System and method for indirectly measuring stress distribution of assembly combined surfaces

A technology of stress distribution and joint surface, applied in the direction of measuring force, measuring device, instrument, etc., can solve the problems of high cost, expensive joint surface stress test equipment, complicated operation of geometric characteristics, etc., and achieve the effect of low measurement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

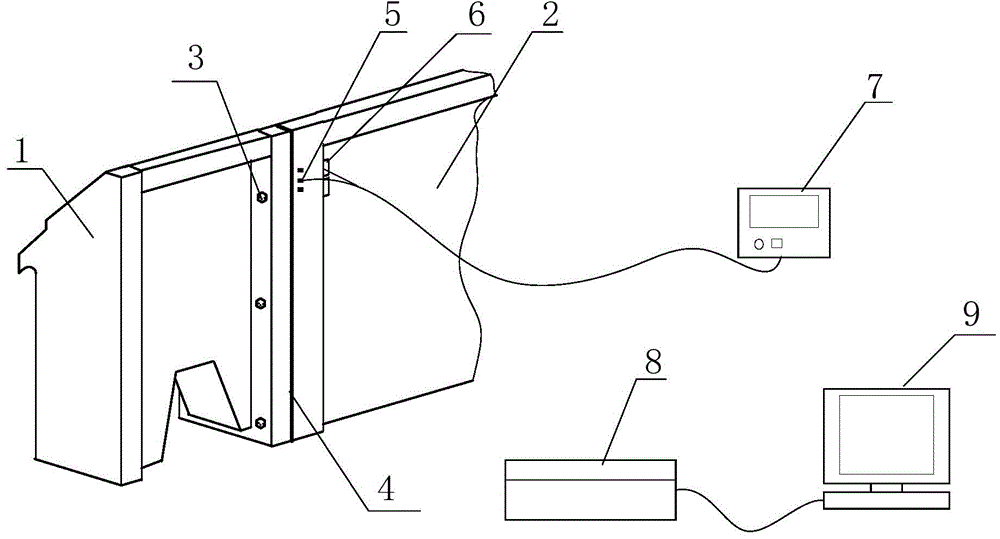

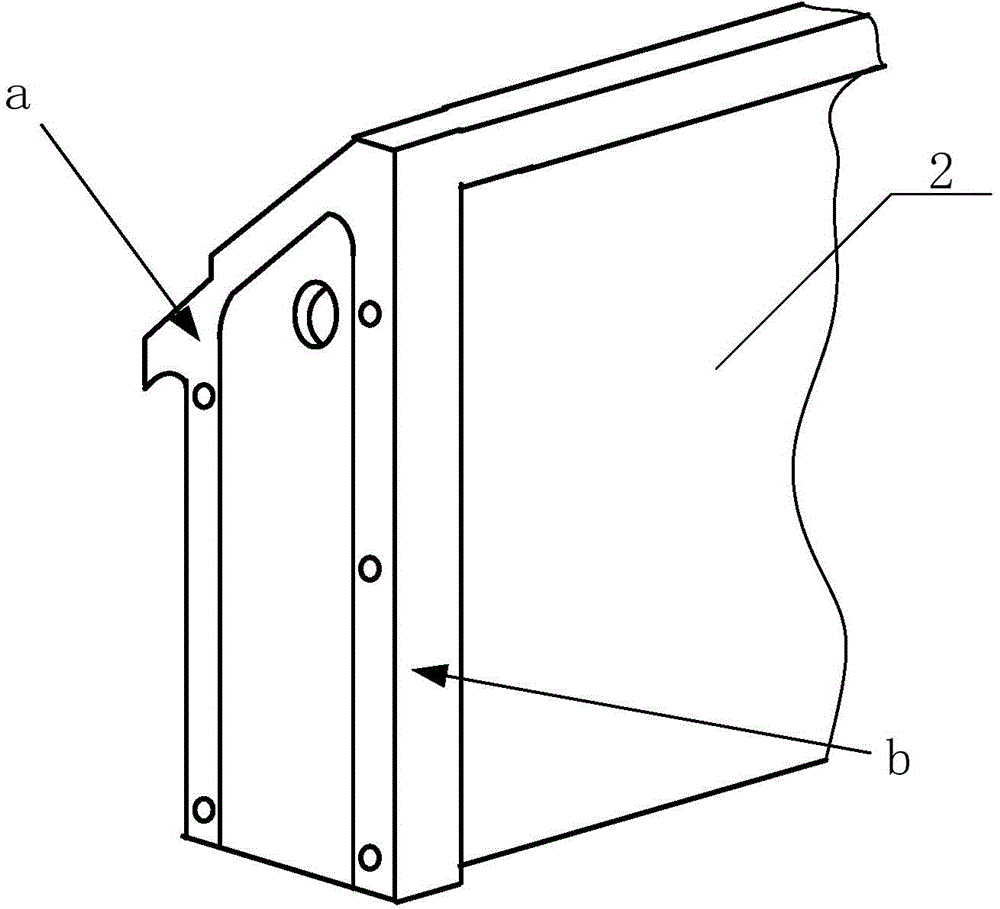

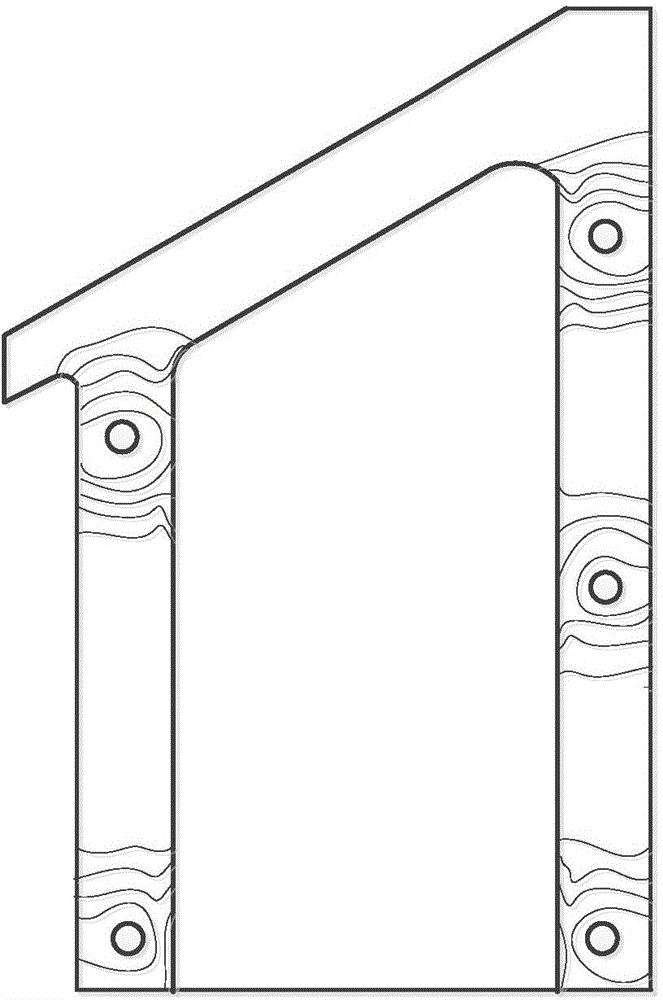

[0035] Figure 1 to Figure 5 A system for indirect measurement of the stress distribution of the joint surface of the assembly shown in , where part I1 and part II2 are joined by bolts 3, the surface where part I1 and part II2 fit together is the joint surface a, and the side adjacent to the joint surface a For the proximal side b, the system for indirectly measuring the stress distribution of the assembled joint surface includes a pressure sensor 6 , a pressure sensitive paper 4 , a strain gauge 5 , a display device 7 , a scanner 8 and a computer 9 . Wherein the pressure sensor 6 is preferably a resistance strain type pressure sensor, which is installed on the head of the bolt 3 on the side of the component II2, and is used for measuring the pretightening force of the bolt 3 . When stress is applied to the pressure-sensitive paper 4, the pressure-sensitive paper 4 will show different colors according to the magnitude of the stress. The time required to sandwich the pressure-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com