Sliding pendulum pneumatic machine

A pneumatic machine, air inlet technology, applied in the direction of rotary or oscillating piston engine, machine/engine, rotary piston engine, etc., can solve the problems of low efficiency, difficult device processing, high precision requirements, and achieve easy device processing, Improve the recovery rate and the effect of low precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with embodiment and accompanying drawing, the present invention is further elaborated:

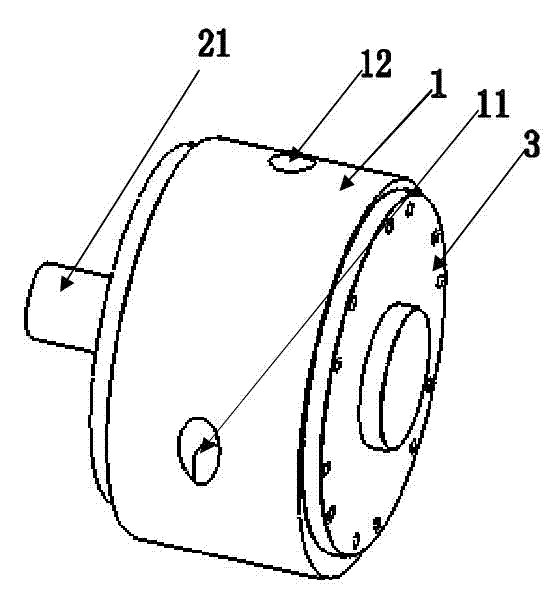

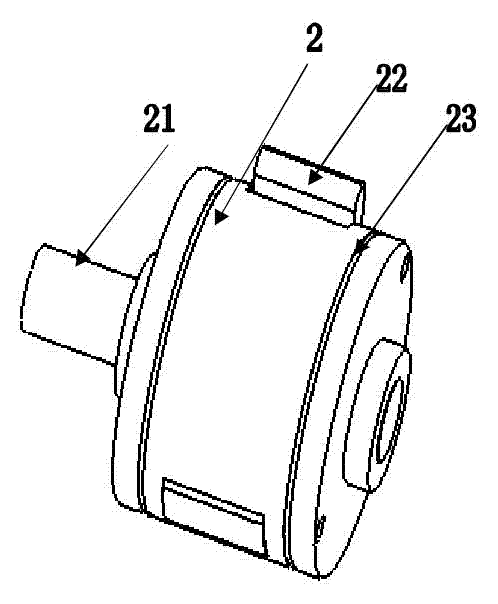

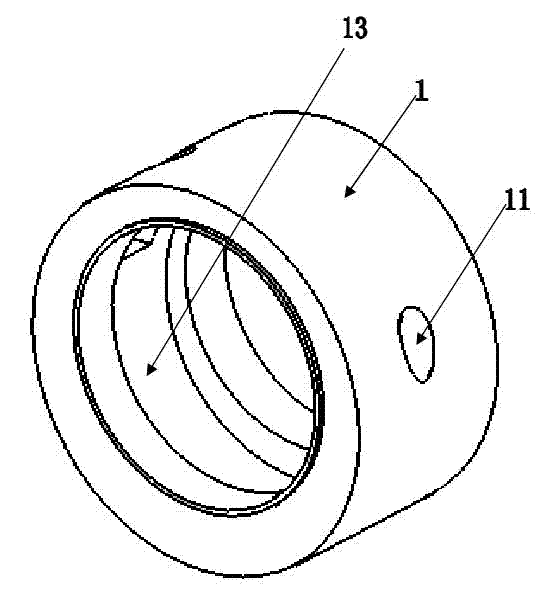

[0016] See attached figure 1 , 2 , 3, 4, 5, a sliding pendulum air motor, which includes a stator 1, a rotor 2 and a cover plate 3, the stator 1 is a ring platform, the outer circle and the inner circle of the ring platform are not concentric, the outer circle and the inner circle The distance between the center points is one-sixth to one-seventh of the diameter of the outer circle. The air inlet 11 and the exhaust port 12 are symmetrically distributed on the circular platform, and the inner wall of the circular platform is provided with a quarter The arc-shaped gas expansion chamber groove 13 of three to four fifths of the inner circumference length, the deepest part of the groove 13 is 1 / 5 to 1 / 4 of the inner diameter of the ring platform, two of the groove 13 The ends are respectively located at the air inlet and exhaust port on the inner wall of the circul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com