Device and method for leading out optical fiber grating sensor from composite axle tube

A technology of composite materials and optical fiber gratings, applied in the direction of measuring devices, instruments, measuring instrument components, etc., can solve the problems of difficult assembly of metal flanges, increased number of optical fiber outlets, and single point distribution direction, so as to improve performance and preparation quality, reduce Quantity, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

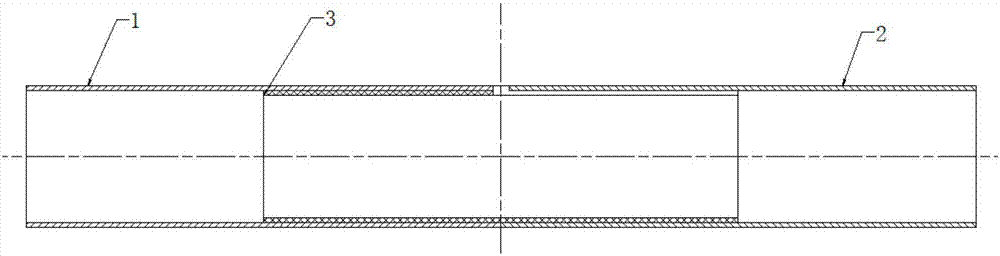

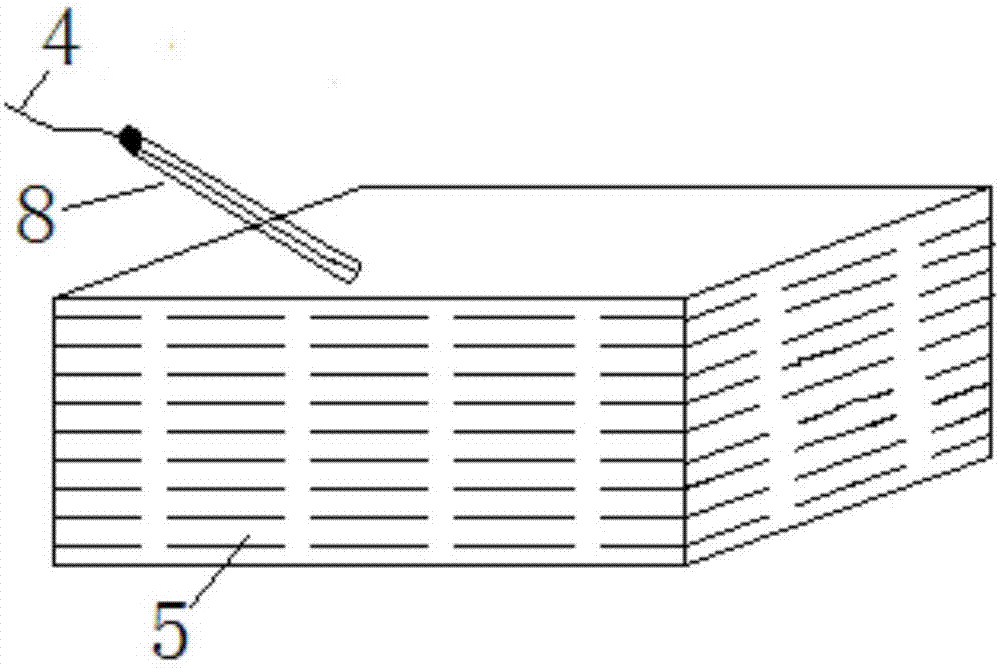

[0029] refer to Figure 1 ~ Figure 4 As shown, the device for drawing out the fiber grating sensor from the composite material shaft tube in one embodiment provided by the present invention, the first outer sleeve 1, the second outer sleeve 2 and the inner sleeve 3, one end of the inner sleeve 3 Set on the inner end of the first outer sleeve 1, the inner sleeve 3 is connected and fixed with the first outer sleeve 1, the other end of the inner sleeve 3 is set on the inner end of the second outer sleeve 2, the first outer sleeve The inner end of 1 is in contact with the inner end of the second outer sleeve 2;

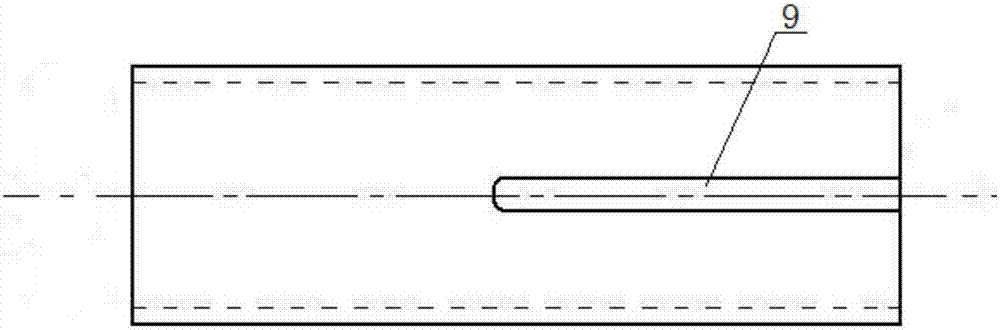

[0030] Wherein, the joint of the first outer sleeve 1 and the second outer sleeve 2 is provided with a through hole, and the through hole penetrates the inner sleeve 3 on one side of the inner sleeve wall, and the inner sleeve 3 is provided alon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com