Embedded metal material connecting method with sealing effect

A metal material and connection method technology, which is applied in the field of embedded metal material connection, can solve the problems of limited change in the length and size of the stirring needle, and is not suitable for parts connection, etc., and achieves the effect of beautiful appearance, airtightness, and improved bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

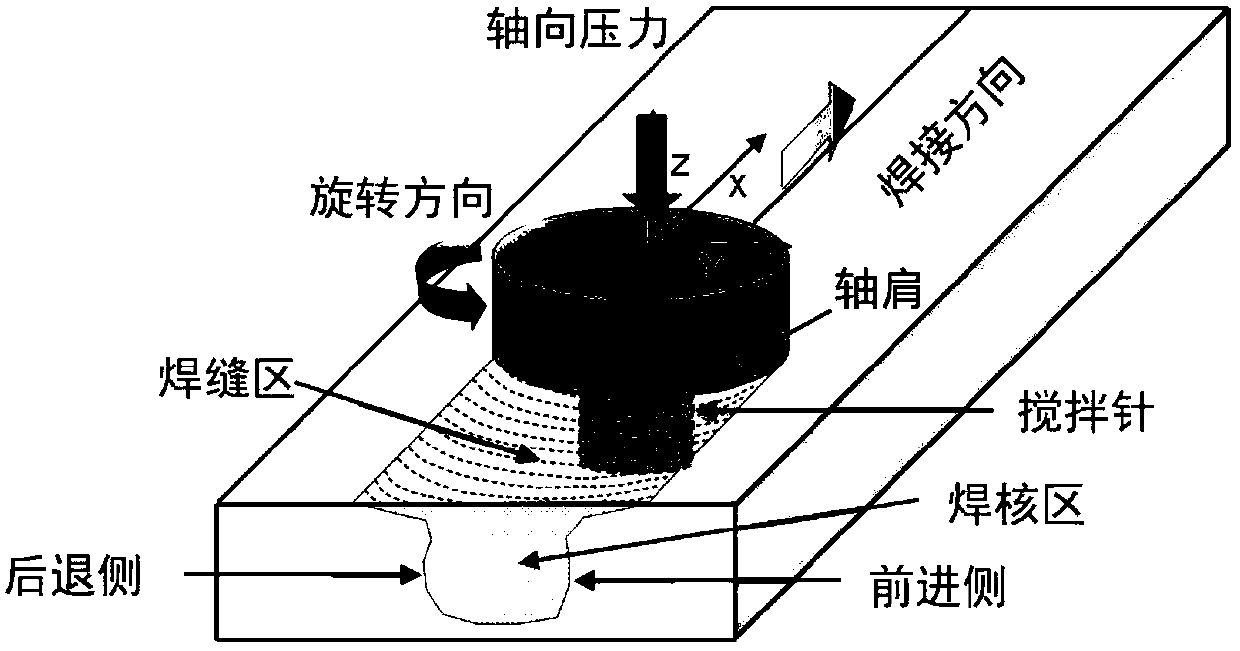

Method used

Image

Examples

Embodiment 1

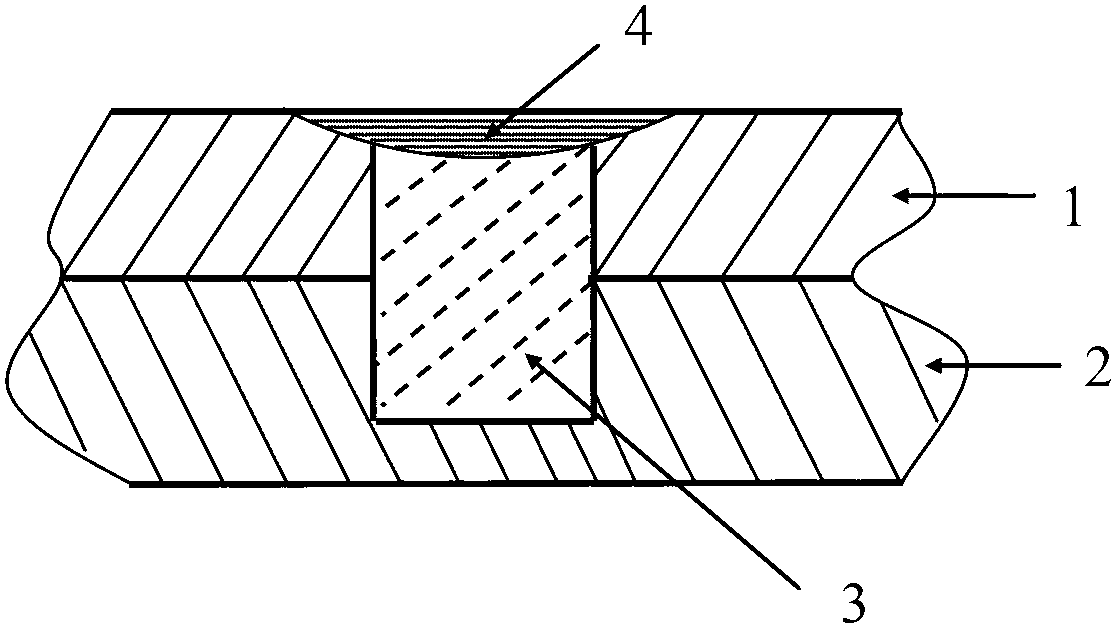

[0018] Use this method to connect two 6061 aluminum alloy plates with a thickness of 10 mm. Fasten with M10 screws of the same material first, and then carry out friction welding fastening without stirring pin under the conditions of rotation speed 2000 rpm, reduction amount 0.5 mm, reduction speed 10 mm / min, and pressure holding time 6 seconds . Under the action of strong plastic deformation and friction heat caused by the stirring tool, the screw is further tightened, and a welding layer with a certain depth is formed at the tail of the screw and the workpiece to be welded. After milling off the surface flash of the solder joint, there is no gap. There is no water leakage when pumping water pressure, indicating that the sealing welding has been realized.

Embodiment 2

[0020] Use this method to connect two AZ91D magnesium alloy cast plates with a thickness of 15 mm. First fasten with M12 screws made of aluminum, and then perform friction stir welding fastening at a speed of 3000 rpm, a reduction of 0.5 mm, a reduction speed of 10 mm / min, and a dwell time of 8. After milling off the surface flash of solder joints, no gaps exist, and sealed welding is realized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com