Tubular bus connection structure

A connection structure and tube busbar technology, applied in the direction of butt busbar connection, connection insulation, busbar installation, etc., to increase the current flow, reduce installation difficulty, and achieve the effect of electrical contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The purpose of the present invention is to solve the development needs of the current flow performance and miniaturization of the switchgear, and can upgrade the rated current without changing the existing switchgear; provide a reliable voltage resistance, strong flow capacity, and compact structure. , easy to install pipe bus connection structure.

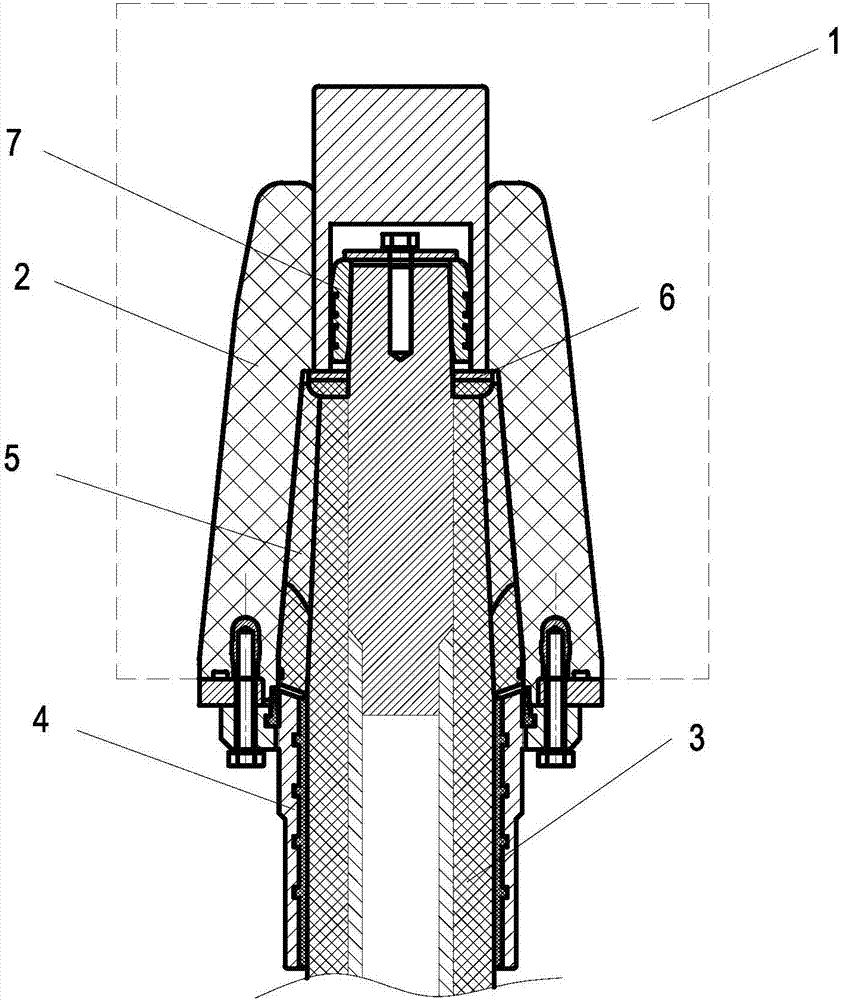

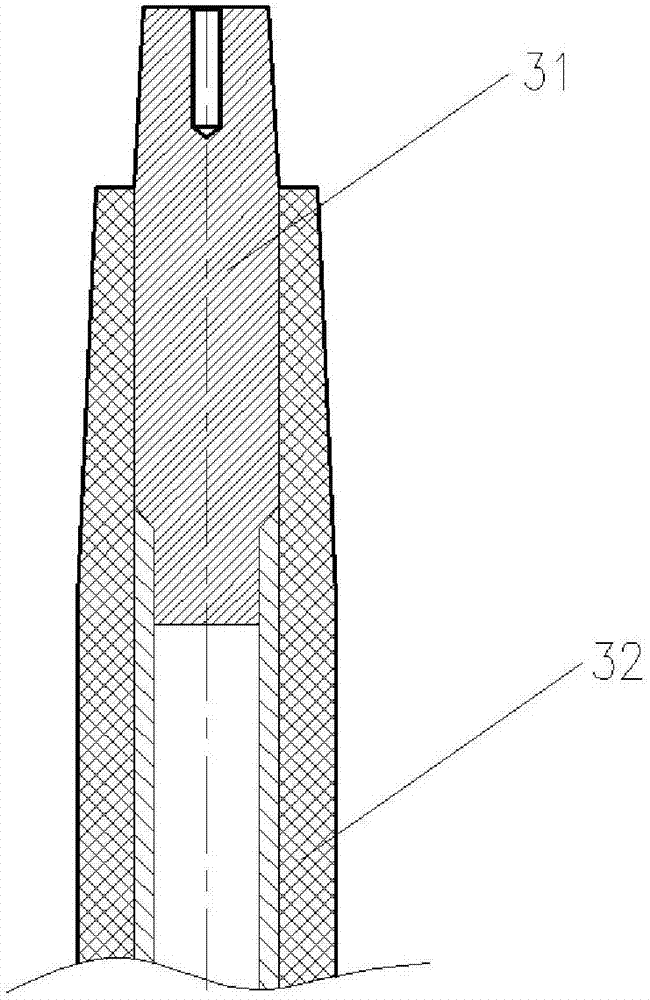

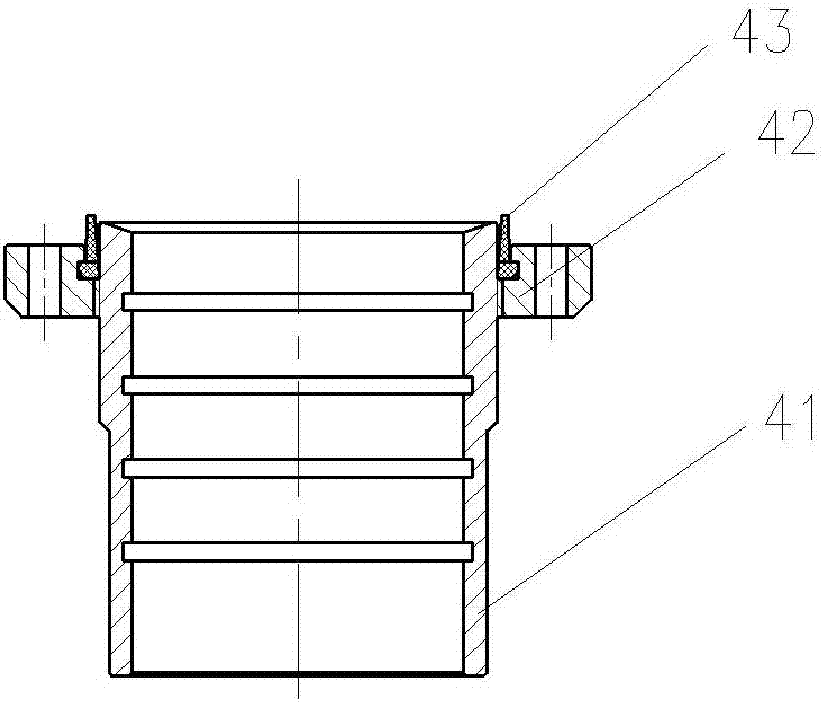

[0031] In order to achieve the above purpose, if figure 1 As shown, the present invention is realized through the following technical solutions: a connection structure for pipe busbars, including a pipe busbar 3 , fasteners 4 , silicone rubber insulating parts 5 , stress support parts 6 and conductor connectors 7 . Among them, the entire pipe busbar connection structure is assembled into the socket 2 of the switch cabinet 1, and is electrically connected with the socket conductor in the socket 2 to realize the electrical conduction of the incoming and outgoing lines of the switch cabinet 1, so that the entire power system o...

Embodiment 2

[0038] The only difference between this embodiment and the first embodiment is that the stress support member 6 is not needed in this example, and other structures are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com