Monitoring system and analyzing system based on image recognition and used for steel rail longitudinal resistance experiment

A resistance test and image recognition technology, which is applied in the direction of analyzing materials, character and pattern recognition, and measuring devices, can solve problems such as insufficient accuracy of strain monitoring, and achieve the effect of simple structure, low maintenance cost, and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A monitoring system for a longitudinal resistance test of a steel rail based on image recognition, comprising a calibration plate and sequentially connected cameras I, an image extraction system I and an image processing system I;

[0043] The number of the calibration plate is one, which is fixed on the side of the rail waist of the rail test piece; the calibration plate is located in the field of view of the camera I, and the camera I is fixed on the side of the rail test piece for video recording during the longitudinal resistance test of the rail, During the video recording process, the shooting angle of view of the camera I is fixed;

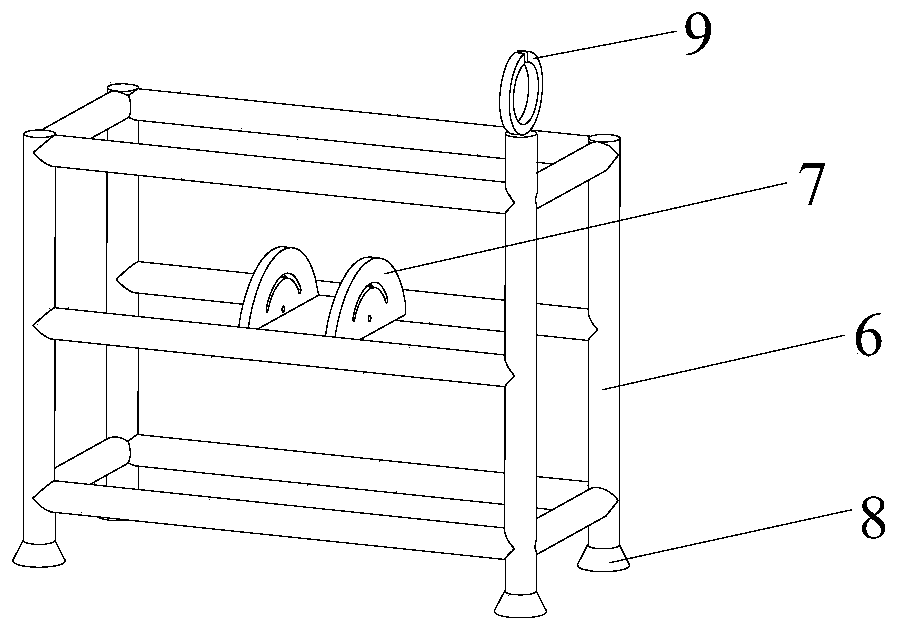

[0044] Camera I is fixed in such as Figure 4 On the camera fixing device 10 shown, the camera fixing device 10 is hingedly connected with the camera fixing platform 7, and the camera fixing platform 7 is movably connected with the camera bracket 6, as shown in FIG. image 3 As shown, the camera bracket 6 is used to move the camera fi...

Embodiment 2

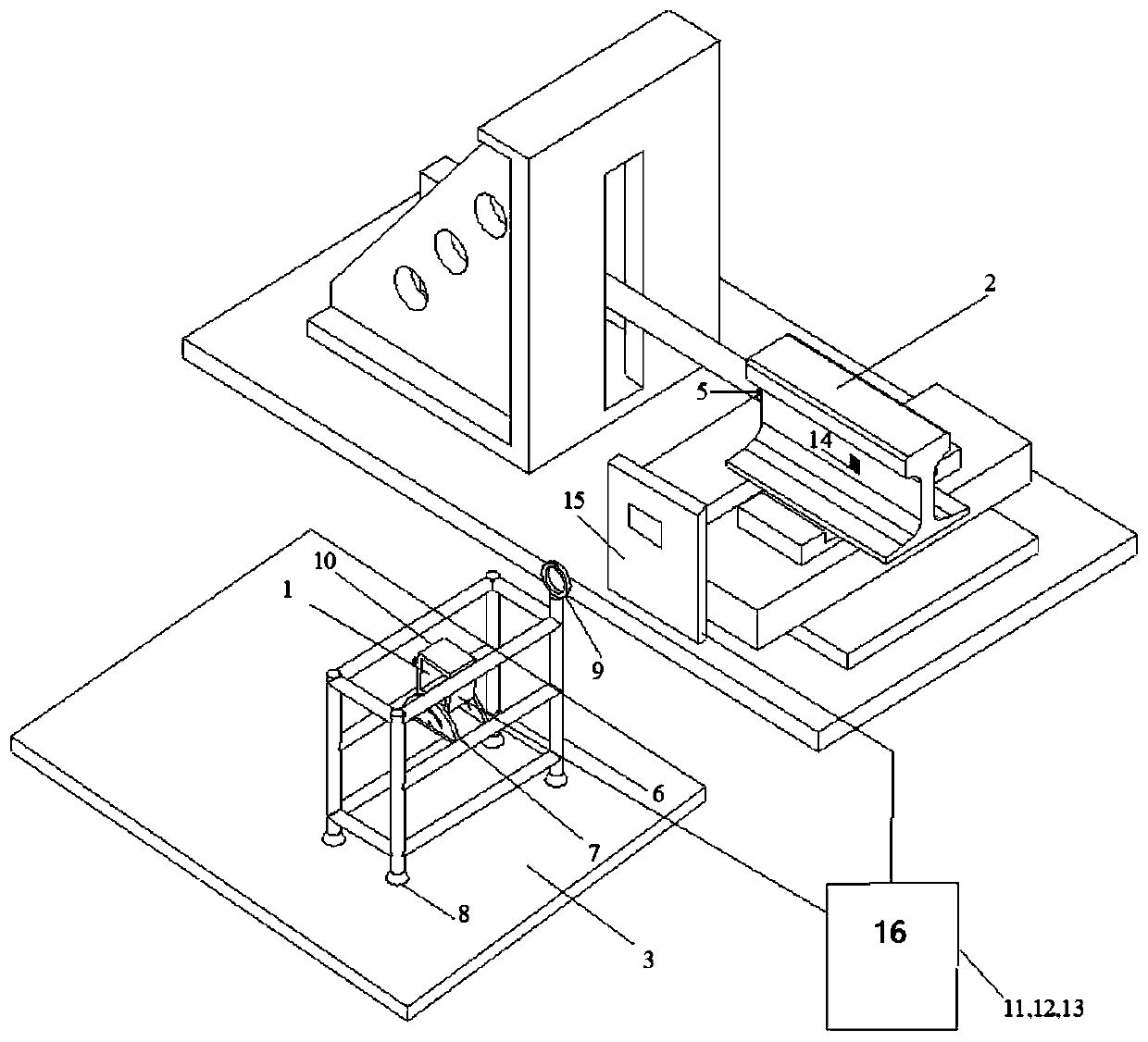

[0048] An analysis system for rail longitudinal resistance test based on image recognition, such as figure 1 As shown, including a kind of monitoring system of the rail longitudinal resistance test based on image recognition in the embodiment 1 (1 is the camera 1 in the figure, 2 is the rail test piece, 3 is the iron working platform, 11 is the image extraction system 1, 12 is the image processing system 1, 14 is the calibration board), the interconnected stress acquisition system and the data processing system 13;

[0049] The stress acquisition system is used to collect the stress data that changes at any time during the longitudinal resistance test of the rail;

[0050] The stress acquisition system is composed of the interconnected strain gauges 5 and the stress sensor display screen 15, as well as the sequentially connected camera II, the image extraction system II and the image processing system II, and the image processing system II is connected with the data processing...

Embodiment 3

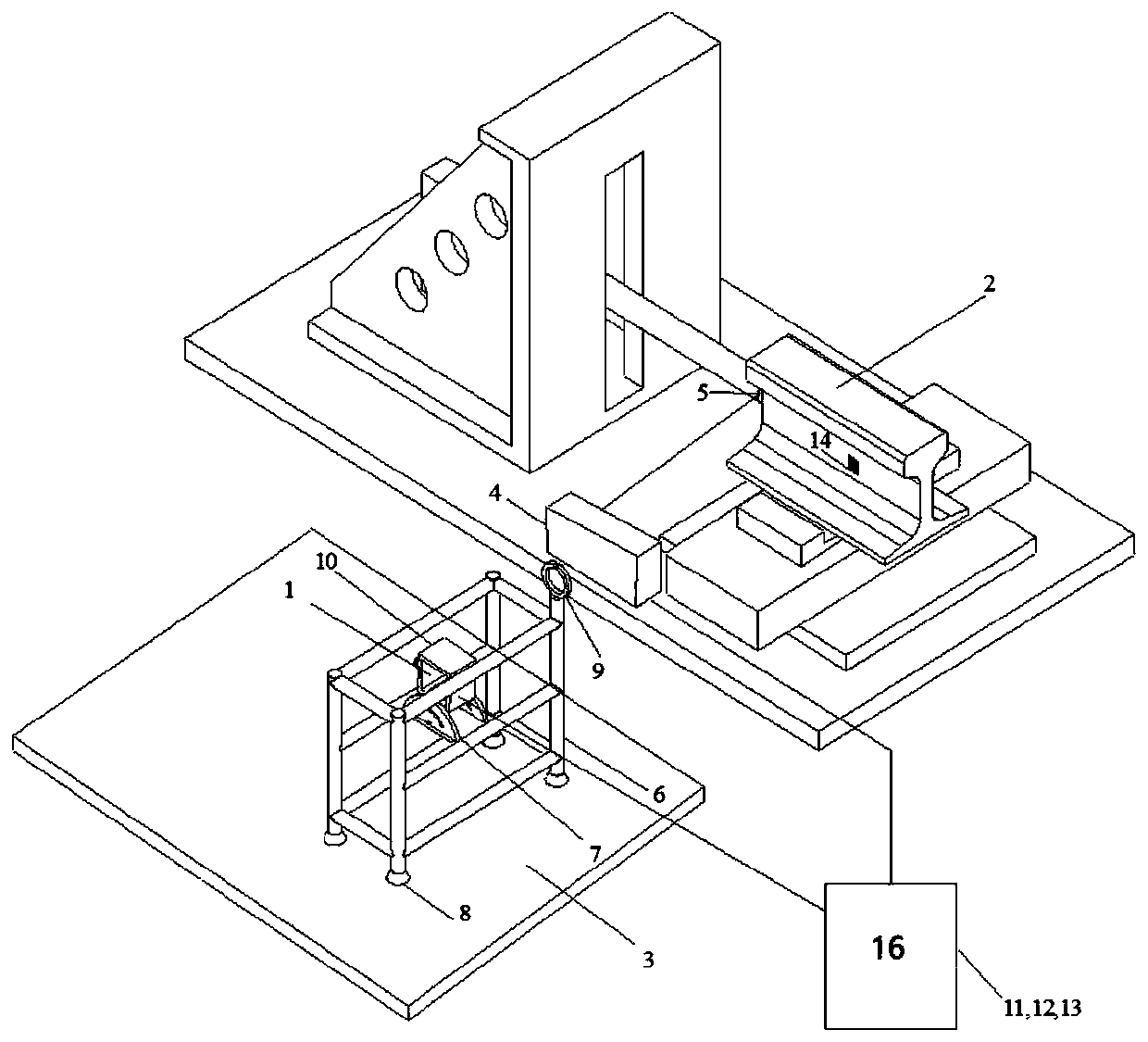

[0059] An analysis system for rail longitudinal resistance test based on image recognition, such as figure 2 As shown, including the monitoring system of the image recognition-based longitudinal resistance test of the rail, the interconnected stress acquisition system and the data processing system 13 in Example 1;

[0060] The stress acquisition system is used to collect the stress data that changes from time to time during the longitudinal resistance test of the rail. The image processing system 112 in the monitoring system is connected with the data processing system 13. The stress acquisition system consists of the sequentially connected strain gauges 5, data acquisition instruments 4 and PC machine is composed of 16; the strain gauge 5 is installed on the rail test piece, which is used to measure the stress data that changes from time to time during the longitudinal resistance test of the rail; the data acquisition instrument is used to collect the stress data that change...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com