Concrete dam abrupt slope foundation surface repeated contact grouting structure and grouting method thereof

A contact grouting and concrete dam technology, which is applied in infrastructure engineering, dams, buildings, etc., can solve problems such as opening and repeated opening, and achieve the effect of reducing safety risks and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

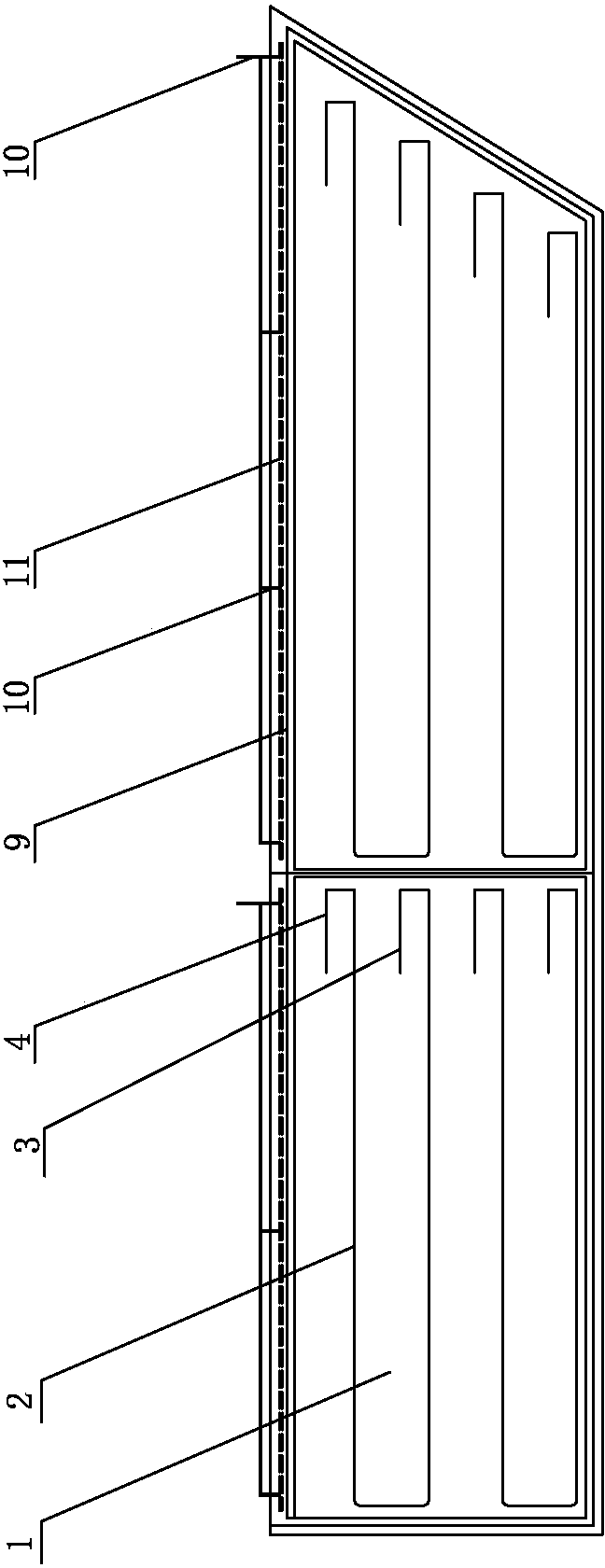

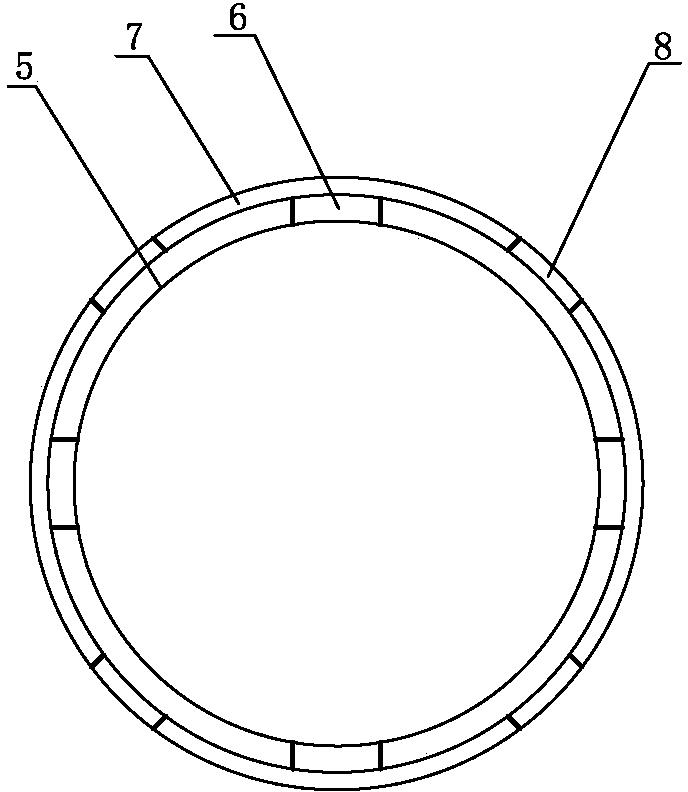

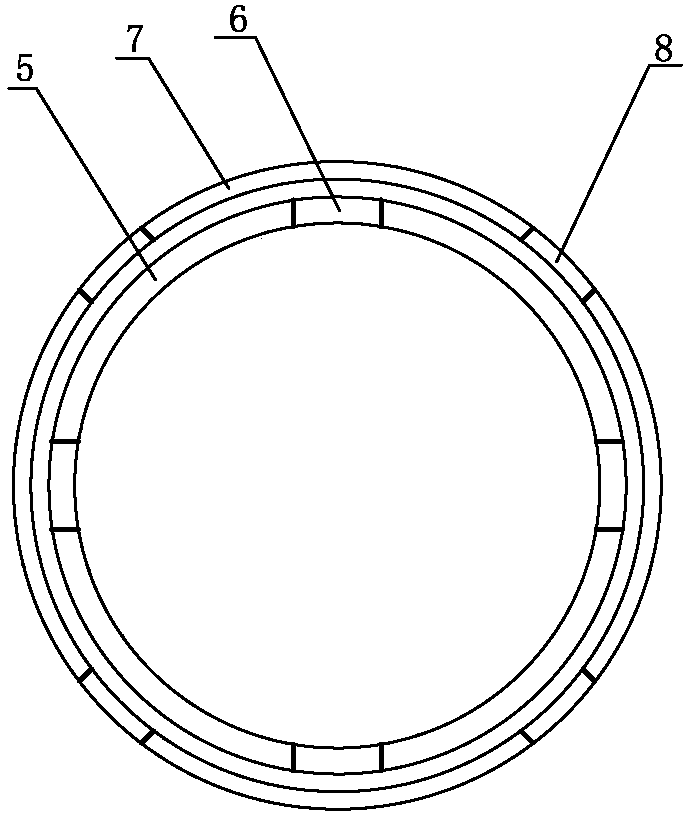

[0028] Embodiment 1: A concrete dam steep slope foundation surface repeated contact grouting structure, the grouting structure is set in the steep slope section of the concrete dam, each steep slope section is divided into several irrigation areas 1 according to the vertical water flow direction, and the area of each irrigation area 1 is no more than 2000m2 2 ; Two sets of grouting pipes 2 are arranged in each grouting area 1. The two sets of grouting pipes 2 are arranged on the upper and lower sides. Each set of grouting pipes 2 includes a grouting pipe 2. The grouting pipe is a single-circuit design, the bottom nozzle is the grout inlet 3, and the upper nozzle is the grout return port 4; the grouting pipe 2 has an inner and outer two-layer structure, and the interior is a PVC pipe 5, and the PVC pipe 5 is staggered with outlets. The grout hole 6, the outside of the grout pipe 2 is an elastic rubber sleeve 7, the rubber sleeve 7 is tightly wrapped on the outer wall of the PV...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com