Novel explosion-proof flame-retardant belting material for cable

A cable and tape technology, applied in the field of flame retardant materials, can solve the problems of complicated installation methods, unfavorable cable construction and maintenance, and failure to consider fire separation and other problems, so as to reduce thermal hazards and toxicity, and achieve good fire and heat insulation effects. , good for air circulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

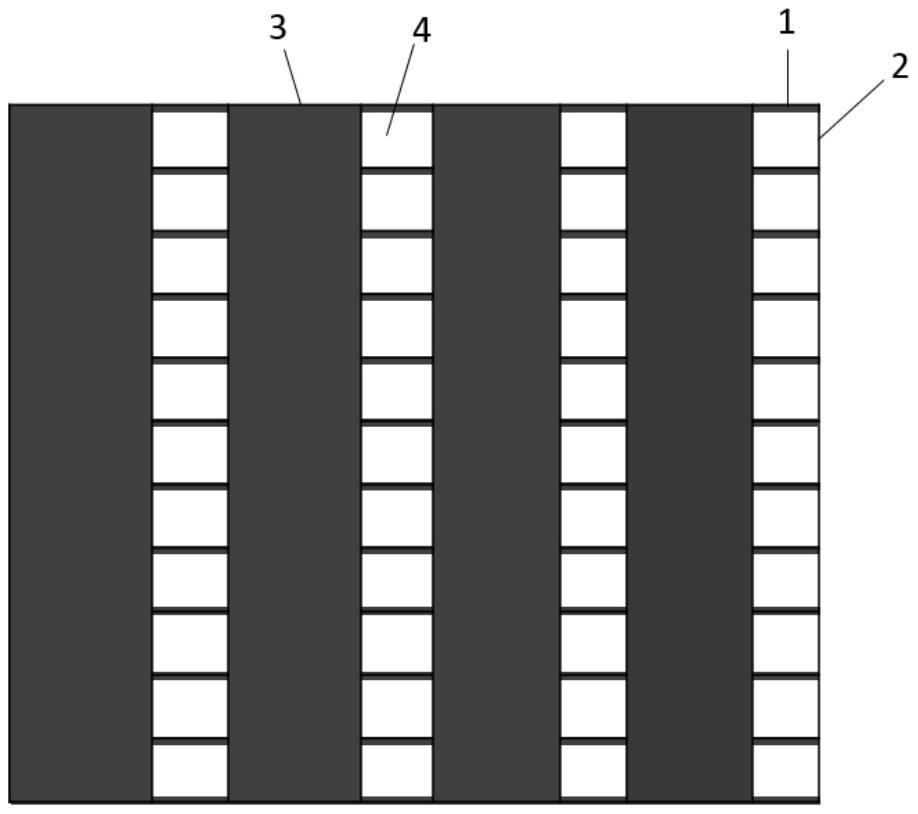

Image

Examples

Embodiment 1

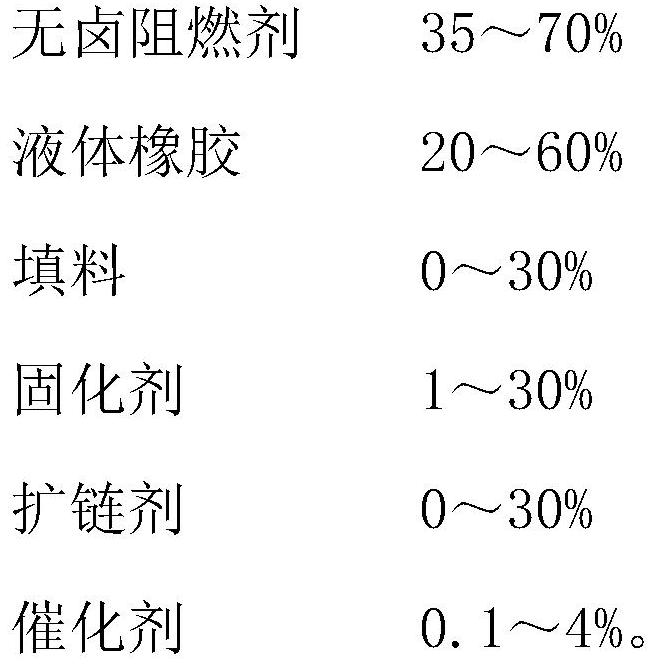

[0055] This embodiment provides a new type of explosion-proof flame-retardant tape material for cables, including a flame-retardant rubber material and a skeleton material; based on the total mass of the flame-retardant rubber material and the skeleton material, the content of the skeleton material is 5%, and the content of the flame-retardant rubber material is 5%. 95%.

[0056] Among them, based on the total mass of the flame-retardant rubber material, in terms of mass percentage, the flame-retardant rubber material includes 35% hydroxyl-terminated polybutadiene, 5% hydroxyl-terminated nitrile rubber, 15% expandable graphite, 6% polyphosphoric acid Ammonium, 2% melamine, 2% pentaerythritol, 5% aluminum hydroxide, 2% zinc borate, 5% MDI, 15% triisopropylphenyl phosphate, 3% white carbon black, 3% 1,4-butanedi alcohol, 2% triethylenediamine.

[0057] Among them, the flame-retardant fiber rovings that make up the skeleton material are polyimide fibers, and each flame-retardant...

Embodiment 2

[0060] This embodiment provides a new type of explosion-proof flame-retardant tape material for cables, including a flame-retardant rubber material and a skeleton material; based on the total mass of the flame-retardant rubber material and the skeleton material, the content of the skeleton material is 3%, and the content of the flame-retardant rubber material 97%.

[0061] Among them, based on the total mass of the flame-retardant rubber material, in terms of mass percentage, the flame-retardant rubber material includes 20% hydroxyl-terminated polybutadiene, 5% hydroxyl-terminated nitrile rubber, 25% expandable graphite, 6% polyphosphoric acid Ammonium, 2% melamine, 2% pentaerythritol diacetal, 5% magnesium hydroxide, 2% polymeric MDI, 20% triisobutyl phosphate, 2% carbon black, 10% 1,4-cyclohexanediol, 1 % Dibutyltin Dilaurate.

[0062] Among them, the flame-retardant fiber rovings that make up the skeleton material are aramid fibers, and each flame-retardant fiber roving in...

Embodiment 3

[0065] This embodiment provides a new type of explosion-proof flame-retardant tape material for cables, including a flame-retardant rubber material and a skeleton material; wherein, based on the total mass of the flame-retardant rubber material and the skeleton material, the skeleton material content is 8%. The content of fuel rubber material is 92%;

[0066] Among them, based on the total mass of the flame-retardant rubber material, in terms of mass percentage, the flame-retardant rubber material includes 50% hydroxyl-terminated polybutadiene, 11% expandable graphite, 5% aluminum diethyl hypophosphite, 5% HDI Trimer, 10% melamine pyrophosphate, 15wt% tricresyl phosphate, 4% dibutyltin dilaurate.

[0067] The flame-retardant fibers that make up the skeleton material are aramid fibers, and each flame-retardant fiber roving includes two bundles of aramid flame-retardant fiber multifilaments; and each bundle of aramid flame-retardant fiber multifilaments includes 36 flame-retarda...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com