Submersible electric pump control system and method

A technology of submersible electric pump and control system, applied in pump control, electrical components, electromechanical devices, etc., can solve the problems of inability to monitor and control the running state of submersible electric pump, meet the requirements of sealing and pressure bearing, and facilitate installation and disassembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

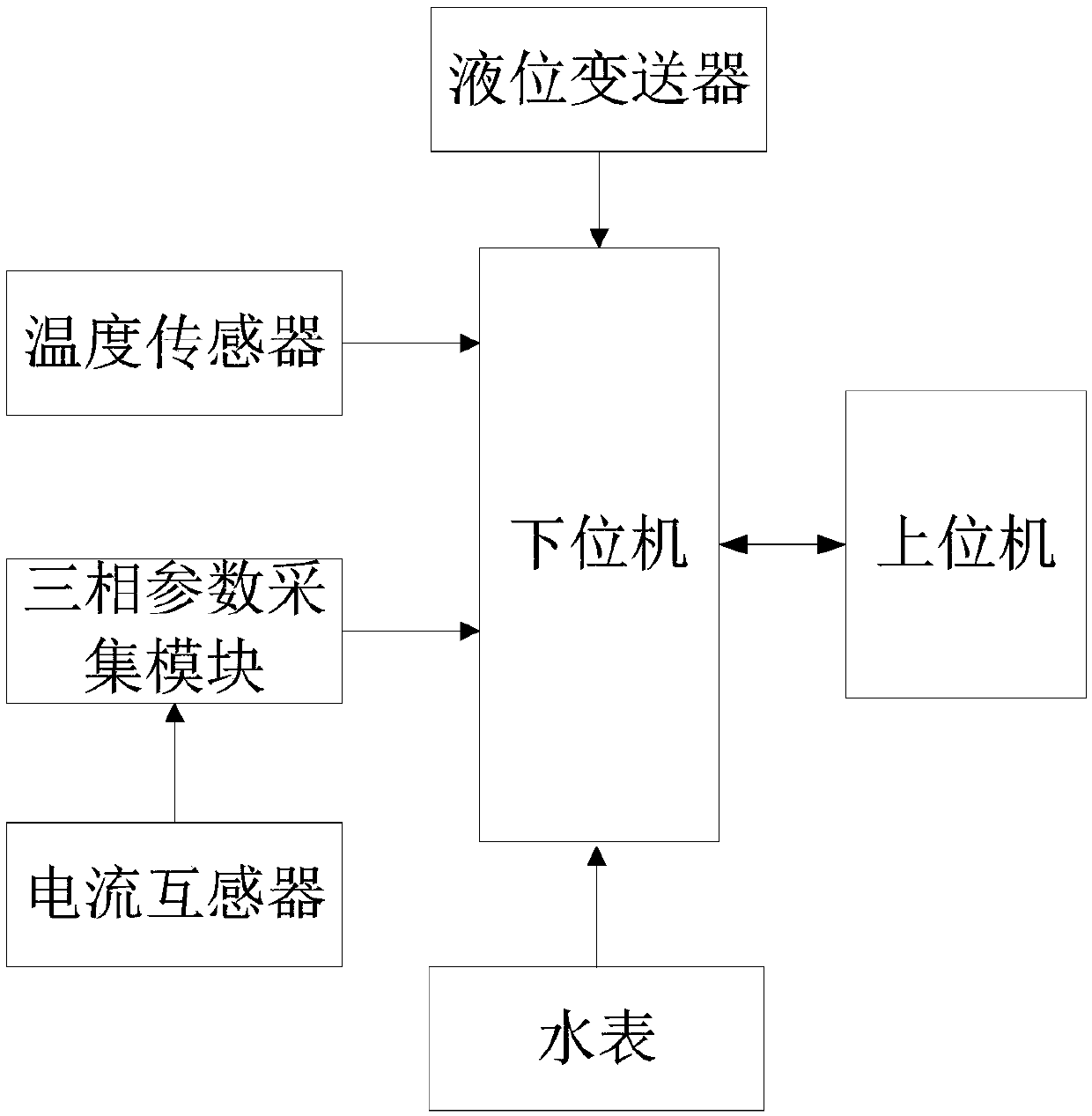

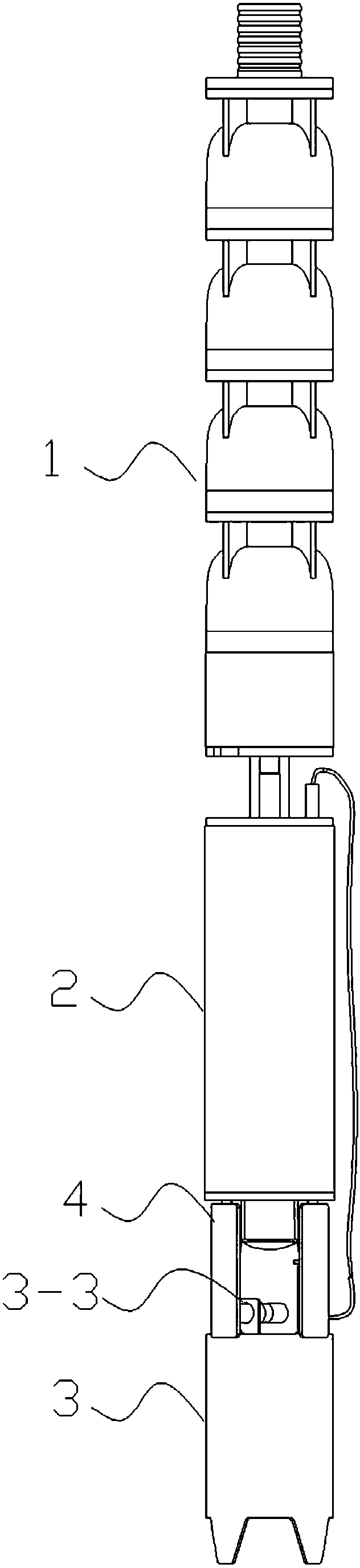

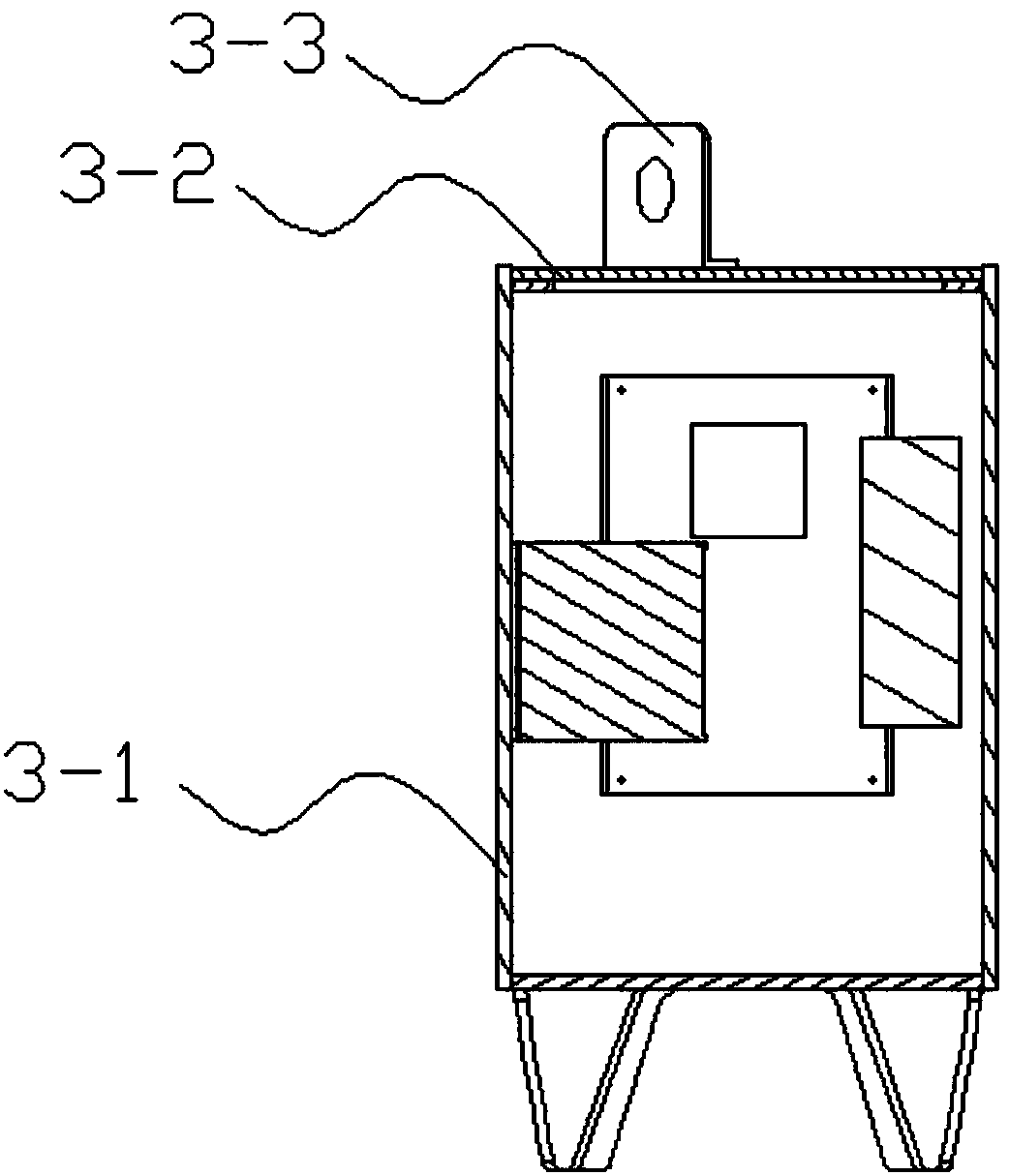

[0023] Please also refer to figure 1 and figure 2 , the submersible electric pump control system provided by the embodiment of the present invention will now be described. The submersible electric pump control system includes a motor 2, a pump body 1 arranged at the output end of the motor 2, a control mechanism 3 arranged at the base end of the motor 2, and a host computer arranged above the liquid level. The control mechanism 3 includes a waterproof sealed casing, a lower computer and a three-phase electrical parameter acquisition module and a power carrier module arranged in the cavity of the waterproof sealed casing, and also includes a liquid level transmitter arranged outside the waterproof sealed casing device, and a current transformer and a temperature sensor arranged in the motor housing. The output terminals of the liquid level transmitter, the temperature sensor and the three-phase electrical parameter acquisition module are respectively connected to the corresp...

Embodiment 2

[0039] An embodiment of the present invention provides a control method for a submersible electric pump, including the following steps:

[0040] The liquid level transmitter, temperature sensor and three-phase electrical parameter acquisition module collect the operating parameters of the submersible electric pump and transmit them to the lower computer; the operating parameters include the liquid level of the submersible electric pump, the temperature, current, voltage and power.

[0041] The lower computer controls the power carrier module to perform data modulation and loading on the collected working parameters, and uploads them to the upper computer in real time through power carrier communication.

[0042] The host computer compares the received parameters with corresponding thresholds, and when the parameters exceed the corresponding thresholds, it sends a disconnection command to the electromagnetic relay installed on the power line of the submersible electric pump.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com