Oil sprayer compress tightly screw cap and fixing method thereof

A technology of pressing nuts and fixing methods, which is applied in fuel injection devices, machines/engines, charging systems, etc., can solve the problems of inconvenient disassembly and assembly of fuel injectors, and achieve easy disassembly, effective sealing, and convenient disassembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

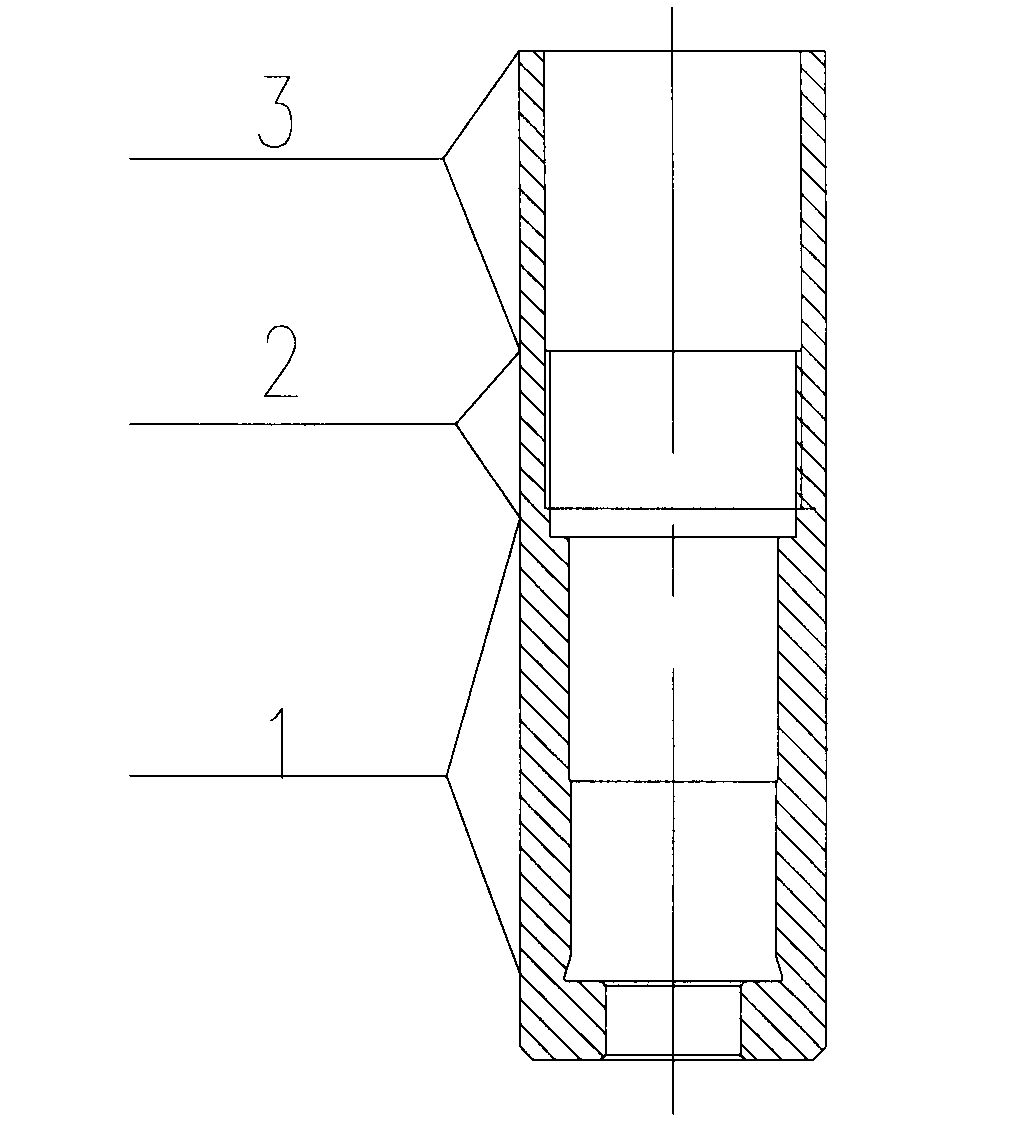

[0018] Preferably, the radial thickness of the extension section is larger than 2mm, so as to ensure the reliability of the extension section under a certain pressing force. Preferably, the length of the extension section is 1 / 4 to 1 / 3 of the total length of the compression nut of the fuel injector.

[0019] The length of the extension section is adjusted according to the height of the engine cylinder head, and generally protrudes 5mm-8mm from the cylinder head.

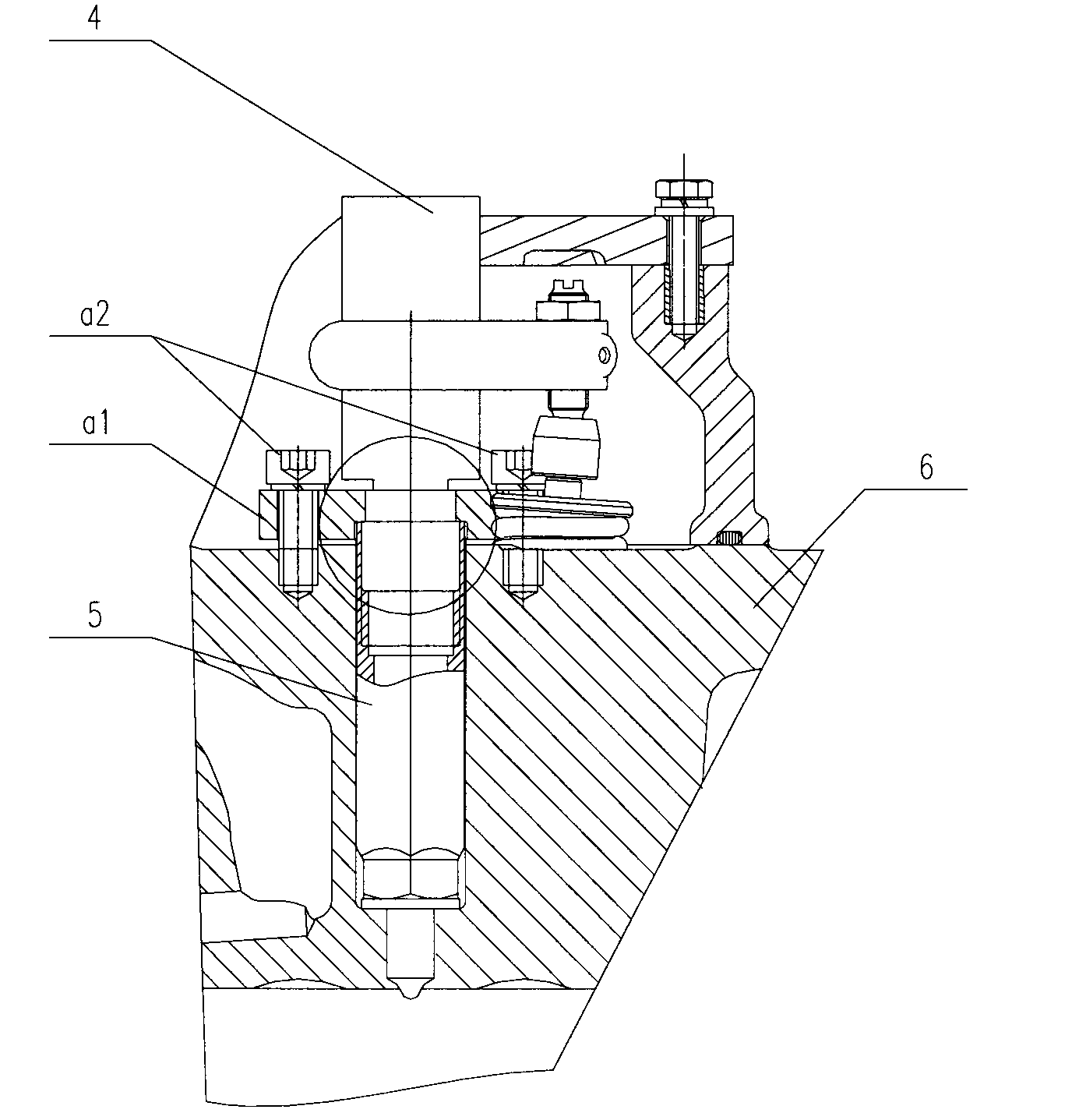

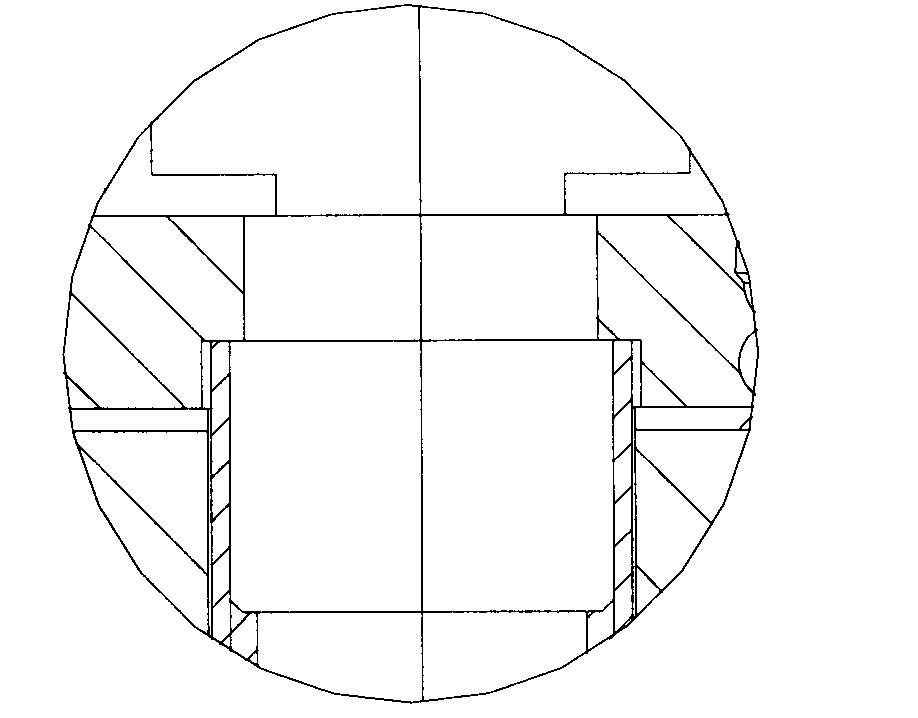

[0020] The pressing device is a fixing method when pressing the screw and the pressure plate of the fuel injector: there is a stepped structure inside the pressure plate of the fuel injector, and the stepped structure is in contact with the top surface of the extended section of the pressure nut of the fuel injector. The screw fixes the fuel injector pressure plate, the fuel injector compression nut and the engine cylinder head as a whole.

[0021] Attached below figure 2 Further describe the plan of the injector ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com