Patents

Literature

137results about How to "Does not affect assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

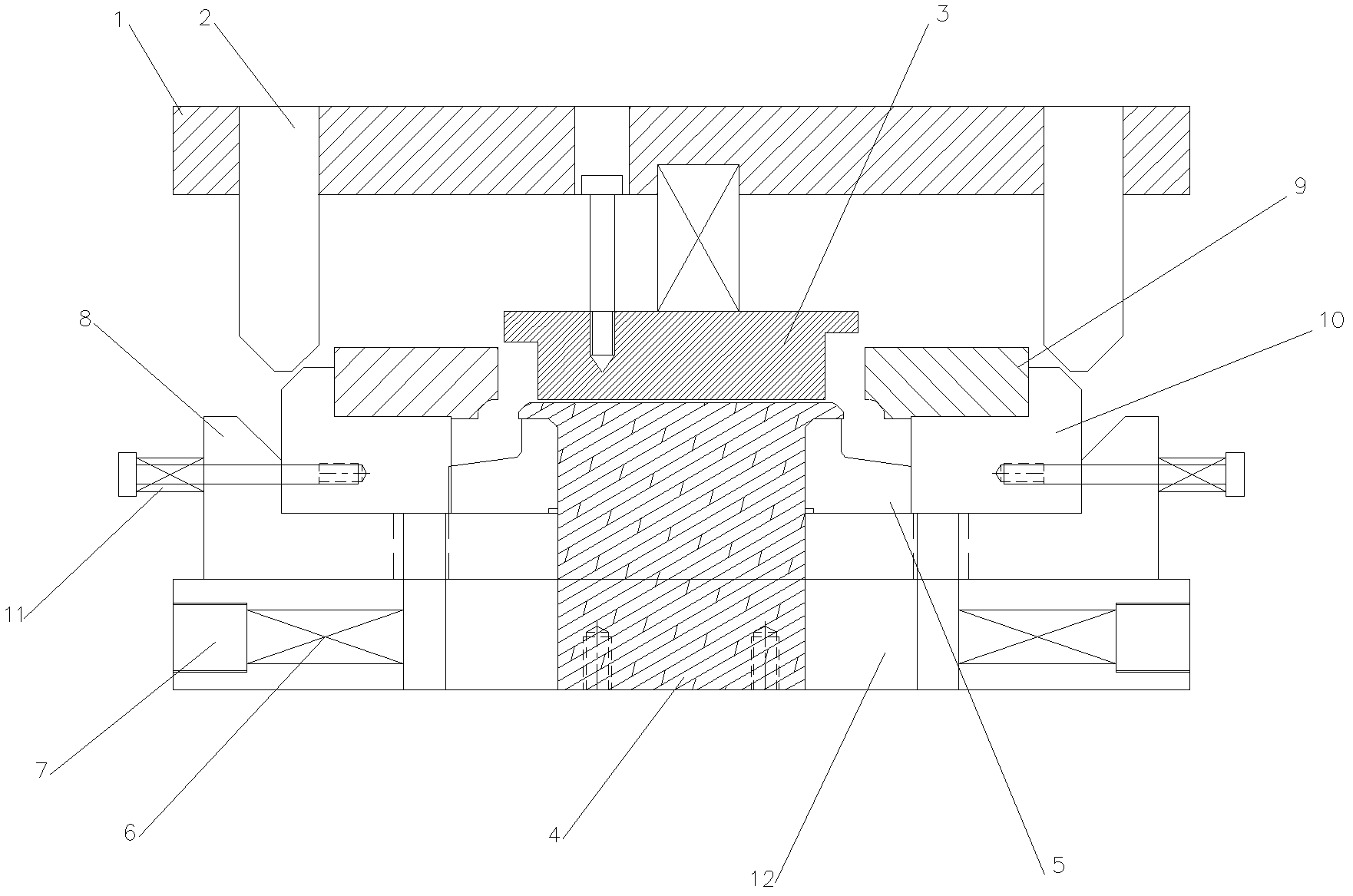

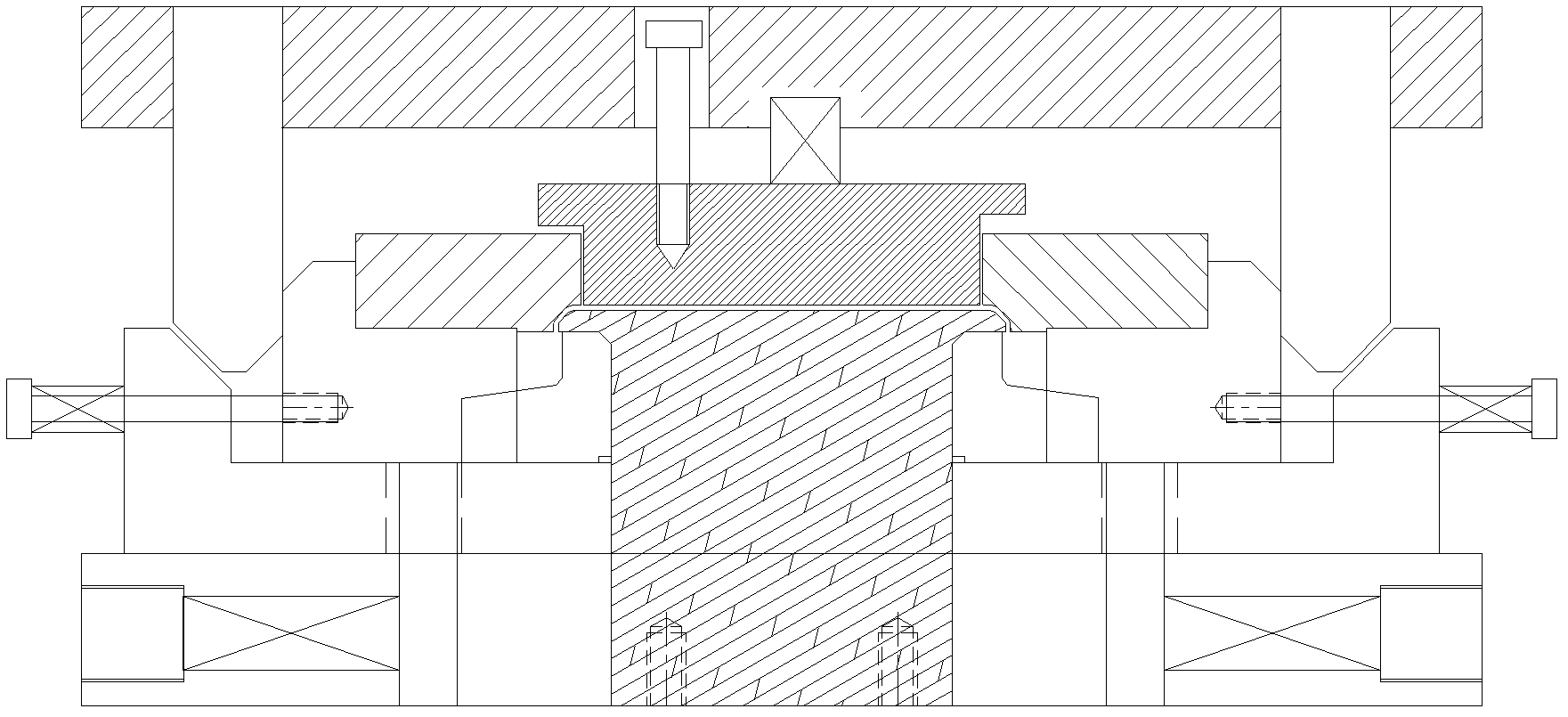

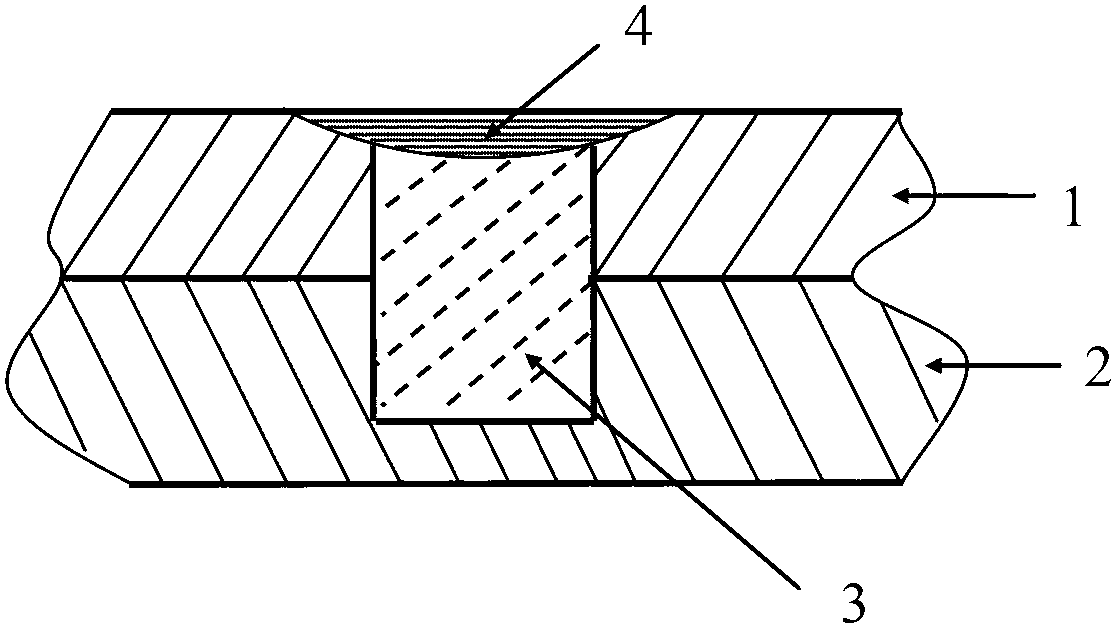

Trimming die structure for mobile phone casing

The invention provides a trimming die structure for a mobile phone casing. The structure comprises an upper die part and a lower die part, and is characterized in that: the upper die part comprises an upper splint, a slanted wedge and a stripper plate; and the lower die part comprises a product positioning die core, a male die cutter, a male die return spring, a male die return stop screw, a maledie cutter slide block, a female die cutter, a female die cutter slide block, a female die cutter slide block return spring and a lower die holder. By the trimming die structure for the mobile phone casing, the mobile phone casing is punched from inside to outside by a punching head, so that burrs are generated on the outer surface of the mobile phone casing, assembly of electronic parts of a mobile phone is not influenced, and the use effect of the mobile phone is ensured.

Owner:上海隆江医疗器械有限公司

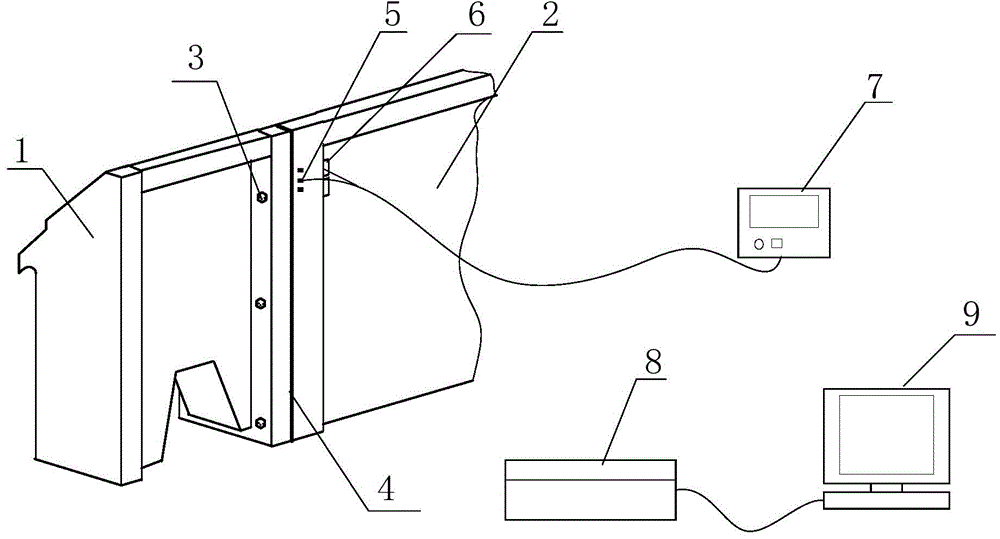

System and method for indirectly measuring stress distribution of assembly combined surfaces

ActiveCN104359595ADoes not affect assemblyDoes not affect practicalityForce measurementStrain gaugeEngineering

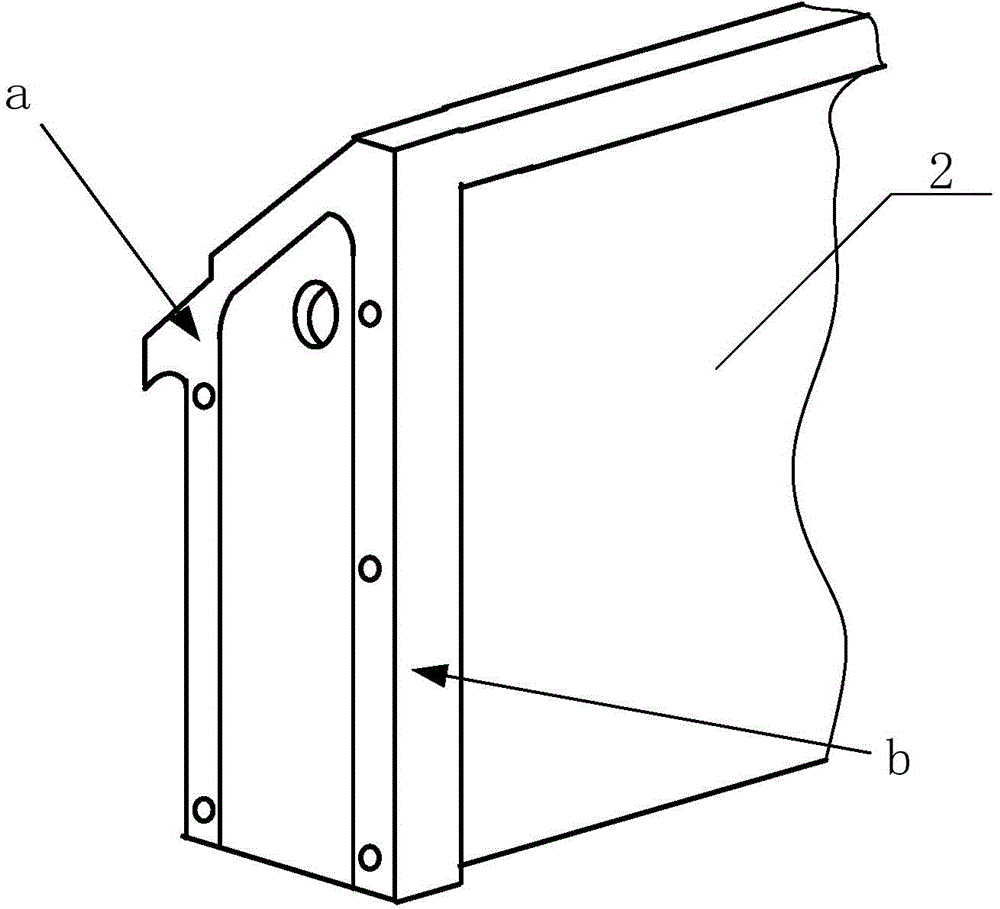

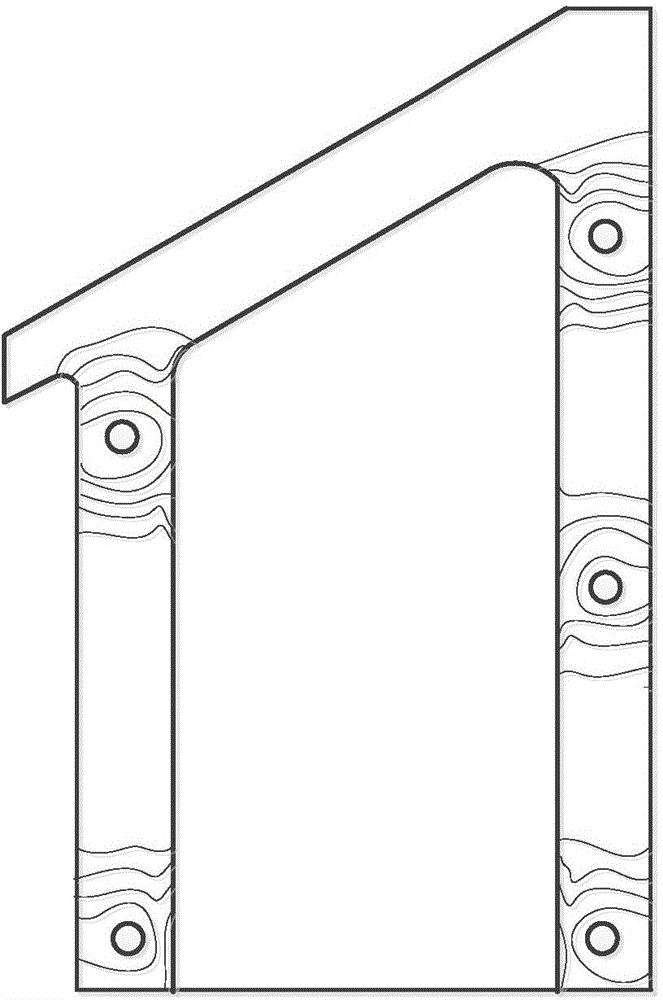

The invention discloses a system and a method for indirectly measuring stress distribution of assembly combined surfaces. The system comprises pressure sensing paper, strain gages, a pressure sensor, a display device, a scanner and a computer. The method includes firstly constructing the correspondence between the stress of the adjacent sides and the stress distribution of the combined surfaces, placing the pressure sensing paper between the combined surfaces of a part I and a part II for some time and taking the paper out, scanning the color distribution condition of the pressure sensing paper to be images inputted into the computer by the scanner, drawing a stress contour map of the combined surfaces by the computer, and affixing the strain gages on the extending lines of the stress contour on the adjacent sides; determining the stress distribution of the combined surface by measuring the stress of the stress gages. The method provided is a novel method for measuring the stress distribution of the assembly combined surfaces, and the method for measuring is low in cost in measurement of the stress distribution and is simple.

Owner:DALIAN UNIV OF TECH

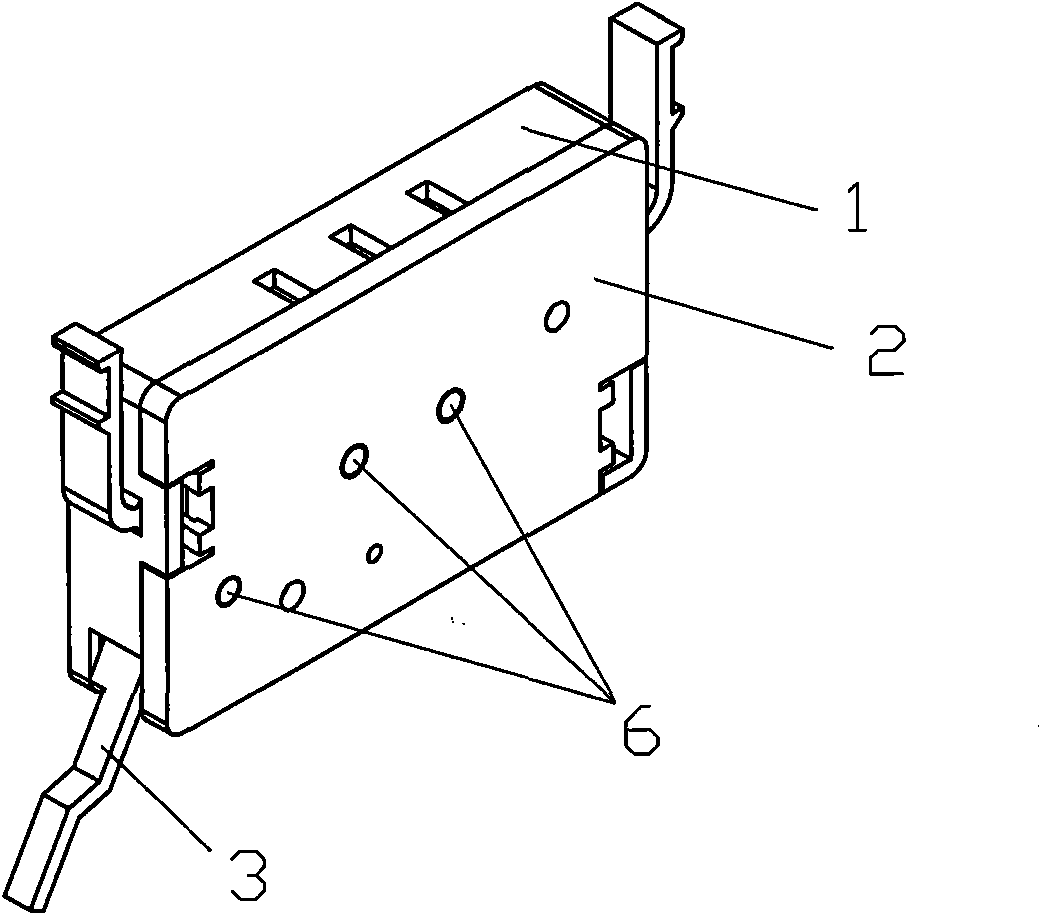

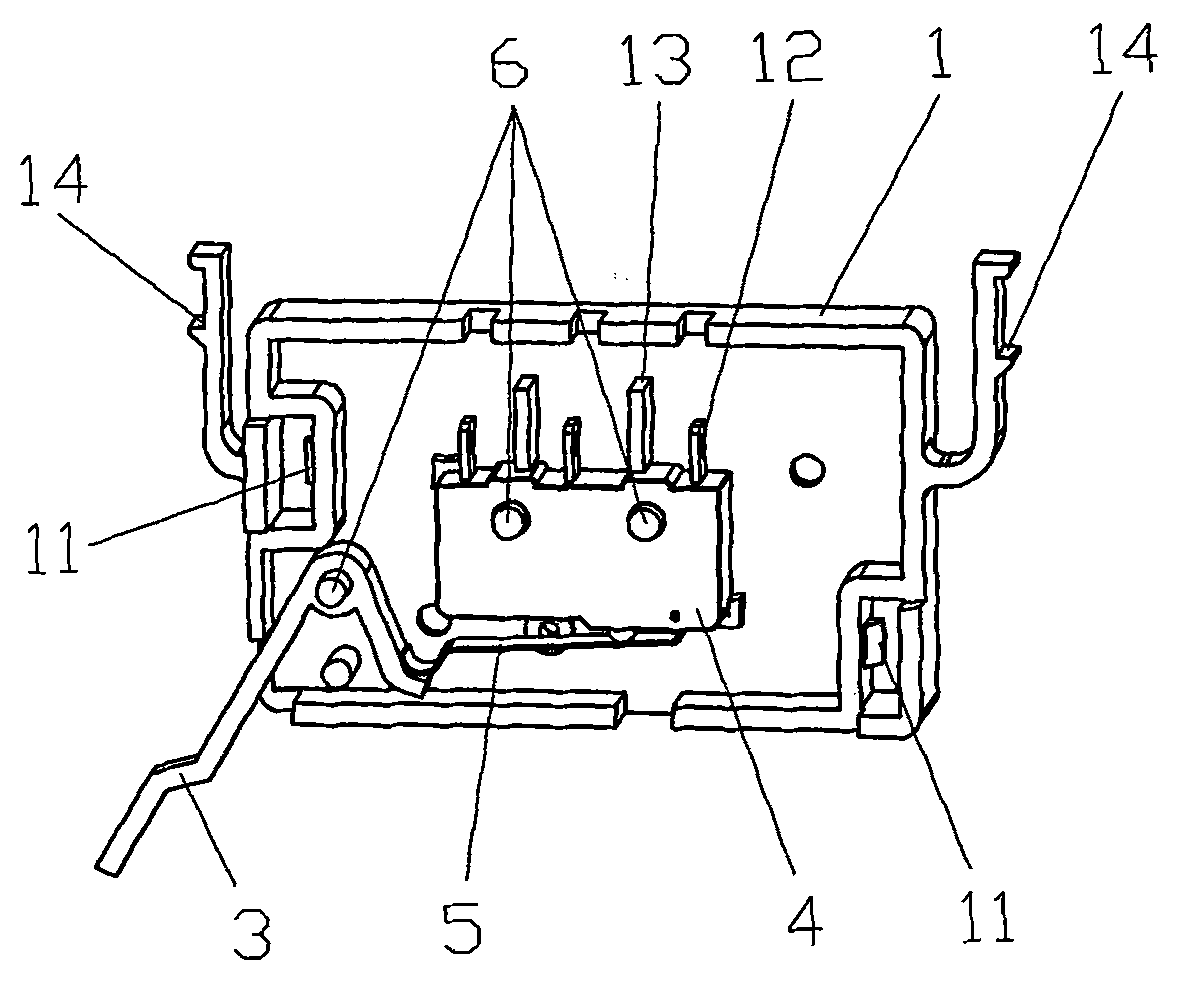

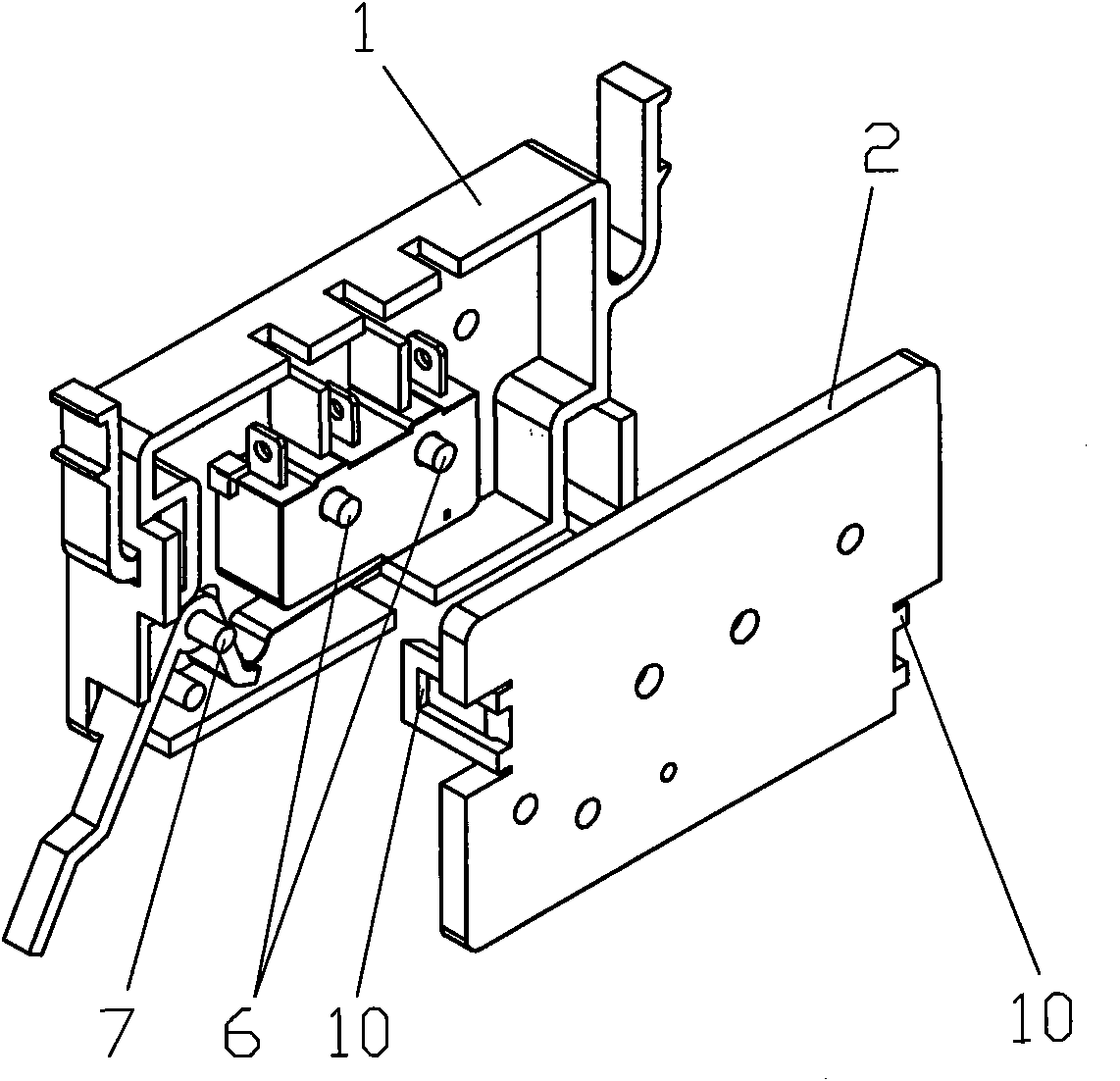

Alarming contact device of moulded case circuit breaker

InactiveCN101944458AEasy to installIncrease productivityProtective switch detailsCircuit-breaking switch contactsModular designEngineering

The invention relates to an alarming contact device of a moulded case circuit breaker. The alarming contact device consists of a base, a rear cover, a push rod, a microswitch and a microswitch toggle plate, wherein the base and rear cover are used for installing and fixing the push rod, microswitch and microswitch toggle plate in the base which is provided with positioning pins for positioning and installing the microswitch and push rod by molding; and based on the principle of lever, the push rod is pushed by enlarging the release force of a circuit breaker mechanism to push the push rod to pry the microswitch toggle plate by using a lower release force with no additional influence on the release force of the circuit breaker body. The alarming contact device has the advantages of adopting modular design, improving interchangeability and universality, along with simple and convenient installation, no influences on the assembly of other accessories after installation in the accessory camber of the circuit break due to the total thickness of 9.5mm only, simple assembly, convenient installation and uninstallation, stable performance and high reliability.

Owner:江苏西门控电器有限公司

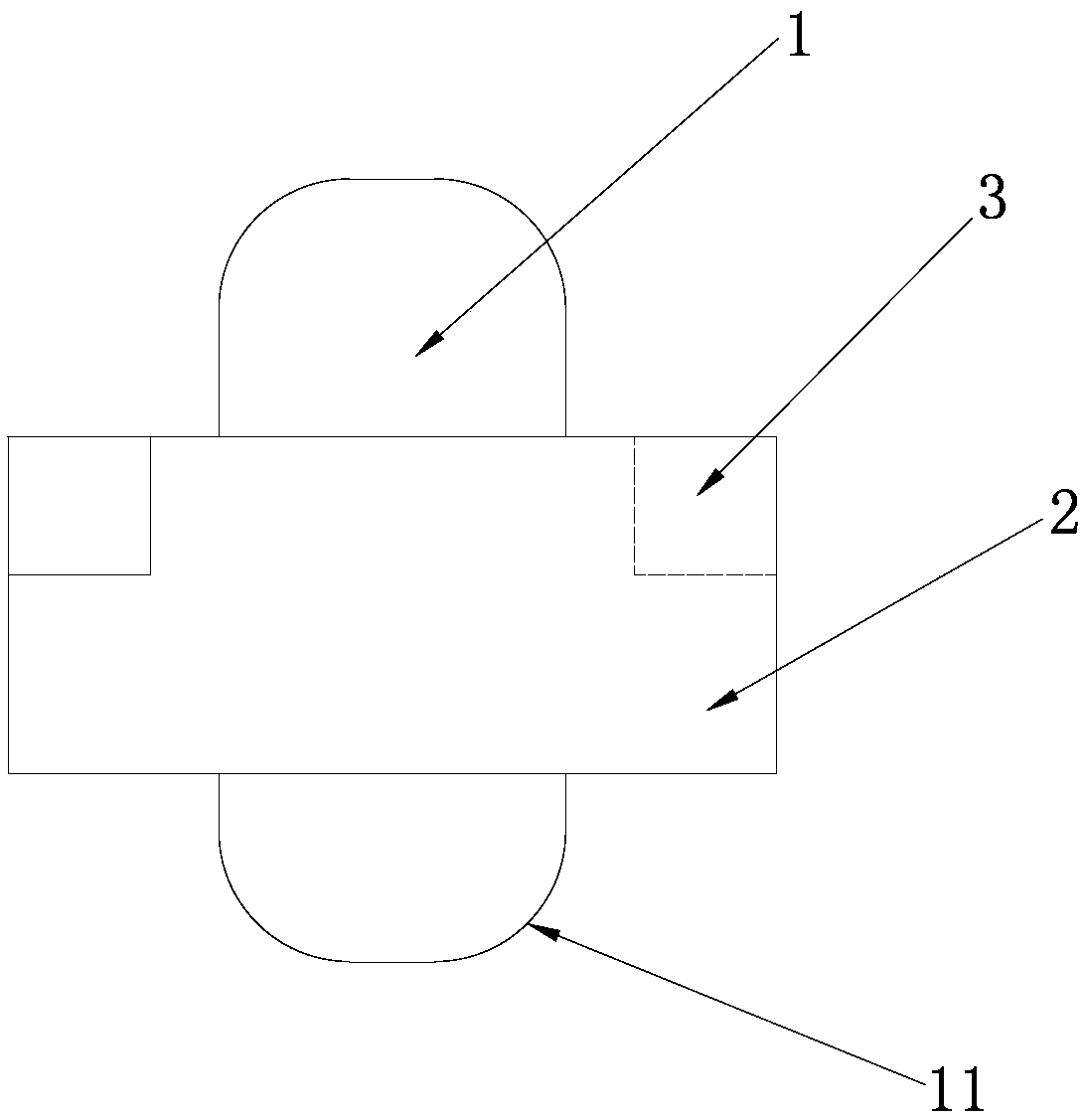

Lithium ion battery tab and lithium ion battery packaging method

ActiveCN109301149ACause poor exposureAccurately Control AlignmentFinal product manufactureCell component detailsEngineeringPlastic film

The invention discloses a lithium ion battery tab which comprises a switching positive tab and a switching negative tab which are arranged on a lithium ion battery. Tab glue is arranged on the switching positive tab and the switching negative tab, and a positioning device is arranged on the tab glue and used for positioning aluminum-plastic films in folding. The tab glue of the switching tabs is provided with two positioning projections or lugs which are positioned on two side surfaces of the switching tabs, the shell-entering position of a bare cell can be accurately positioned by the aid ofthe positioning projections or lugs on one surface of each switching tab, and alignment of the aluminum-plastic films after turnover can be accurately controlled by the aid of the positioning projections or lugs on the other surface of each switching tab. On one hand, poor exposure of packaged tab glue due to the inaccurate shell-entering position of the bare cell in packaging can be prevented, exposure consistency of the tab is improved, and assembly positioning accuracy of a battery pack assembled by the cell is improved. On the other hand, top edge sealing dislocation can be decreased and even eliminated, and cell length consistency is improved. The lithium ion battery tab is applied to the technical field of batteries.

Owner:余姚市海泰贸易有限公司

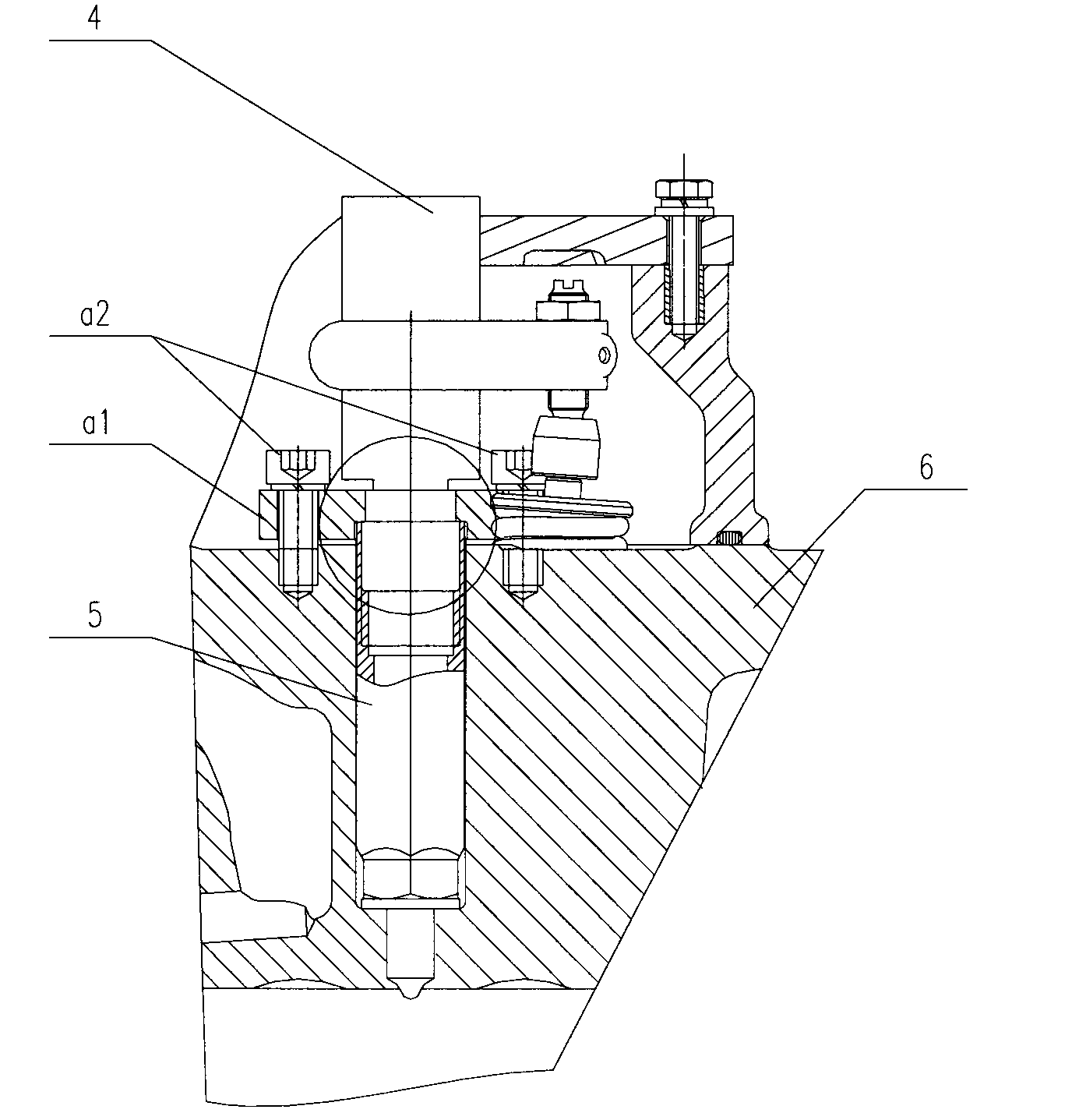

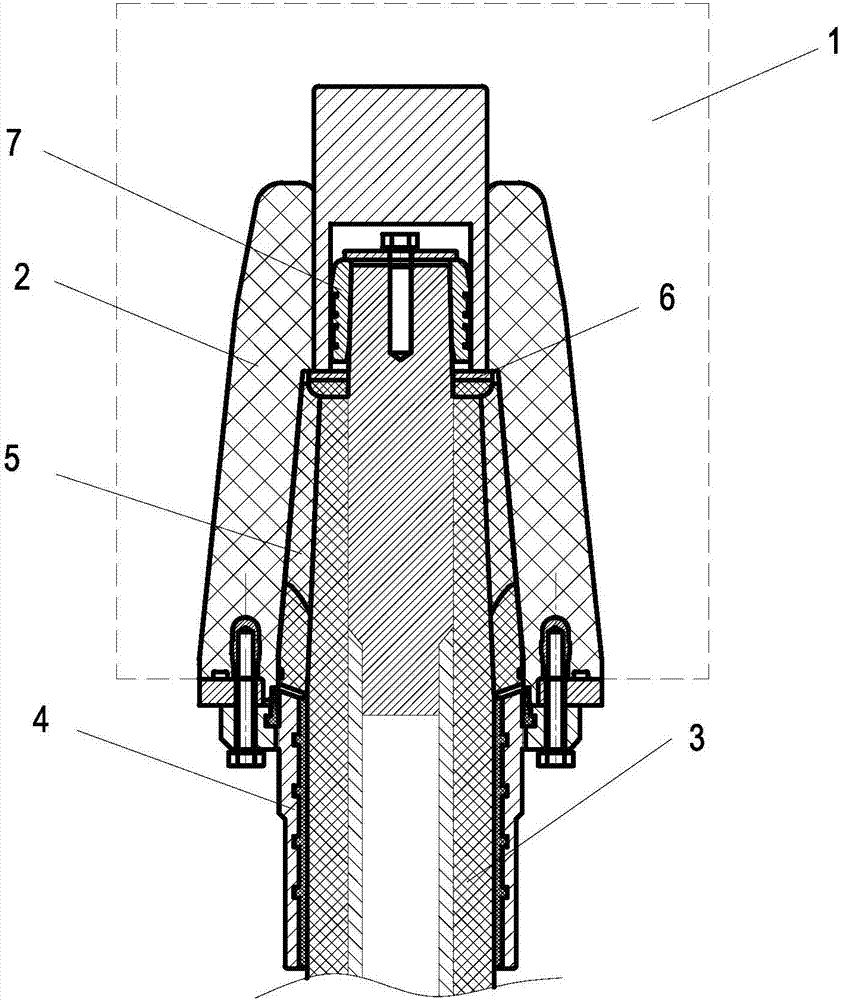

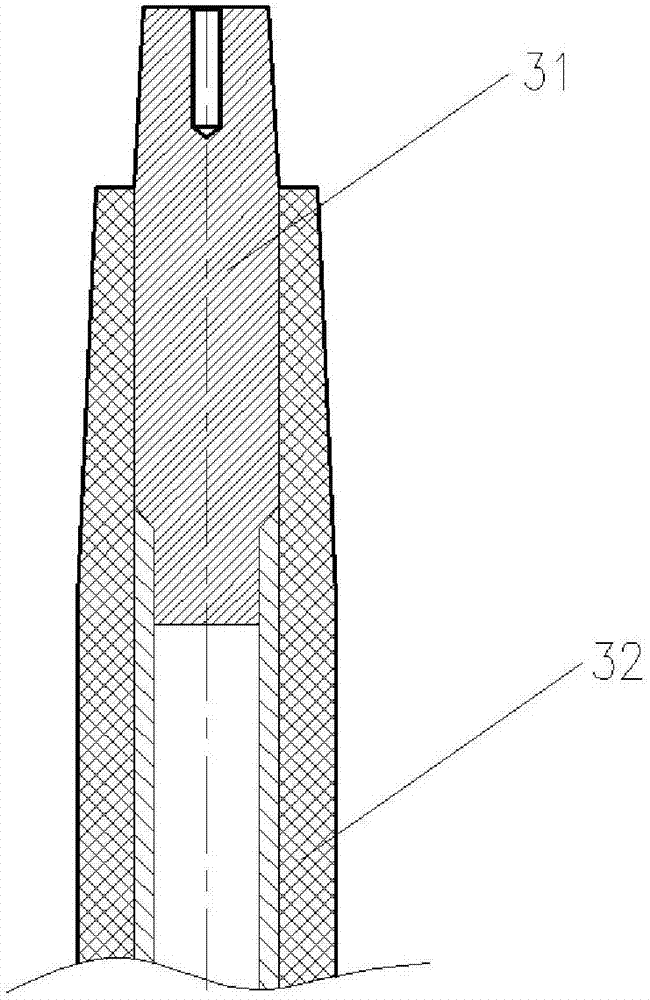

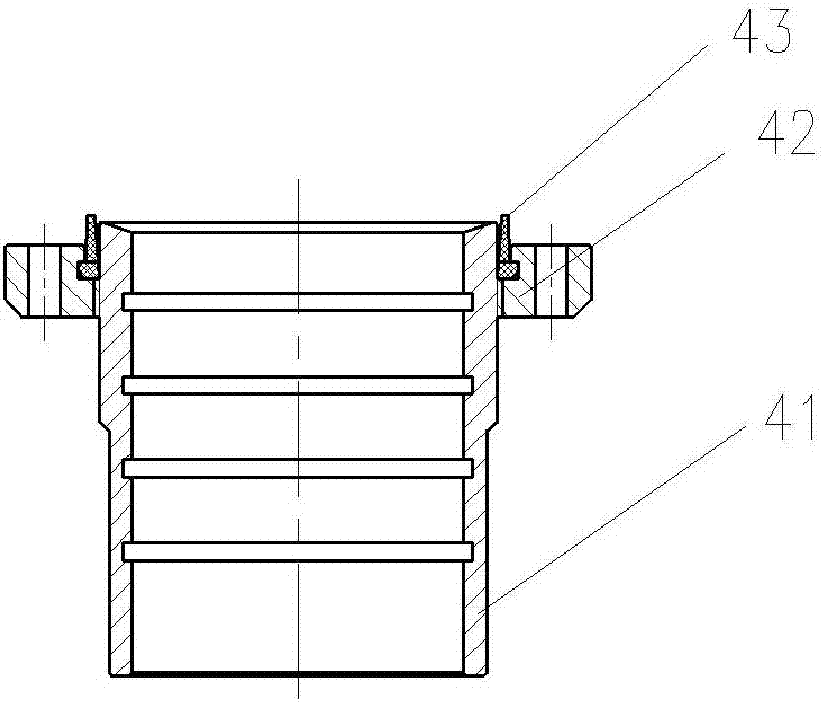

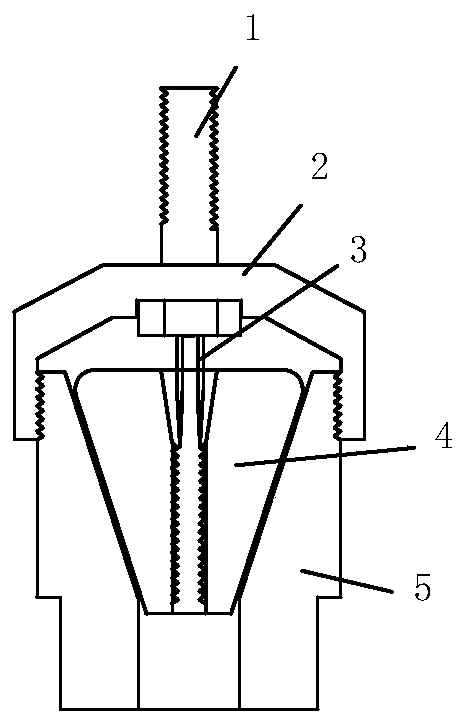

Oil sprayer compress tightly screw cap and fixing method thereof

ActiveCN102937063AEliminate interferenceDoes not affect assemblyFuel injection apparatusMachines/enginesSprayerScrew thread

The invention relates to an oil sprayer compress tightly screw cap. The oil sprayer compress tightly screw cap comprises an installing section and a screw thread section, the installing section is used for installing an oil sprayer couple part, a spring and a backing block, and the screw thread section is used for connecting the compress tightly screw cap and an oil sprayer body. The oil sprayer compress tightly screw cap is characterized in that a lengthening section is arranged, and the lengthening section is located above the screw thread section. The compress tightly screw cap is matched with a pressing plate or a compress tightly sleeve, so that an oil sprayer can be fixed on a cylinder cover, the interference of oil sprayer fixing structure with a valve spring and an air inlet and outlet rocker arm is eliminated, simultaneously the fuel gas in a cylinder can be effectively sealed, and assembly and disassembly are convenient.

Owner:CHINA NORTH ENGINE INST TIANJIN

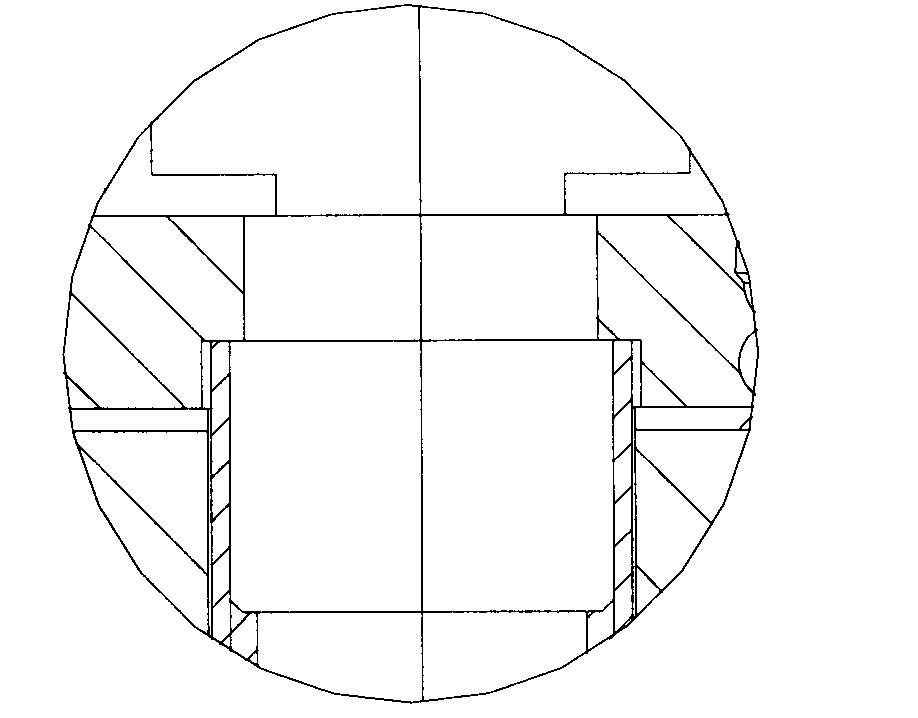

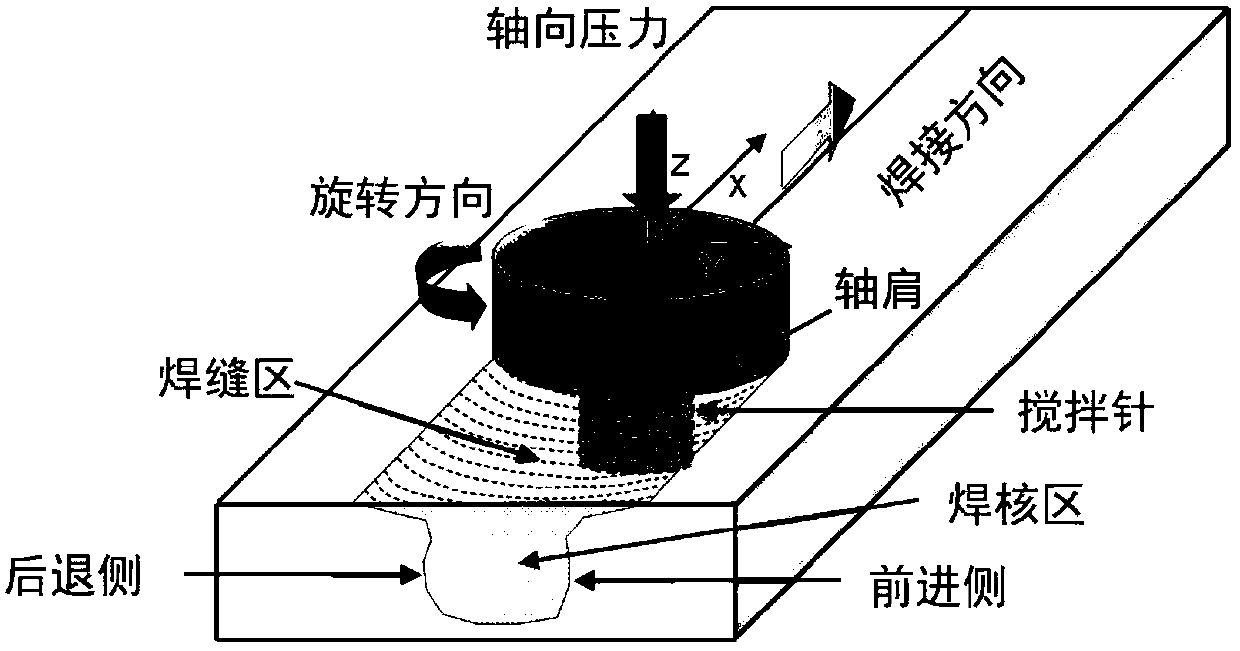

Embedded metal material connecting method with sealing effect

InactiveCN102990221ADoes not affect assemblyHigh bonding strengthNon-electric welding apparatusTitaniumCopper

An embedded metal material connecting method with a sealing effect comprises the following steps of forming a threaded hole in a metal piece such as aluminum, magnesium, copper, zinc, titanium, steel or other metals to be connected; screwing a screw into the threaded hole and tightening the screw; rotating and holding down the screw in the tightening direction by using needleless friction stir welding (a welding tool is only provided with a shaft shoulder without a stirring needle), fastening the screw through heat generated by violent friction and plastic deformation; and forming a welding layer which is several millimeters deep between the tail part of the screw and the metal piece to be connected. According to the connecting method, bonding strength is high and the joint is hidden without affecting assembling and beauty; and the sealing property is good so that gas and liquid can be effectively prevented from leakage.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Electrophoresis coating technique for fasteners

InactiveCN101387003AImprove corrosion resistanceAppropriate coefficient of frictionElectrophoretic coatingsLiquid temperatureChemistry

The present invention discloses a process for electrophoretic painting of a fastener, which comprises the following; firstly, a step of phosphatization of zinc series, in which the phosphatization is carried out in a phosphatization tank at a temperature of between 30 and 40 DEG C for 3 to 5 minutes, and the sample piece is subjected to ceaseless shaking, washing, drying for 20 minutes at a temperature between 80 and 100 DEG C; secondly, a step of cathodic electrophoresis, in which the cathodic electrophoresis is carried out in an electrophoresis tank, the tank liquid temperature is between 28 and 32 DEG C, the electrophoresis time is between 2 and 3 minutes and the painting voltage is between 140 and 180 volt, and water washing is adopted; thirdly, a step of drying, in which the surface is dried for 40 minutes at a temperature of between 170 and 180 DEG C. The process solves the problem of processing main Cr6+ pollution in the most universal fastener surface treatment (zinc plating+passivation process, Dacro coating process, darkening process, and the like). The cathodic electrophoretic painting process adopted by the fastener is a novel technology, which improves the corrosion resistance of the fastener and has capacity of protecting environment as well. The composite cost of the process is lower than that of the barrel plating.

Owner:CHINA FIRST AUTOMOBILE

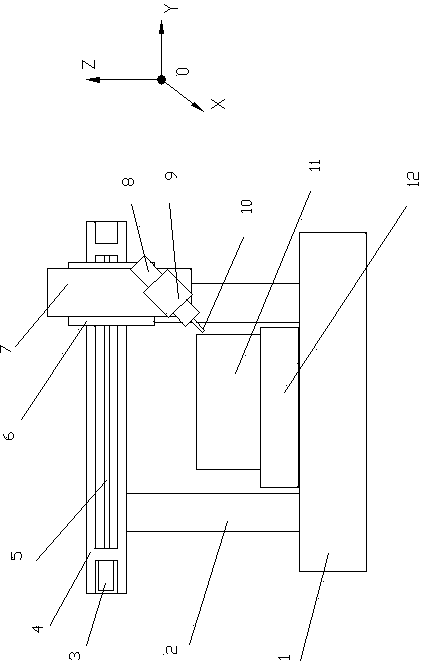

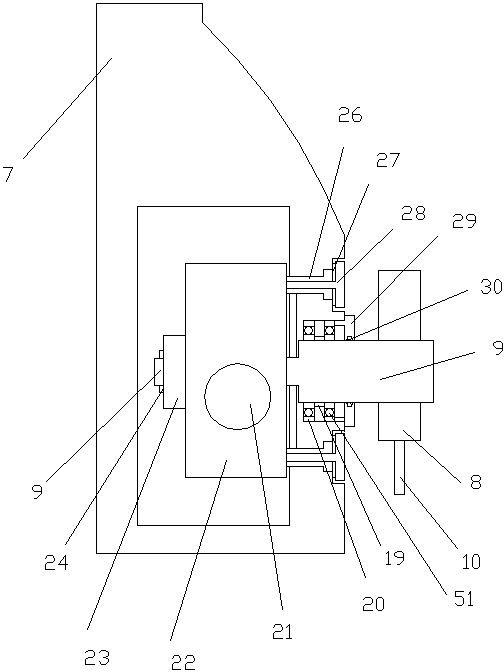

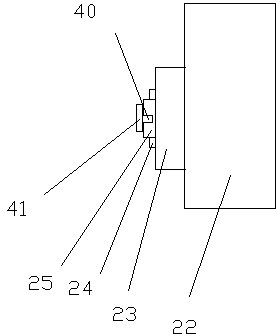

Vertical five-shaft linkage machine tool

The invention discloses a vertical five-shaft linkage machine tool. The vertical five-shaft linkage machine tool comprises an overhanging-eave-type portal frame, a swing input motor (21), a swing speed reducer (22), a motorized spindle clamping head (9) and a motorized spindle (8), wherein the swing speed reducer (22) is arranged in a ram (7) and is in bolted connection with the ram (7), the swing input motor (21) is connected with the swing speed reducer (22) through a coupling, the swing speed reducer (22) is of a worm and gear structure, a worm-wheel shaft is a hollow output shaft (24), a worm is connected with the swing input motor (21) through a coupling, the rear end of the motorized spindle clamping head (9) is connected with the worm-wheel hollow output shaft (24) through an expansion sleeve (23), and the front end of the motorized spindle clamping head (9) is installed on the ram (7) through a bearing. The rigidity of the machine tool is improved by more than four times when compared with that of a traditional series machine tool, a connection gap between the swing input motor and the motorized spindle is avoided, swing precision is improved, rolled steel can be efficiently machined at the speed of 10000 turn / min, and the overall performance, including the rigidity, precision and machining speed, of the machine tool is substantially improved when compared with that of existing domestic and overseas machine tools.

Owner:NANJING GEWAI TRACK TRAFFIC EQUIP CO LTD

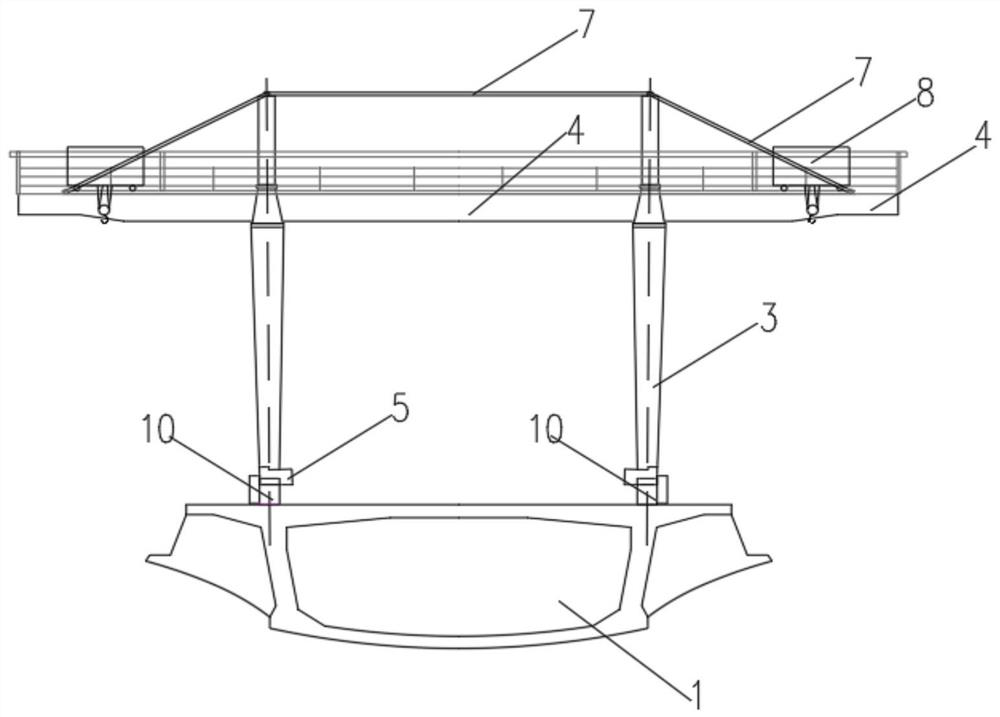

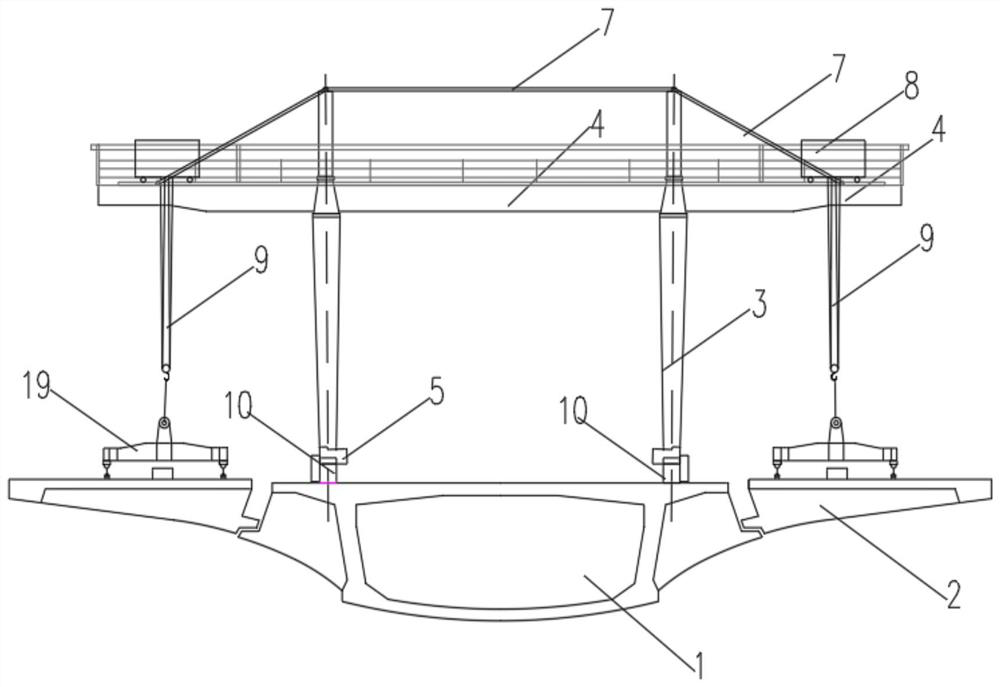

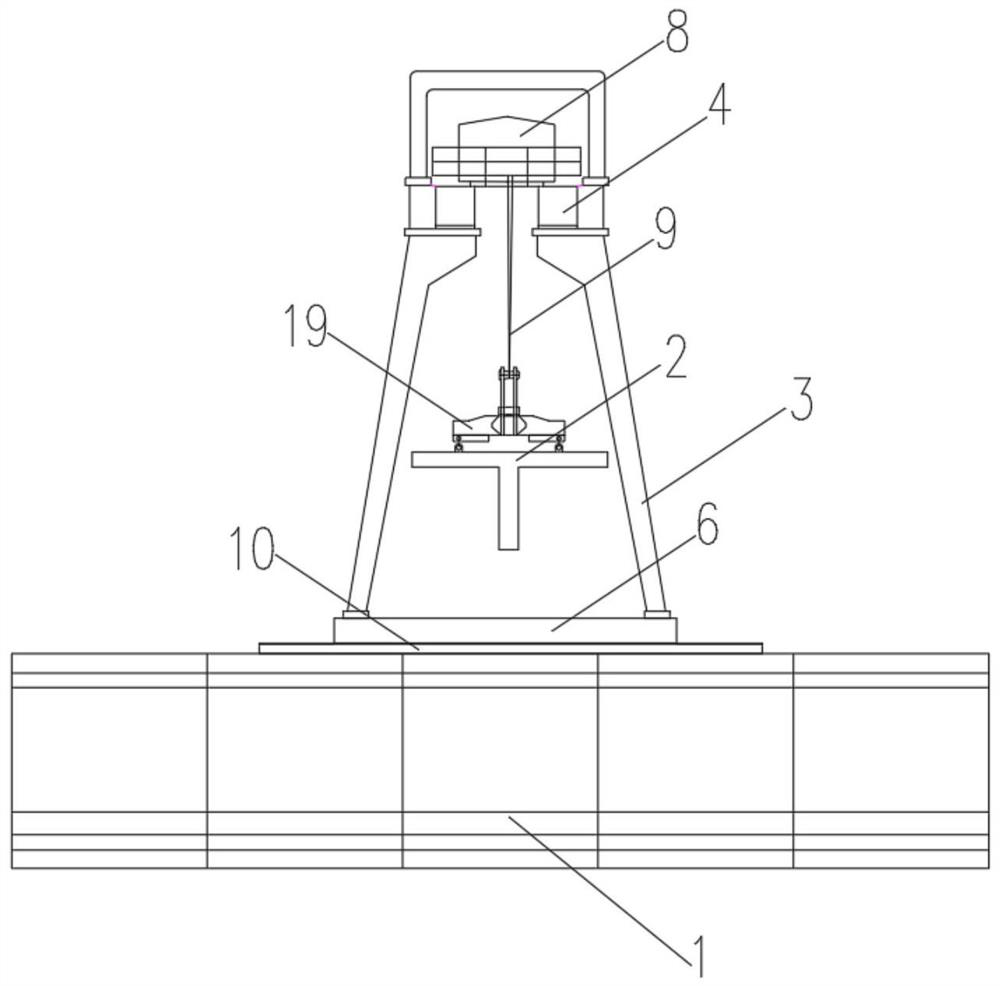

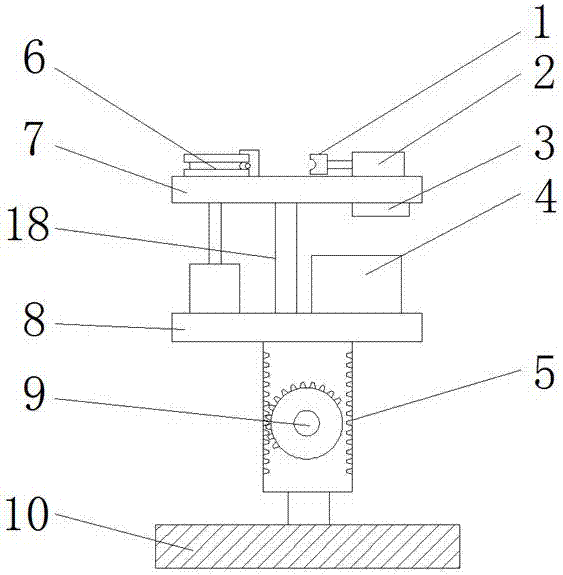

Double-side synchronous hoisting equipment suitable for after-assembled cantilevers of composite-section segmental beam bridge and construction method

PendingCN113120771AImprove turnover efficiencySave time at workBase supporting structuresBraking devices for hoisting equipmentsArchitectural engineeringBridge deck

The invention discloses hoisting equipment and a construction method which are suitable for synchronously hoisting prefabricated cantilevers on the two sides of a composite-section segmental beam. The hoisting equipment mainly comprises a gantry system, an anchoring system, a hoisting system and a walking system. The gantry system is fixed to a core longitudinal beam through the anchoring system, the prefabricated cantilevers are hoisted to the two sides of the core longitudinal beam through the hoisting system, after the installation of a pair of cantilevers is completed, anchoring between the hoisting equipment and the core longitudinal beam is relieved, and the hoisting equipment is moved forwards through the bridge deck walking system for hoisting of the next segment. The hoisting equipment can ensure sufficient on-beam beam transportation space, so that the hoisting equipment does not influence subsequent cross-core-longitudinal-beam transportation and assembly when a site lacks parking conditions for a large crane ship or a hoisting crane, the efficiency is improved, and the construction period is shortened.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Bending machine for steel pipes

The invention discloses a bending machine for steel pipes, which comprises a pressing plate, a hydraulic cylinder, a hydraulic driving device, a storage box, a motion frame, a turntable, a workbench, a support plate, a half-toothed gear, a base, a fixed plate, a limit pin, The second transmission shaft, the second motor, the first motor, the first transmission shaft, the motor mounting plate and the connecting rod are characterized in that, the upper surface of the base is fixedly connected with a motor mounting plate, and one side of the motor mounting plate A first electric motor is fixedly connected. This product can reduce the work intensity of the workers, improve the bending efficiency, and the bending degree is fixed, the bending quality is controllable, and will not affect the assembly of the subsequent process; this product has a storage box, which can facilitate the temporary storage of workers' items. The design is more user-friendly; the fixed height of the workbench of this product can be adjusted, allowing workers to bend steel pipes at a comfortable working height, thereby reducing the discomfort of workers and improving the bending efficiency of steel pipes.

Owner:王祖友

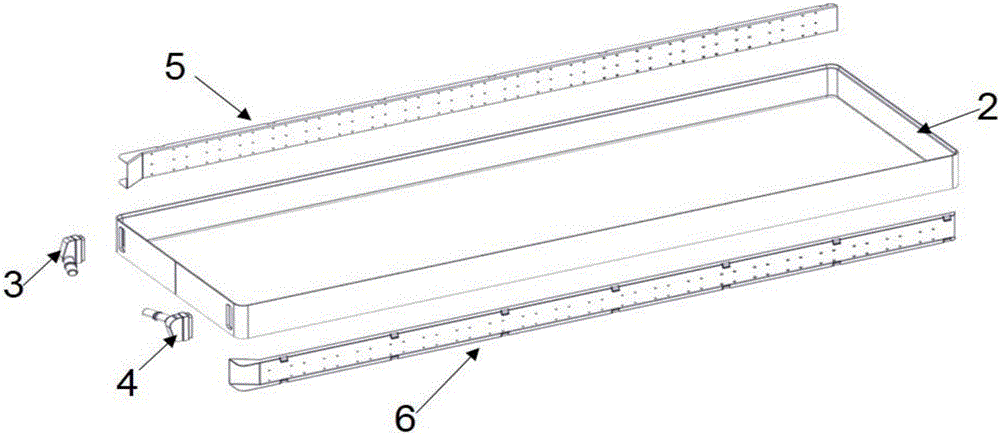

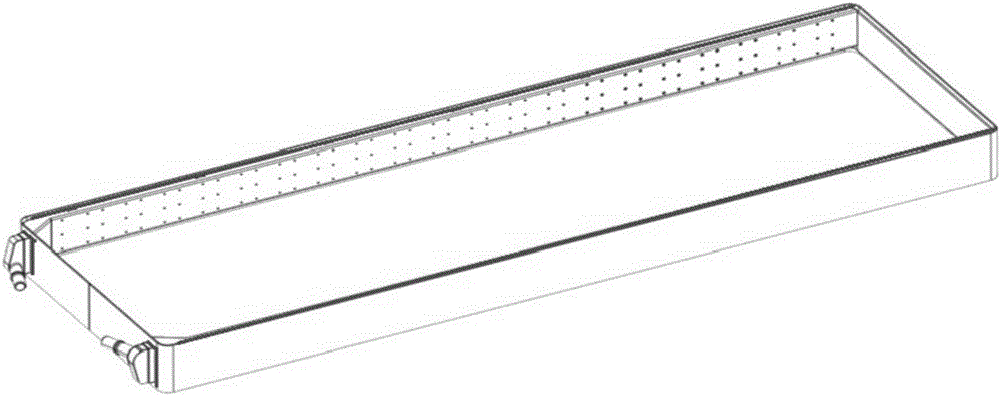

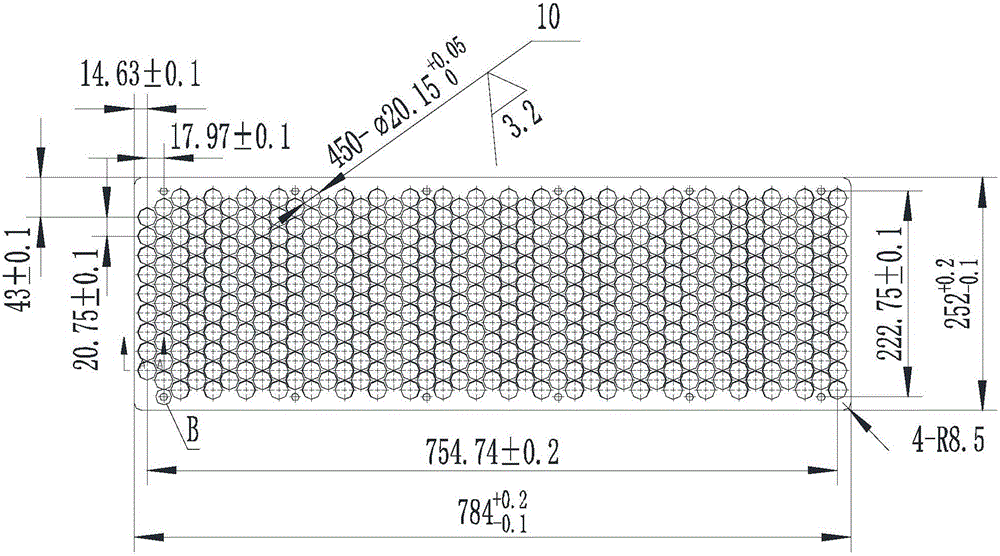

Welding method for cooling tank in new energy electric vehicle

ActiveCN106181082AImprove sealingReduce distortionWelding/soldering/cutting articlesHeat exchange apparatusElectrical batteryNew energy

The invention discloses a welding method for a cooling tank in a new energy electric vehicle. The cooling tank comprises a lower cover plate, an outer frame, an inlet side edge plate, an outlet side edge plate, an inlet tail end, an outlet tail end, a battery supporting cylinder, an upper cover plate and multiple supporting pillars. The welding method includes the following steps that the inlet side edge plate and the outlet side edge plate are symmetrically assembled on one outer side of the outer frame. The inlet tail end and the outlet tail end are assembled on the two opposite inner sides of the outer frame correspondingly, and the inlet tail end and the outlet tail end communicate with the inlet side edge plate and the outlet side edge plate correspondingly to form a water tank water guide system. The battery supporting cylinder and the supporting pillars are inserted in corresponding holes in the lower cover plate, after installation, the lower cover plate is then inserted in an insertion groove in the outer frame, and it is ensured that the installation gap between the lower cover plate and the outer frame is within 0.2 mm. The upper cover plate is installed, and meanwhile it is ensured that the installation gap between the upper cover plate and the outer frame is within 0.2 mm. The edge part of the cooling tank is welded through lasers, and the cooling tank is welded in a tin immersion manner. The welding method is suitable for sealing welding of related aluminum and aluminum alloys, and the welding technology is simple.

Owner:安徽新富新能源科技股份有限公司

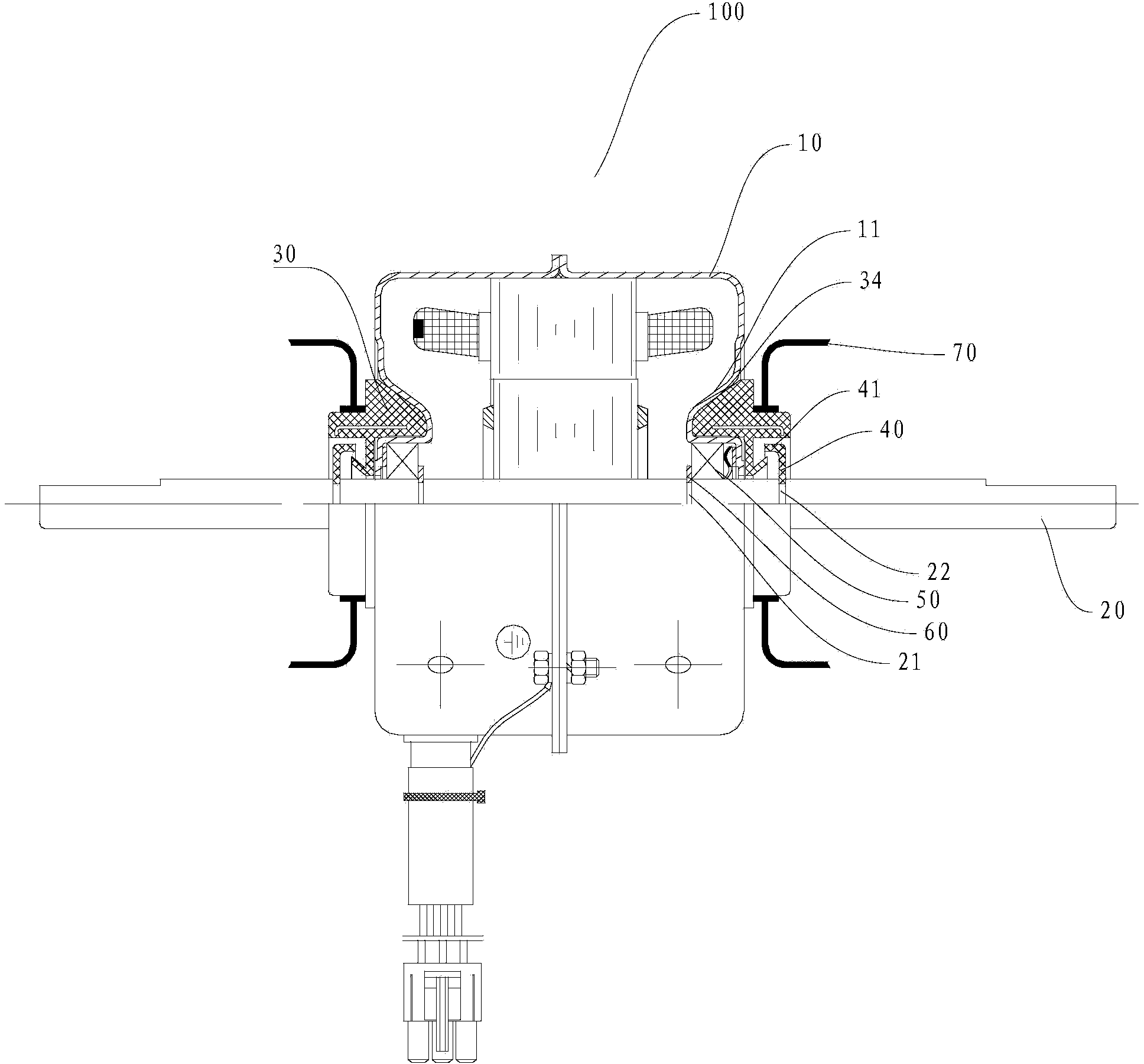

Tubular bus connection structure

ActiveCN107294030ASimplify the installation processReduce installation difficultyButt joining bus-barsConductor screwing into otherElectrical conductorSwitchgear

The invention discloses a tubular bus connection structure, which is used for realizing electrical conduction of incoming and outgoing lines of a switch cabinet after being inserted into a socket of the switch cabinet. The tubular bus connection structure comprises a conductor connector, a tubular bus, a silicone rubber insulation member, a fastener and a strain supporting member, wherein the conductor connector is fixedly connected to the top part of the tubular bus, and is used for being inserted into the socket of the switch cabinet so as to be electrically connected with conductors of the socket; the silicone rubber insulation member sleeves the outer surface of a part between the portion (positioned below the conductor connector) of the tubular bus and the portion (positioned inside the switch cabinet) of the tubular bus when the tubular bus is in operation, and is used for carrying out insulation and electrical isolation on the socket of the switch cabinet; the fastener is mounted under the silicone rubber insulation member, and is used for being fixedly connected with the switch cabinet when in operation; and the strain supporting member comprises a metal force bearing ring and a semiconductive silicone rubber ring covering the metal force bearing ring. The tubular bus connection structure meets the development requirements for the through-flow performance and miniaturization of the switch cabinet, and can upgrade the rated current without changing the existing switching equipment.

Owner:GCA CO LTD

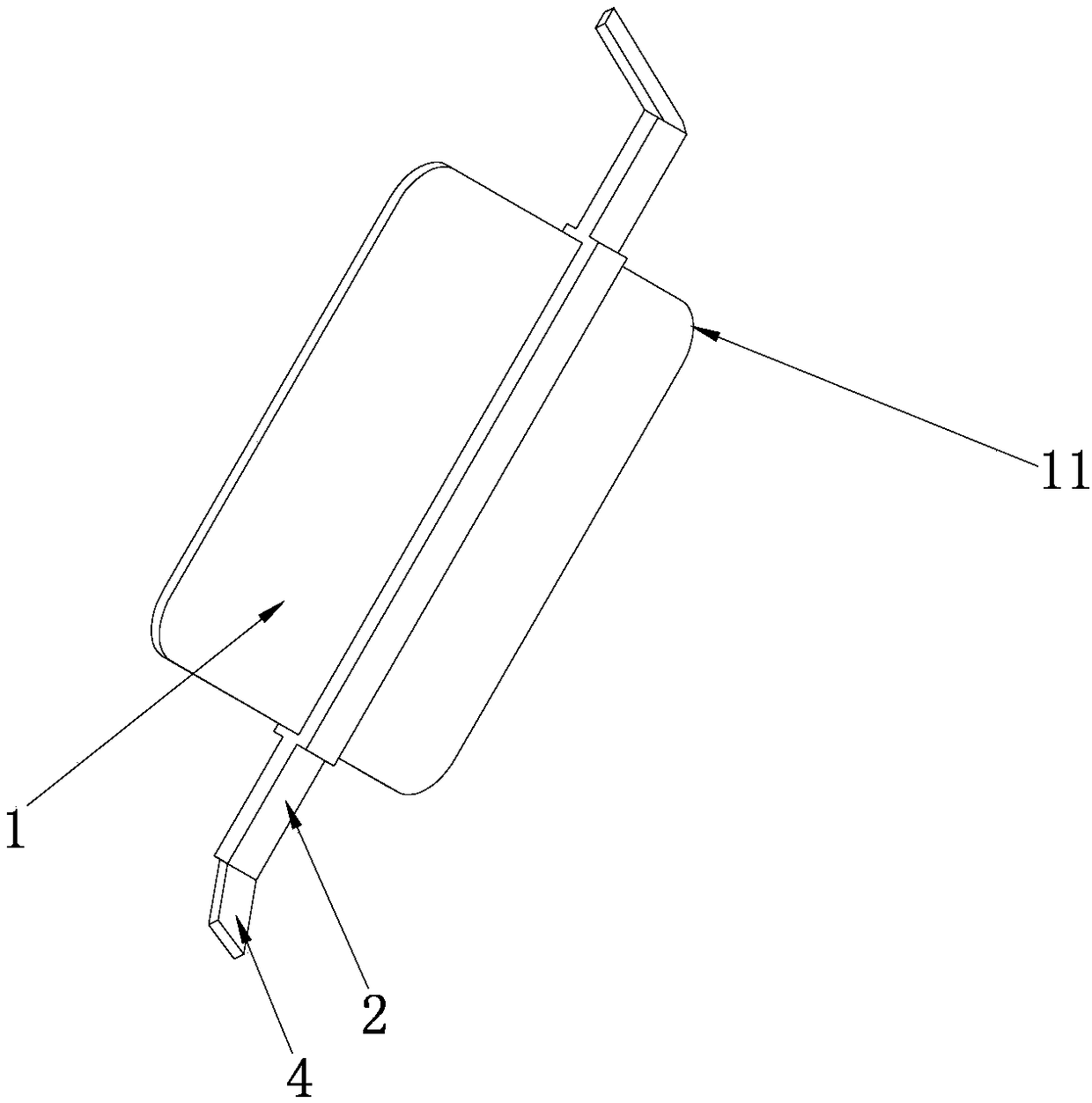

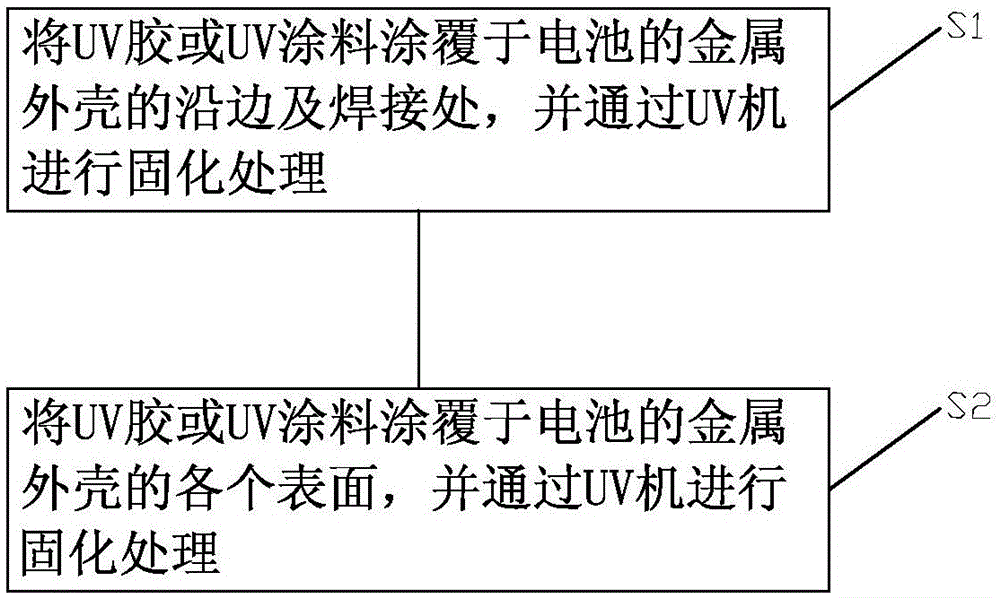

Metal housing structure of battery and insulating treatment method for metal housing structure

InactiveCN105098106AIncrease productivityDoes not affect assemblyJackets/cases materialsMetallic enclosureAdhesive

The invention provides a metal housing structure of a battery and an insulating treatment method for the metal housing structure. The insulating treatment method comprises the following steps: coating the edges and the welded parts of a metal housing of the battery with an ultraviolet (UV) adhesive or UV paint, and carrying out solidification treatment through a UV machine; and coating various surfaces of the metal housing of the battery with the UV adhesive or the UV paint, and carrying out solidification treatment through the UV machine. According to the metal housing structure of the battery and the insulating treatment method for the metal housing structure provided by the invention, the production efficiency of the battery can be greatly improved; and good insulating property of the metal housing of the battery can be ensured.

Owner:王新峰

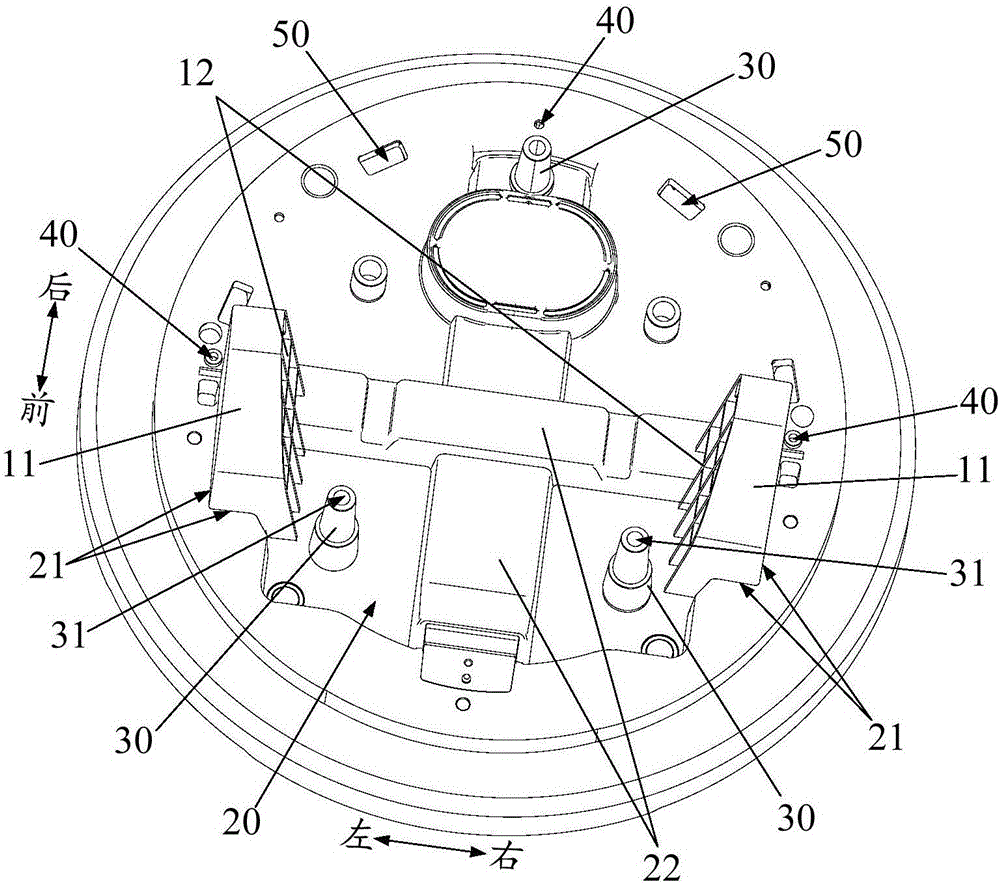

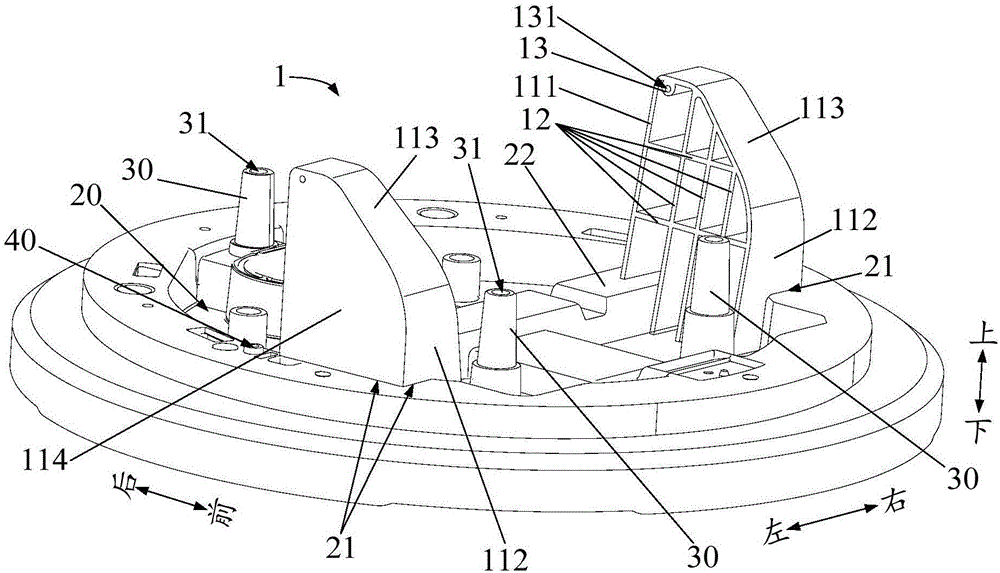

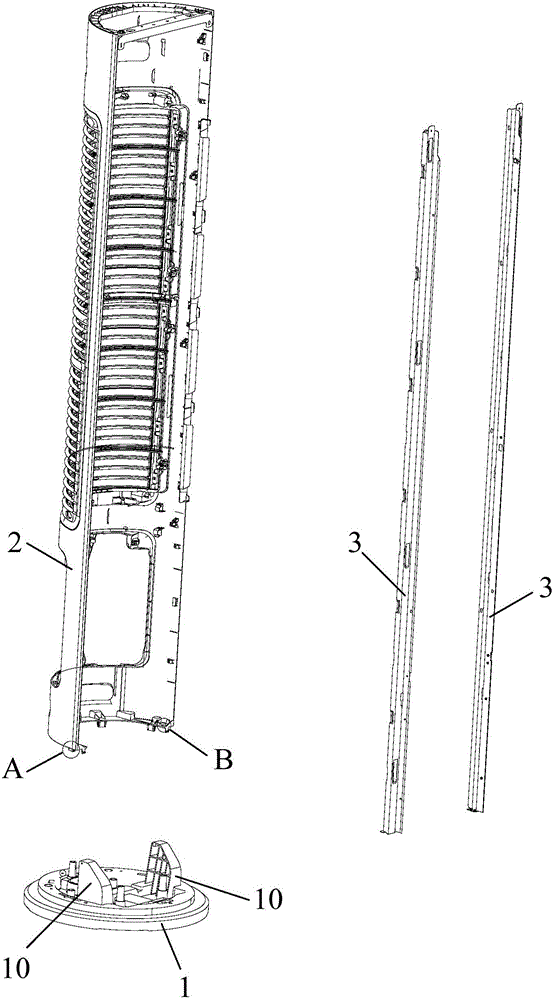

Chassis and air conditioner

ActiveCN106288311AHigh strengthFasten the connectionLighting and heating apparatusSpace heating and ventilation detailsEngineeringFuselage

The invention provides a chassis and an air conditioner. The air conditioner comprises a rear casing assembly with an opening in the front end, a connecting part capable of being tightly connected with the bottom of the rear casing assembly is arranged at the rear part of the chassis, and reinforcing parts capable of being tightly connected with the front opening end of the rear casing assembly are arranged at the front part of the chassis. According to the chassis provided by the invention, the reinforcing parts are additionally arranged at the front part of the chassis, so that the integral strength of the chassis is enhanced; besides, the reinforcing parts can be tightly connected with the front opening end of the rear casing assembly, the connecting strength and the stability of the chassis and the rear casing assembly of the air conditioner are improved, and the stability of a machine body is enhanced accordingly; meanwhile, the reinforcing parts are arranged at the front parts of the chassis, thus, the rear casing assembly and the front part of the chassis are also tightly connected, a casing of the air conditioner and the whole chassis are connected more stably, and the stability of the machine body is further enhanced.

Owner:WUHU MATY AIR CONDITIONING EQUIP CO LTD +1

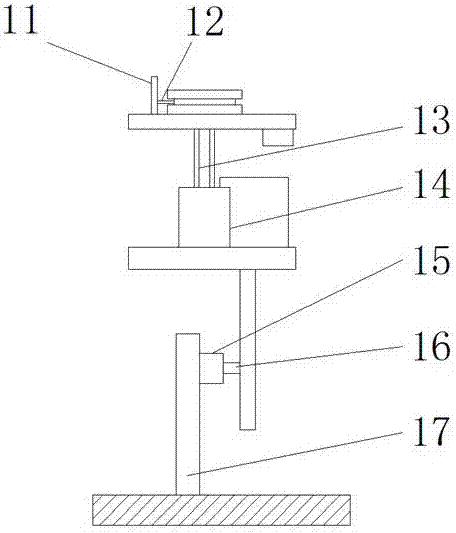

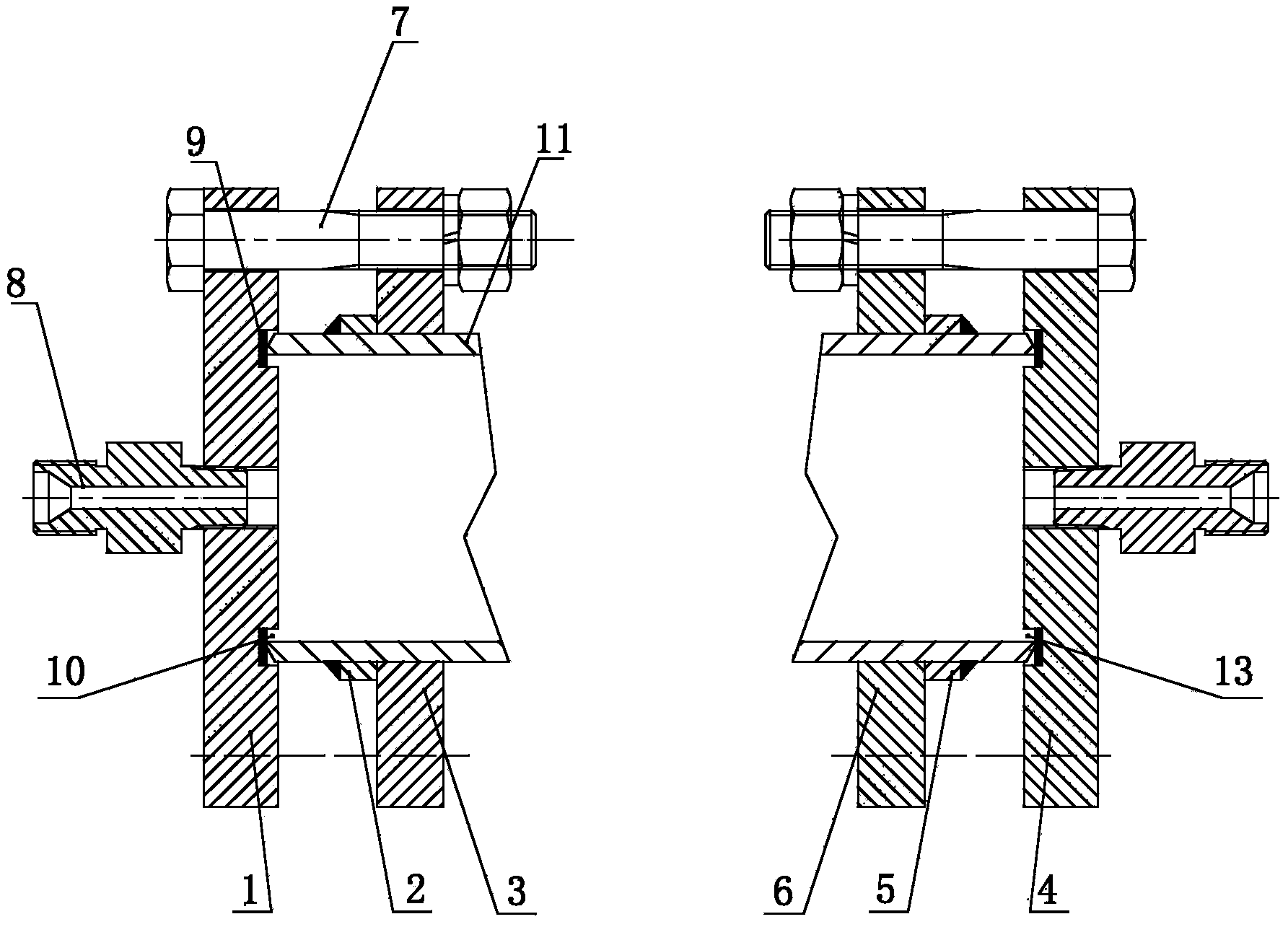

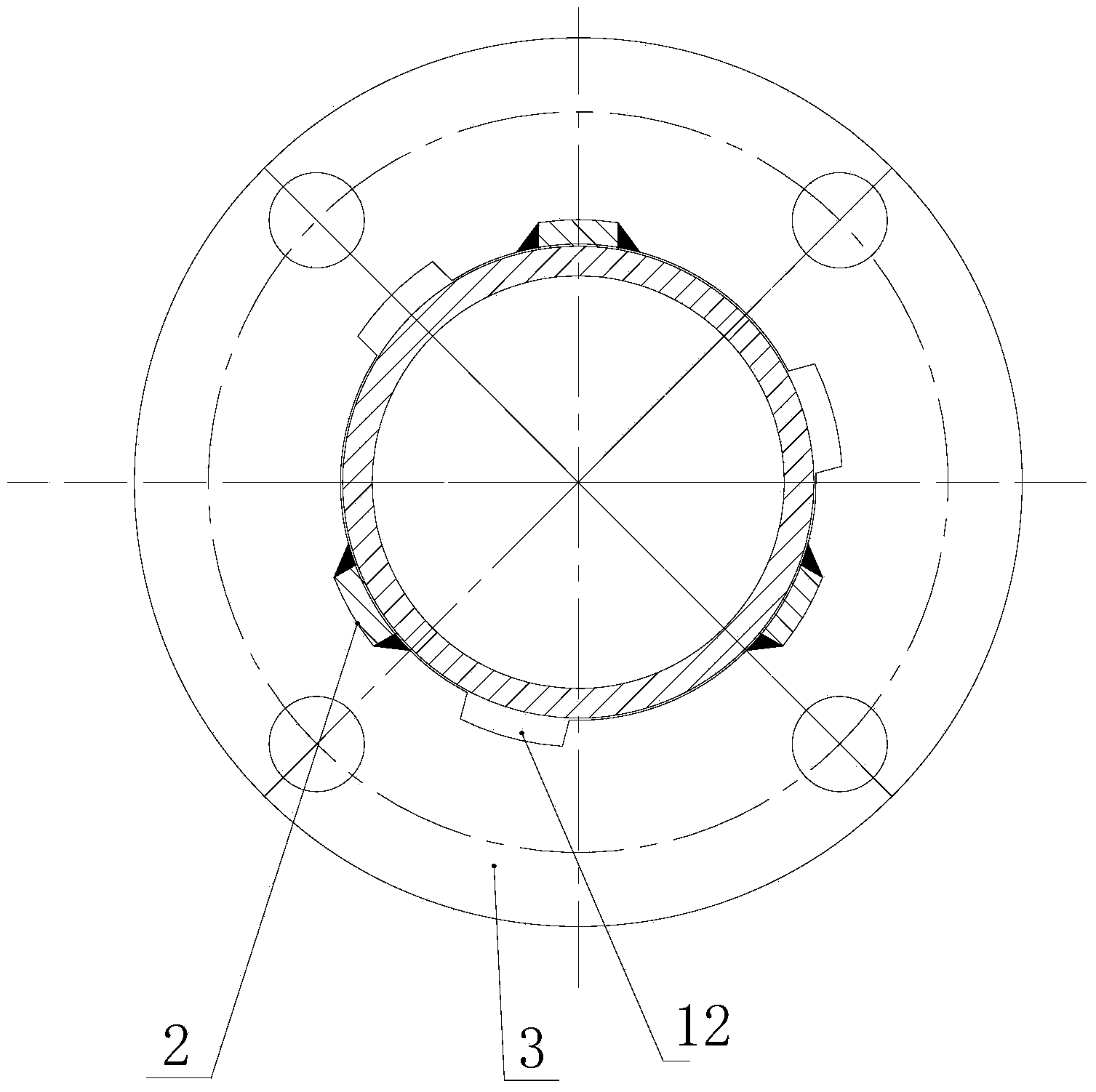

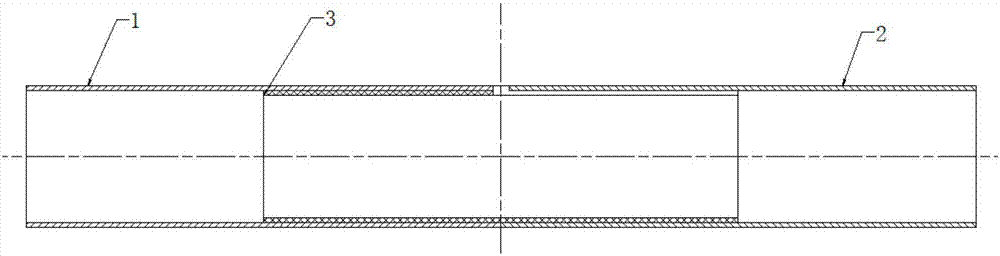

Low-temperature valve testing device

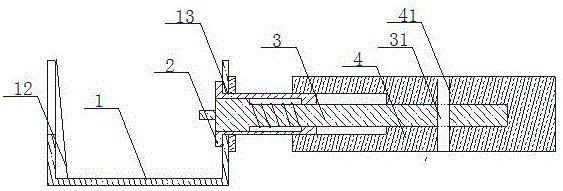

ActiveCN103776591ADoes not affect assemblyShorten the lengthFluid-tightness measurementEngineeringFastener

The invention discloses a low-temperature valve testing device which comprises a first sealing supporting plate, a second sealing supporting plate, a first connecting plate, a second connecting plate, an outlet stopping block component and an inlet stopping block component. When the testing device is used, the first connecting plate and the second connecting plate are mounted on the periphery of the outlet end of a low-temperature valve and the periphery of the inlet end of the low-temperature valve in a sleeved mode and are stopped and supported by the outlet stopping block component and the inlet stopping block component, the first connecting plate and the first sealing supporting plate are fixed through a fastener, and the second connecting plate and the second sealing supporting plate are fixed through a fastener. The testing device solves the problem that according to an existing testing device, leakage easily happens, the torque is reduced by shortening the length of a stud, the sealing performance of the low-temperature valve and the sealing supporting plates is good, and normal operation of a low-temperature valve test is guaranteed.

Owner:ZHANGJIAGANG FURUI SPECIAL EQUIP CO LTD

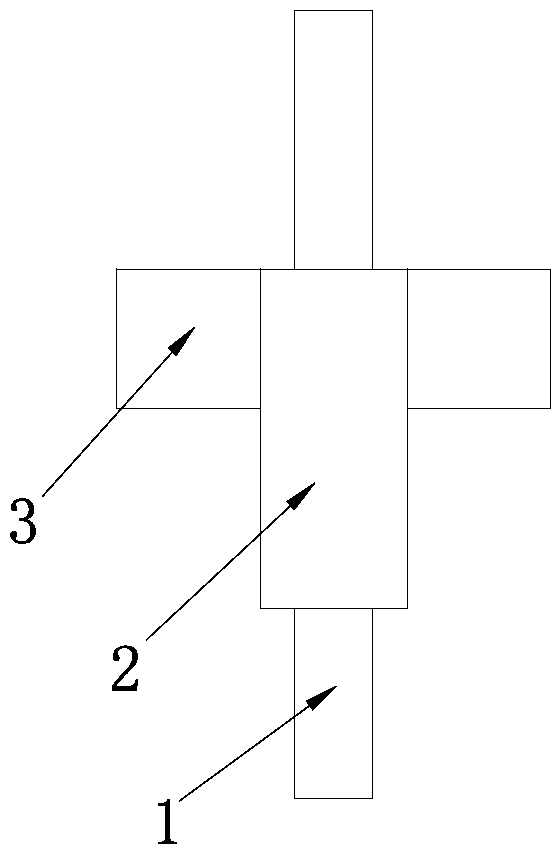

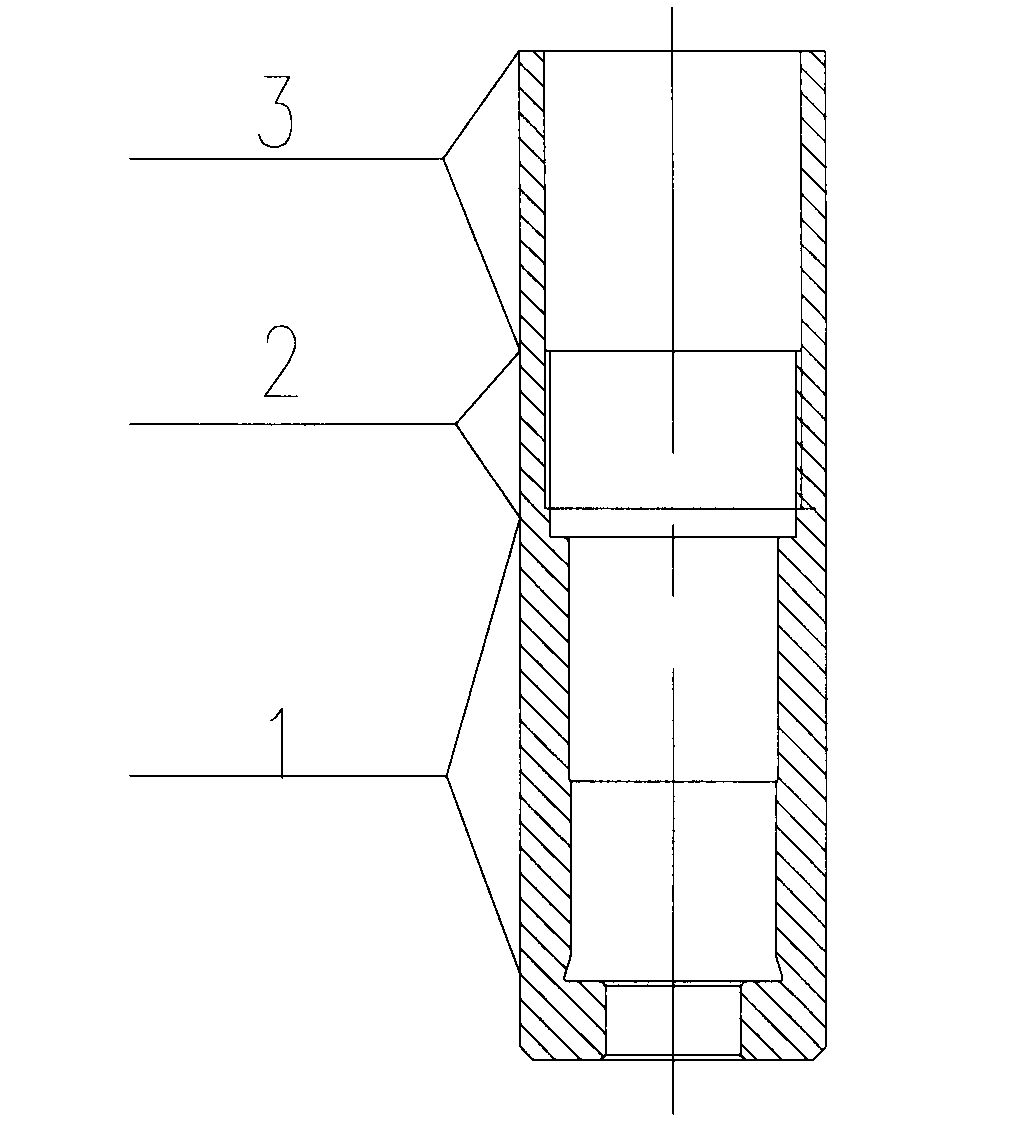

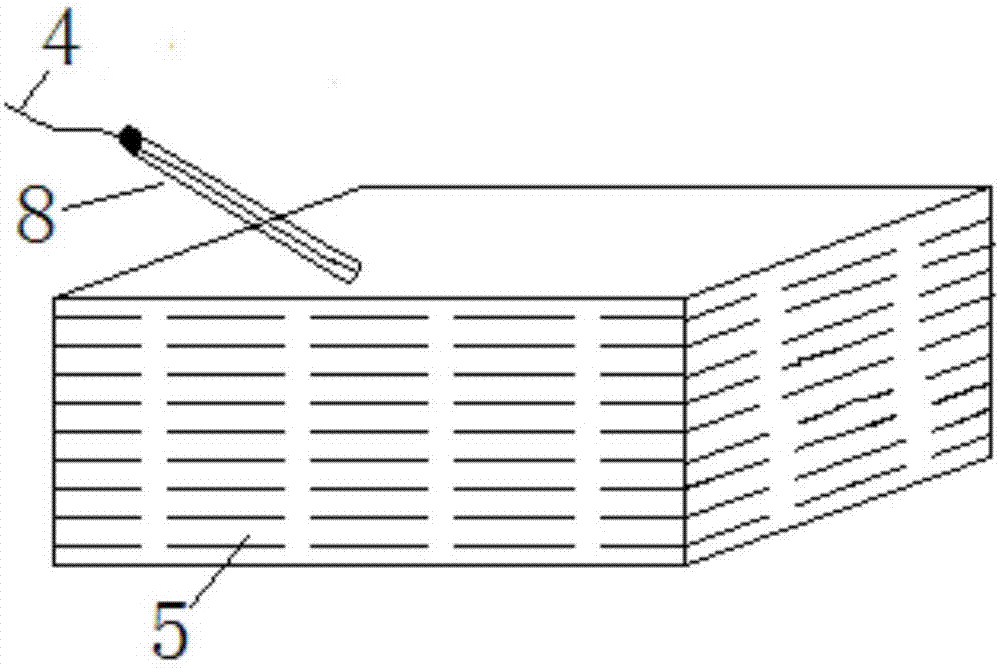

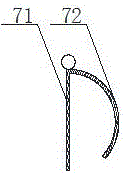

Device and method for leading out optical fiber grating sensor from composite axle tube

ActiveCN107314783AAchieve strainAchieve temperatureMeasurement apparatus componentsGratingEngineering

The invention discloses a device and method for leading out an optical fiber grating sensor from a composite axle tube. The device includes a first outer sleeve, a second outer sleeve and an inner sleeve; one end of the inner sleeve is sleeved with the inner side end of the first outer sleeve; the inner sleeve is fixedly connected with the first outer sleeve; the other end of the inner sleeve is sleeved with the inner side end of the second outer sleeve; the inner side end of the first outer sleeve is in contact spliced connection with the inner side end of the second outer sleeve; a through hole is formed at the spliced joint of the first outer sleeve and the second outer sleeve; the through hole passes through the sleeve wall of one side of the inner sleeve; an open groove along the length direction of the sleeve wall of the inner sleeve is formed in the sleeve wall of the inner sleeve; and one end of the open groove is communicated with the through hole, and other end of the open groove extends to an end surface of one side of the inner sleeve, the second sleeve being located at the one side of the inner sleeve. With the device and method adopted, the problem that an optical fiber can be only led out from end surfaces of the axle tube can be solved; and optical gratings are distributed in an all-round multi-point manner between the laid layers of prepregs, and therefore, damage to the optical fiber and the composite axle tube in the separation process of the optical fiber and composite axle tube can be avoided, and the performance and preparation quality of the composite axle tube can be improved.

Owner:WUHAN UNIV OF TECH

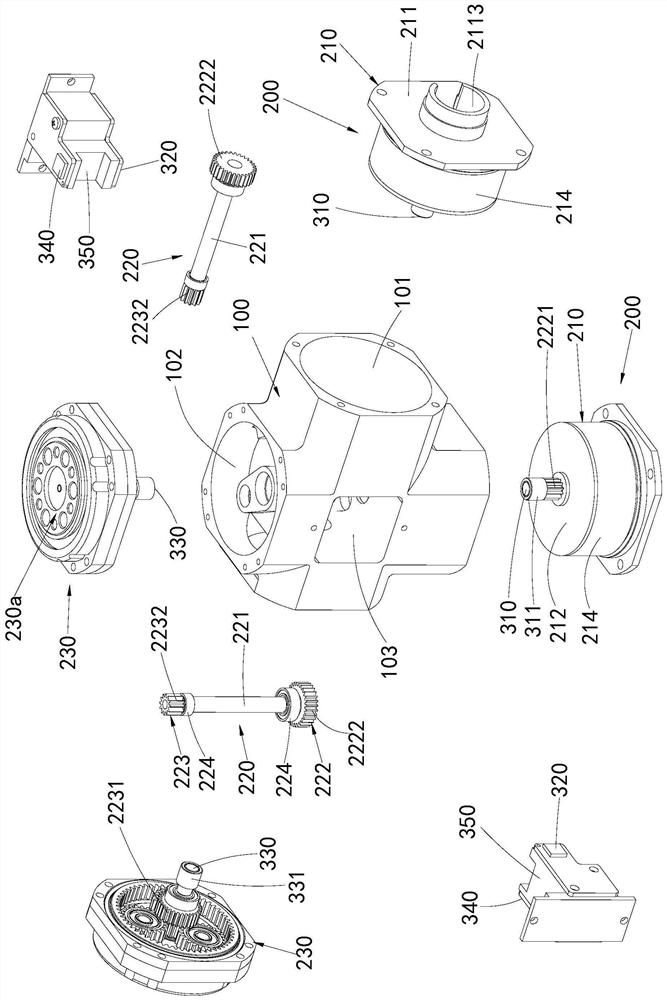

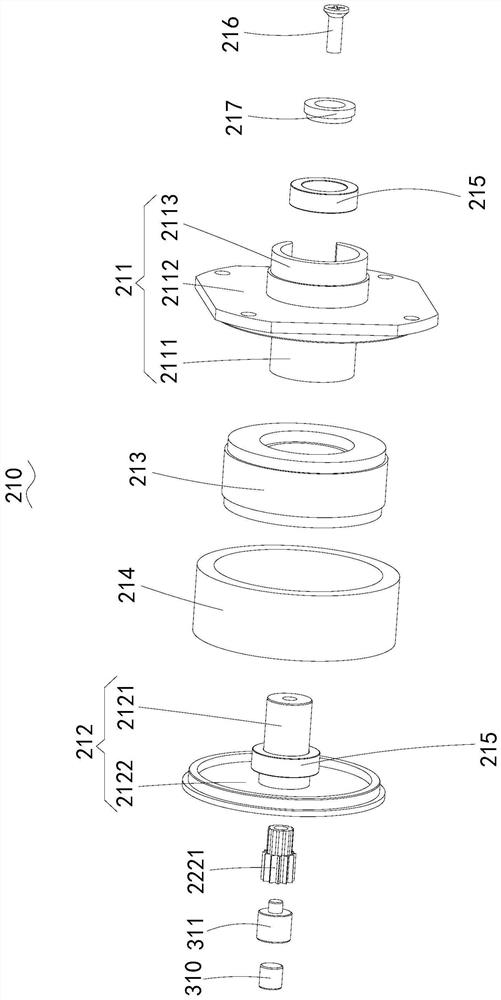

Three-side-turning advertising board prism transmission assembly

PendingCN108150632AEasy to placeEasy to assemble on siteCouplings for rigid shaftsGearing detailsDrive shaftPrism

The invention discloses a three-side-turning advertising board prism transmission assembly. The three-side-turning advertising board prism transmission assembly comprises a support base, an upper transmission central spindle, a lower transmission central spindle, a transmission wheel, a transmission shaft sleeve and a spring, wherein a containing cavity is arranged in the center of the support base; the upper transmission central spindle is arranged on the upper portion of the containing cavity; the lower transmission central spindle is arranged on the lower portion of the containing cavity; the transmission wheel is arranged below the support base and connected with the lower transmission central spindle; the transmission shaft sleeve is vertically arranged along the containing cavity; the upper end of the transmission shaft sleeve is in transmission connection with the upper transmission central spindle; the lower end of the transmission shaft sleeve is connected with the lower transmission central spindle; and the upper transmission central spindle and the lower transmission central spindle are spaced, and the spring is arranged in the space formed by the upper transmission central spindle and the lower transmission central spindle. The transmission shaft sleeve and the spring are additionally arranged, the upper transmission central spindle is downwards pressed, the springis made to be compressed, the upper transmission central spindle moves downwards by a certain distance after the spring is compressed, and thus field assembly and maintenance and replacement when a three-prism advertising board is damaged later are facilitated.

Owner:绵阳市海拍汇商贸有限公司

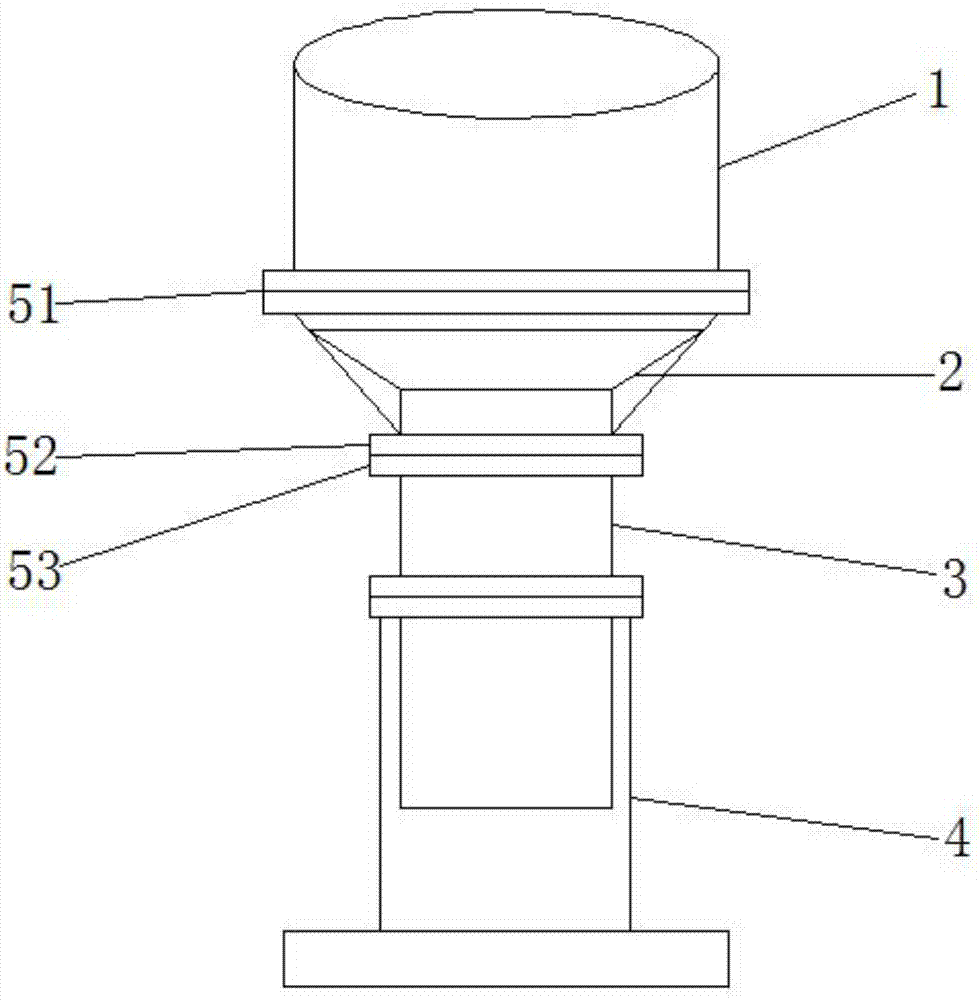

Batch drilling well wellhead design and assembling-disassembling method for modular drilling machine

InactiveCN107503703ASolve the high risk factorIncreased cost of resolution timeSealing/packingWellheadSpecial design

The invention discloses a batch drilling well wellhead design and assembling-disassembling method for a modular drilling machine. The wellhead design comprises the following design of supporting facilities: wellhead deck design, split bell mouth design, bell mouth fixing mode design, bell mouth fixed suspension design, grouting pipeline fixed design of bell mouths, reflux pipes and metering pumps, bell mouth variable diameter design, bell mouth variable diameter hoisting special tool design, telescopic inner and outer drum horn tube design, sealing design of special pressure plate sealing or gas inflatable pneumatic tires, lifting pipe hoisting special design, and special lifting pipe suspending channel design which are easy enough to operate. The batch drilling well wellhead design and matched wellhead assembling-disassembling method for the modular drilling machine provided by the invention can solve the problem of time consumption caused by frequently moving of a derrick in batch drilling operation of the modular drilling machine, reduce hoisting risks and risks of high falling objects caused by dissembling and throwing wellhead parts and optimize assembling and disassembling method of wellheads, and further are simple and convenient in design and simple in operation mode.

Owner:CHINA NAT OFFSHORE OIL CORP +1

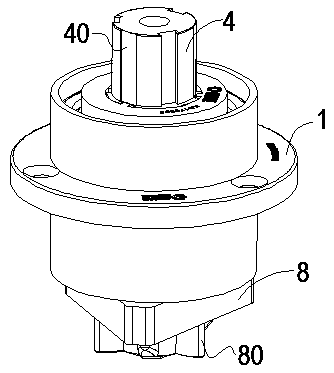

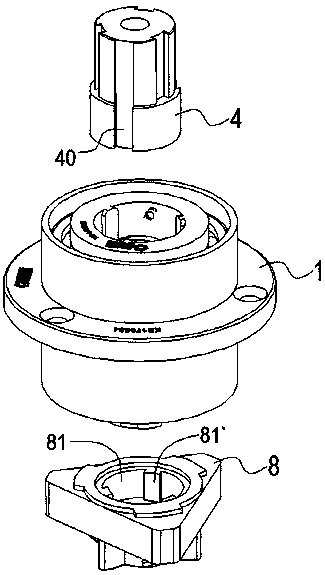

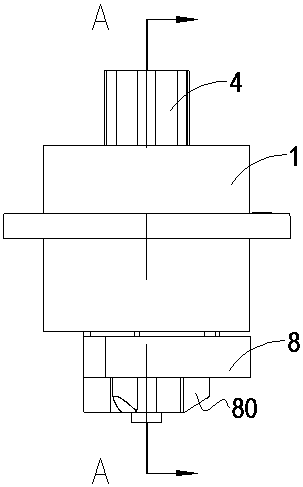

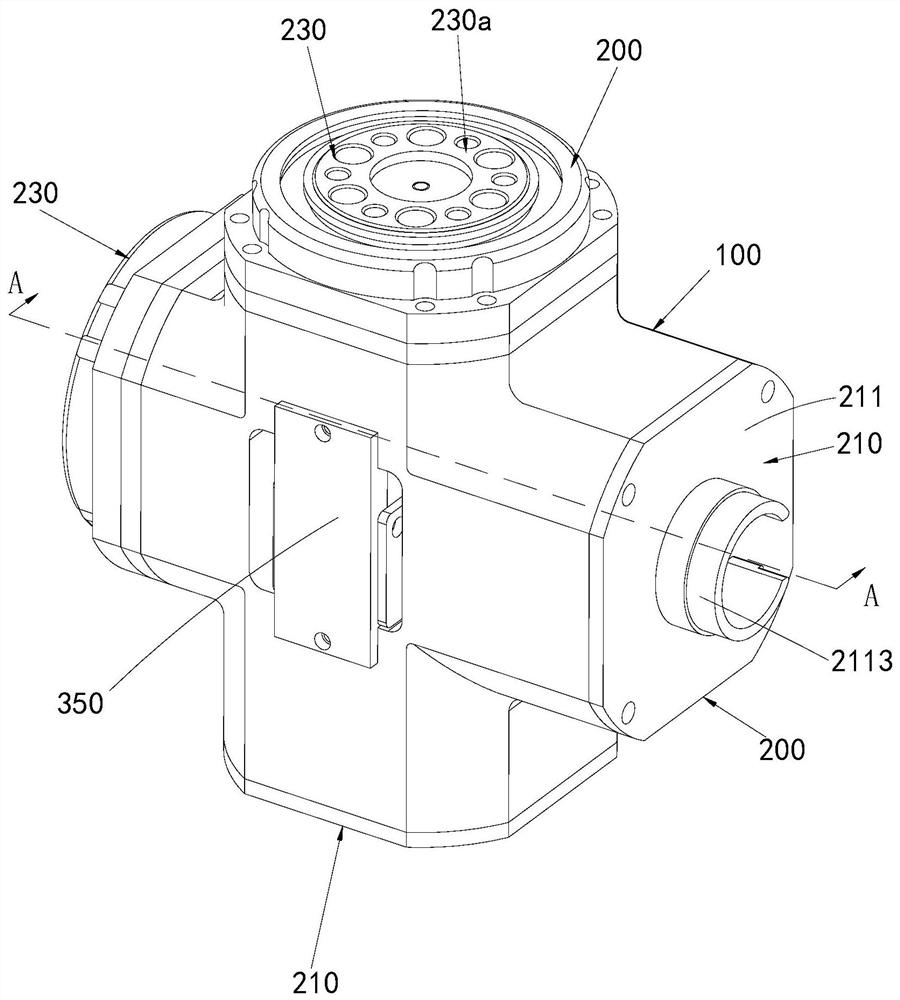

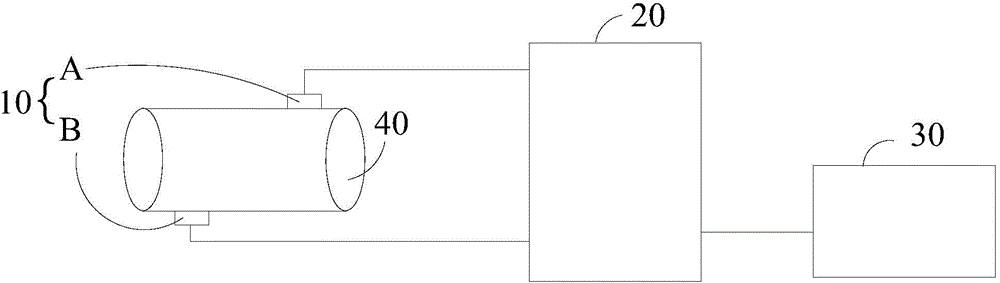

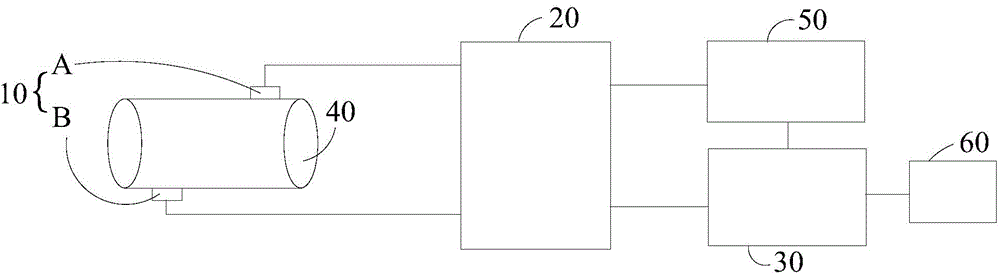

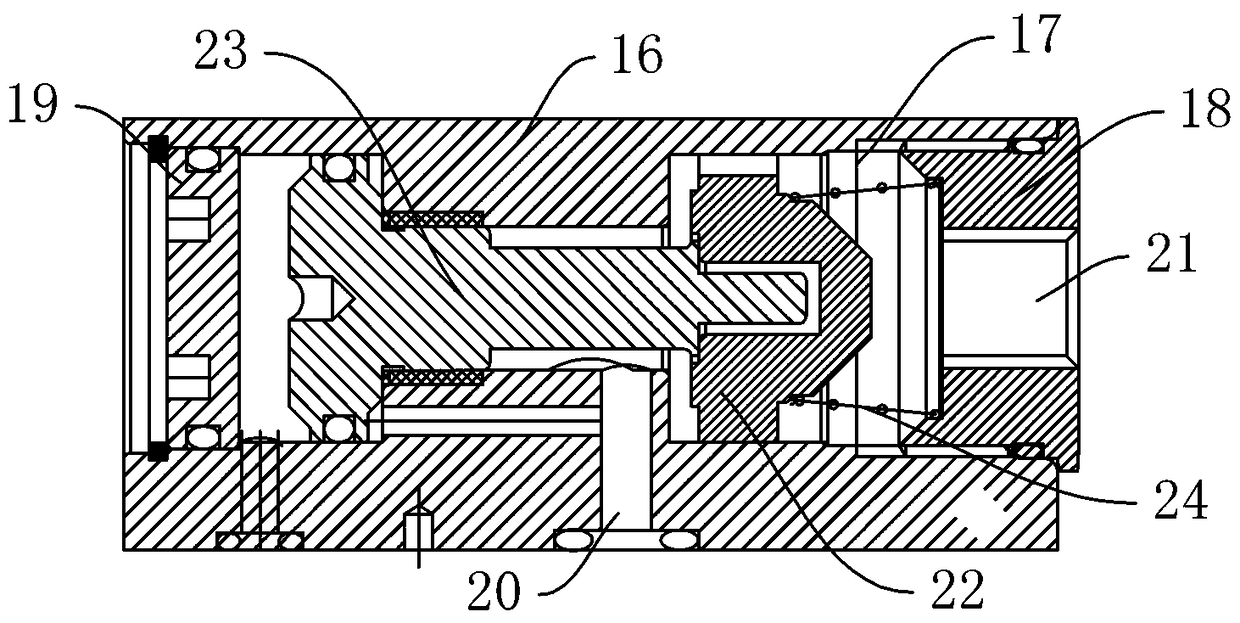

Double-shaft output steering gear and robot

ActiveCN112720560ADoes not affect assemblySimple structureProgramme-controlled manipulatorJointsControl engineeringElectric machinery

The invention belongs to the technical field of robot accessories, and particularly relates to a double-shaft output steering gear and a robot. According to the double-shaft output steering gear, two driving mechanisms are integrated on one shell, and the axes of the two driving mechanisms are arranged in a staggered manner at a preset angle. In the same driving mechanism, a motor assembly and a speed reduction assembly are installed at two sides of the shell separately, the axis of the motor assembly coincides with the rotating central axis of the output end of the speed reduction assembly, and power of the driving mechanism is transmitted to the speed reduction assembly through a transmission assembly to output rotation. The two driving mechanisms work to output rotation in two directions. First inducted parts and first inducting parts are separately matched to detect rotation information of the output ends of the corresponding speed reduction assemblies in real time and then feed back the rotation information to a system to accurately control output of corresponding motor shafts, and assembling of the output ends of the speed reduction assemblies and an external mechanism cannot be affected. The double-shaft output steering gear and the robot are simple in structure, high in integration level, small in occupied space and low in cost, and can be used in a modular manner.

Owner:UBTECH ROBOTICS CORP LTD

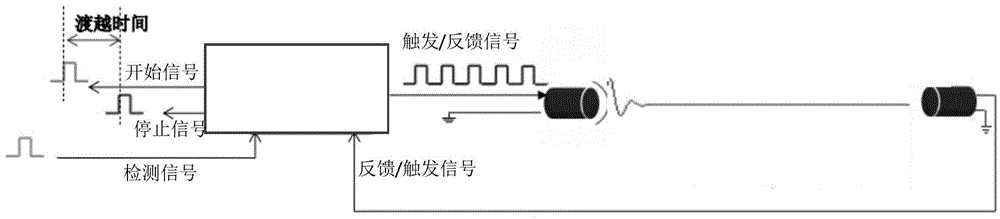

Heat pump water heater and water amount monitoring device of heat pump water heater

InactiveCN104931106AExtended service lifeEasy to installDetection of fluid at leakage pointVolume/mass flow measurementElectricityWater flow

The invention discloses a heat pump water heater and a water amount monitoring device of the heat pump water heater. The device comprises a both-piezoelectric ceramic transducer, a signal processing chip and a master control chip. A first piezoelectric ceramic and a second piezoelectric ceramic included in the both-piezoelectric ceramic transducer are arranged on the two sides of a water outlet / inlet pipe respectively. The signal processing chip sends a triggering signal to one of the first piezoelectric ceramic and the second piezoelectric ceramic to trigger one piezoelectric ceramic to be started, and receives a feedback signal sent by the other piezoelectric ceramic, and a first time difference between the feedback signal and the triggering signal is obtained; a triggering signal is sent to the other piezoelectric ceramic to trigger the other piezoelectric ceramic to be started, a feedback signal sent by one piezoelectric ceramic is received, a second time difference between the feedback signal and the triggering signal is obtained, and the water flow in the water outlet / inlet pipe is calculated according to the first time difference and the second time difference. The master control chip calculates the water usage amount within a first preset time according to the water flow within the first preset time, and therefore the measuring accuracy can be improved, installing is convenient, and the assembling of the whole machine is not affected.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

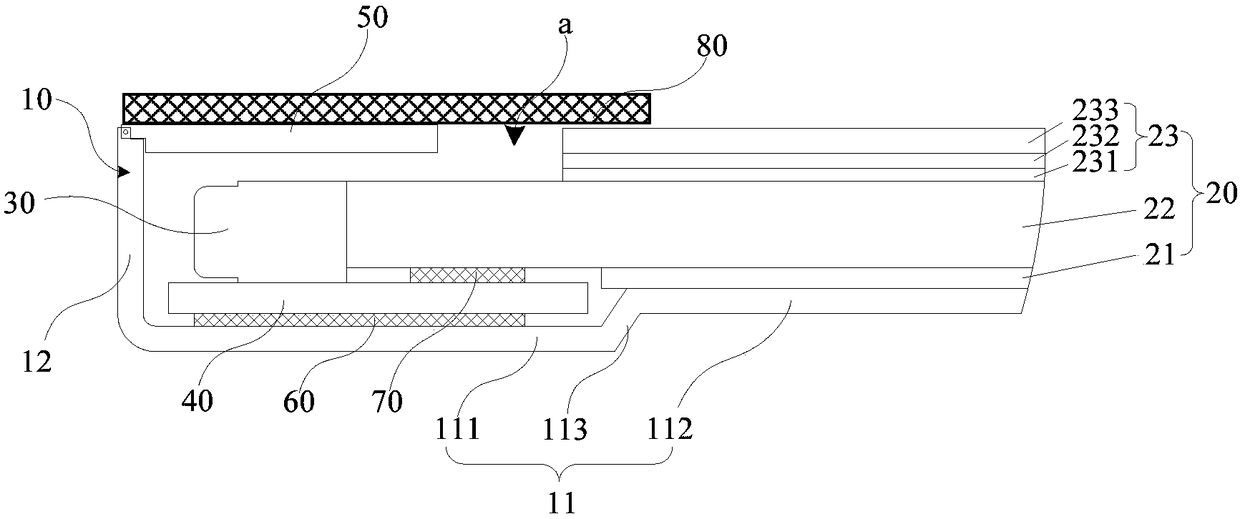

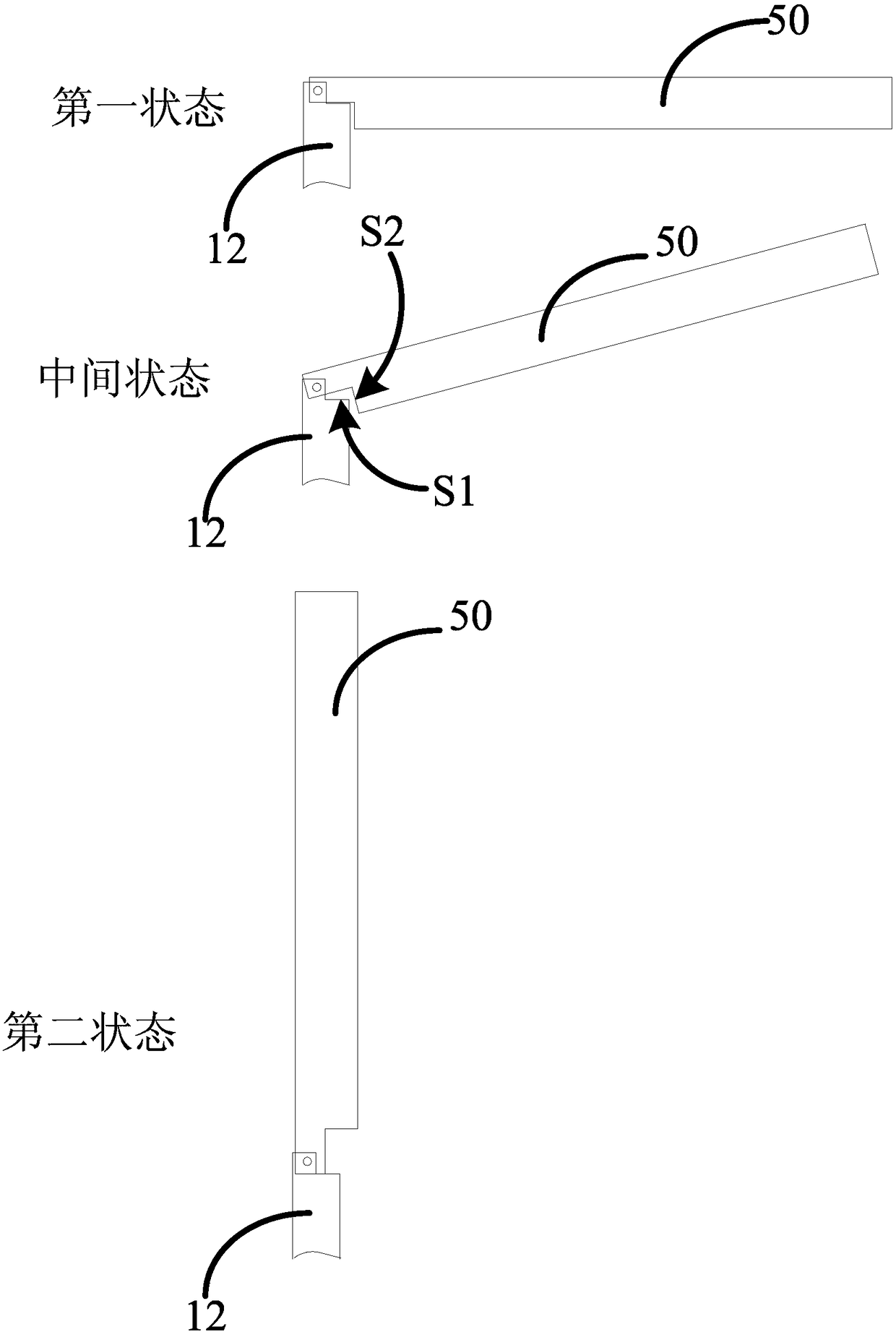

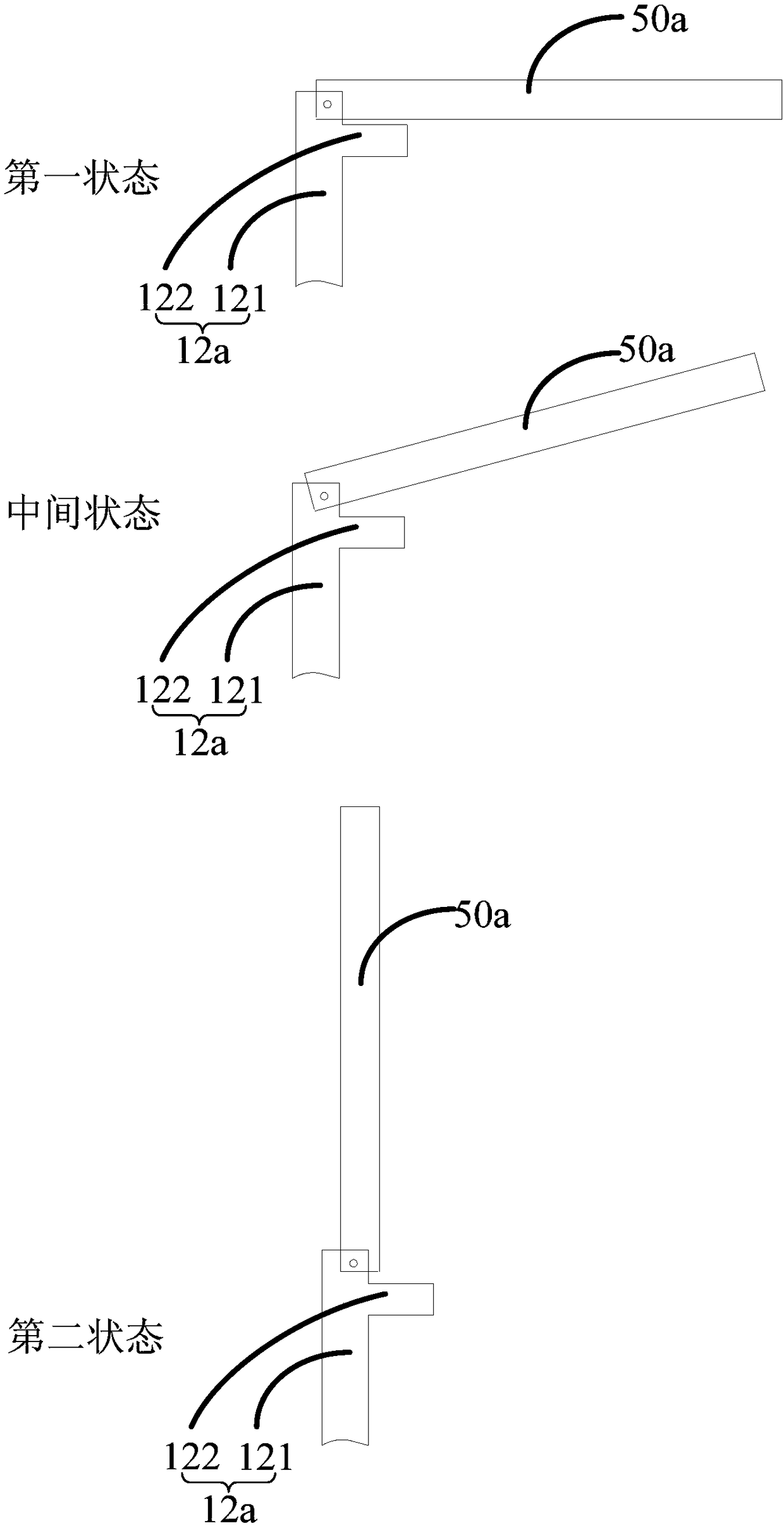

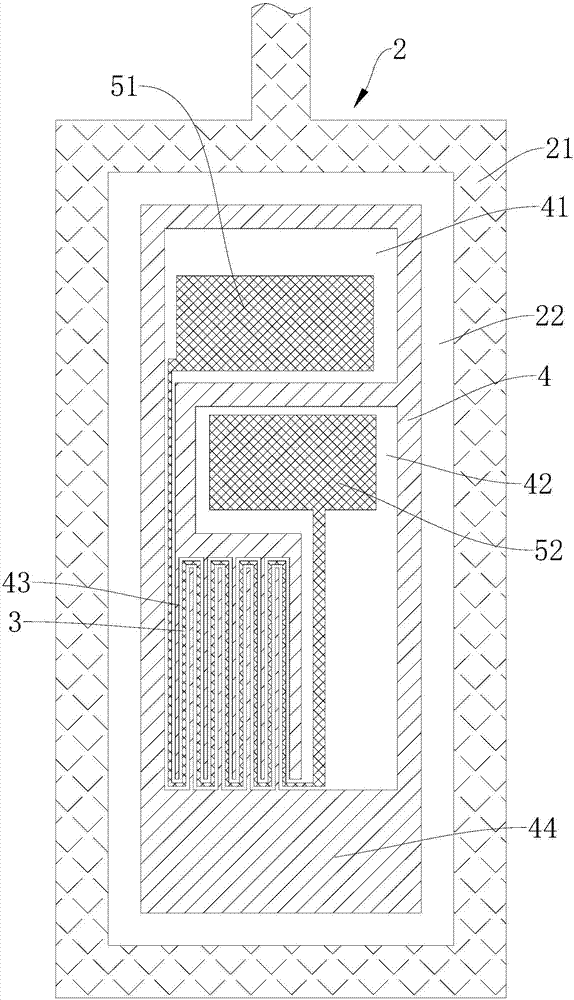

Electronic device, display assembly thereof, backlight module and assembling method thereof

ActiveCN108303825ADoes not affect assemblyReduce footprint widthNon-linear opticsFlexible circuitsEngineering

The invention discloses a backlight module. The backlight module comprises a back frame, a supporting wall, an optical assembly, a flexible circuit board and a light source, wherein the back frame comprises a bottom wall and a side wall which is in bent connection with the bottom wall, and the bottom wall and the side wall form a containing space; the supporting wall is hinged to the side wall, the supporting wall can be turned over at least in the direction close to the containing space to the first state of being parallel to the bottom wall and can be turned over at least in the direction away from the containing space to the second state of being parallel to the side wall; the optical assembly is arranged on the bottom wall and located inside the containing space; the flexible circuit board is arranged on the bottom wall and at least partially overlapped with the optical assembly; the light source is arranged on the face, away from the bottom wall, of the flexible circuit board, andthe light source is opposite to the side edge, facing the side wall, of the optical assembly. The invention further discloses an assembling method of the backlight module, a display assembly and an electronic device. In this way, on the condition that the width occupied by a non-display region of the backlight module can be lowered, the stability of a supporting display panel of the backlight module is ensured, and assembling of the backlight module is not affected.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

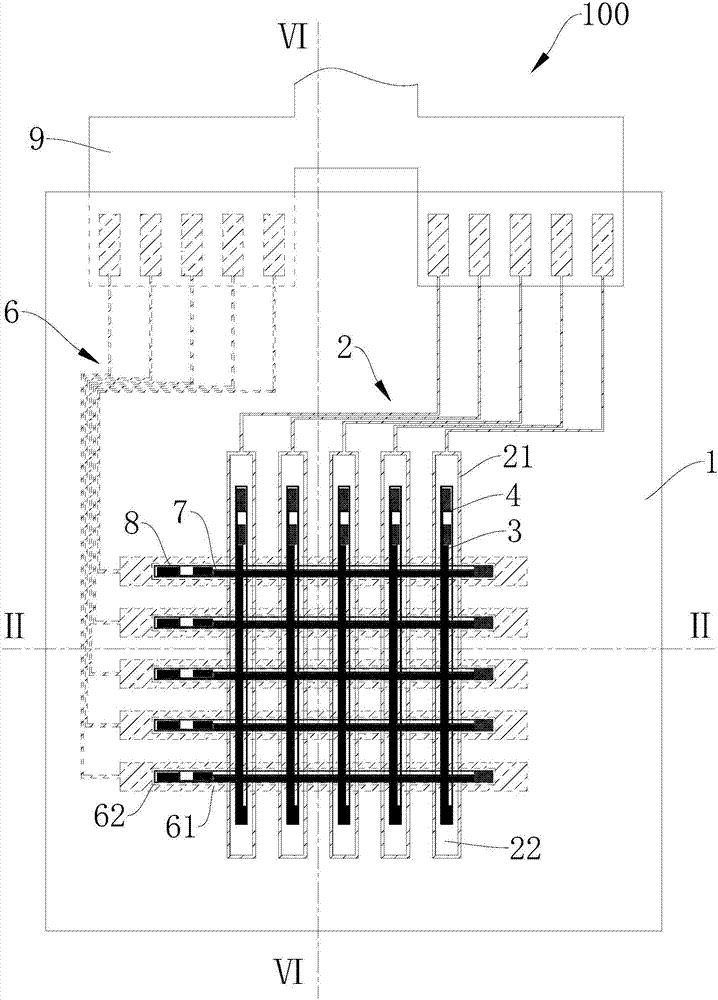

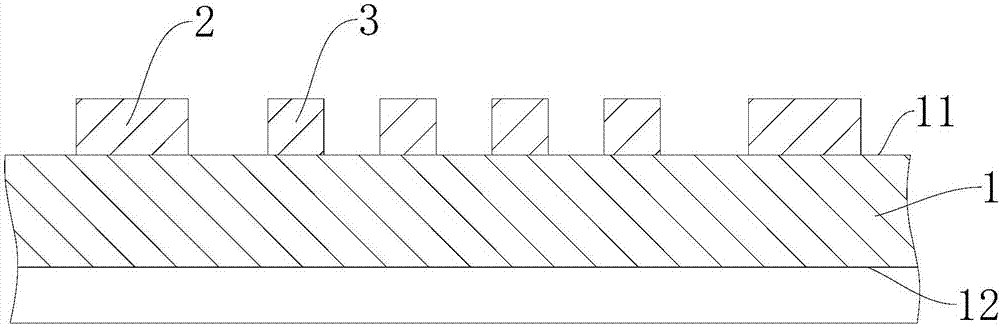

Electrical conductivity module and touch screen

InactiveCN107015702AShorten the development cycleUnderstand the limitInput/output processes for data processingEngineeringTouchscreen

The invention discloses an electrical conductivity module, which comprises a substrate, a first electrical conductivity circuit and a first superfine circuit. The line width of the first superfine circuit is less than that of the first electrical conductivity circuit. The first electrical conductivity circuit and the first superfine circuit are arranged on the same surface of the substrate and arranged with each other at intervals. The electrical conductivity module can shorten the development cycle of the superfine circuit. The invention further discloses a touch screen.

Owner:江西卓讯微电子有限公司

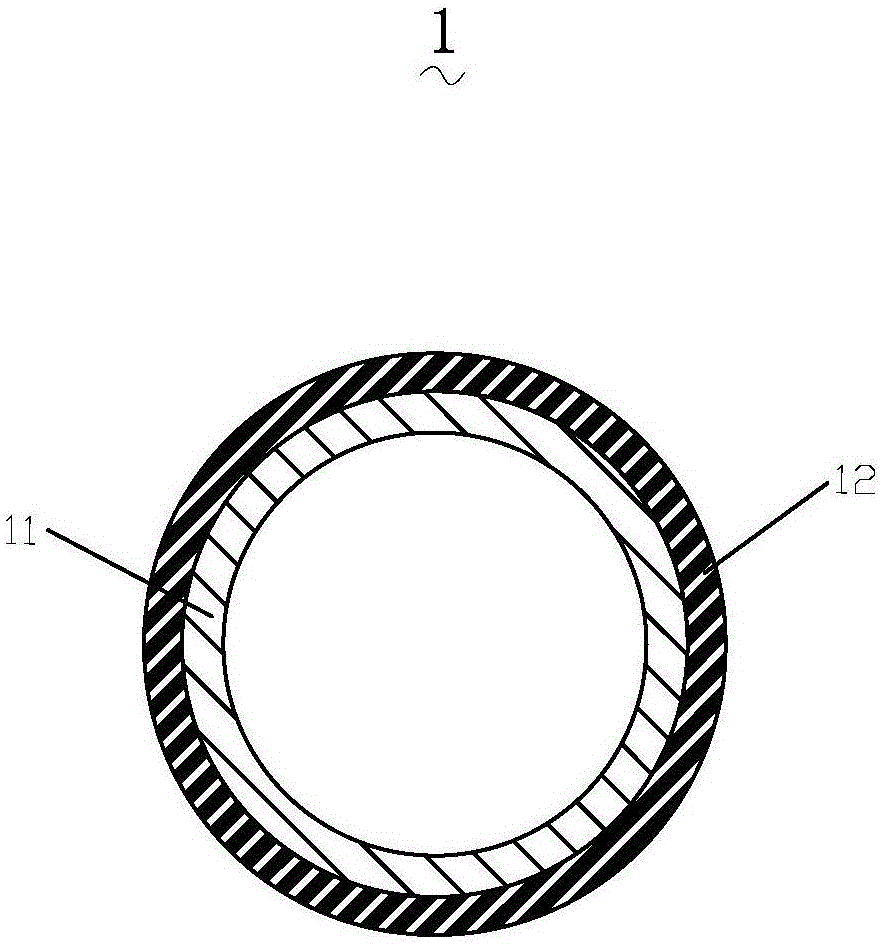

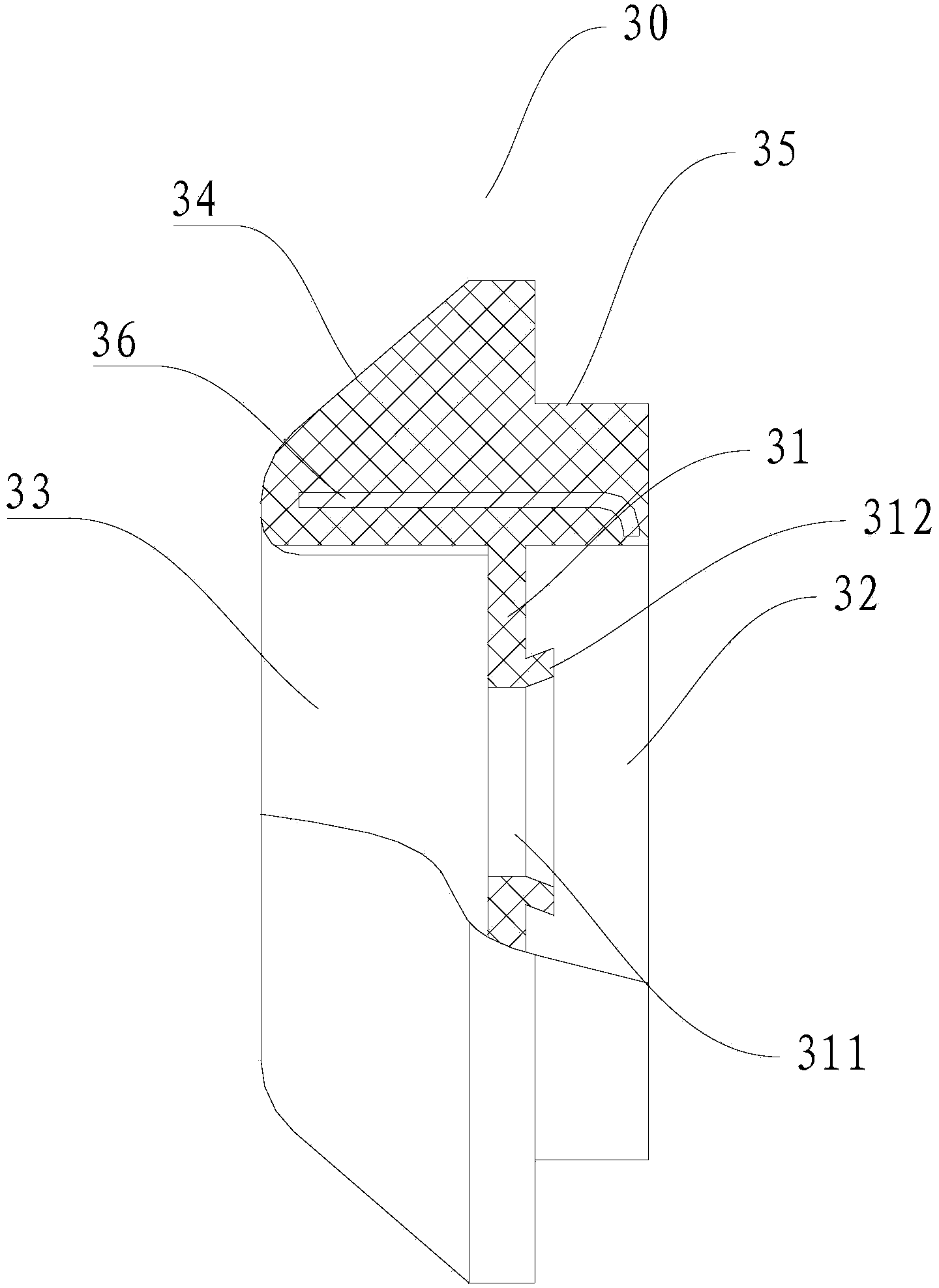

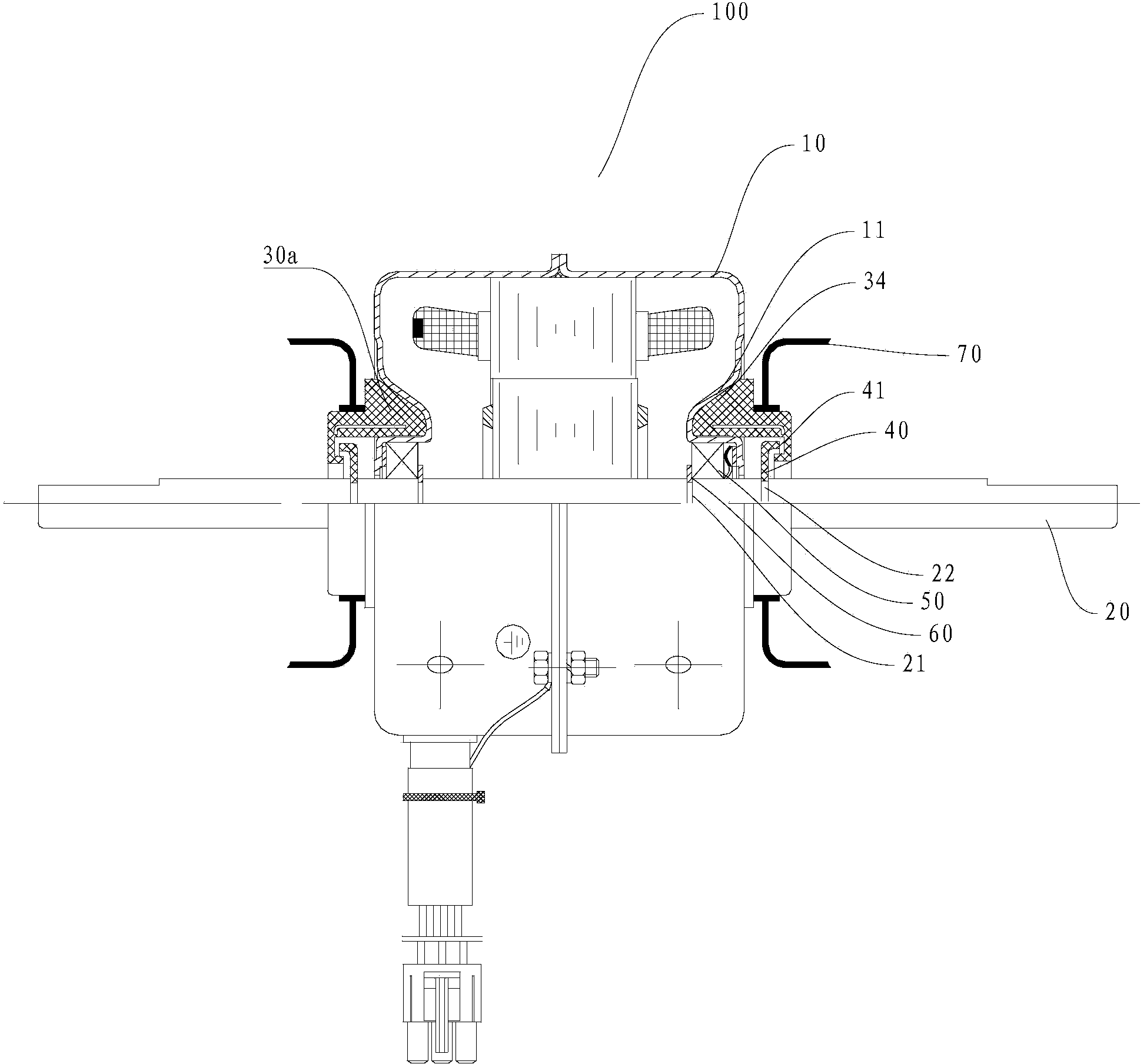

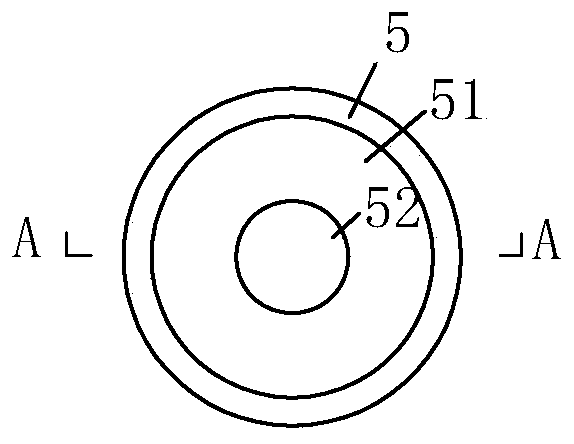

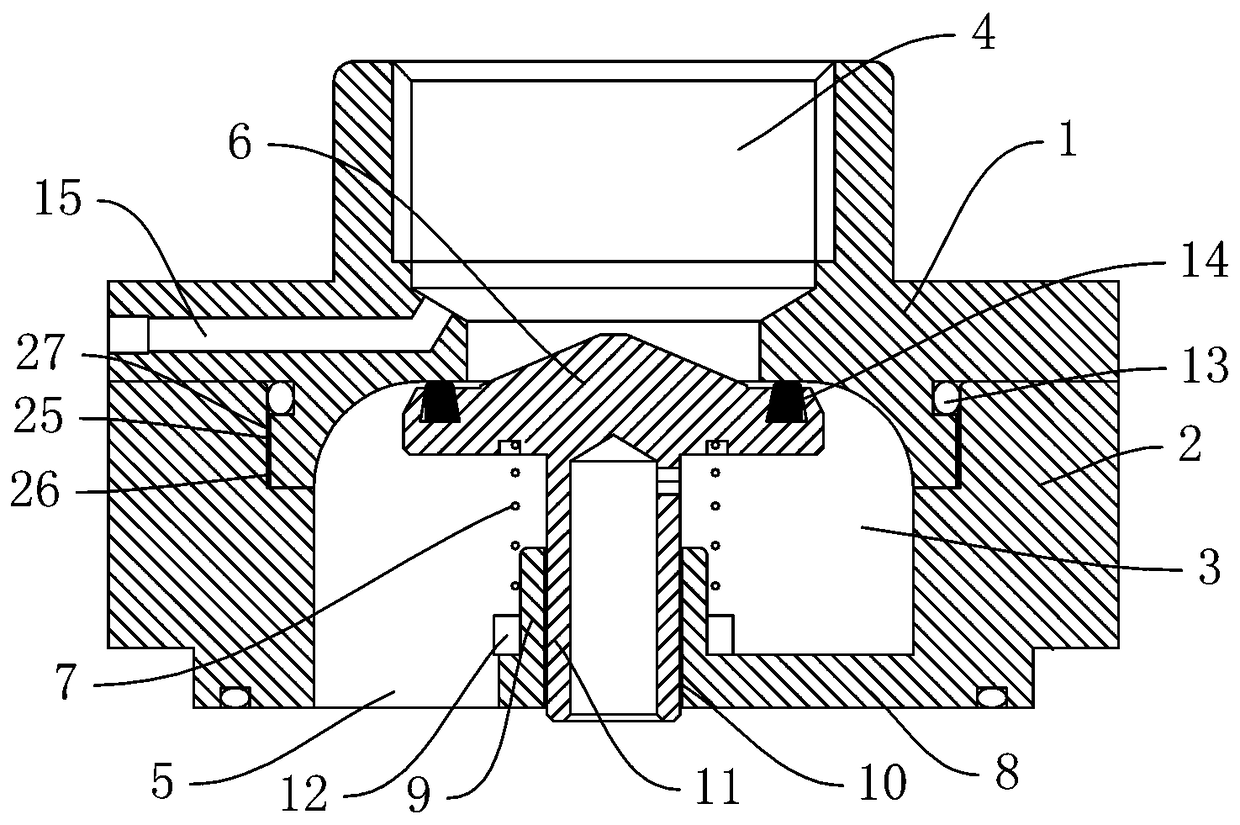

Motor, sealing ring for same and air conditioner provided with same

ActiveCN104242532ACompact structureMeet various needsSupports/enclosures/casingsEngineeringWater block

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

ABS/ESC valve body machining method for automobile braking system

ActiveCN111112943ALow costProcess assembly impactVehicle componentsEngineeringMechanical engineering

The invention discloses an ABS / ESC valve body machining method for an automobile braking system. The ABS / ESC valve body machining method is characterized by comprising the following steps that firstly, a valve body machined face and hole are selected as a machining rough positioning datum after oxidation, and the machining allowance is reserved; b, a rough positioning datum hole and a rough positioning datum face of a valve body and an energy accumulator hole in the valve body are machined; c, integral sulfuric acid hard oxidation is conducted on the valve body obtained after machining in thesecond step; and d, the rough positioning datum hole and the rough positioning datum face on the valve body serve as the datum, the rest of holes of the valve body obtained after oxidation in the third step are machined, and the rough positioning datum hole and the rough positioning datum face are machined to the size through datum conversion. According to the ABS / ESC valve body machining method,the anode oxidation surface area is small, only the surface of the energy accumulator hole of the valve body is provided with an oxidation film through machining finally, and the later procedure assembling and functions of the ABS / ESC valve body cannot be influenced.

Owner:JIANGSU RUIER LONGDING IND CO LTD

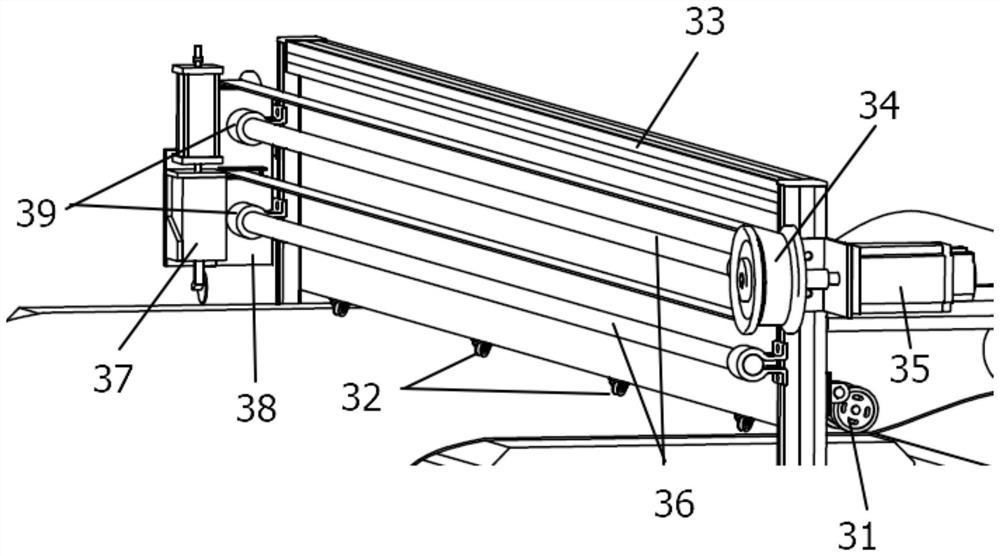

Automatic coiling device for cloth for spinning

The invention belongs to the technical field of textile equipment, and discloses an automatic coiling device for cloth for spinning. The automatic coiling device is characterized by comprising a cloth conveying mechanism arranged on a rack, a cutting mechanism is arranged above the cloth conveying mechanism, a coiling mechanism is arranged below the cloth conveying mechanism, the cloth conveying mechanism adopts a belt conveying structure and is used for turning the cloth by 180 degrees and conveying the cloth to the coiling mechanism through the cutting mechanism, the cutting mechanism is used for cutting the cloth meeting the coiling length requirement, and the coiling mechanism adopts a belt conveying structure, is used for coiling the cloth conveyed by the cloth conveying mechanism and adopts a connecting rod structure to automatically convey the coiled cloth to a transporting mechanism so as to complete coil unloading operation.

Owner:SHANGHAI UNIV OF ENG SCI

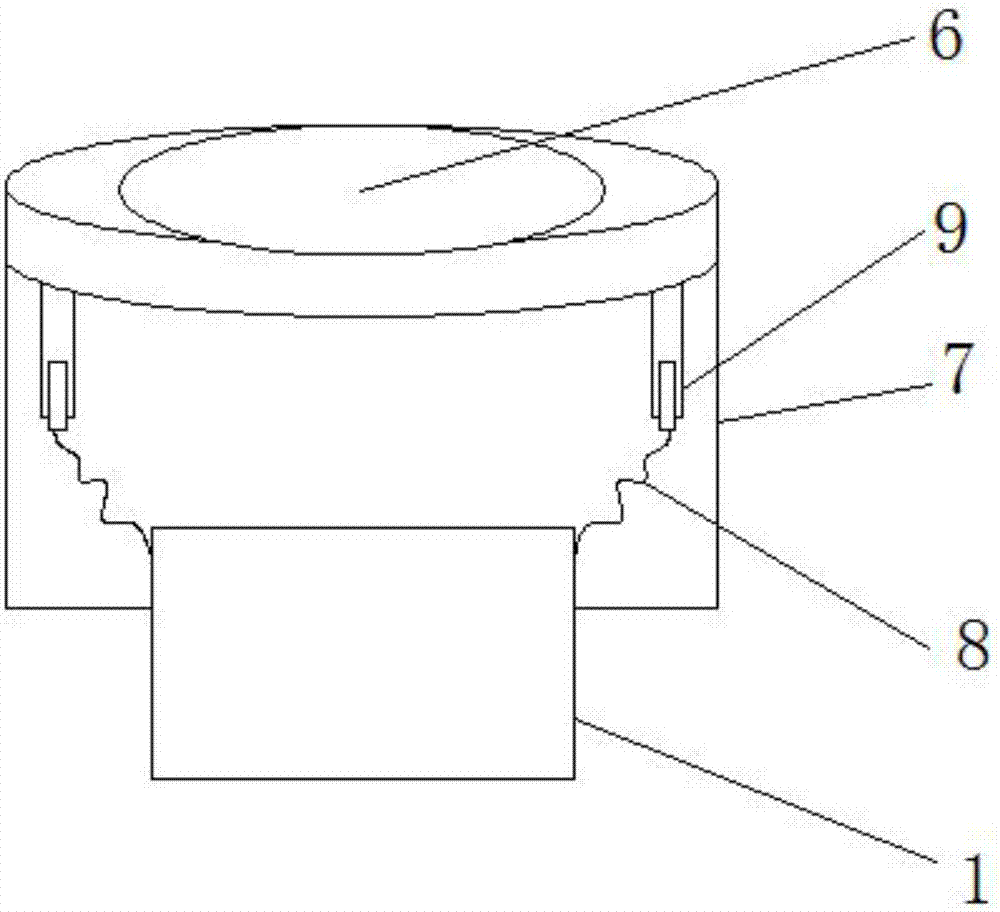

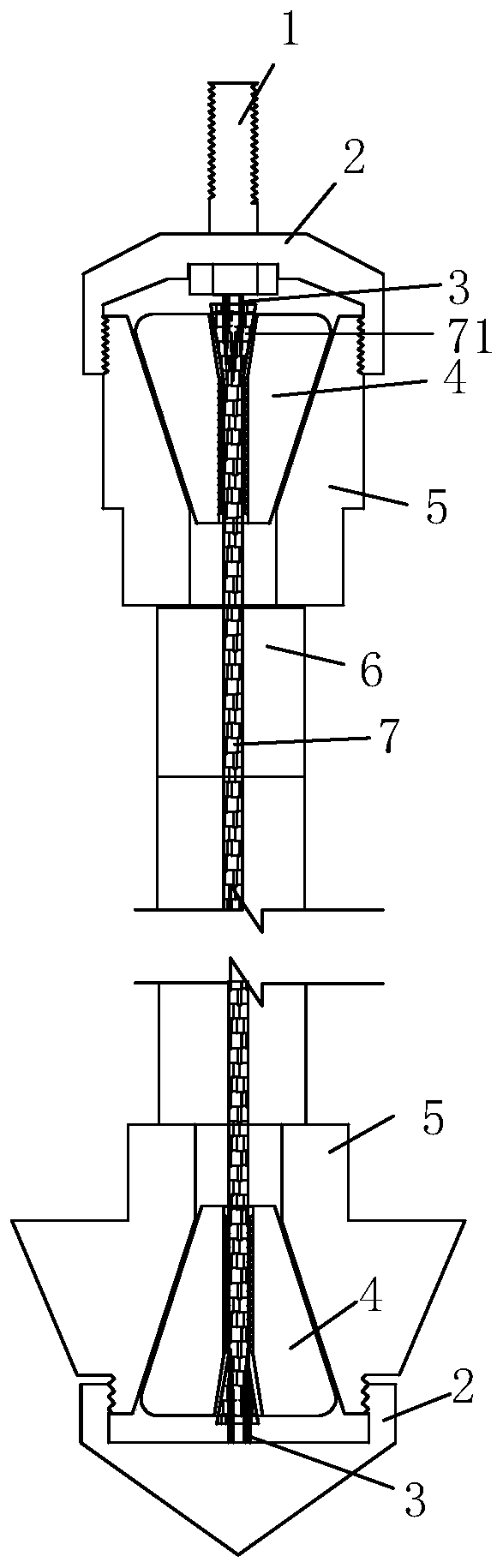

Turbine handpiece provided with needle locker

The invention discloses a turbine handpiece provided with a needle locker, which comprises a support, an ejector needle, a needle guard and a sleeve. Mutually adaptive through holes are formed in the radial direction in the tail end of the ejector needle and the sleeve; a fixing needle is inserted into the through holes for fixing the ejector needle and the sleeve, and comprises a fixing part and a limiting arc, the fixing part is a cylinder, the limiting arc is an arc connected with one end of the fixing part, and the arc is matched with the outer surface of the sleeve. According to the invention, the ejector needle and the sleeve are connected by utilizing the fixing needle, all that is needed for connection is to align the through hole in the ejector needle to the through hole in the sleeve, and then insert the fixing part of the fixing needle into the through holes, the installation is convenient and simple, and the fixation is relatively stable, so that conditions of misplacement and ejector needle deflection are avoided; the ejector needle comprises the limiting arc, the fixing part inserted into the through holes can sleeve the sleeve to prevent the fixing needle from falling off and causing a potential safety hazard; a needle groove matched with the limiting arc is arranged on the sleeve and can hide the limiting arc in the needle groove without influencing the assembly of other parts in the handpiece.

Owner:李艳霞

Flexible high-strength connecting rib and assembly method thereof

PendingCN109826323AStrong pull-out resistanceSatisfy internal force transmissionBuilding reinforcementsEngineeringRebar

The invention provides a flexible high-strength connecting rib and an assembly method thereof. The flexible high-strength connecting rib comprises two anchoring ends, a sleeve and a wire rope; each anchoring end is provided with an anchor cap, a restraining sleeve and at least one wedge block, each restraining sleeve is provided with a reducing hole, the wedge blocks are located in the reducing holes and provided with through holes, and the anchor caps cover one ends of the restraining sleeves; the two ends of the wire ropes are inserted in the restraining sleeves of the two anchoring ends andpenetrate through the through holes, needle bodies are also hammered into the ends of the wire rope and are formed into external expansion ends, and the needle body ends press the anchor caps; the sleeve sleeves the wire rope and is located between the two anchoring ends. The flexible high-strength connecting rib and the assembly method thereof are suitable for fabricated structures, and can effectively avoid the problem of difficult splicing or difficult slip casting caused by deformation of steel bars.

Owner:HUAQIAO UNIVERSITY +1

Vehicle-mounted air inlet valve

PendingCN109282067AReduce noiseDoes not affect assemblyValve members for absorbing fluid energyValve housingsEngineeringMechanical engineering

The invention discloses a vehicle-mounted air inlet valve. The vehicle-mounted air inlet valve comprises an upper valve body and a lower valve body. The upper valve body is fixedly connected with thelower valve body. A valve cavity is cooperatively formed in the upper valve body and the lower valve body, an air inlet communicating with the valve cavity is formed in the upper valve body, an exhaust port communicating with the valve cavity is formed in the lower valve body, a valve element and a valve element spring are arranged in the valve cavity, one end of the valve element spring abuts against the lower valve body, and the other end of the valve element spring abuts against the valve element. The valve element abuts against the upper valve body under the effect of the valve element spring in order to block the portion between the air inlet and the valve cavity, multiple shunting blocks are arranged at the position, located on an air outlet, of the lower valve body, one ends of themultiple shunting blocks are evenly distributed along the circumference of the inner wall of the lower valve body, the other ends of the multiple shunting blocks are connected with the position of thecircle center of the inner wall of the lower valve body, and the shunting blocks and the lower valve body are of an integrally-formed structure. The upper valve body and the lower valve body are arranged, the effect of lowering noise can be achieved, and the shunting blocks and the lower valve body are of the integrally-formed structure, so that it is guaranteed that the shunting blocks are not separated from the lower valve body.

Owner:FENGHUA EAGURT MACHINERY MFR

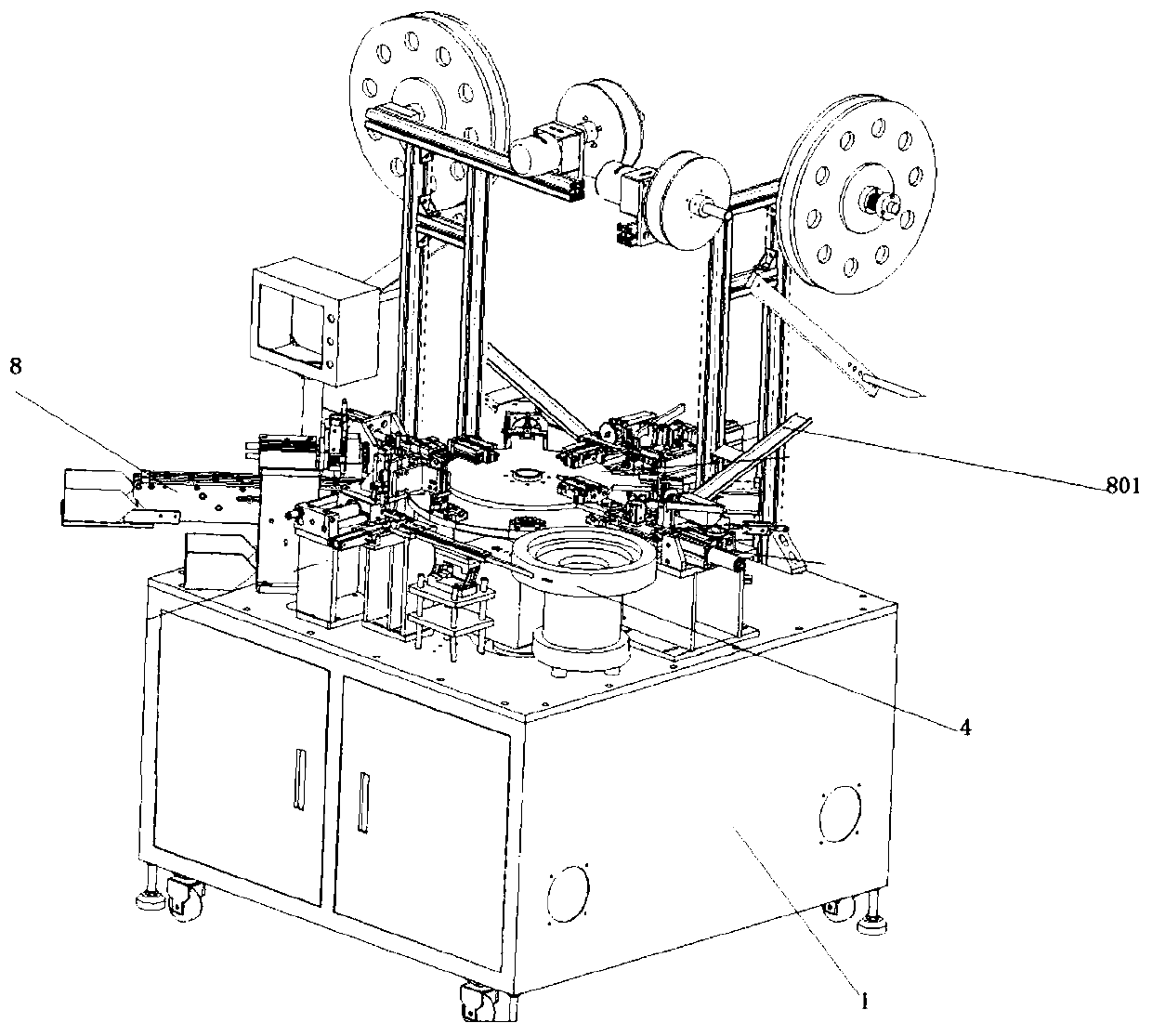

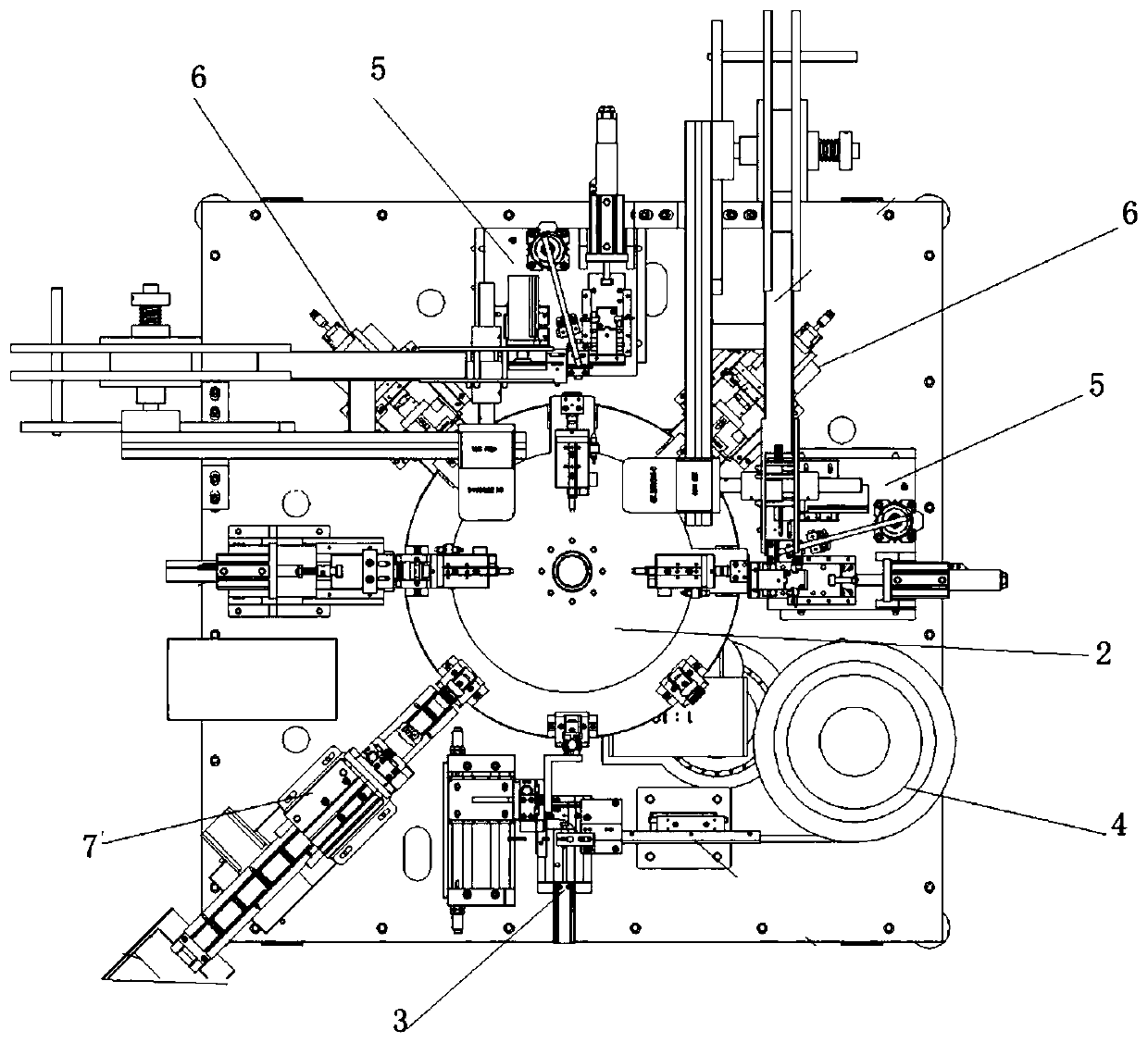

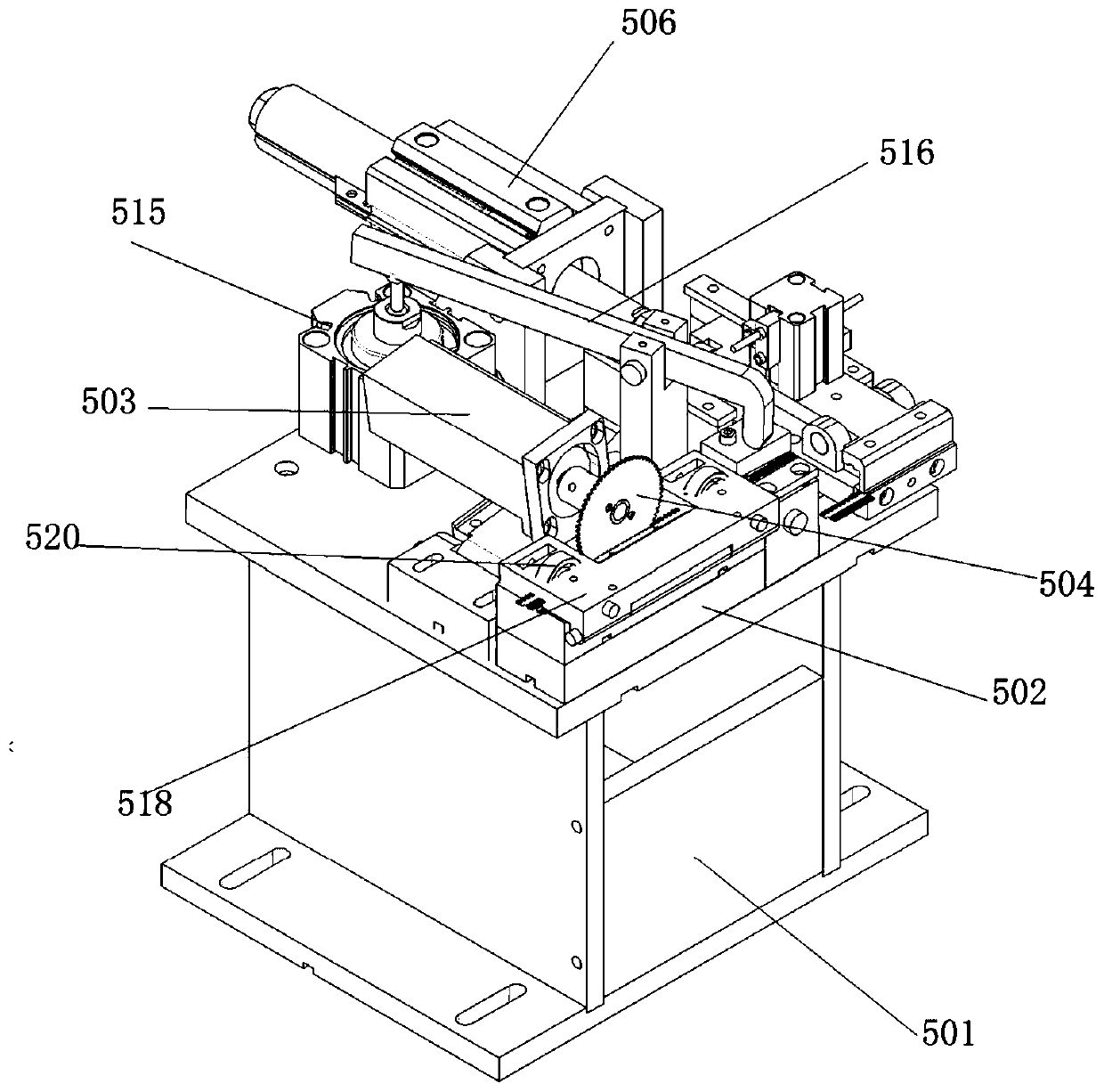

Wiring double-terminal automatic assembling machine and assembling process thereof

ActiveCN110212392AReduce the probability of strip breakageReduce the probability of breakageContact member assembly/disassemblyEngineeringMechanical engineering

The invention discloses a wiring double-terminal automatic assembling machine and an assembling process thereof, and belongs to the technical field of terminal assembling equipment; the wiring double-terminal automatic assembling machine comprises a rack, wherein the rack is provided with an insulator feeding mechanism, a vibrating disk, a material belt conveying mechanism, a material folding mechanism, a material belt conveying mechanism, a material folding mechanism and a clamping mechanism; the material belt conveying mechanism comprises a first fixed seat fixed on the rack, a lower mounting plate transversely arranged on the first fixed seat, a placement groove transversely formed in the lower mounting plate, a first support which is fixed on the rack and is positioned on the rear sideof the first fixed seat, a first rotary motor arranged on the first support, and a rotary gear in transmission connection with the output shaft of the first rotary motor. According to the automatic assembling machine, a U-shaped rotating gear which can be clamped with a material belt is arranged in the material belt conveying mechanism to drive the material belt to move forwards slowly in a placing groove inner seat, so that the probability of breakage of the material belt is lowered.

Owner:FEILKE NANJING IND EQUIP

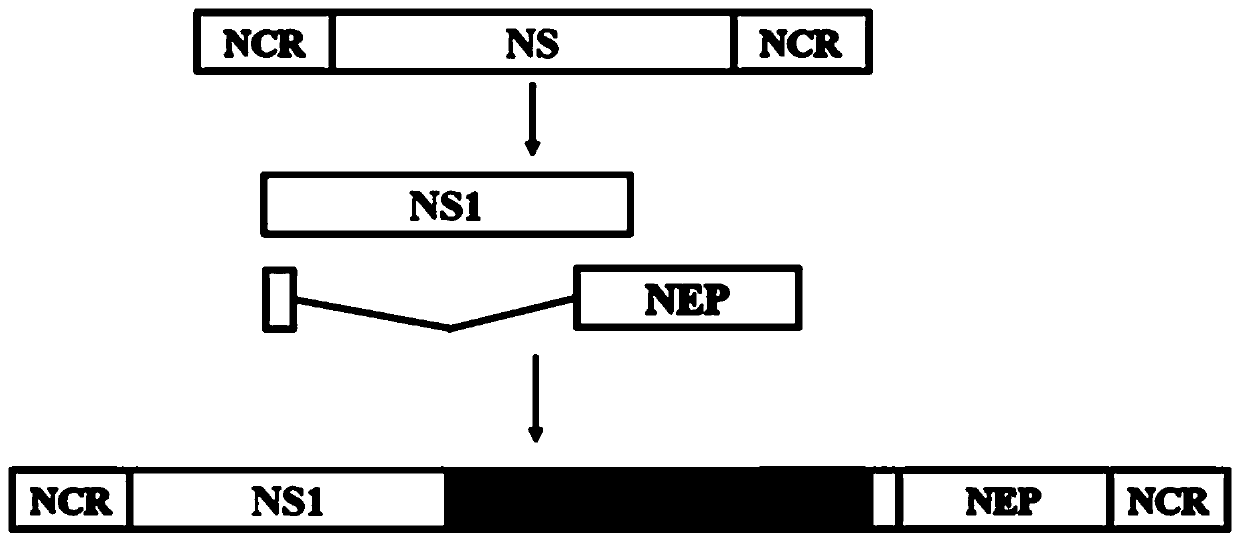

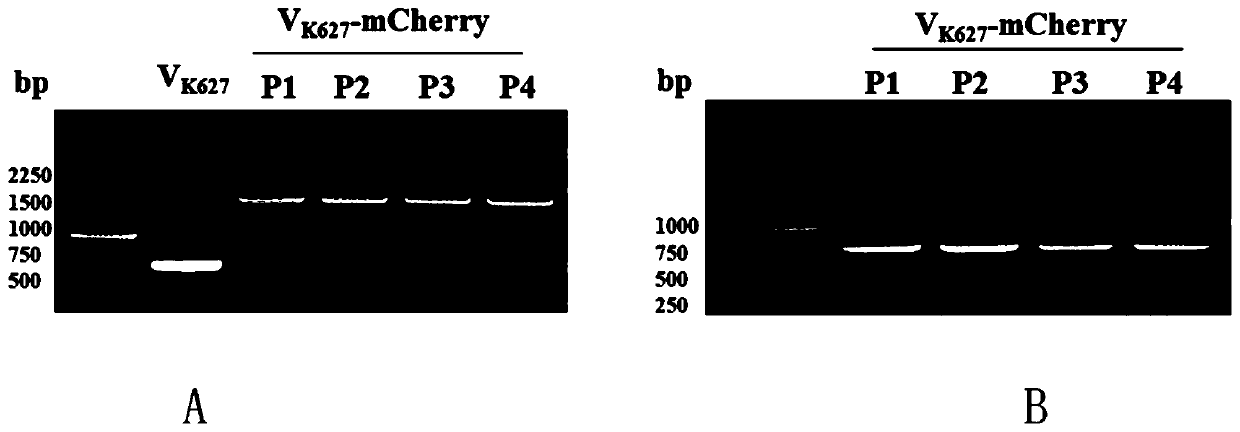

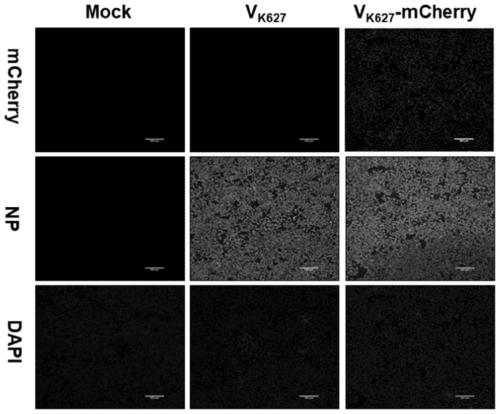

DNA fragment and application thereof in construction of recombinant influenza virus expressing red fluorescent protein gene

ActiveCN110205321ADoes not affect processing modificationDoes not affect assemblySsRNA viruses negative-sensePeptidesFluorescenceA-DNA

The invention discloses a DNA fragment and an application thereof in construction of a recombinant influenza virus expressing a red fluorescent protein gene. An mCherry fluorescent gene is inserted behind an NS1 gene of an H9N2 influenza virus strain, wherein the complete NS gene is formed by sequentially linking an NS1 gene, the mCHerry fluorescent gene and an NEP gene; the gene and the NEP geneare connected by a PTV-1 2A sequence which can be recognized and cut by protease, so a fluorescent protein-labeled NS fusion gene is constructed and has the nucleotide shown in SEQ ID NO:1. The constructed recombinant influenza virus can produce live virus expressing red fluorescent proteins, is relatively stable in the process of virus passage, does not affect the function of the virus itself, has the growth curve and the titer similar to those of a wild virus strain, can be used for subsequent research, and is of great significance on development, screening and production of anti-influenza virus drugs.

Owner:SOUTH CHINA AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com