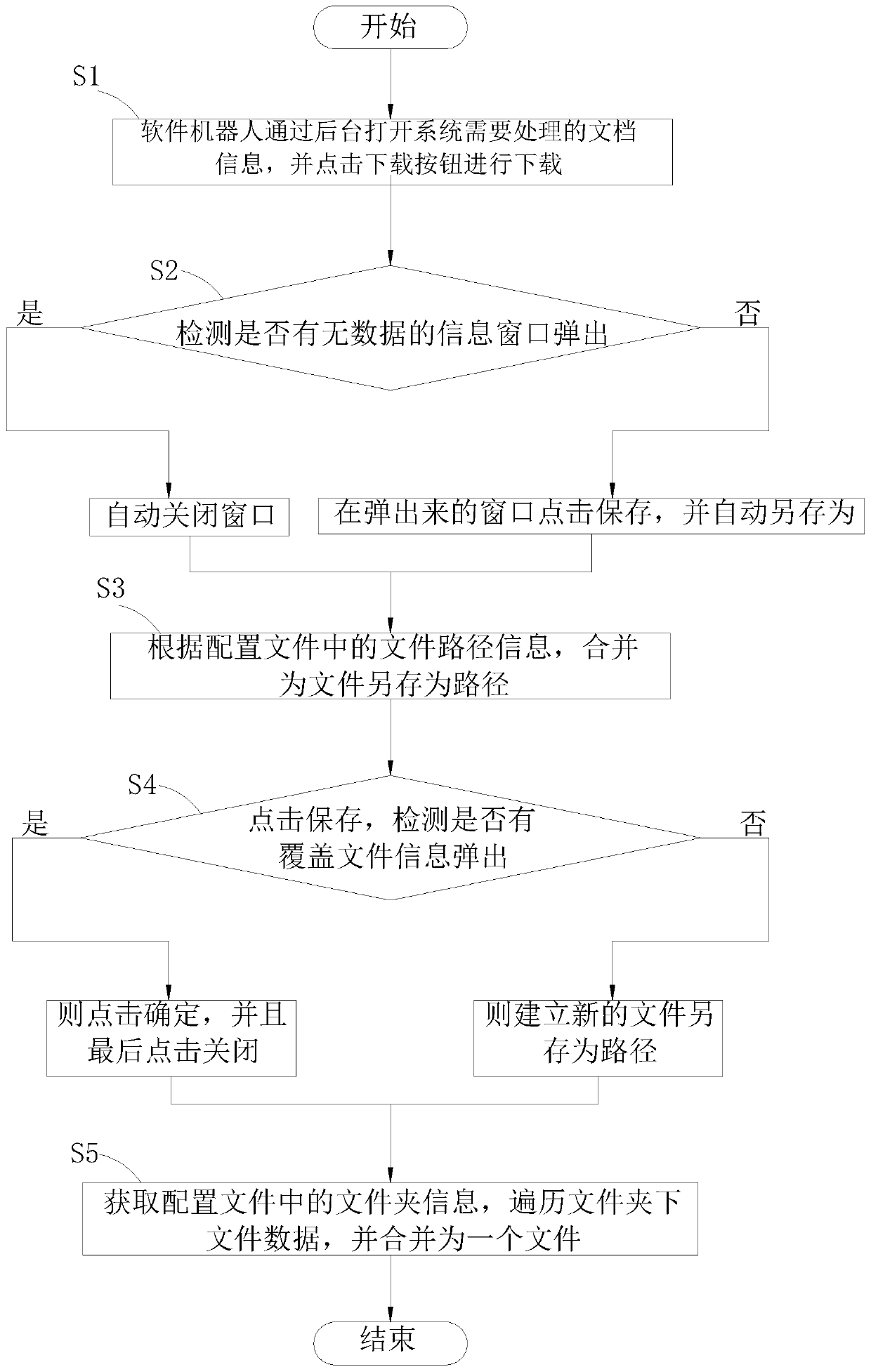

Automatic process valuation method

PendingCN110807001AQuick statisticsFast downloadFile system administrationFile/folder operationsEngineeringData mining

The invention belongs to the technical field of automatic process valuation methods, and particularly relates to an automatic process valuation method, which comprises the following steps: S1, enabling a software robot to open document information required to be processed by a system through a background, and click a downloading button to download the document information; s2, detecting whether adata-free information window pops up or not, if so, automatically closing the window, and if not, clicking the pop-up window for storage and automatically saving the pop-up window for another time; s3, according to the file path information in the configuration file, combining the file path information into a file and saving the file as a path, and S4, clicking to save the file information and detecting whether coverage file information pops up or not. The software robot can replace white-collar workers to work, automatically processes documents through a system, automatically processes and reasonably archives the documents in a computer, organizes and archives the documents, merges the documents into one document, can rapidly organize, count and download reports in busy days, and does notinfluence normal operation and acceptance of the system.

Owner:苏州数字力量教育科技有限公司

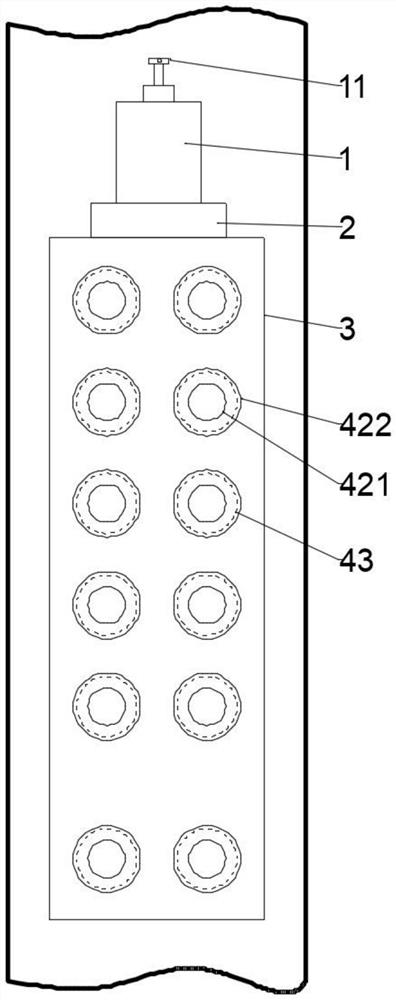

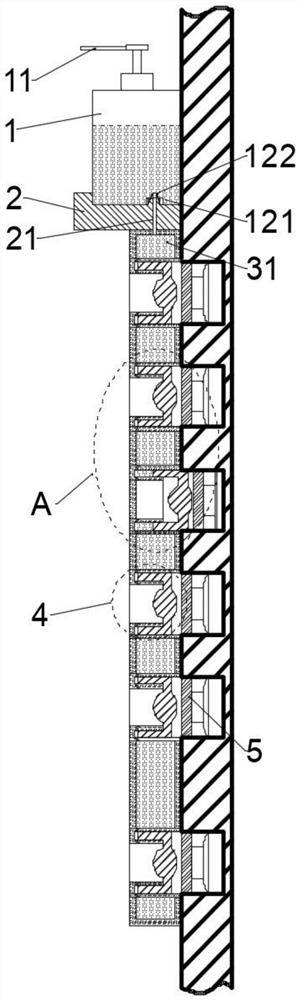

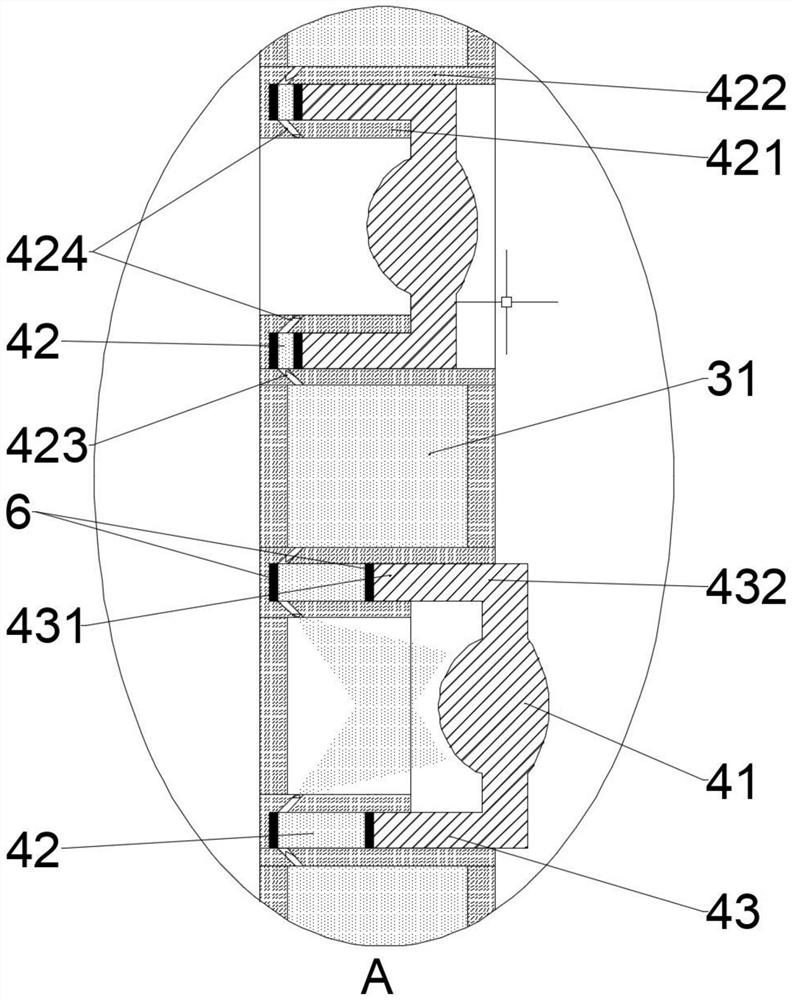

Medical antibacterial elevator panel auxiliary control device

PendingCN112079218AEasy to useDoes not affect normal economic operationLavatory sanitoryElevatorsControl cellStructural engineering

The invention relates to a medical antibacterial elevator panel auxiliary control device. The medical antibacterial elevator panel auxiliary control device comprises a disinfection bottle, a bearing plate and a control panel, wherein control units are arranged on the control panel; each control unit is aligned and matched with one key on an elevator panel; the control units comprise transmission pressing keys, suction cylinders and piston connecting pieces; the transmission pressing keys are matched and opposite to the keys on the elevator panel; when the transmission pressing keys are pressed, the transmission pressing keys can move corresponding to the control panel, and press and trigger the corresponding keys on the elevator panel; the suction cylinders further comprise one-way liquidinlet switches and antibacterial nozzles; the one-way liquid inlet switches communicate with suction cavities and guide cavities; liquid spraying directions of the antibacterial nozzles are towards the transmission pressing keys; and after users finish pressing, return pieces reversely pull back piston ends, and the piston ends reversely slide in the suction cylinders. The device can quickly and conveniently update elevators, can timely disinfect the keys after pressing use each time, and effectively reduces bacterial propagation.

Owner:王丽萍

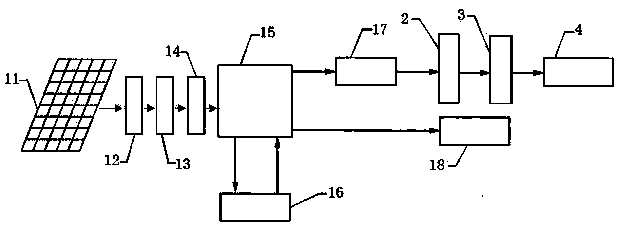

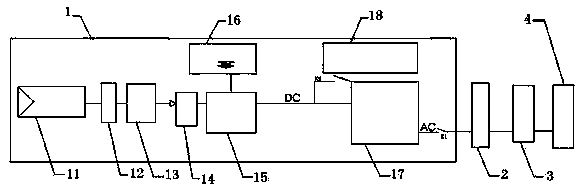

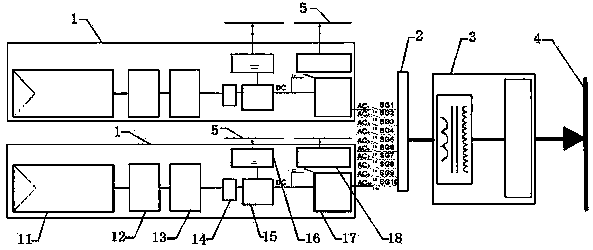

Multi-combination device of large-scale solar photovoltaic off-grid power generation system

InactiveCN104079239AMeet the powerImprove the quality of lifeBatteries circuit arrangementsPhotovoltaicsElectricityLow voltage

The invention discloses a multi-combination device of a large-scale solar photovoltaic off-grid power generation system. The multi-combination device is characterized by being composed of n off-grid power generation units (1), a low-voltage power distribution cabinet (2), a transformer (3) and an alternating load (4), wherein n is larger than or equal to 1 and is a positive integer. The off-grid power generation units (1) are connected with the low-voltage power distribution cabinet (2), the low-voltage power distribution cabinet (2) is connected with the transformer (3), and the transformer (3) is connected with the alternating load (4). According to the multi-combination device of the large-scale solar photovoltaic off-grid power generation system, abundant solar energy in the remote areas can be fully converted into electric energy needed by people in the life of the remote areas, the multi-combination mode can adapt to various environments, the solar energy can be utilized to the maximum degree, and unified management is convenient. Thus, the multi-combination device is an ideal power source in the non-electricity areas.

Owner:张祈泰 +1

Drying device

PendingCN106440696ADoes not affect walkingExtended storage timeDrying chambers/containersDrying solid materialsAutomatic controlVacuum pump

The invention provides a drying device. The drying device comprises a main body; an end cover is arranged at the upper end; a drying fixed frame is arranged in the main body; a temperature monitor and a humidity monitor are arranged in the main body, and are both electrically connected with a control box; the control box is arranged at the external of the main body; and an air replenishing machine and a vacuum pump are arranged out of the main body, and are both electrically connected with the control box. The drying device can keep dry environment through automatic control of temperature and humidity, and facilitates long-time storage.

Owner:天津龙川鑫汇实验设备制造有限公司

Concrete dam abrupt slope foundation surface repeated contact grouting structure and grouting method thereof

InactiveCN110306555ADoes not affect water storage tasksDoes not affect runnabilityDamsFoundation engineeringWater flowEngineering

The invention discloses a concrete dam abrupt slope foundation surface repeated contact grouting structure and a grouting method thereof, and particularly discloses a concrete dam abrupt slope foundation surface repeated contact grouting structure for carrying out repeated supplementary grouting when the contact surface of a concrete dam and a foundation surface is expanded and a grouting method thereof. The grouting structure is arranged at an abrupt slope section of the concrete dam and is divided into a plurality of irrigated areas in a direction vertical to the water flow; each irrigated area is internally provided with two sets of grouting pipelines, each set of grouting pipeline comprises a grouting pipe, the grouting pipes are transversely arranged U-shaped pipes, the bottom pipe orifices are grout inlets and the upper pipe orifices are grout return ports; and the grouting pipes are two-layer structures which respectively comprise an inner layer and an outer layer, the inner parts of the grouting pipes are PVC pipes, grout outlets are alternately formed in the PVC pipes, the outer parts of the grouting pipes are elastic rubber casing pipes, and diffusion holes are alternately formed in the rubber casing pipes. The structure is capable of carrying out contact grouting construction for the first time when the field practical condition achieves the design requirements, andadopting the same set of pipeline to carry out complementary grouting when the contact surface of the concrete dam and the foundation surface is expanded again.

Owner:POWER CHINA KUNMING ENG CORP LTD

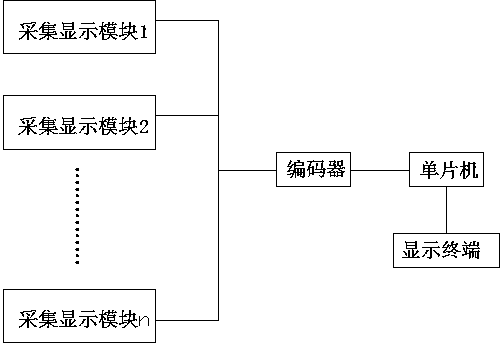

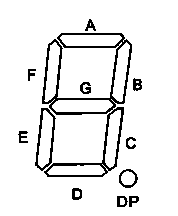

Non-contact distance early warning device suitable for elevators

The invention discloses a non-contact distance early warning device suitable for an elevator. The non-contact distance early warning device suitable for the elevator comprises a collection display module, an encoder for receiving a segment code signal output by the collection display module, a singlechip connected with the encoder, and a display terminal used for receiving signals of the single-chip microcomputer; the collection display module is placed on the display module of the elevator in an overlapping manner, and comprises a plurality of photosensitive diodes arranged on a back side and in the same positions of the self display elements of the elevator, and a plurality of light emitting diodes arranged on a front side and in positions corresponding to the photosensitive diodes. The non-contact distance early warning device suitable for elevators has the beneficial effects as follows: the early warning device provided by the invention adopts a photoelectric conversion technology, can remotely and reliably monitor the operational parameters and the running states of the elevator, and provides an effective mean for improving the security and the reliability of the elevator, and the early warning device, as a third party, is completely isolated from the self control system of the elevator, and cannot influence the self running of the control system of the elevator.

Owner:SUZHOU HANSEN HUANA ENERGY SAVING TECH

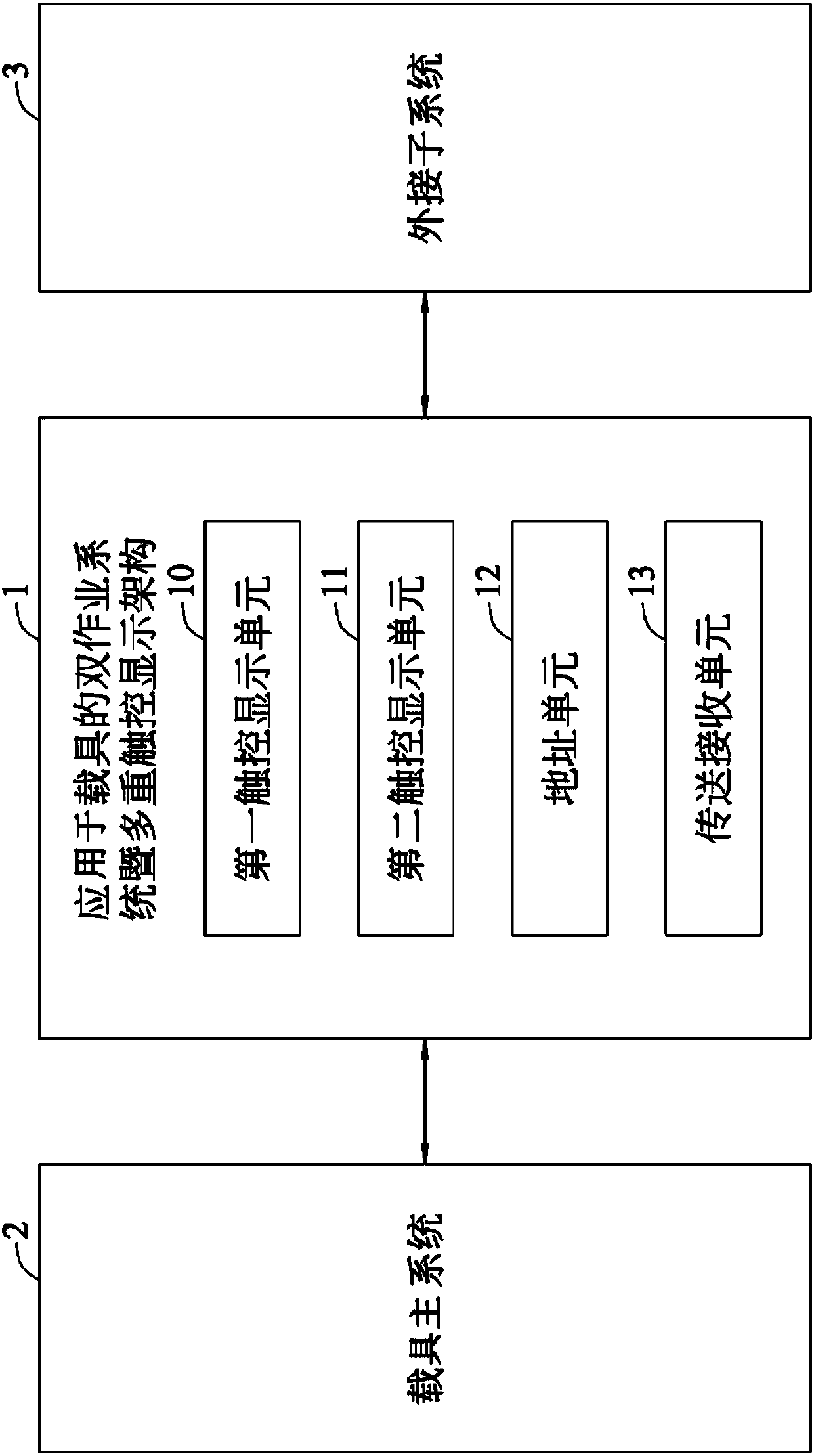

Dual operation system and multiple touch control display configuration applicable to carrier

InactiveCN107914653ADoes not degrade stabilityWithout compromising securityElectric/fluid circuitInput/output processes for data processingEmbedded systemSecond screen

The invention provides a dual operation system and multiple touch control display configuration applicable to a carrier and connected to a carrier major system and an externally connected subsystem, comprising: a first touch control display unit, a second touch control display unit, an address unit, and a transmitting / receiving unit, the first touch control display unit displaying a first screen picture of the carrier major system, the second touch control display unit displaying a second screen picture of the externally connected subsystem; the address unit acquiring address information according to the user's command with respect to the coordinate positions of the first screen picture and / or the second screen picture; the transmitting / receiving unit transmitting the address information to the carrier major system and the externally connected subsystem for allowing both systems to selectively and individually perform corresponding algorithms and to receive the algorithm result therefrom, thereby displaying the first and / or second screen pictures correspondingly.

Owner:MCLOUDWARE TECH CO LTD

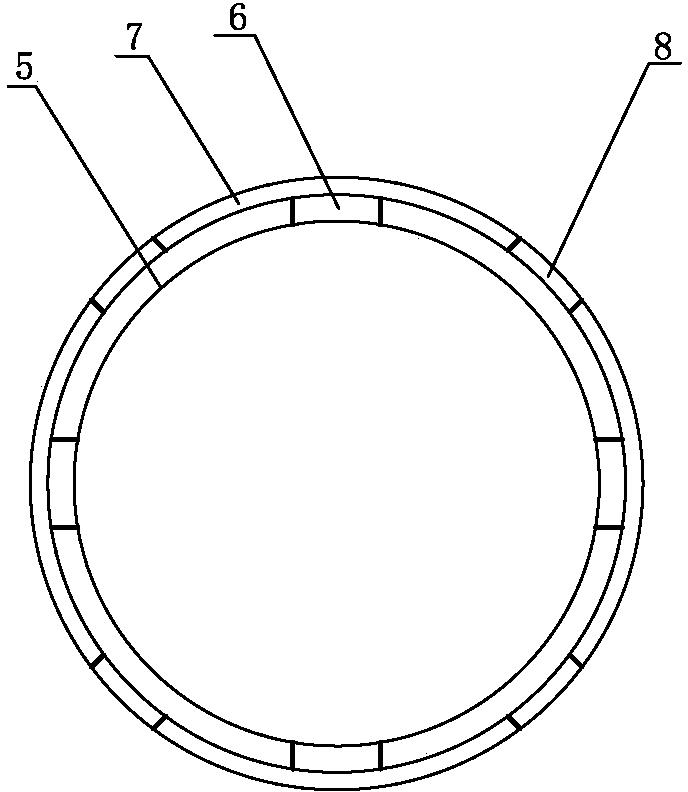

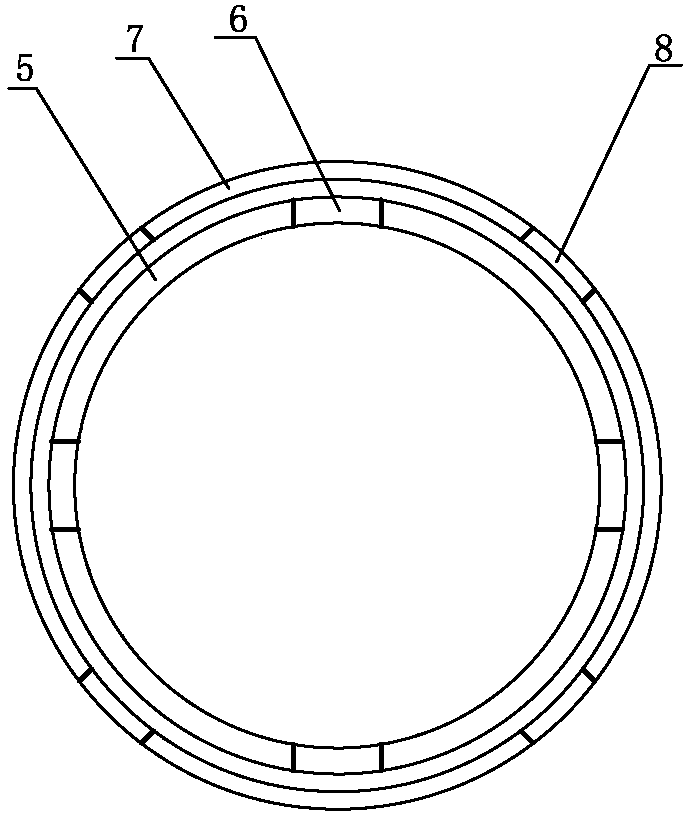

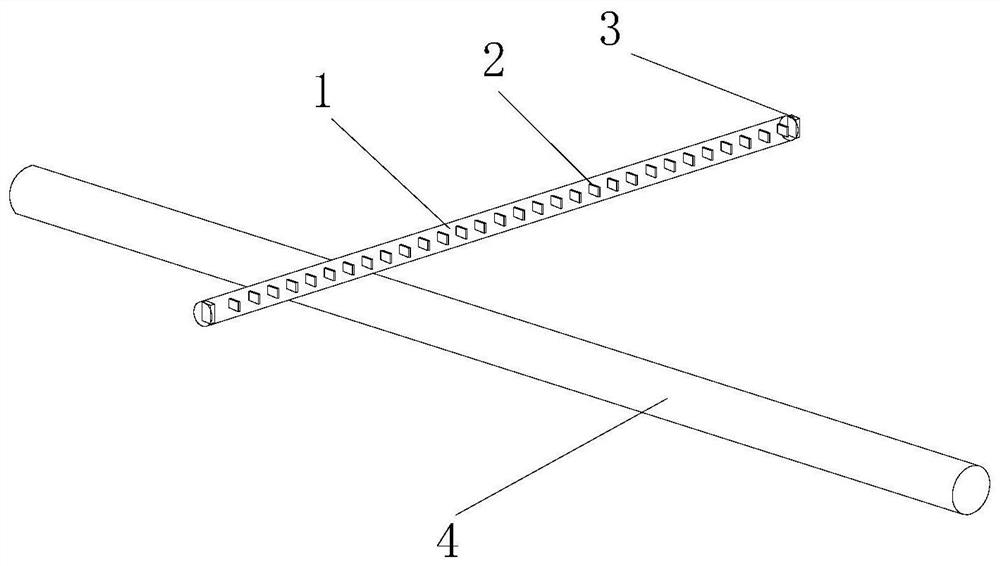

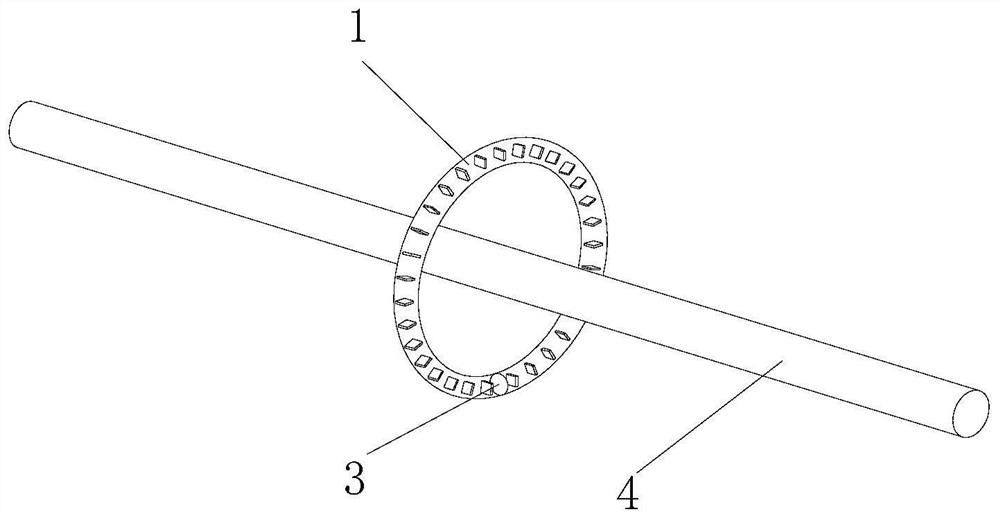

A wireless networked current non-contact measuring device and method for magnetic sensing units

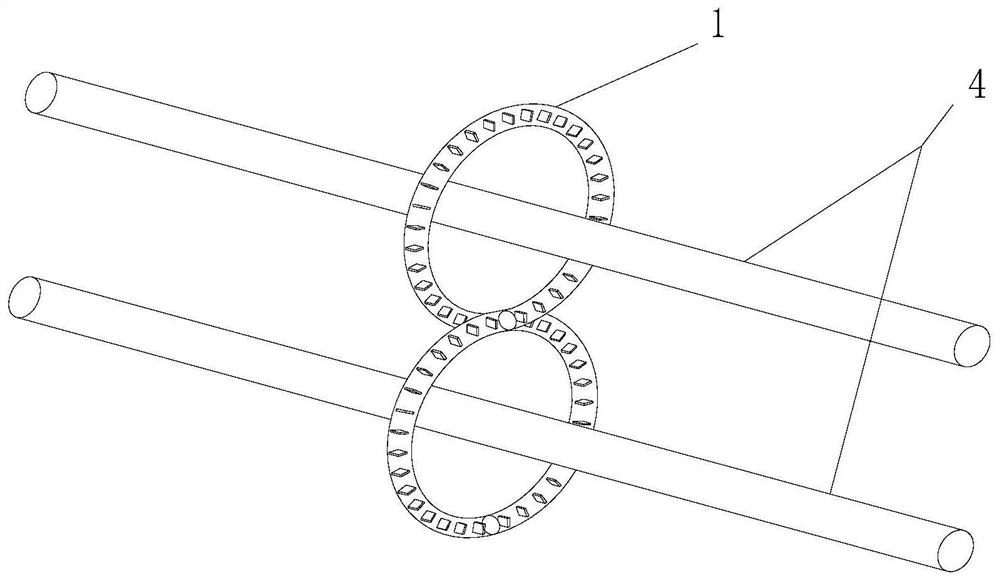

ActiveCN110726869BImprove anti-interference abilityImprove stabilityMeasurement using digital techniquesInterference resistanceElectrical conductor

The invention discloses a wireless networked current non-contact measuring device and method for a magnetic sensing unit, comprising a flexible fixed support, a magnetic sensing unit, and a collection and receiving unit, and the magnetic sensing unit is arranged on the flexible fixed support , the magnetic sensing unit is connected to form a closed loop through the converging receiving unit, and the magnetic sensing unit is communicatively connected with the converging receiving unit. When in use, the flexible fixing bracket equipped with the magnetic sensing unit is wrapped around the conductor under test, and connected by the collecting and receiving unit to form a closed loop for detection. According to the Ampere loop theorem, there is a magnetic field around the conductor under test. The current in the conductor to be measured can be calculated by performing numerical integral calculation on the measured values of each of the magnetic sensing units in the closed loop. This design does not contain an iron core, the magnetic induction equipment has strong anti-interference ability, and the detection range is large, and it is not affected by the shape of the measured conductor.

Owner:四川纽沃思自动化科技有限公司

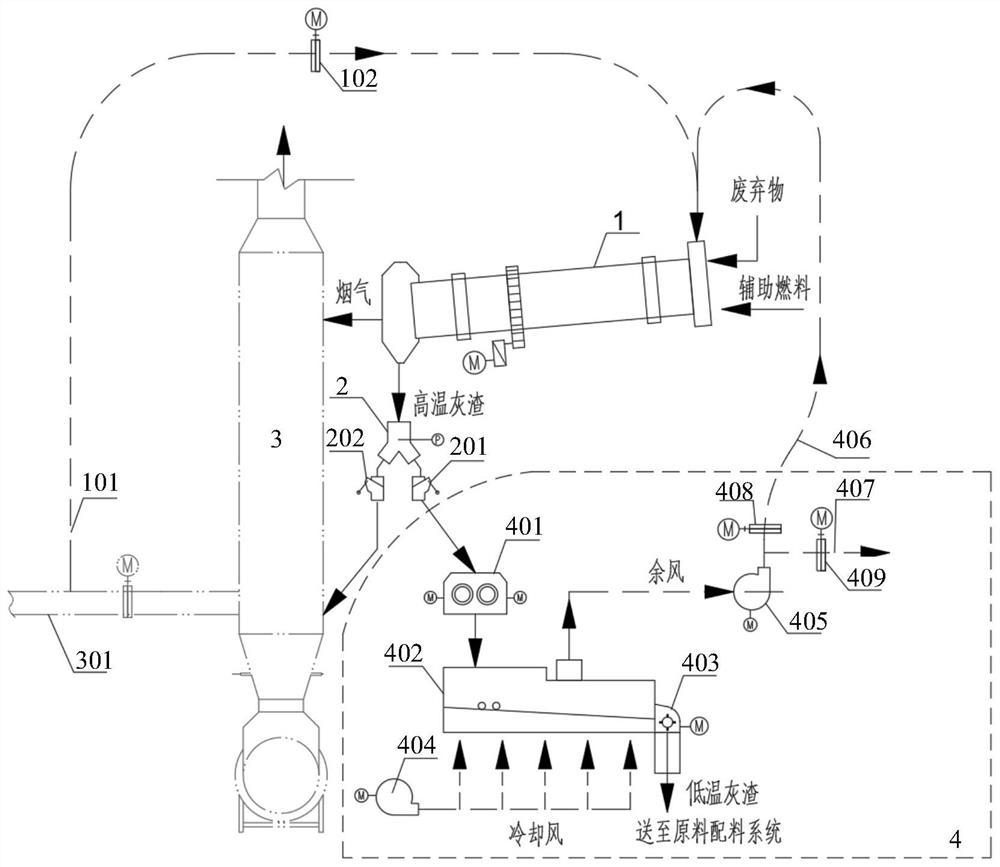

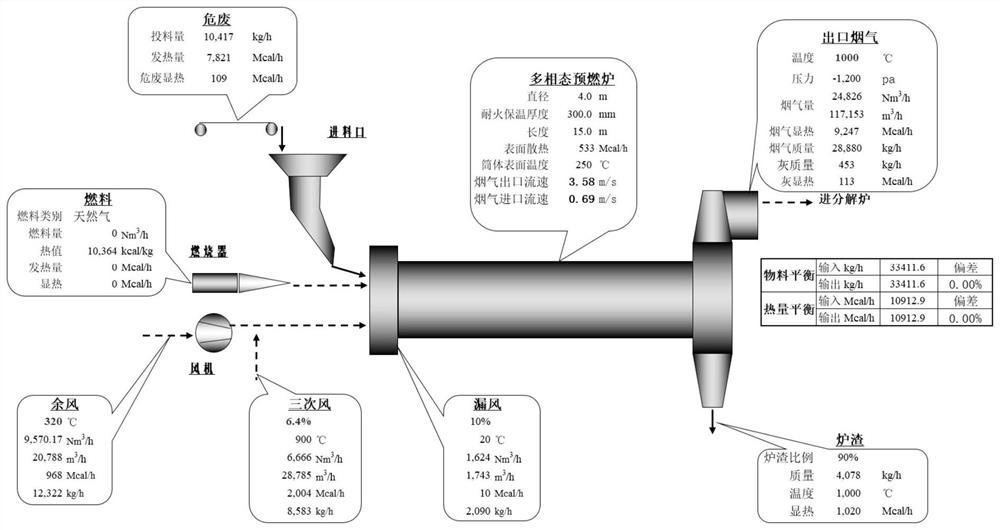

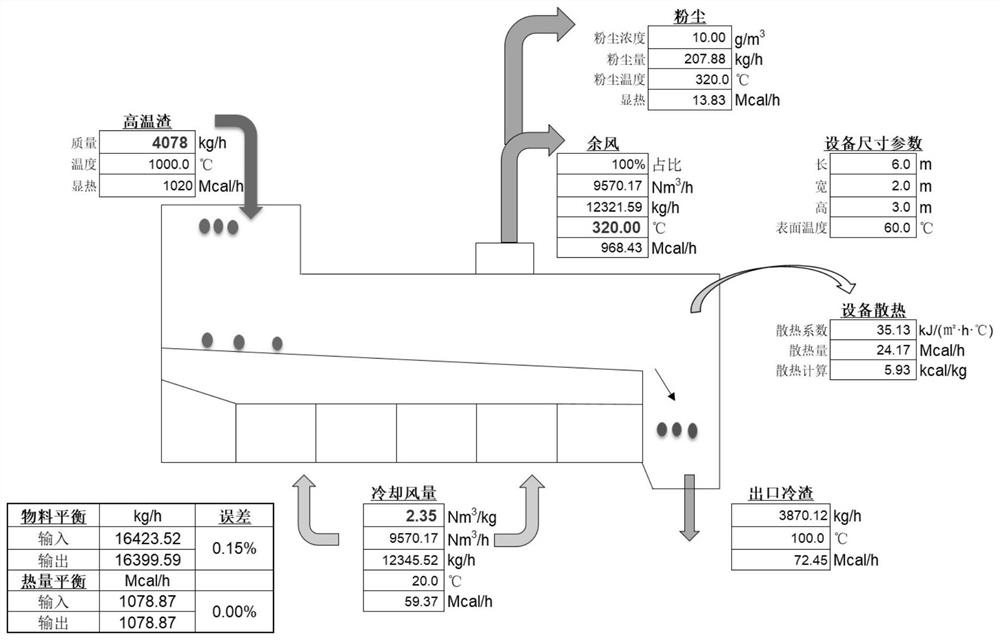

System and method for co-processing organic waste by cement kiln

PendingCN114738764AReduce negative impactControl dwell timeCement productionIncinerator apparatusThermodynamicsClinker (waste)

The invention discloses a system and a method for co-processing organic wastes in a cement kiln. The treatment system comprises a multi-phase pre-combustion furnace and a material distributing device connected with a slag outlet of the multi-phase pre-combustion furnace. An outlet of the material distributing device is respectively connected with the decomposing furnace and the ash cooling system; the ash cooling system comprises a roller type crusher, an ash grate cooler arranged at an outlet of the roller type crusher, a tail roller type crusher arranged at an outlet of the ash grate cooler, an air blower used for providing cooling air for the ash grate cooler and an induced draft fan communicated with a gas outlet of the ash grate cooler. And an air inlet of the multi-phase pre-combustion furnace is respectively communicated with a tertiary air branch pipe and an induced draft fan. The method is suitable for various practical conditions of various organic wastes, complex sources, large component fluctuation, large physical and chemical component differences and the like, and stable operation of a cement clinker sintering system is not affected.

Owner:SINOMA INT ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com