Patents

Literature

284 results about "Strain type" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The arrangement of the different elements in the compound are influenced by the strain each element or compound experiences. A compound can experience three different types of strain: angular strain, torsional strain, and steric strain.

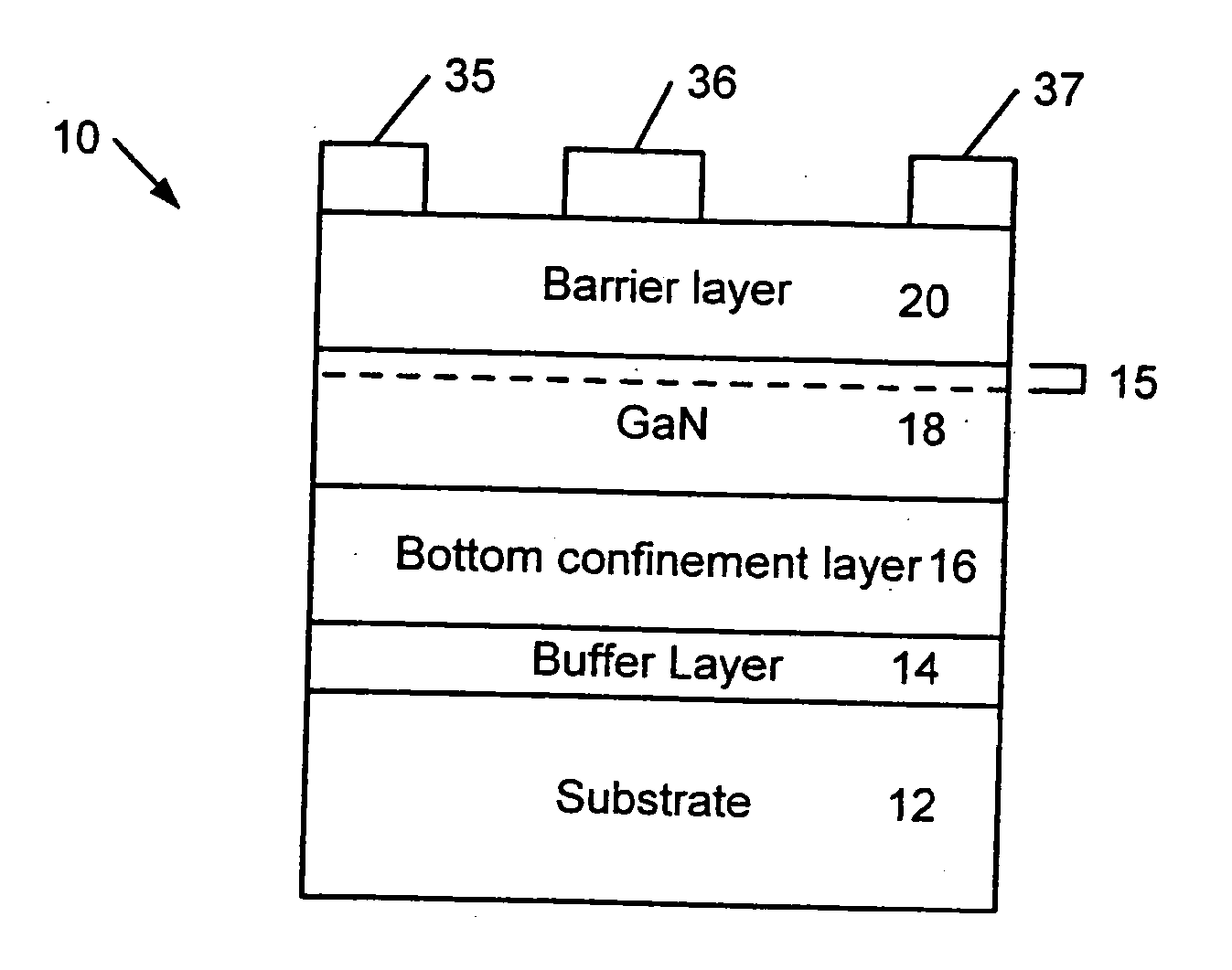

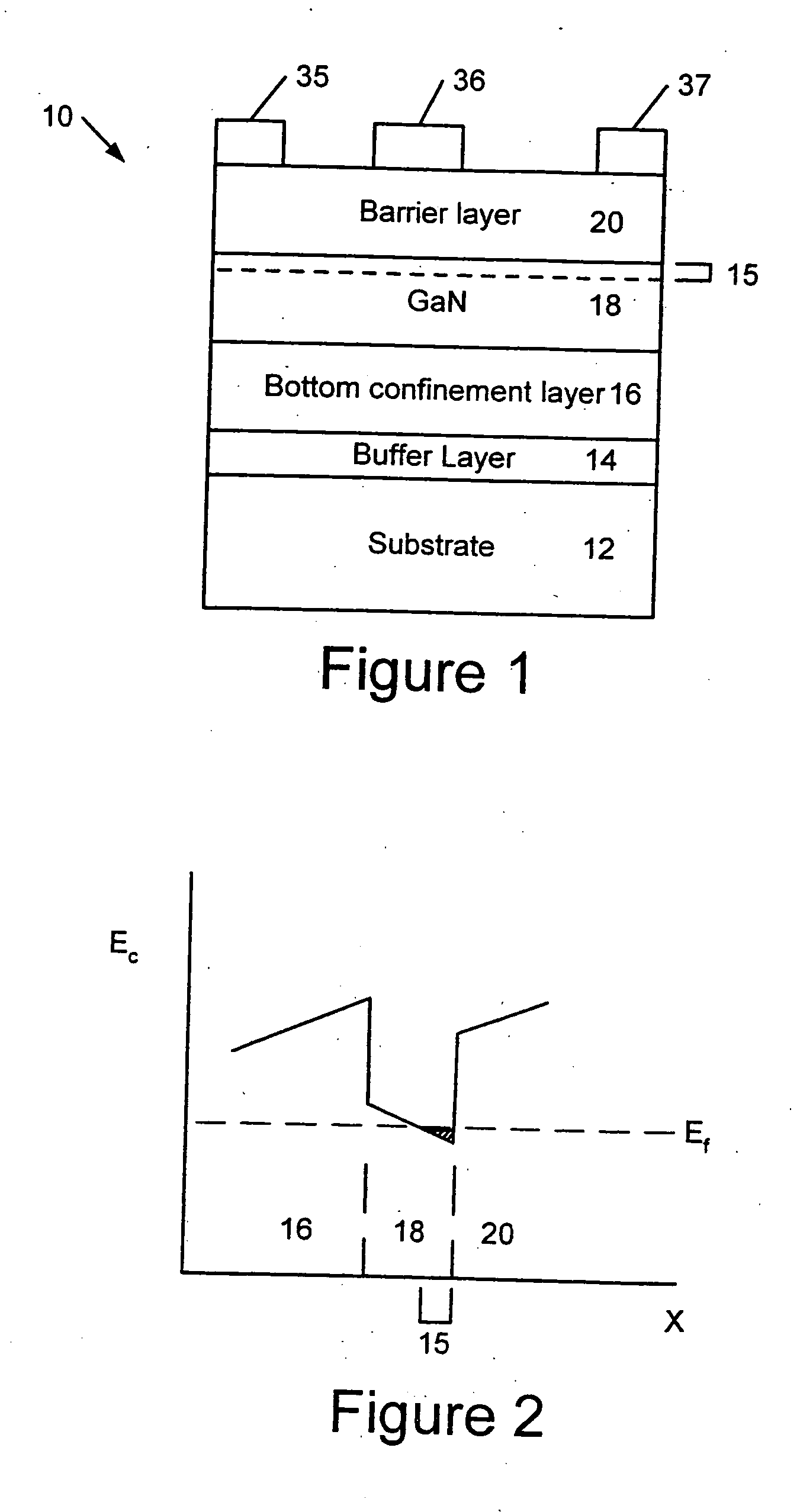

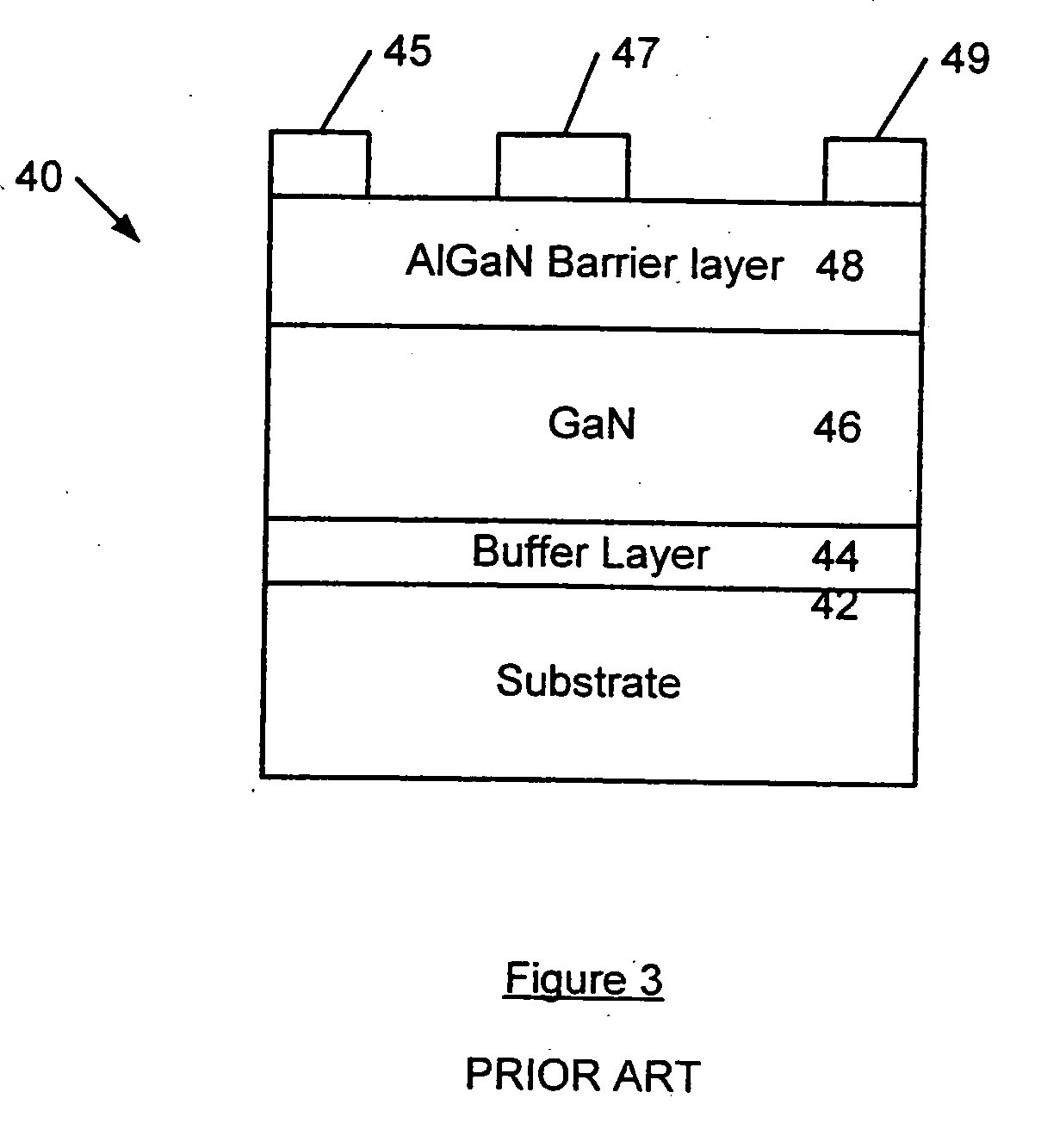

Strain balanced nitride heterojunction transistors and methods of fabricating strain balanced nitride heterojunction transistors

ActiveUS20060121682A1Semiconductor/solid-state device manufacturingSemiconductor devicesHeterojunctionHigh concentration

A nitride based heterojunction transistor includes a substrate and a first Group III nitride layer, such as an AlGaN based layer, on the substrate. The first Group III-nitride based layer has an associated first strain. A second Group III-nitride based layer, such as a GaN based layer, is on the first Group III-nitride based layer. The second Group III-nitride based layer has a bandgap that is less than a bandgap of the first Group III-nitride based layer and has an associated second strain. The second strain has a magnitude that is greater than a magnitude of the first strain. A third Group III-nitride based layer, such as an AlGaN or AlN layer, is on the GaN layer. The third Group III-nitride based layer has a bandgap that is greater than the bandgap of the second Group III-nitride based layer and has an associated third strain. The third strain is of opposite strain type to the second strain. A source contact, a drain contact and a gate contact may be provided on the third Group III-nitride based layer. Nitride based heterojunction transistors having an AlGaN based bottom confinement layer, a GaN based channel layer on the bottom confinement layer and an AlGaN based barrier layer on the channel layer, the barrier layer having a higher concentration of aluminum than the bottom confinement layer, are also provided. Methods of fabricating such transistor are also provided.

Owner:CREE INC

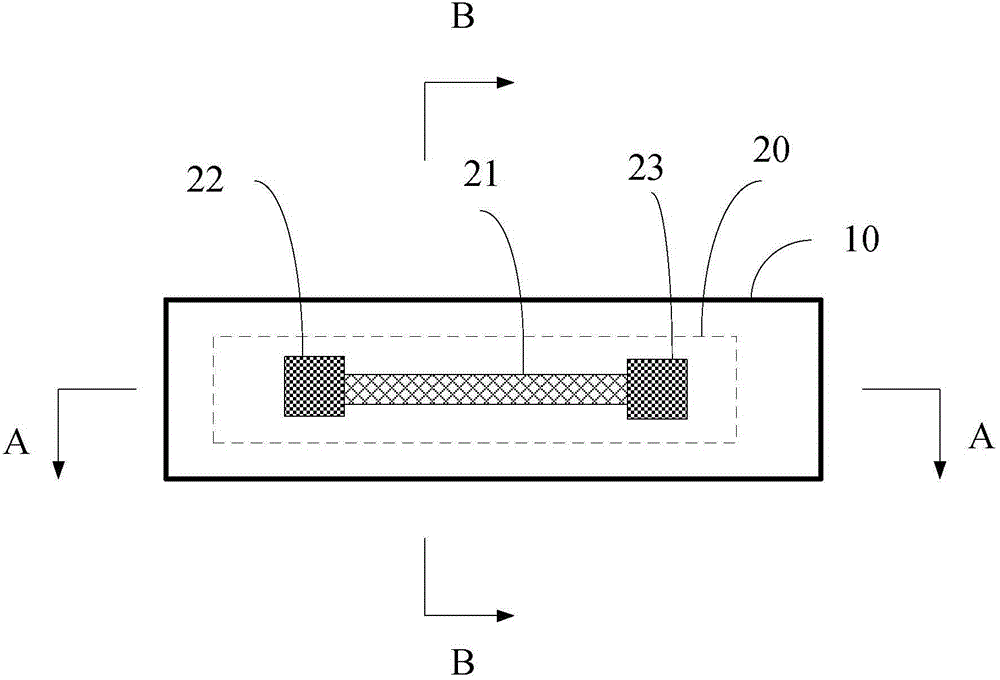

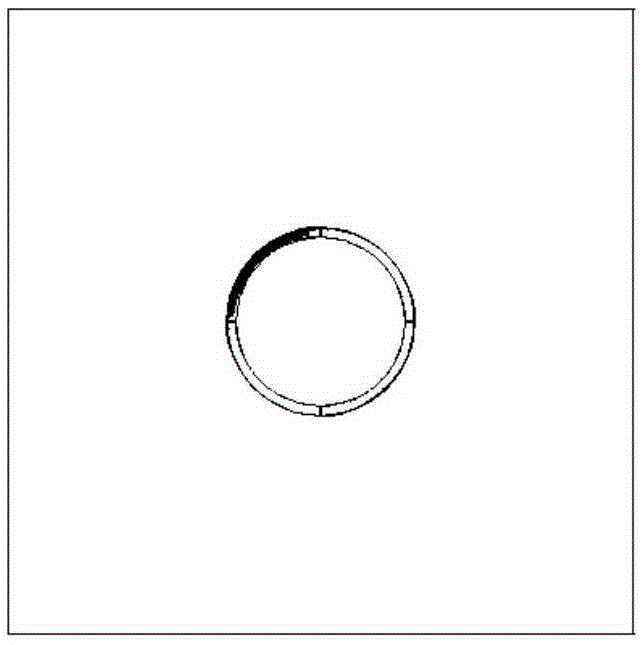

Resistance strain gauge and resistance strain type sensor

ActiveCN104880206ASimple structureHighly integratedConverting sensor output electrically/magneticallyMicrobiologyStrain type

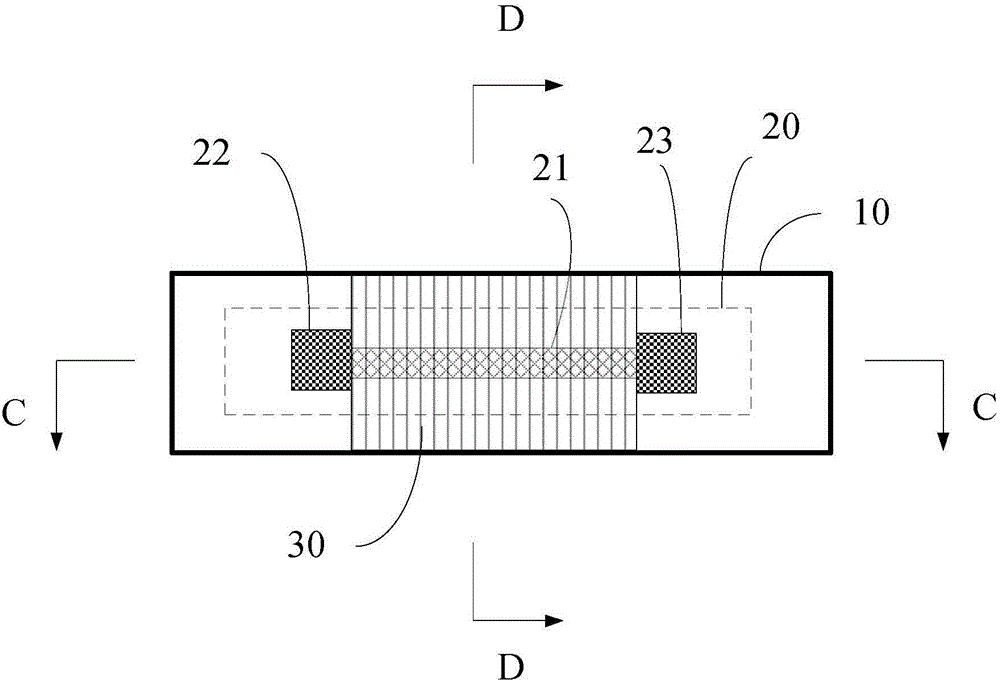

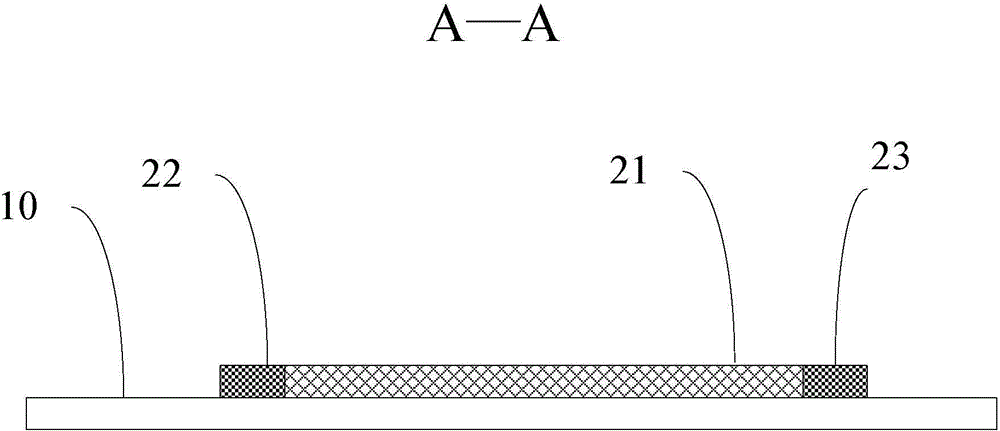

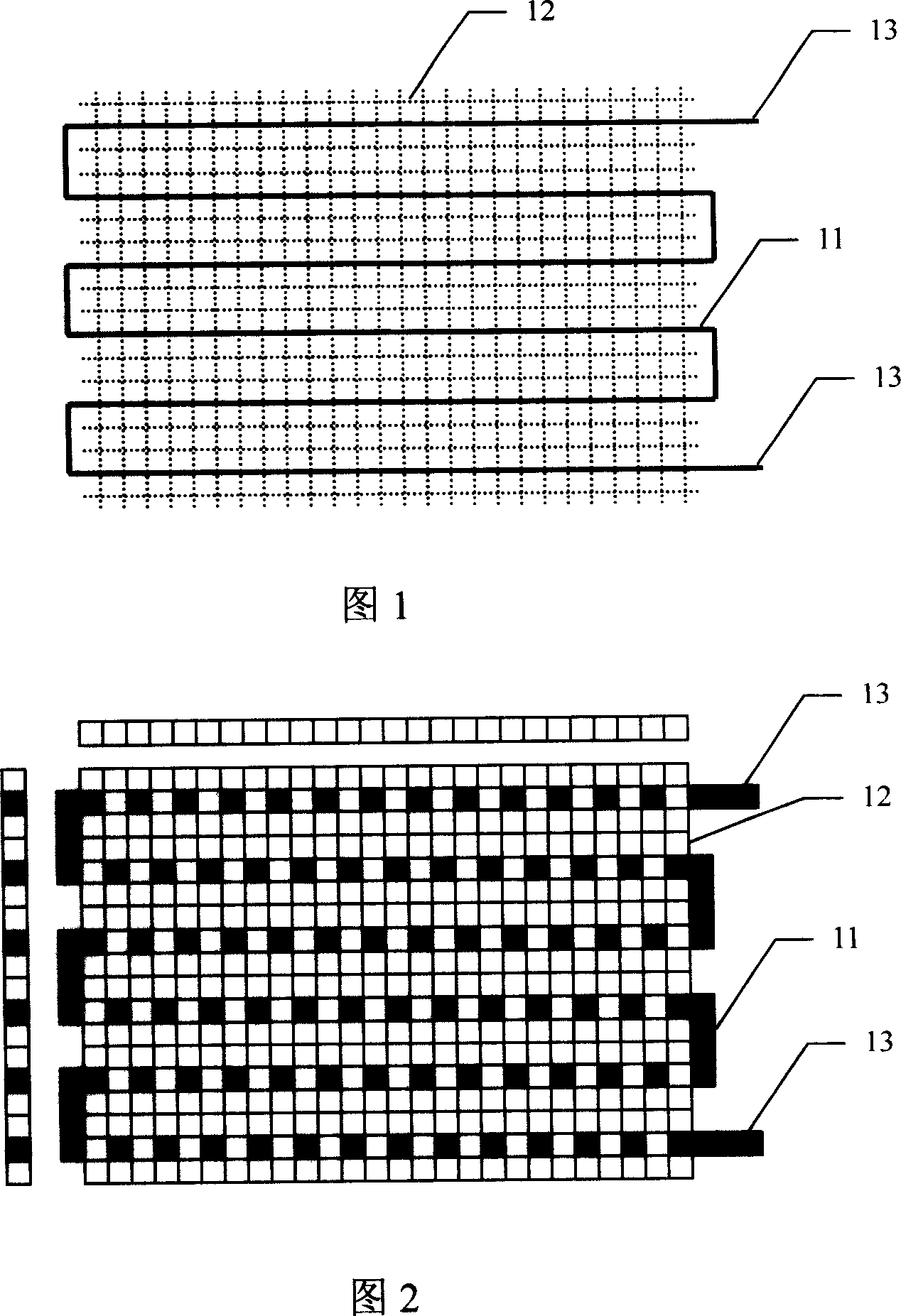

The invention provides a resistance strain gauge and a resistance strain type sensor. The resistance strain gauge comprises a flexible substrate and a resistance strain sensing unit attached to the flexible substrate. Extraction electrodes are arranged at the two ends of the resistance strain sensing unit. The resistance strain type sensor consists of a resistance strain gauge and a tested component. The resistance strain gauge and the tested component are deformed together under the effect of the physical quantity; and the physical quantity of the tested component is measured by measuring the resistance variable quantity of the resistance strain gauge during the deformation measurement process. According to the invention, 200% of maximum strain as well as the corresponding physical quantity can be measured. Moreover, the integration degree and the expansibility are high; and the resistance strain gauge and the resistance strain type sensor can be realized easily.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI +1

Strain-type flexible respiration transducer for electronic fabric and its application

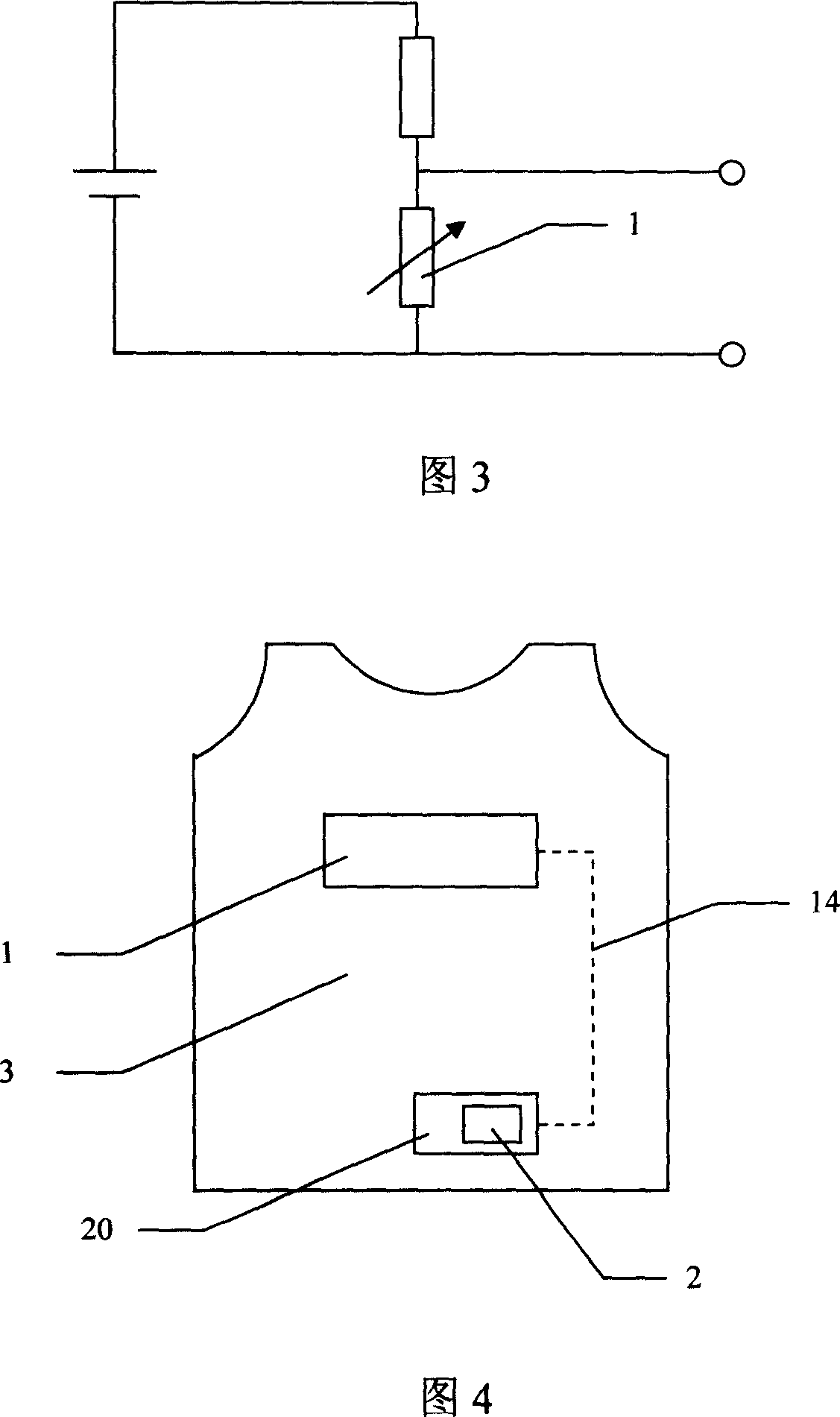

The strain-type flexible respiration transducer for electronic fabric includes transducer sensing element in the form of fabric comprising elastic conducting fiber and insulating fiber, and the transducer sensing element has lead or joint for electric connection. The clothing with the respiration transducer for monitoring the respiration of the human body is one maillot with at least one of this flexible respiration transducer in the chest part. The flexible respiration transducer and the clothing with the flexible respiration transducer may be bent, folded, kneaded and washed, are suitable for monitoring the respiration information in the worn state, and have simple structure, low cost and convenient use.

Owner:DONGHUA UNIV

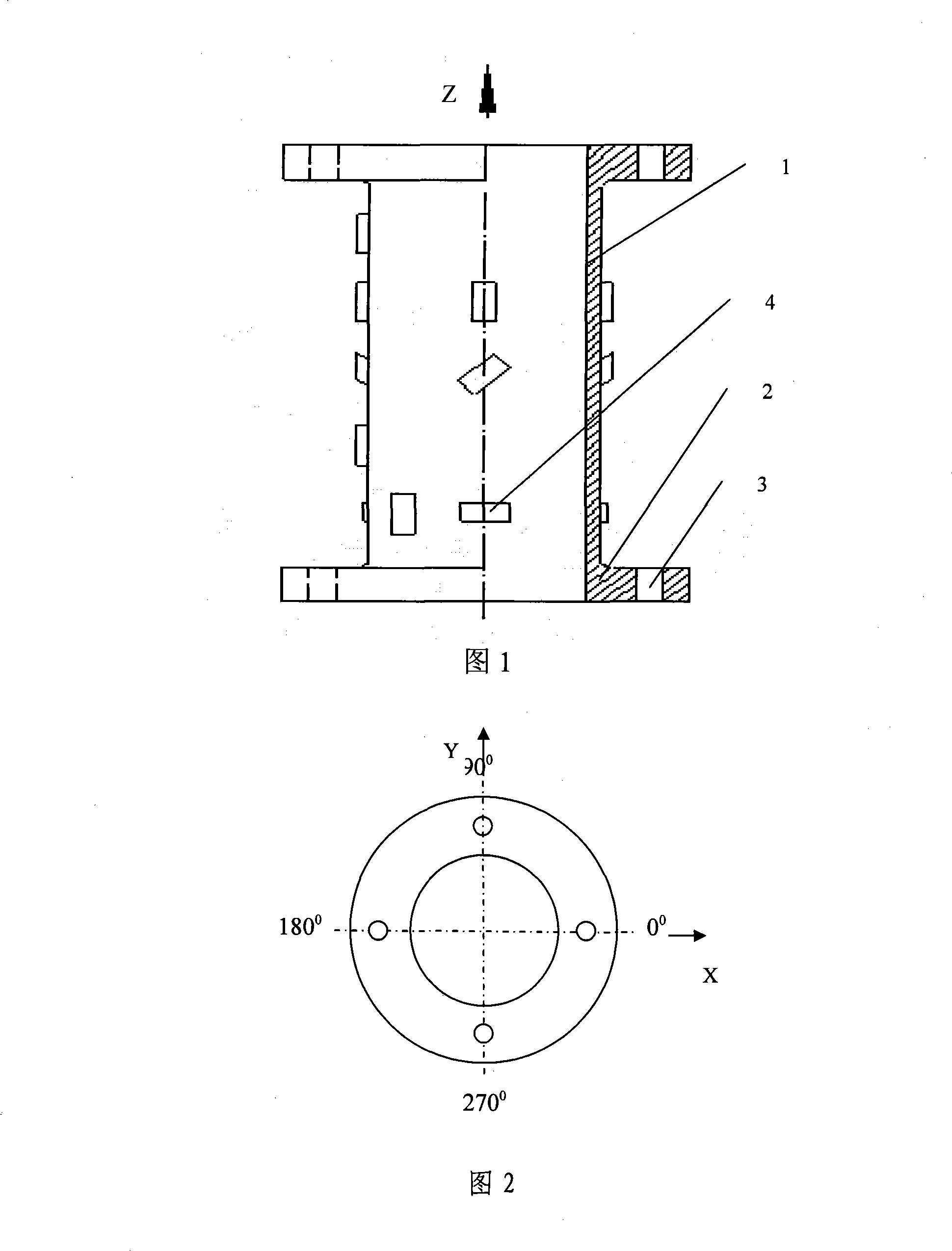

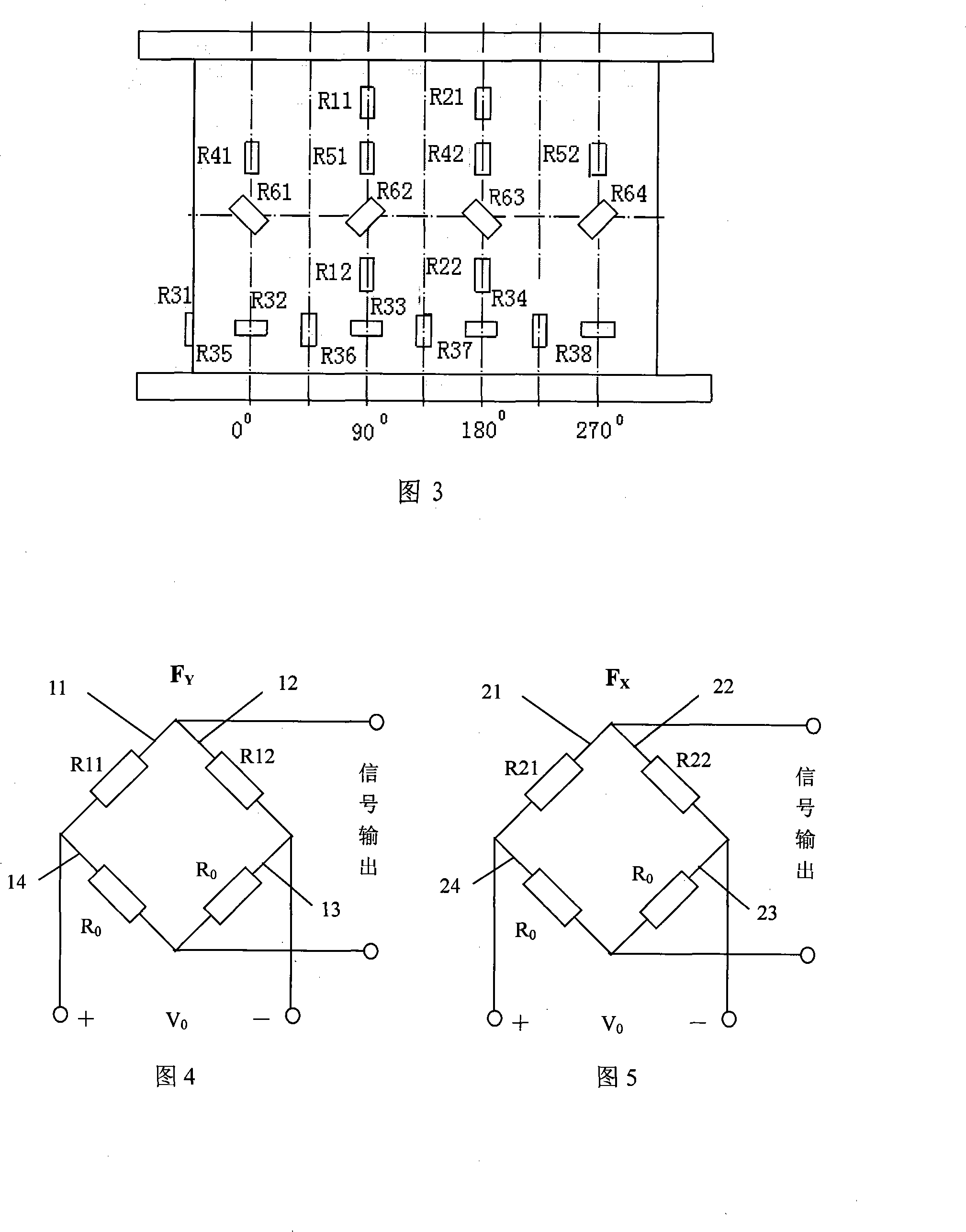

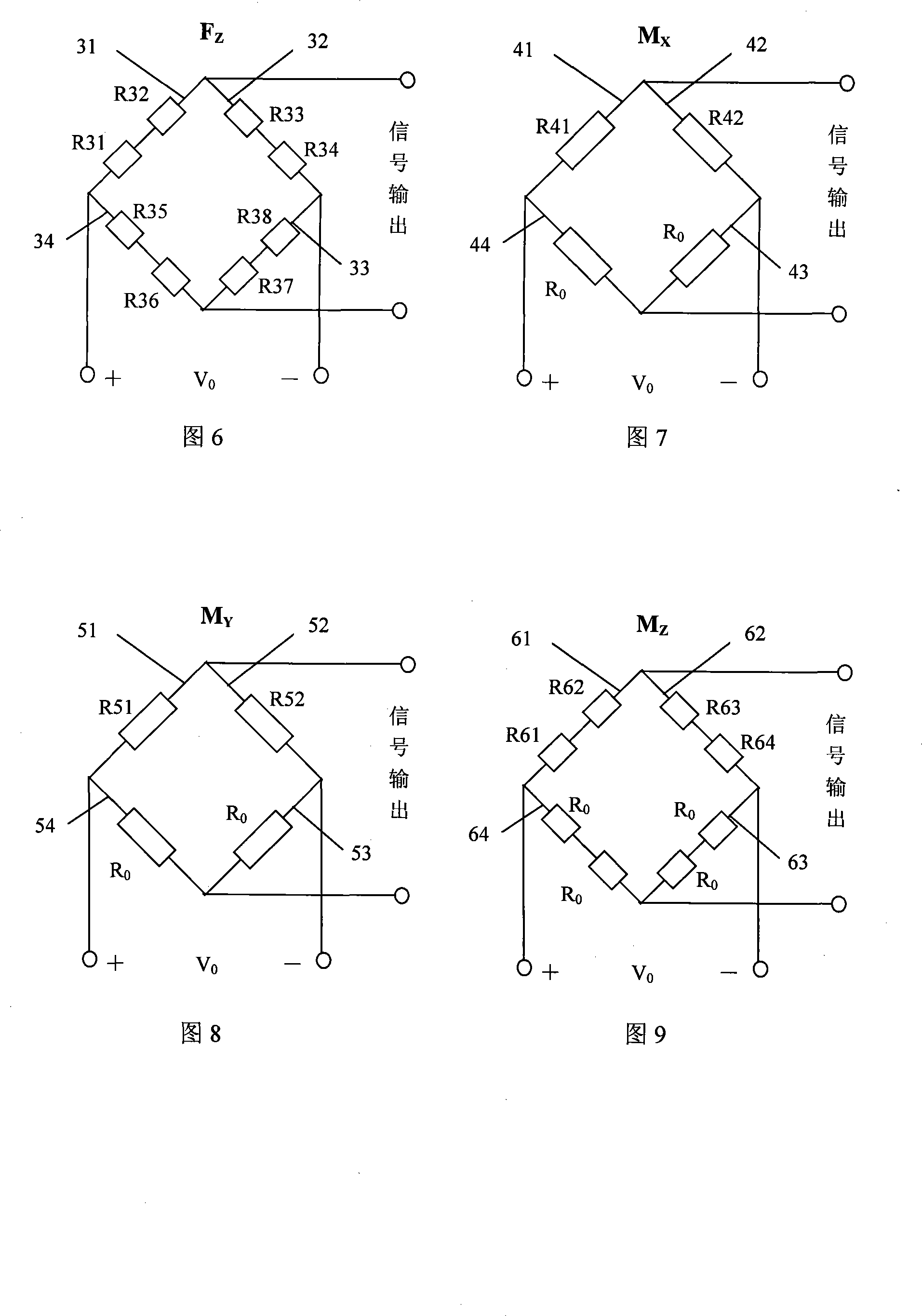

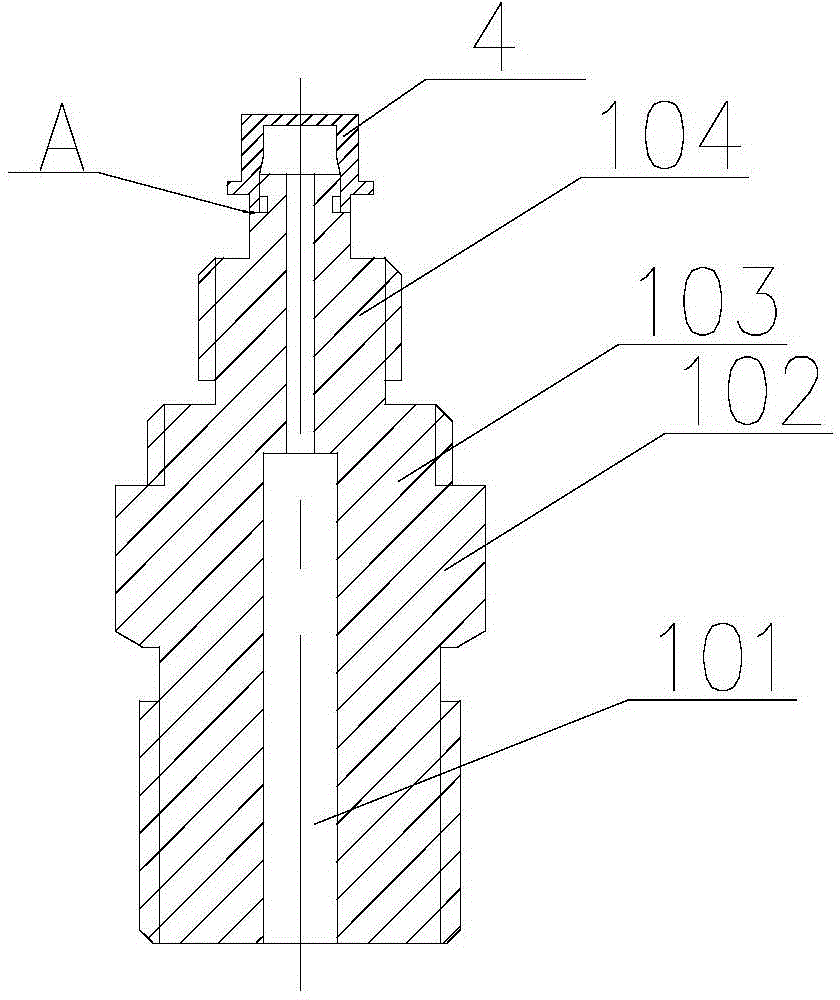

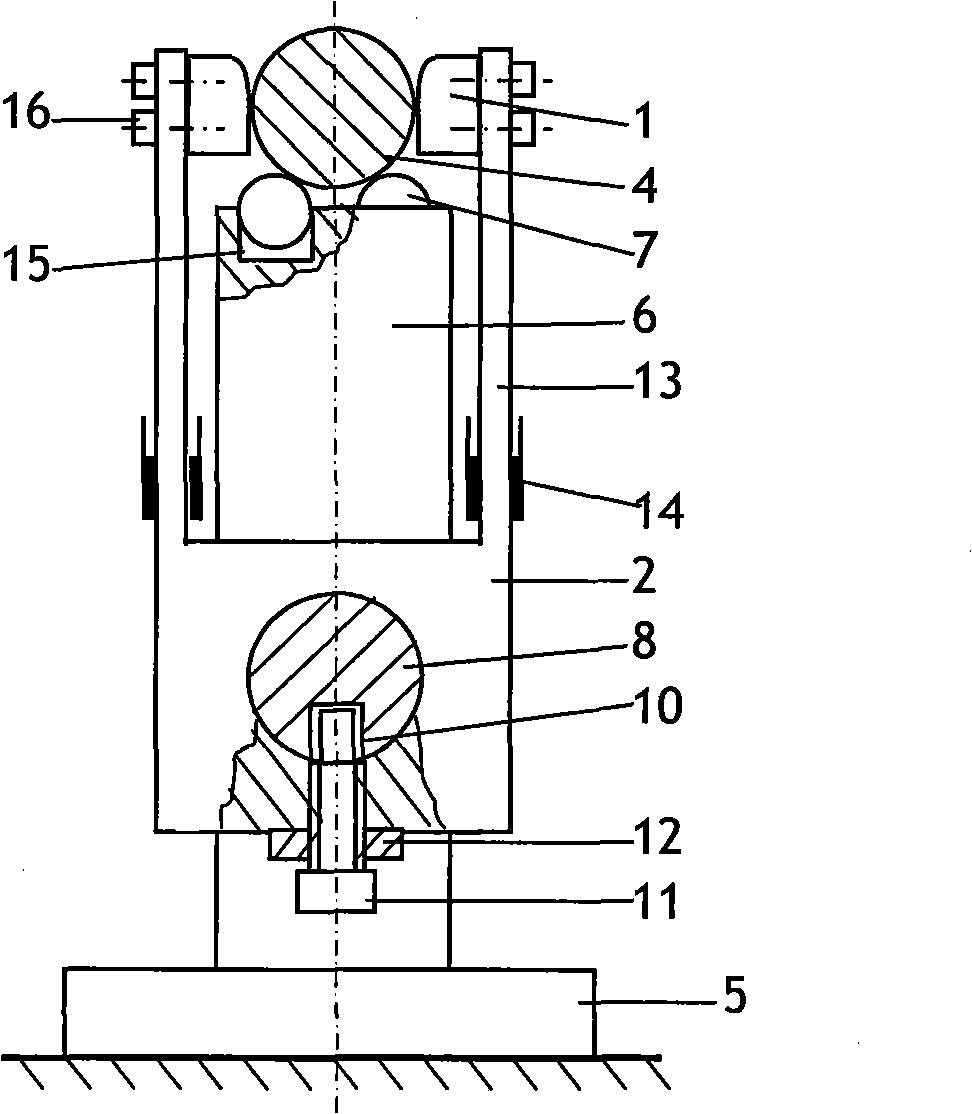

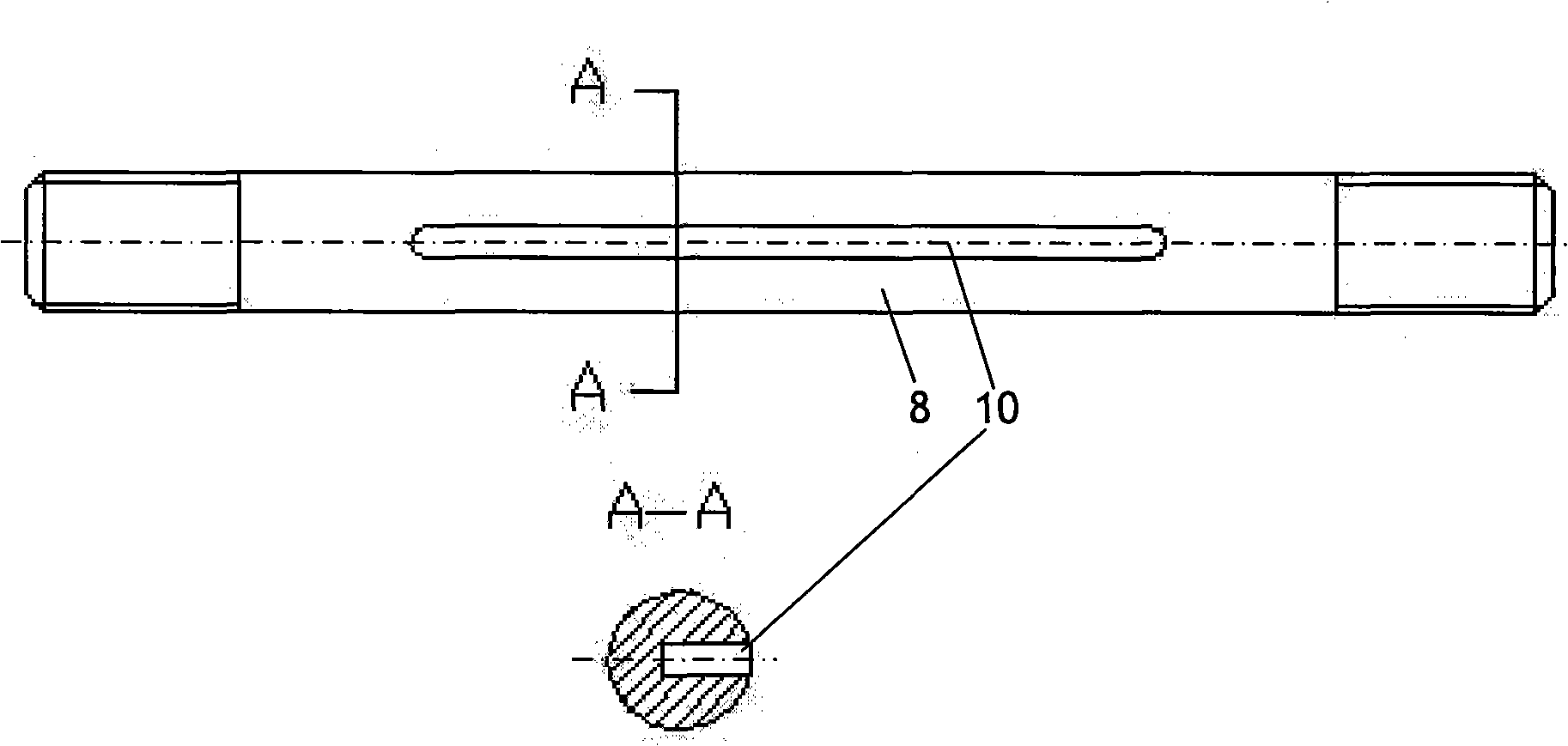

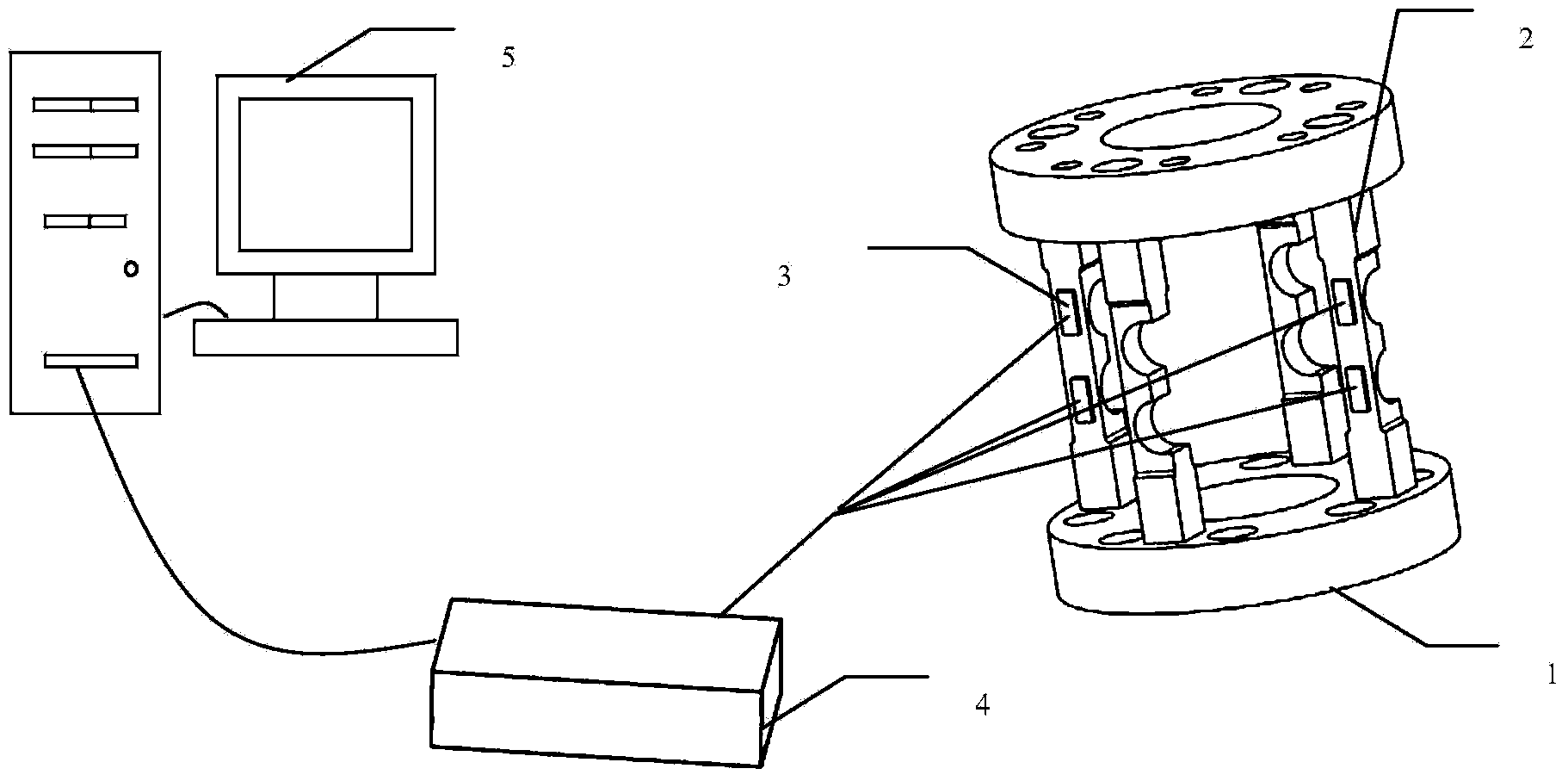

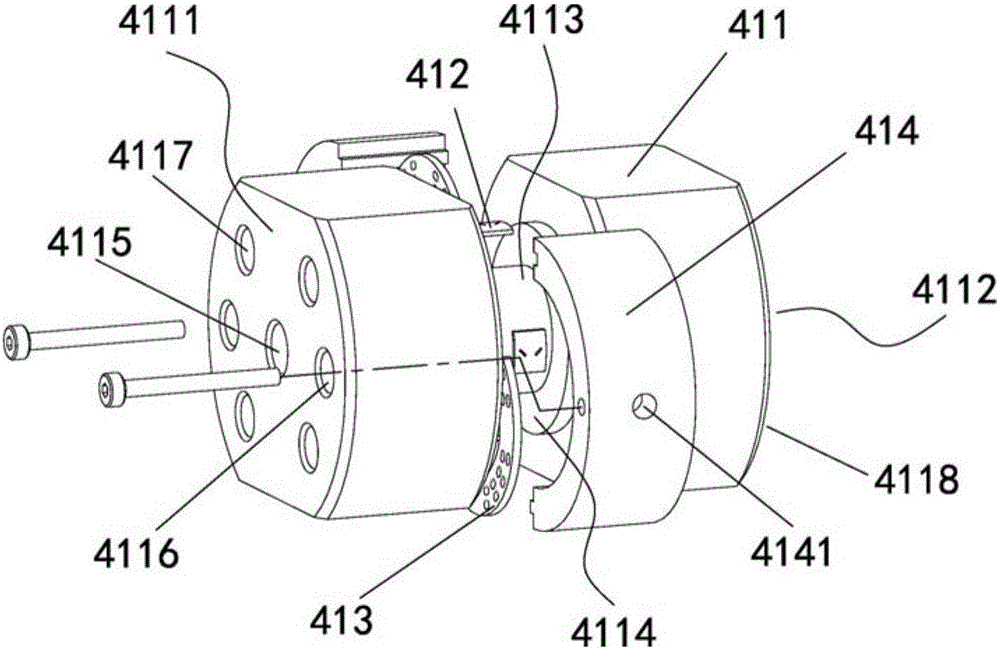

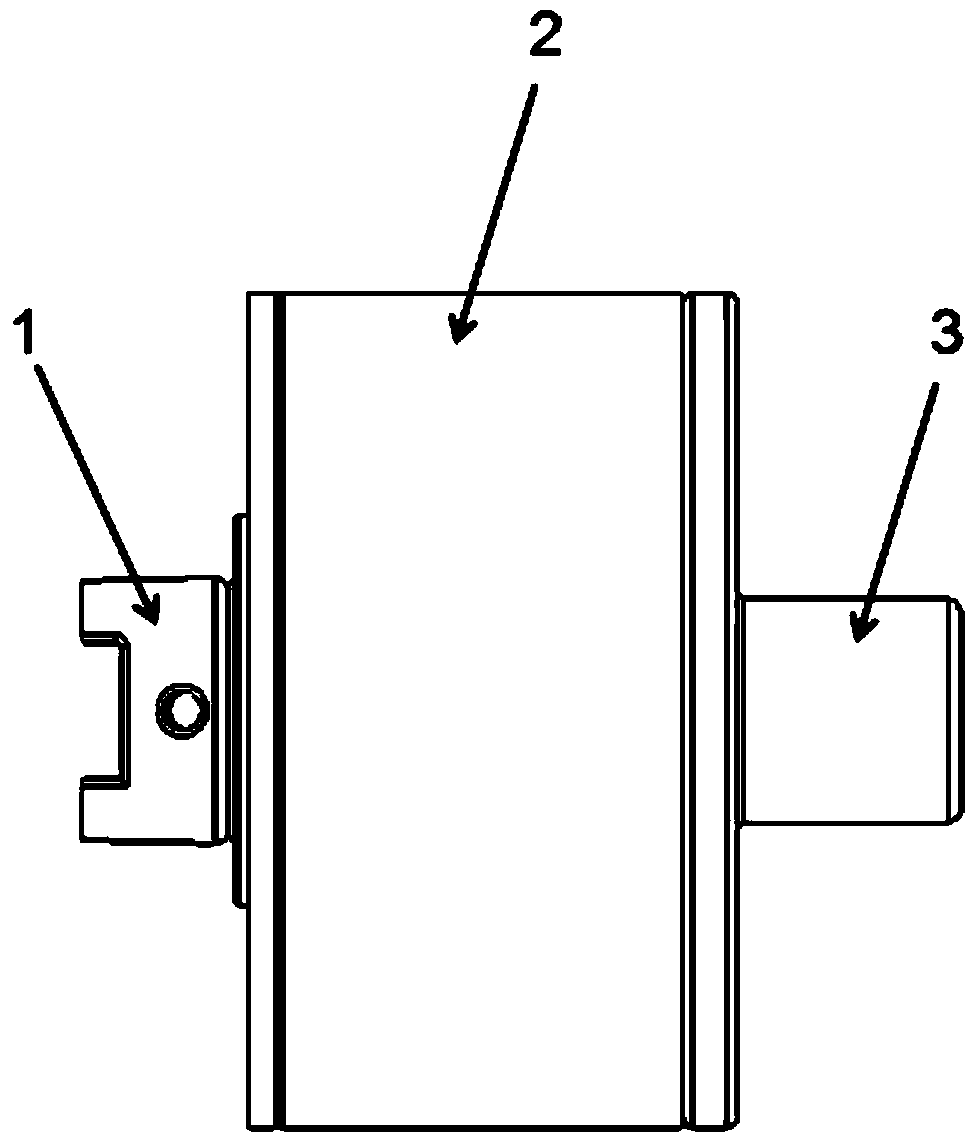

Multi-component force sensor

InactiveCN101210850AConsistent radial mechanical propertiesIncreased longitudinal stabilityForce measurementEngineeringStrain type

The invention provides a strain type force measuring device, more particular a sensor capable of simultaneously measuring component forces of a non-coplanar force at 6 different degree-of-freedom directions. Flanges (2) are arranged at the two ends of a thin-walled cylinder (1) and opened with mounting holes (3), an electric resistance strain gage and a temperature compensation strain gage are adhered on a specific position of the wall of the thin-walled cylinder (1) with a specific manner, and the electric resistance strain gage is bridged. The invention has the advantages of uniform radial mechanical properties, good longitudinal stability, simple structure, light weight, low inertia, no intervals and frictional force, high measurement accuracy and wide application range; and is suitable for measuring either small load and high load with large structure.

Owner:CHINA HELICOPTER RES & DEV INST

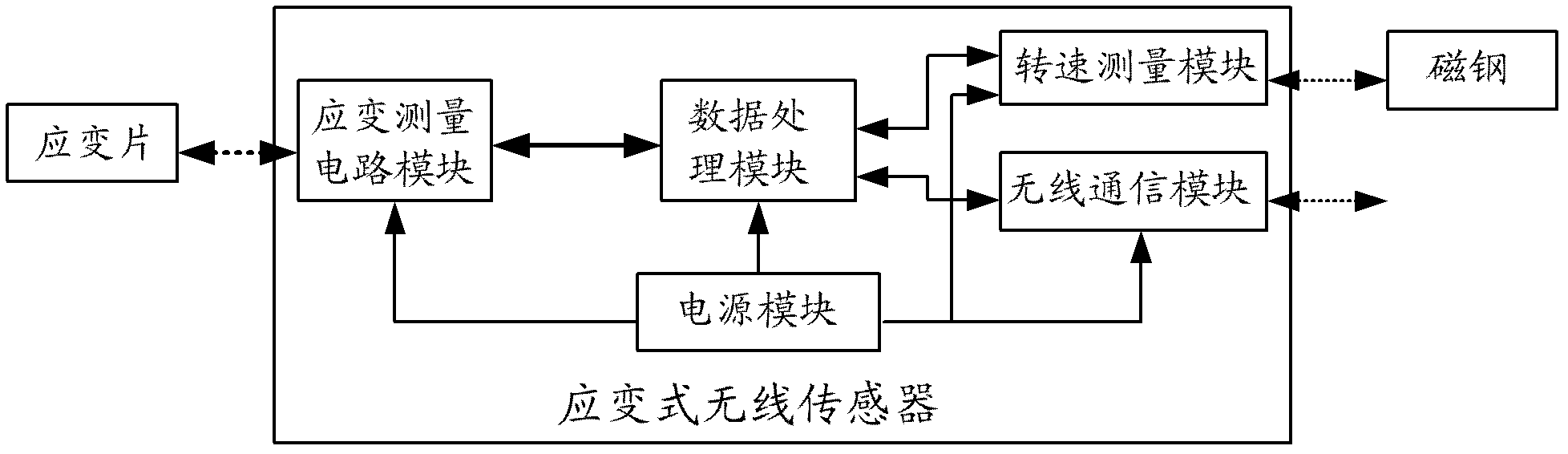

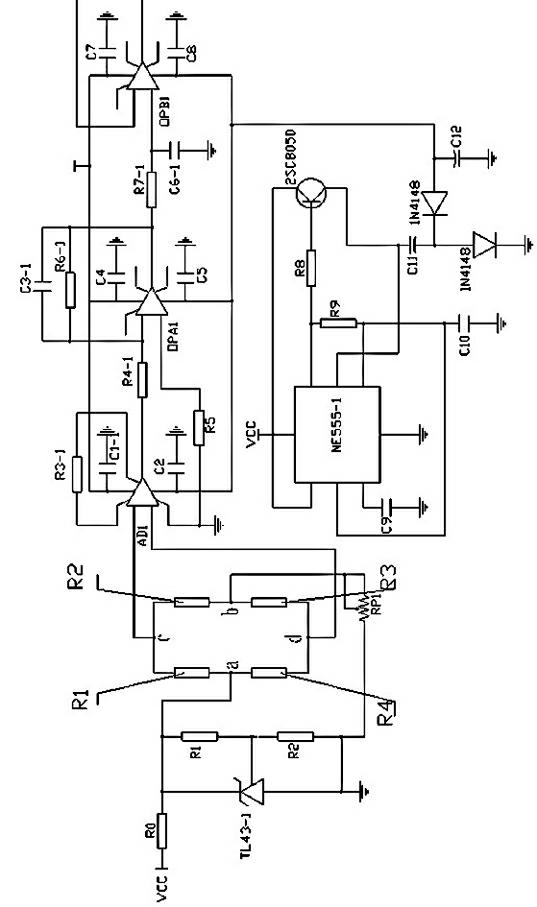

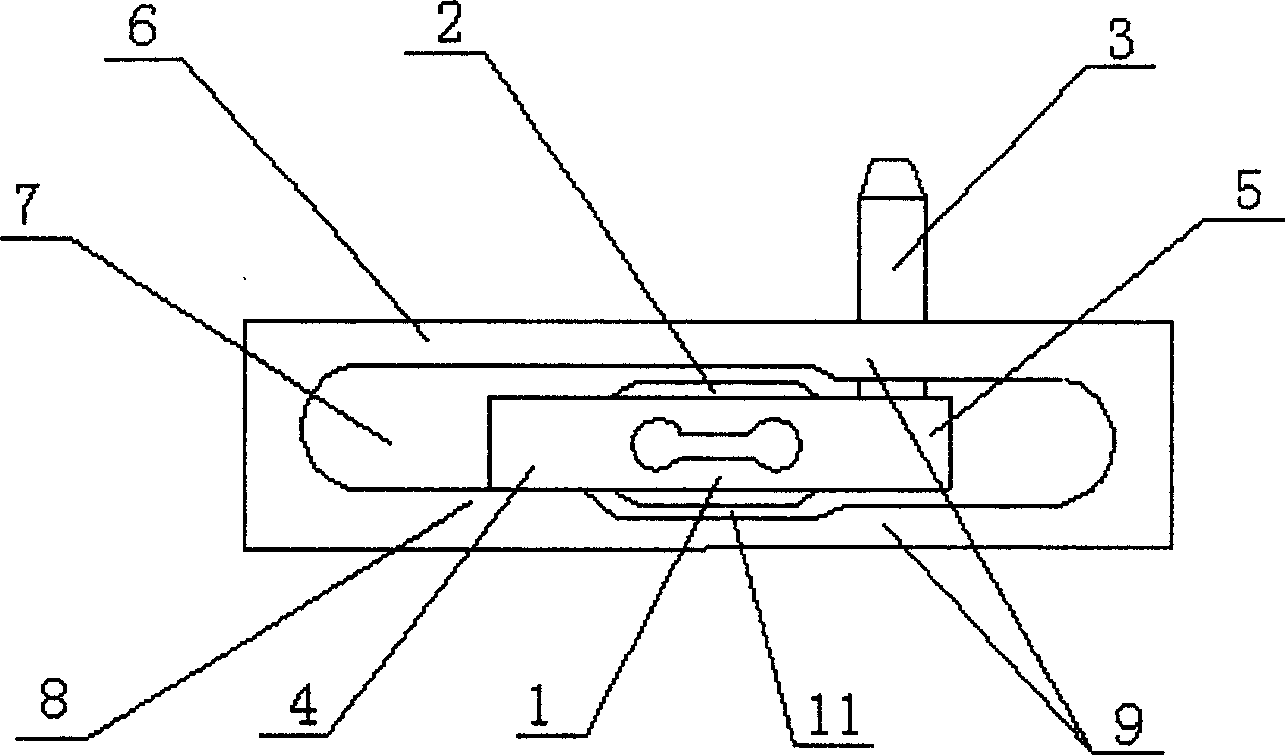

Strain type wireless sensor

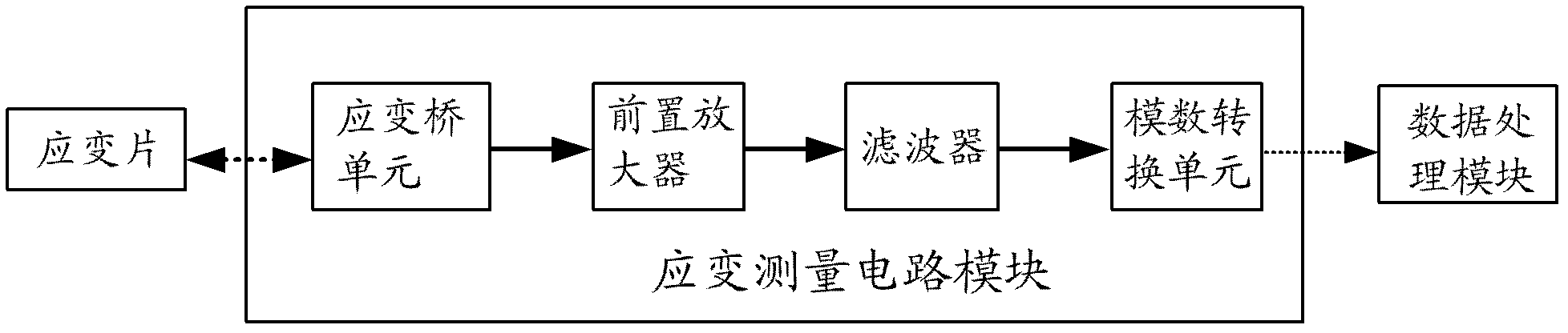

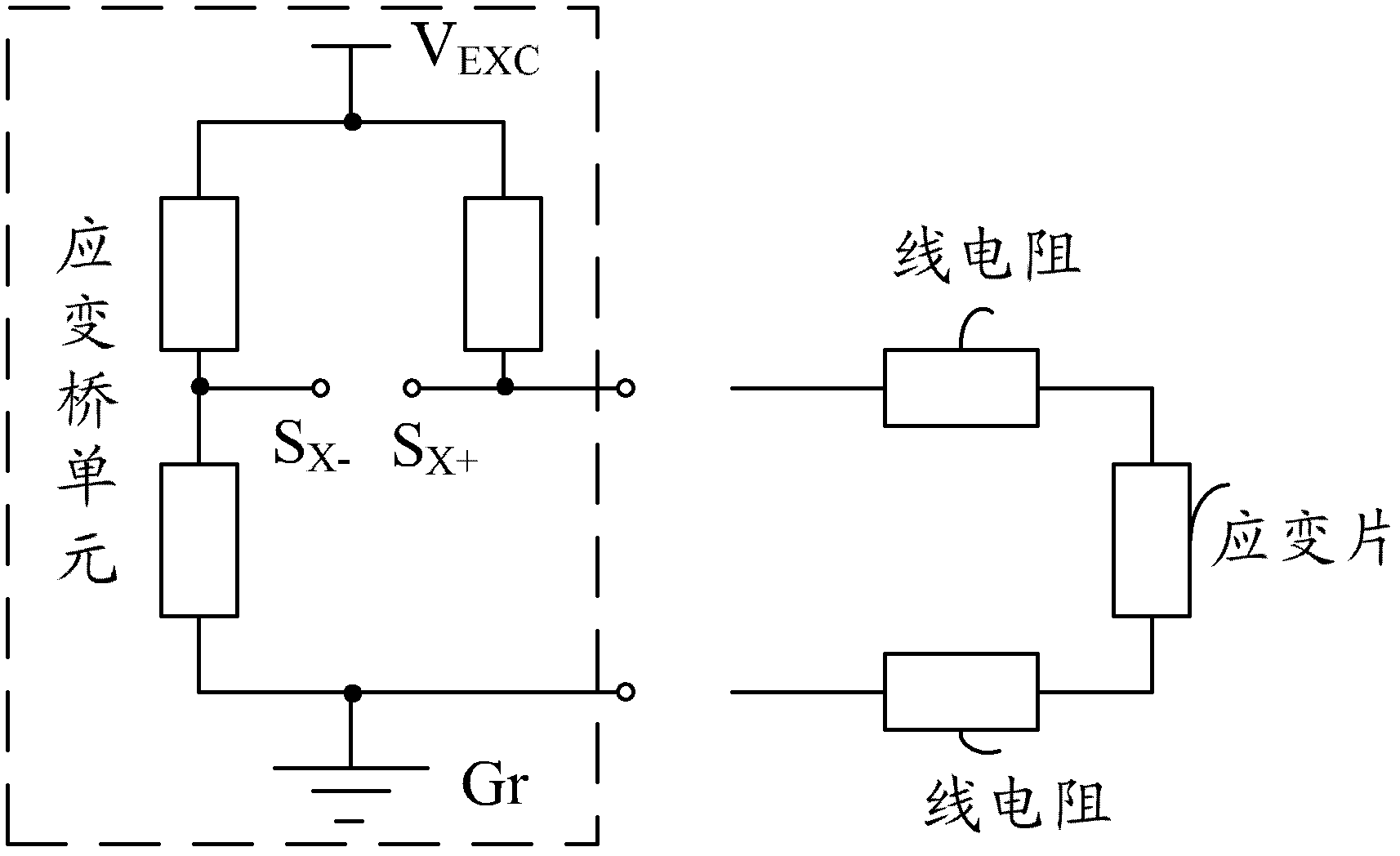

The invention discloses a strain type wireless sensor, comprising a strain measuring circuit module, a rotating speed measuring module, a data processing module, a wireless communication module and a power supply module, wherein an internal-arranged strain bridge is connected with a strain sheet which is mounted on an external transmission shaft through a lead wire so as to receive analogue voltage information output by strain bridge resistance variation which is caused by deformation of the strain sheet, and a voltage strain signal is output after the analogue voltage information is processed; the rotating speed measuring module is arranged at a position to be aligned to the rotating speed measuring module, is located in a magnetic field at a static state, and is used for outputting pulse voltage information; the data processing module is used for counting the pulse voltage information received within a time unit and converting the pulse voltage information into rotating speed information; the rotating speed information and a received voltage strain signal are output to the wireless communication module after being packaged; received information is sent in a wireless manner by the wireless communication module; and the power supply module supplies power to the strain measuring circuit module, the rotating speed measuring module, the data processing module and the wireless communication module. With the adoption of the strain type wireless sensor, the torque and the rotating speed can be measured simultaneously.

Owner:北京必创科技股份有限公司 +1

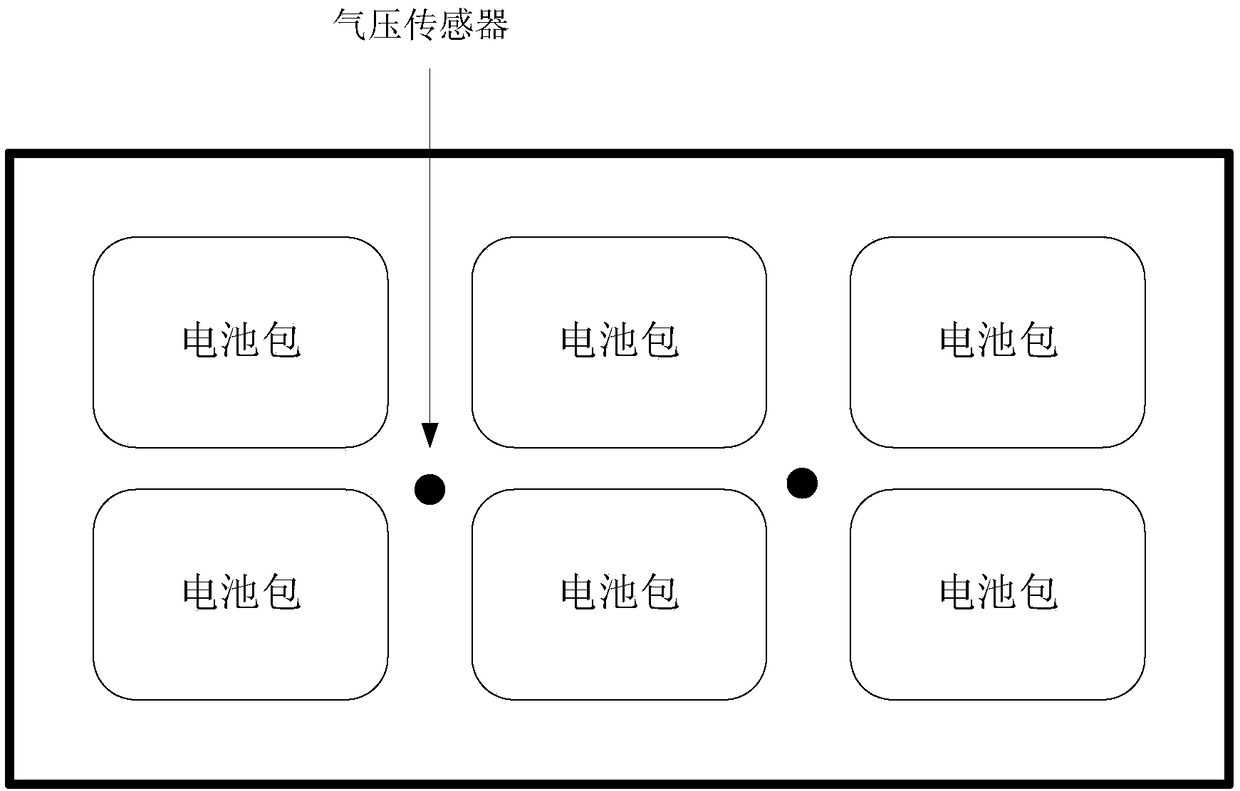

Battery pack abnormality detecting device and battery pack abnormality detecting method

ActiveCN108631015AAvoid the situation where a breakage occurs but the anomaly is not detectedImprove detection accuracySecondary cellsBatteriesAnomaly detectionEngineering

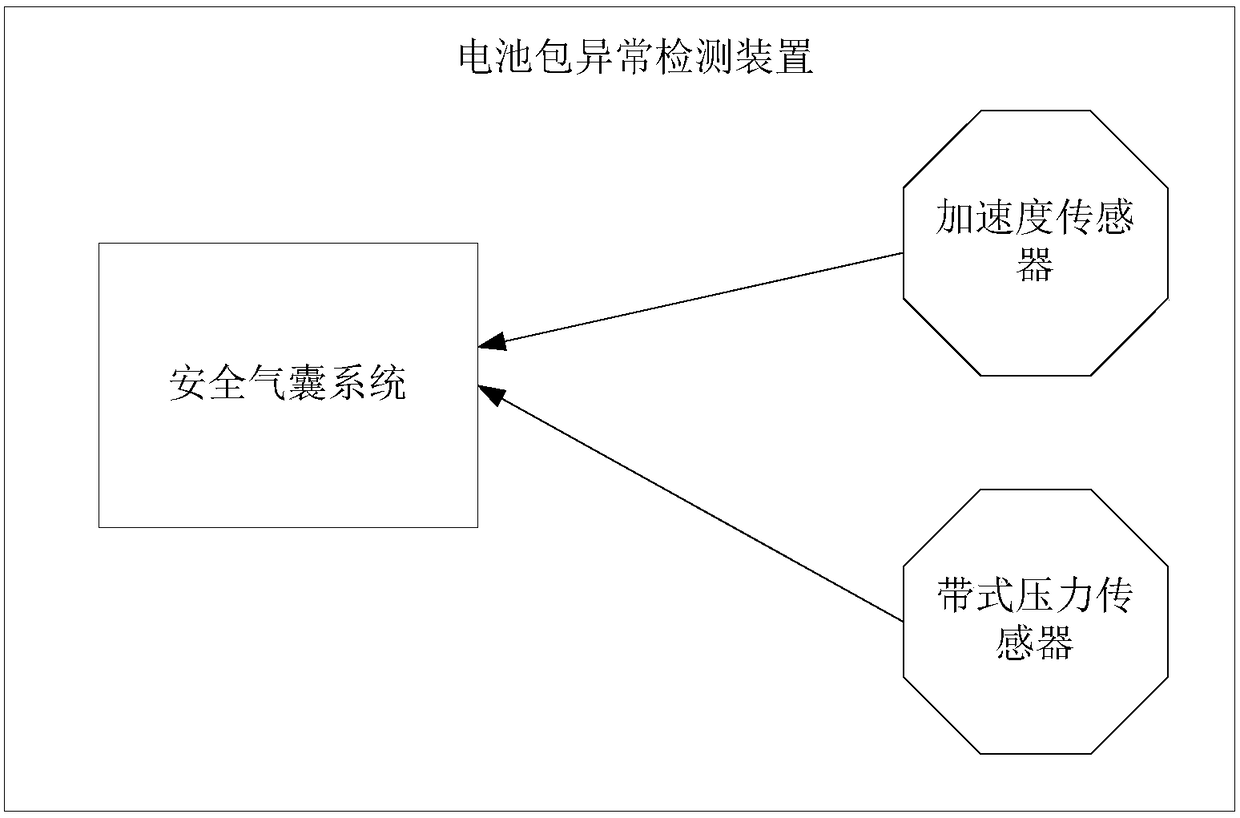

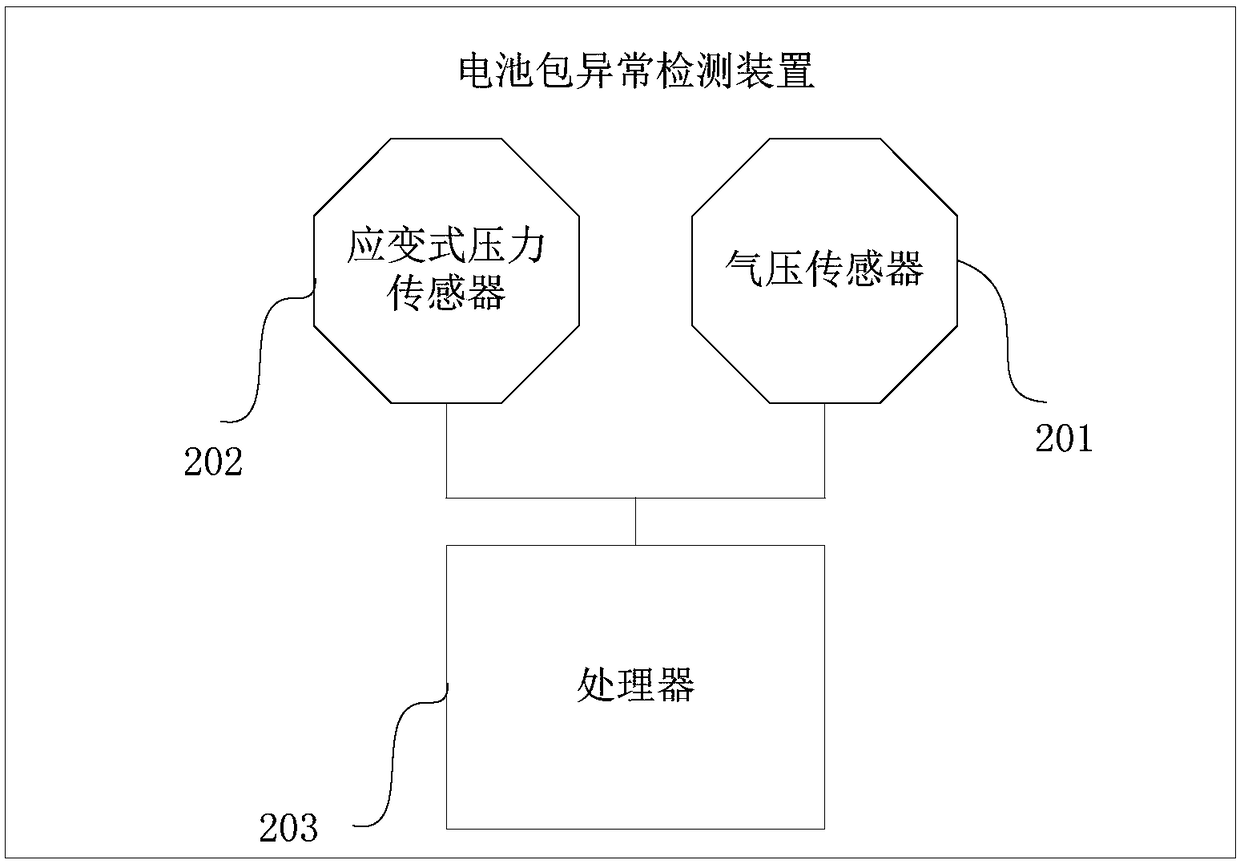

The invention provides a battery pack abnormality detecting device and a battery pack abnormality detecting method, belonging to the field of electric vehicles. The battery pack abnormality detectingdevice comprises an air pressure sensor, a strain type pressure sensor and a processor, wherein the air pressure sensor and the strain type pressure sensor are located in a battery pack; the air pressure sensor is connected with the processor and used for detecting air pressure in the battery pack; the strain type pressure sensor is connected with the processor and used for detecting the pressureof the inner wall of the battery pack; and the processor is used for determining whether the battery pack is abnormal or not on the basis of a first pressure value collected by the air pressure sensorand a second pressure value collected by the strain type pressure sensor, and generates first alarm information under the condition that the battery pack is determined to be abnormal. According to the invention, sensors are placed in the battery pack, so the alarm information generated by the processor on the basis of output pressure data can truly reflect whether the battery pack is really abnormal or not, and detection accuracy is improved.

Owner:HUAWEI TECH CO LTD

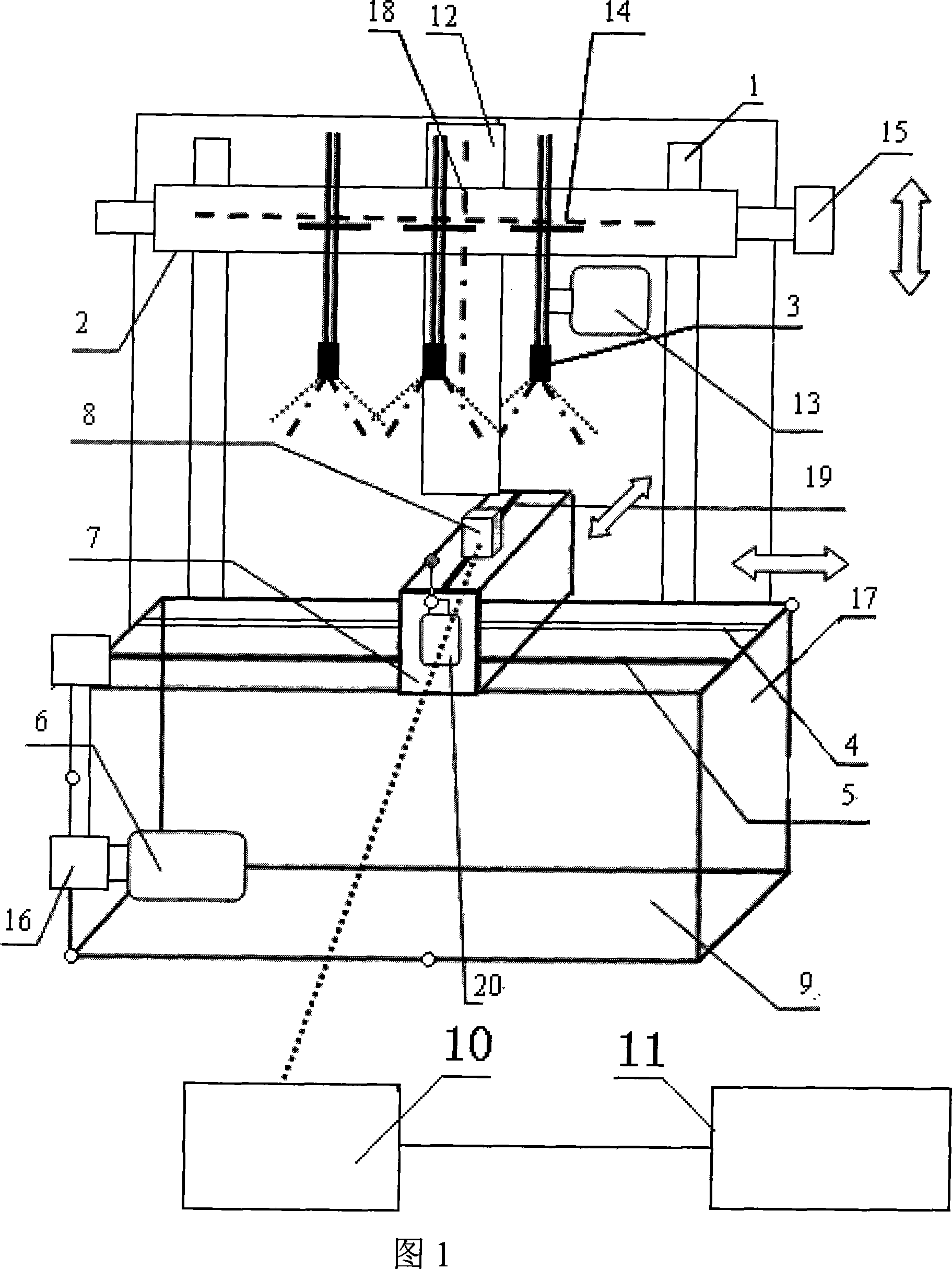

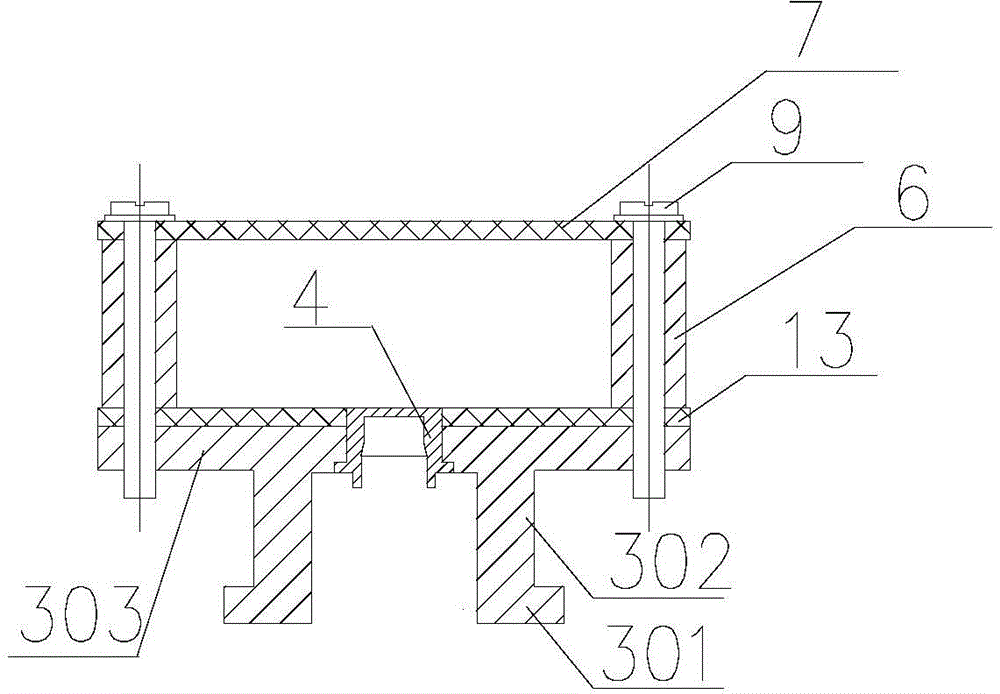

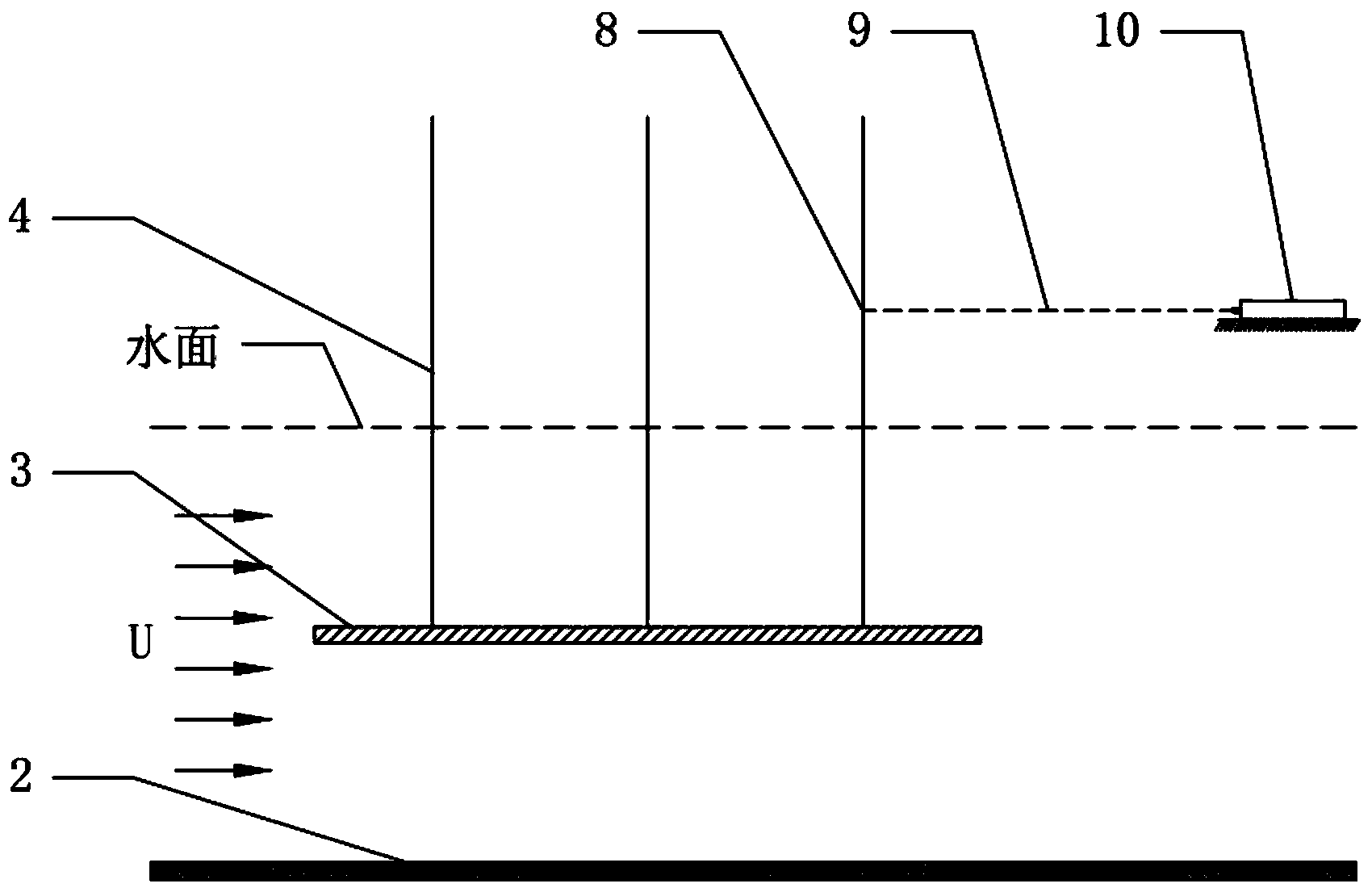

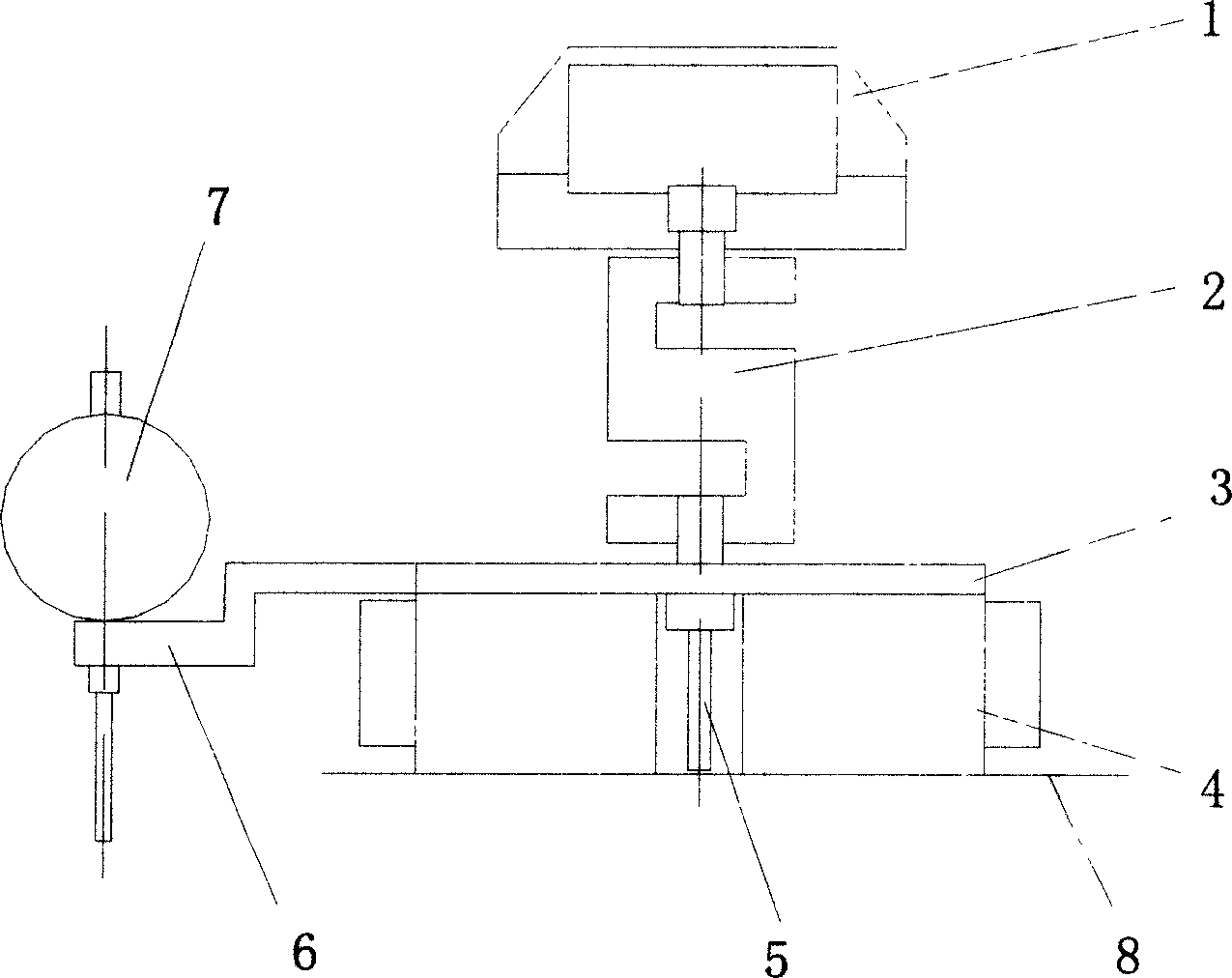

Slab caster two cold nozzle impact measuring system

InactiveCN101187587AMeasuring Impact CharacteristicsAccurate measurementForce measurementStructural/machines measurementSlab casterSignal conditioning

The invention belongs to the metallurgical equipment field, which relates to a testing system for an impact force of a secondary cooling nozzle of a slab caster. The invention is characterized in that a waterproof strain type micro force value sensor (8) is fixed on a sensing shift mechanism, the waterproof strain type micro force value sensor (8) is driven to shift to a testing position through the sensing shift mechanism, a nozzle is fixed on a nozzle shifting mechanism, a nozzle (3) is arranged downwards, the nozzle (3) is shifted to the upper portion of the waterproof strain type micro force value sensor (8) through the nozzle (3) shifting mechanism, the nozzle (3) sprays water, the waterproof strain type micro force value sensor (8) is driven to shift through the sensing shift mechanism, a strain type electric signal is produced by a spraying percussive force in different space which is given by the waterproof strain type micro force value sensor (8), the signal is amplified through a signal conditioner 10, a data which is output by the signal conditioner 10 is transmitted to a data collecting and analyzing unit (11) of a computer, and an inundation distributing graph of three-dimensional water spraying percussive force is given. The invention can accurately measure the percussive force characteristics of a nozzle, which improves measuring accuracy, and reduces measuring cost.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

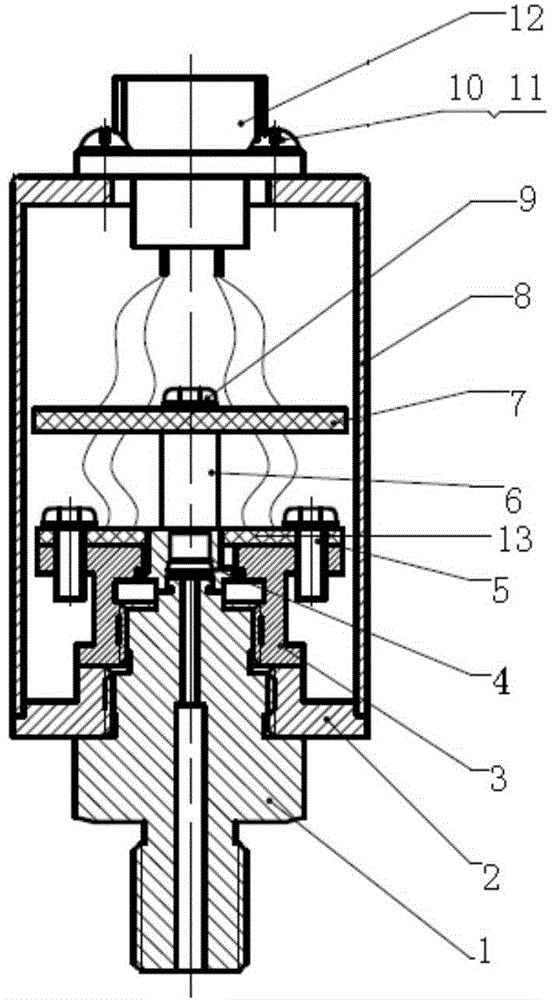

Pressure sensor based on MEMS

ActiveCN104132767ANo damageMeet structural strength requirementsFluid pressure measurement using ohmic-resistance variationElectricitySignal processing circuits

The invention provides a pressure sensor based on MEMS. The pressure sensor based on MEMS comprises a base, a lower cover, a support, a pressure-sensitive core, an insulating pad, a signal processing circuit board, a shell, an electric connector and a lead board. The pressure-sensitive core is based on the sputtered film strain type principle and used for sensing pressure of a medium to be measured and outputting electric signals in proportion to pressure signal changes. A signal processing circuit is a highly integrated sensor signal processing circuit and used for supplying power to the pressure-sensitive core and meanwhile amplifying, calibrating and performing temperature compensation on signals output by the pressure-sensitive core, so that high-precision signal conditioning is achieved. The base and the shell provide connectors to pipelines and used for packaging the pressure-sensitive core and the signal processing circuit board. The pressure sensor is of an integrated structure, high in reliability, small in size, light in weight and suitable for accurately measuring the pressure of a high pressure gas cylinder of a small ultrahigh-pressure cool air propulsion system.

Owner:BEIJING INST OF CONTROL ENG

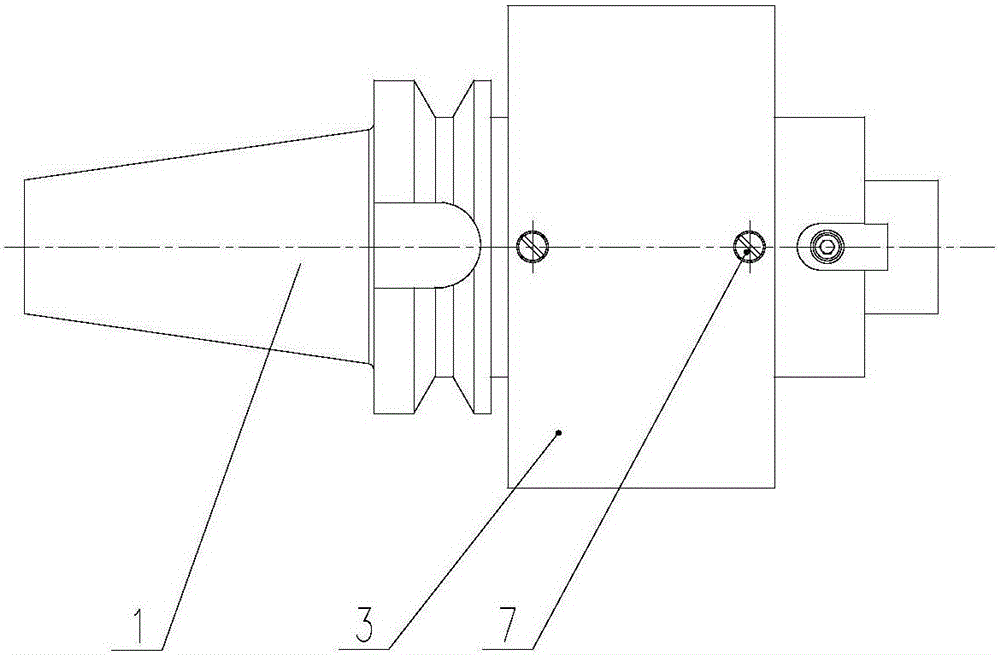

Strain type intelligent handle system for monitoring two-dimensional milling force

InactiveCN106112694ASmall structural changesSimple structureMeasurement/indication equipmentsComputer moduleEngineering

The invention discloses a strain-type intelligent tool handle system for two-dimensional milling force monitoring. The system is mainly composed of a standard tool handle, a circuit carrier, a sealing cover, a power supply module, an acquisition and emission module, and a strain sensor. When the system is working, The circuit carrier, sealing cover, power module, acquisition and emission module, and strain sensor rotate together with the standard tool handle. The power supply module supplies power to the strain sensor and the acquisition and emission module. The Wifi transmission method is transmitted to the host computer terminal for processing and display. The present invention adopts the monitoring scheme of strain sensor, signal collection and transmission assembled on the standard tool handle, which makes little change to the structure of the original tool handle, does not affect the installation and use of the tool and the grasping of the manipulator, and has the advantages of simple structure and strong practicability, etc. It is especially suitable for the cutting of large parts or heavy cutting conditions, which solves the problem that the dynamometer is limited by the size of the parts.

Owner:YANSHAN UNIV

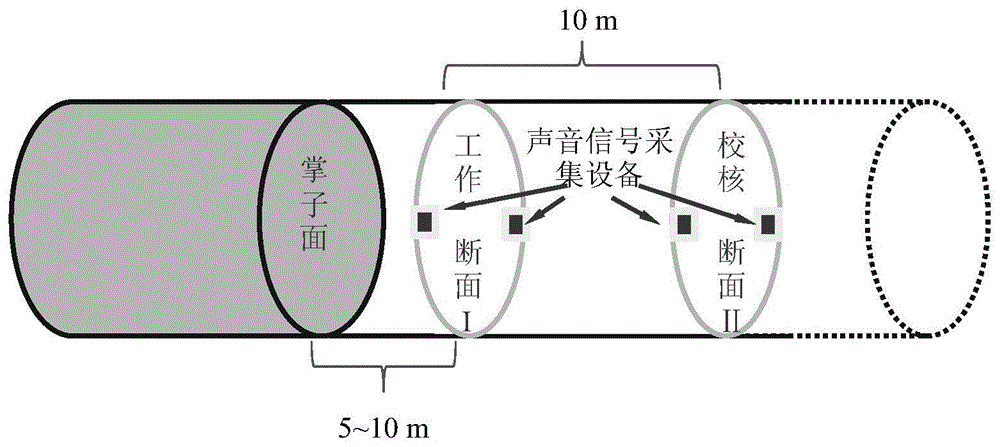

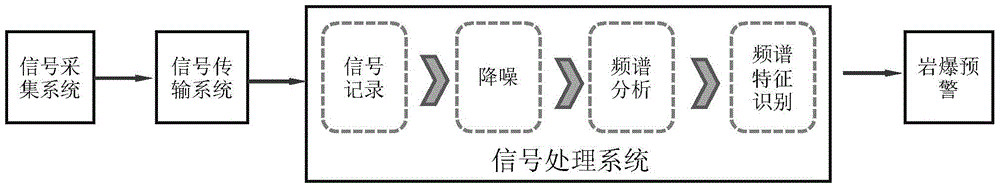

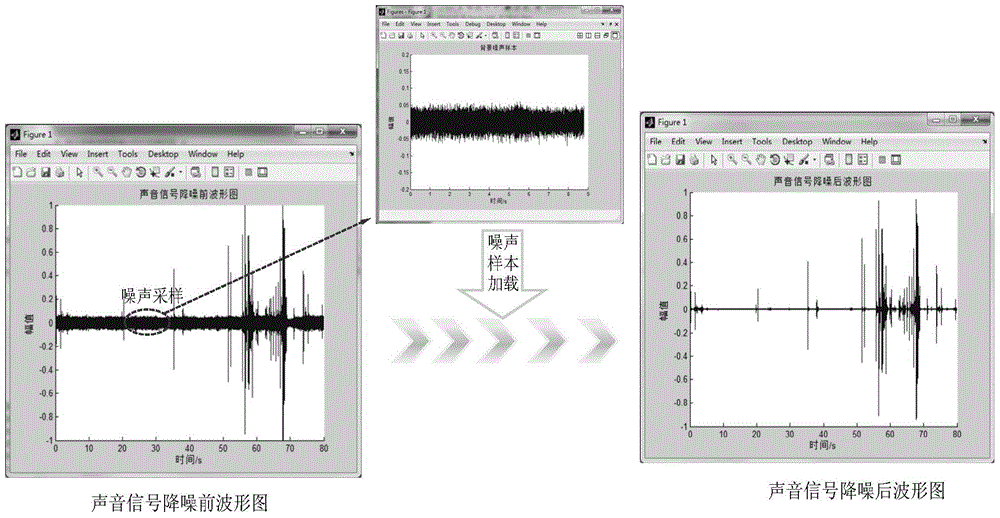

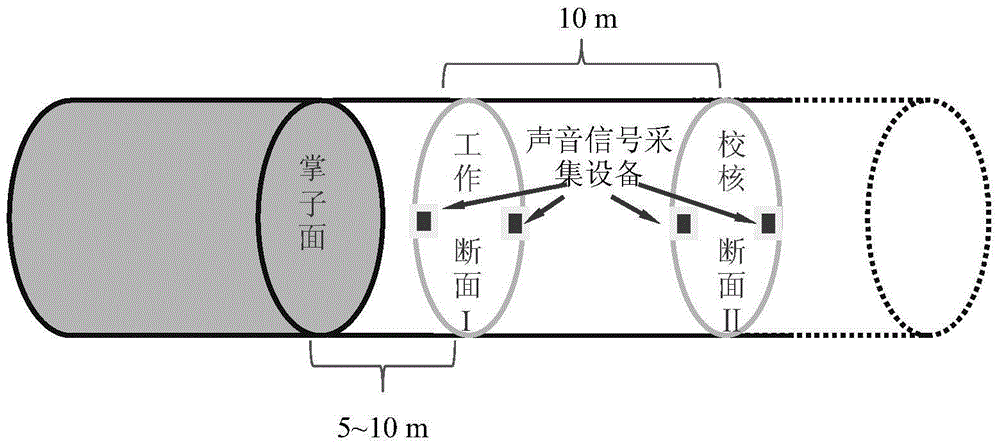

Strain type rockburst early warning method based on acoustic signal spectral analysis

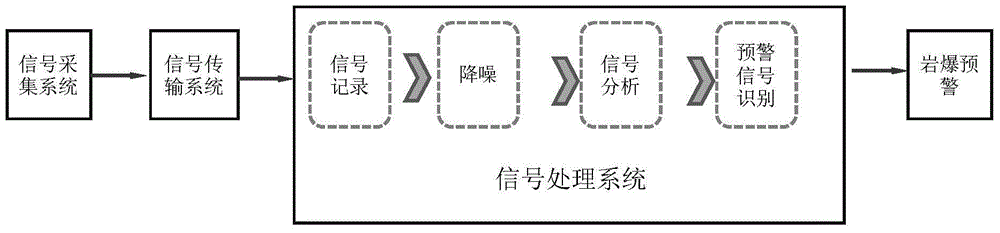

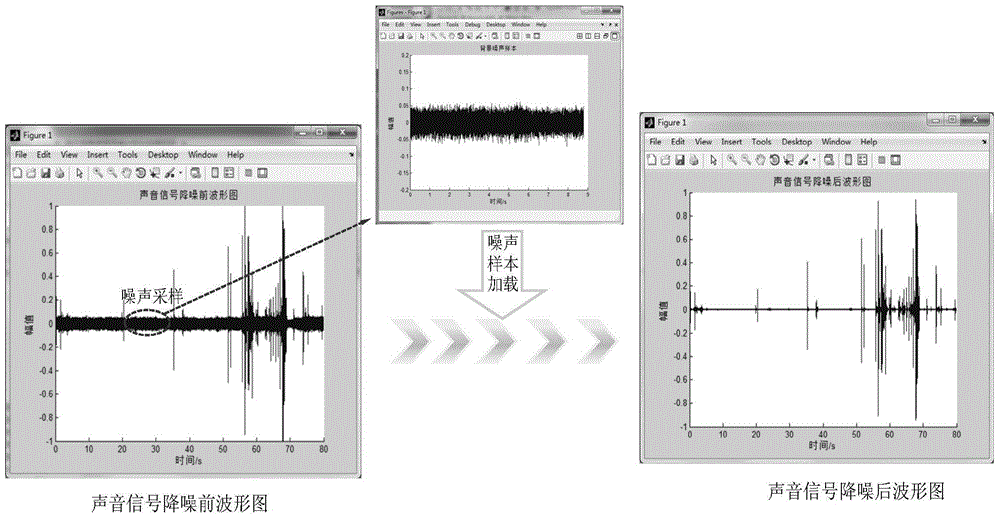

InactiveCN105676267AImprove stabilityReduce adverse effectsSpeech analysisSeismologyFrequency spectrumHandling system

A strain type rockburst early warning method based on acoustic signal spectral analysis includes the following steps: acoustic signal acquisition equipment is utilized to acquire acoustic signals in a strain type rockburst destruction process in real time, the acquired acoustic signals are transmitted to an acoustic signal processing system, and are recorded and analyzed in real time; denoising processing is performed on the acquired acoustic signals first, and then spectral analysis is performed in real time on the acoustic signals after denoising, thereby obtaining an amplitude spectrogram of the acoustic signals; whether the development tendency of strain type rockburst exists is judged by analyzing spectrum characteristics of the acoustic signal, and if ''wideband low-amplitude and multi-peak'' acoustic signals appear later, that a strain rockburst disaster is very likely to happen is predicted, and the acoustic signal processing system gives an alarm at a server terminal. The strain type rockburst early warning method based on acoustic signal spectral analysis belongs to a non-contact real-time monitoring means, and has the advantages of remote controllability, safe installation operation, and reliable and stable signals.

Owner:GUANGXI UNIV

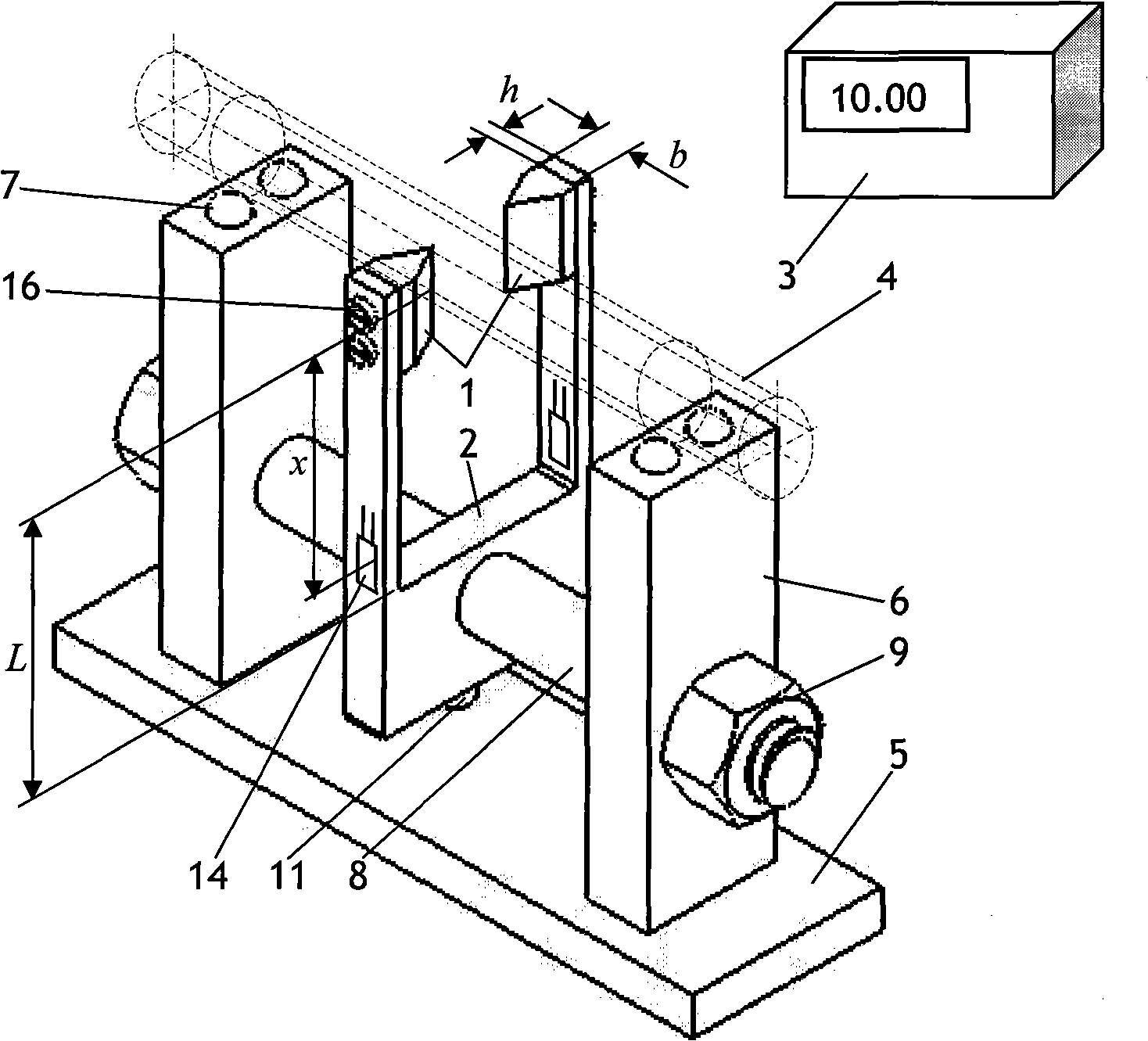

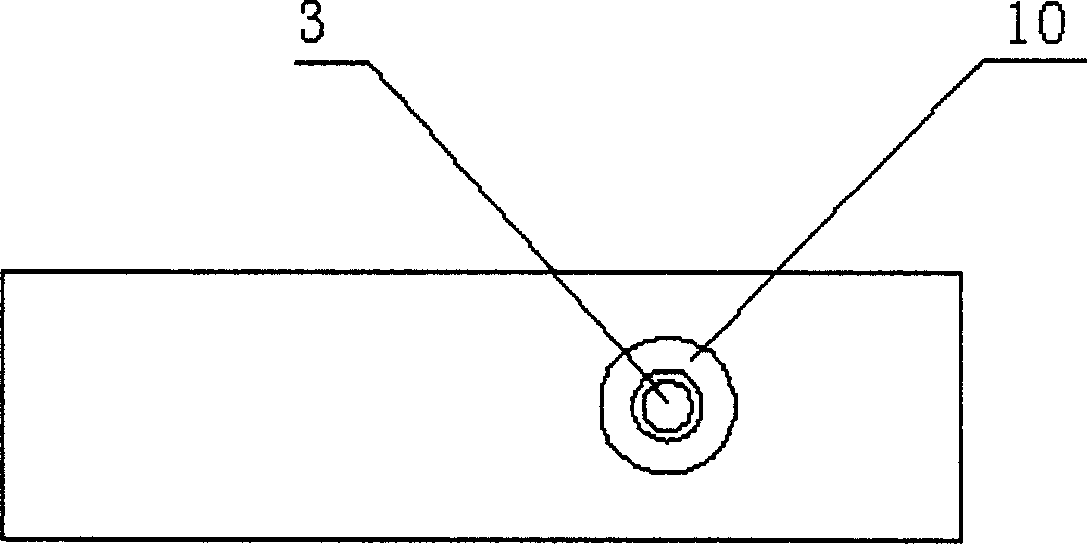

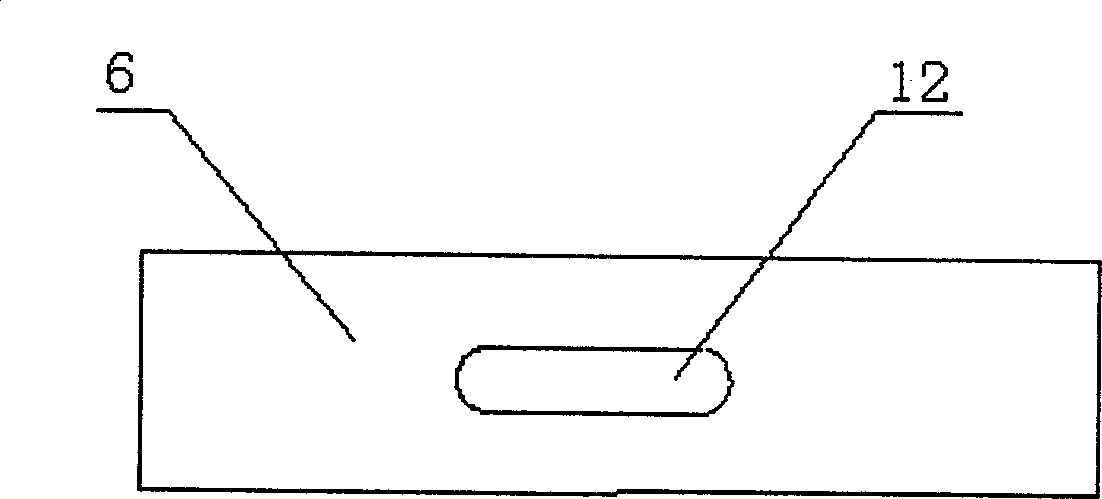

Resistor strain type apparatus for measuring diameter and its use method

InactiveCN101329159APrecise positioningGood repeatabilityElectrical/magnetic diameter measurementsStrength propertiesElectrical resistance and conductanceCantilevered beam

The invention discloses a resistance strain diameter measuring device and a use method thereof. The resistance strain diameter measuring device comprises a resistance strain sensor with a pair of blades and twin cantilever girders, a U-shaped supporting saddle and a resistance strain measuring apparatus. The U-shaped supporting saddle is used for supporting the sensor and providing the locating restriction of a test sample, a cylindrical guide rod is horizontally arranged on the U-shaped supporting saddle, and a locating marble or a V-shaped slot are arranged on the top of the U-shaped supporting saddle. The sensor can be moved on the guide rod, a guide limiting slot is arranged at the bottom of the guide rod, a guide limiting pin is arranged at the bottom of the sensor, and the guide limiting slot and the guide limiting pin are combined, thus leading the blades of the sensor to be located right above the guide rod and rotate around the axial line of the guide rod by small angles; when measuring, the test sample is automatically located between the blades due to self gravity, the cantilever girders are led to generate deflection deformation, and the resistance strain measuring apparatus displays and records the diameter value of the test sample. The resistance strain diameter measuring device of the invention has simple structure, convenient use, high precision and good repeatability, can be conveniently used on line with computers, and consequently is suitable for the digitalizing development requirements of measuring techniques.

Owner:烟台新天地试验技术有限公司

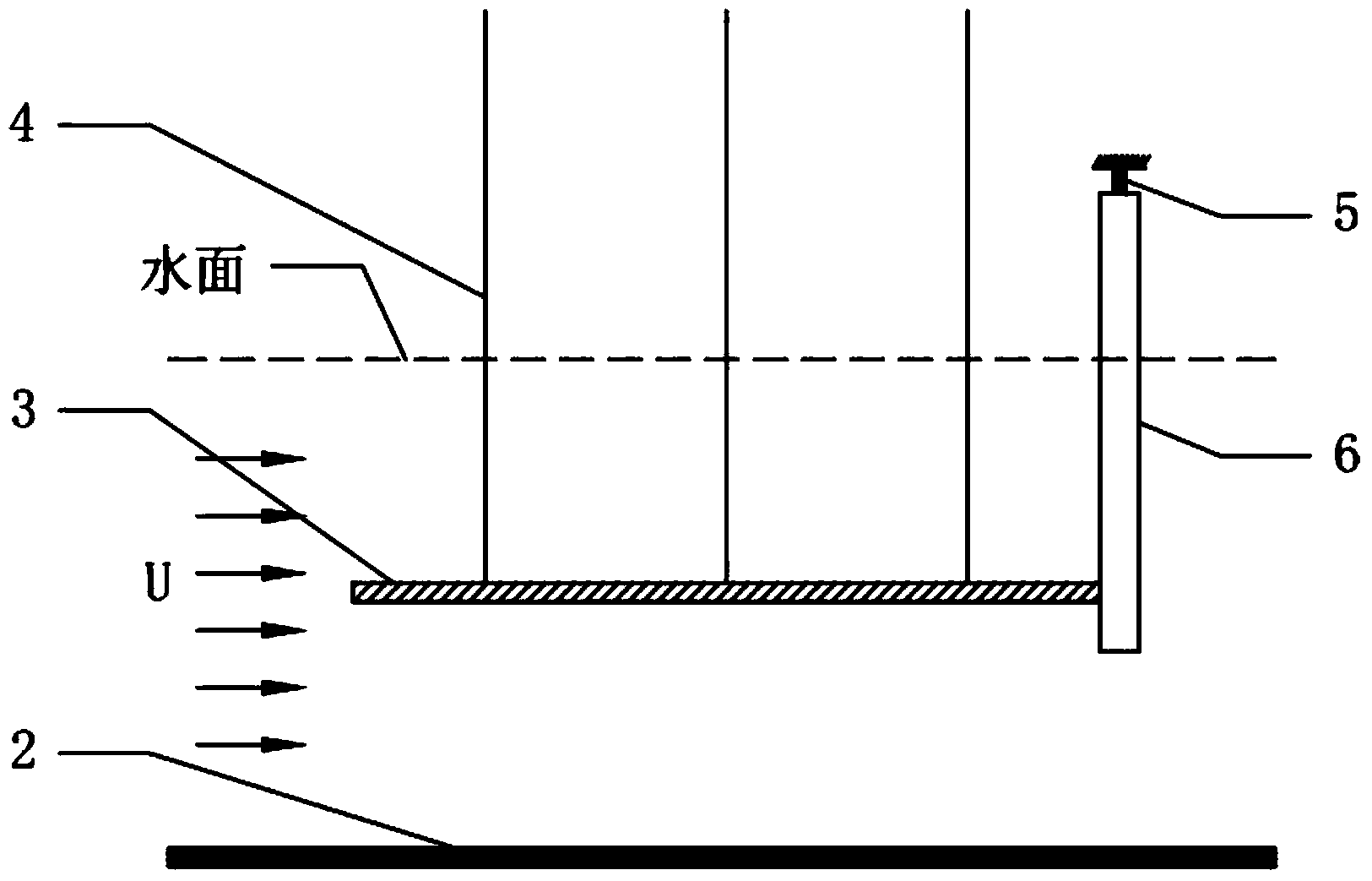

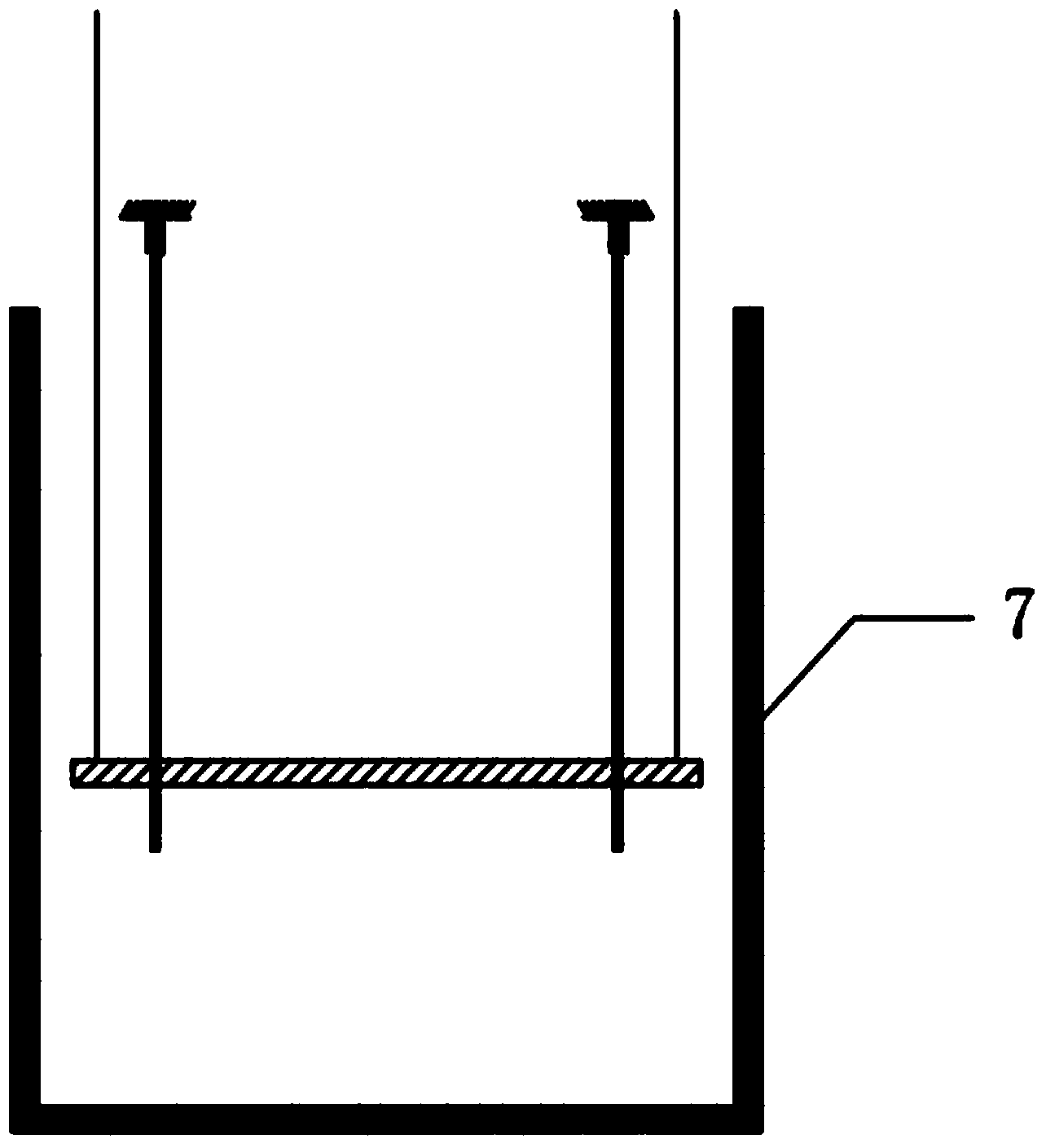

Test device and method for assessing non-smooth surface anti-drag effect

InactiveCN103512724ASimple structureSimple test principleHydrodynamic testingApparatus for force/torque/work measurementVibration measurementLaser light

The invention provides a test device and method for assessing a non-smooth surface anti-drag effect. The device comprises a slab model, a strain type balance supporting force transmission rod, a force measurement element and a laser vibration measurement instrument. The slab model is hung in a water tunnel formed by the water tunnel side wall and the water tunnel bottom wall through steel wire ropes. The lengths of all the steel wire ropes are the same. The tops of the steel wire ropes are at the same height. The strain type balance supporting force transmission rod is vertically arranged in the water tunnel which contains liquid. The front end of the slab model is in contact with the strain type balance supporting force transmission rod. The force measurement element is arranged on the strain type balance supporting force transmission rod. When liquid is static, the reading of the force measurement element is zero. The laser vibration measurement instrument is arranged facing the steel wire ropes. Laser light paths generated by the laser vibration measurement instrument are parallel to the slab model which comprises a smooth surface slab and a non-smooth surface slab to be assessed. According to the test device and method, the test principle is simple, the evaluation method is visual, test results are reliable, and operation is convenient.

Owner:HARBIN ENG UNIV

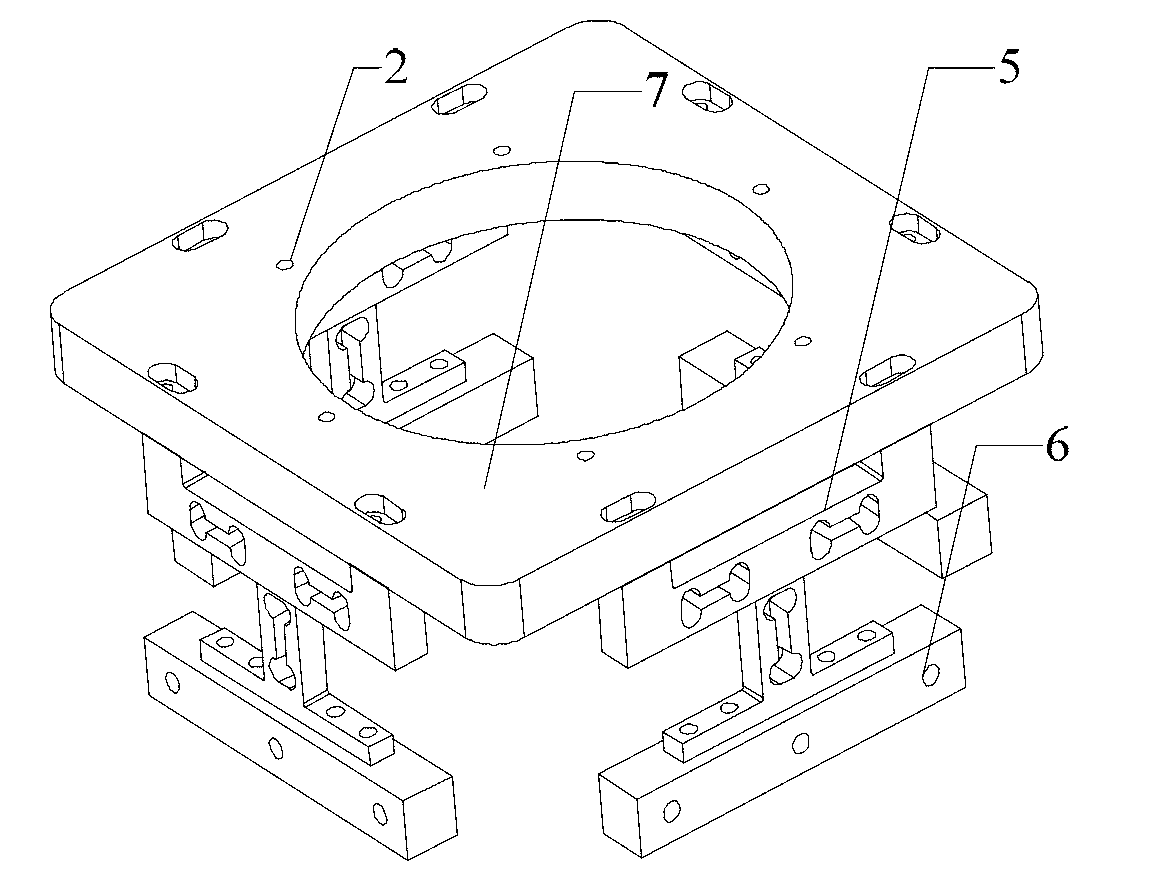

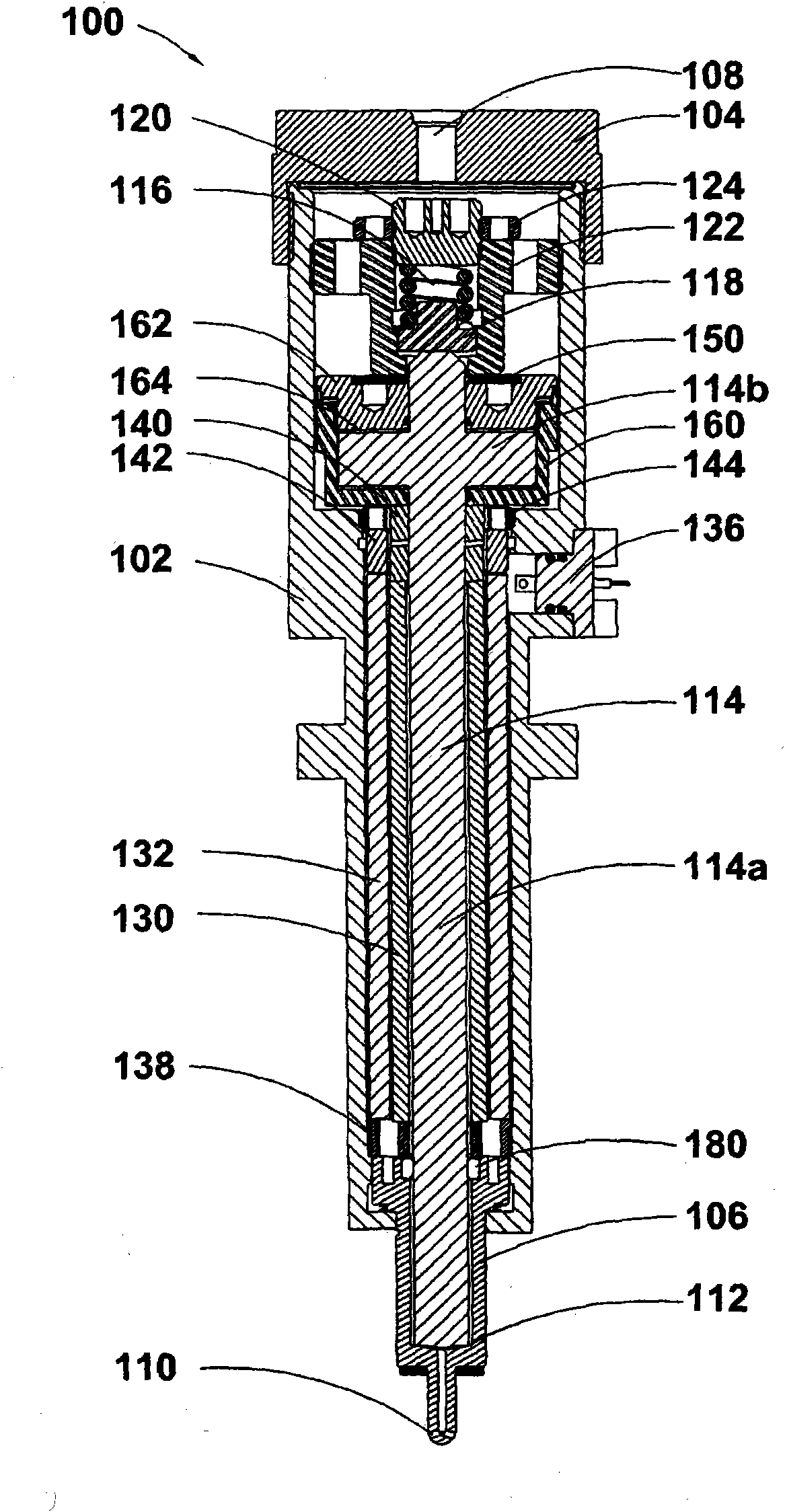

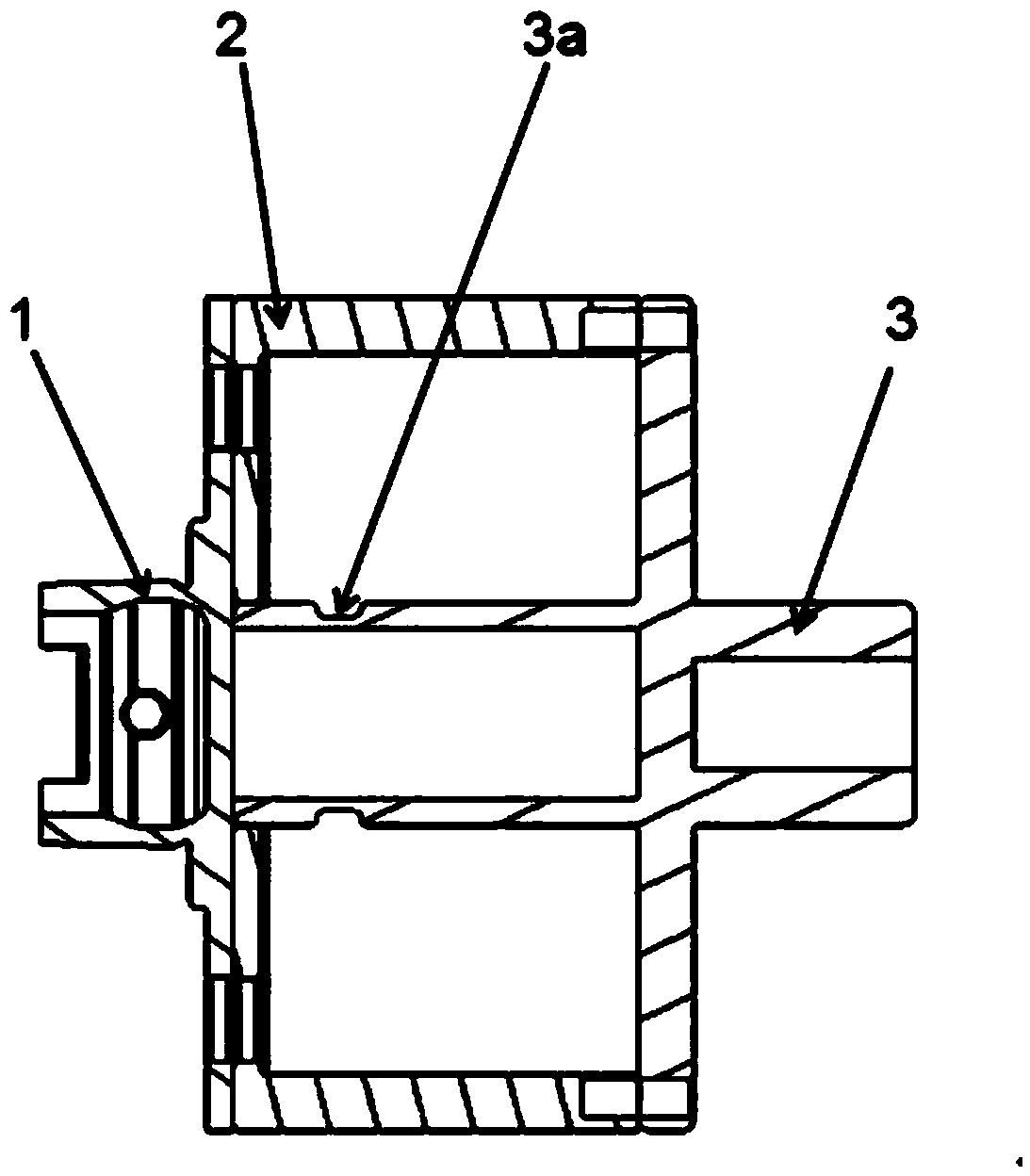

High-precision strain type torque sensor

ActiveCN103471751AOvercome the disadvantage of insufficient low frequency signalHigh precisionWork measurementTorque measurementFull bridgeData acquisition

The invention provides a high-precision strain type torque sensor which comprises two changeover plates (1), four strain columns (2), strain pieces (3), a dynamic strain meter (4) and a data acquisition and processing system (5). The four strain columns (2) and the upper and the lower changeover plates (1) are fixed. The strain columns (2) are of square column structures, each strain column is provided with two semi-circular grooves, the strain pieces (3) are pasted on the backs, above the semi-circular grooves, of the two symmetrical strain columns (2), and the four strain pieces (3) are pasted totally. In the testing process, one changeover plate (1) is fixed, a vibration source is arranged in the center of the other changeover plate (1), and four kinds of strain generated by the four strain pieces (2) form a full-bridge. The dynamic strain meter (4) converts the strain generated by the strain pieces (3) into dynamic voltage signals. The data acquisition and processing system (5) collects the dynamic voltage signals, and torque is obtained according to the dynamic voltage signals.

Owner:BEIJING INST OF SPACECRAFT SYST ENG +1

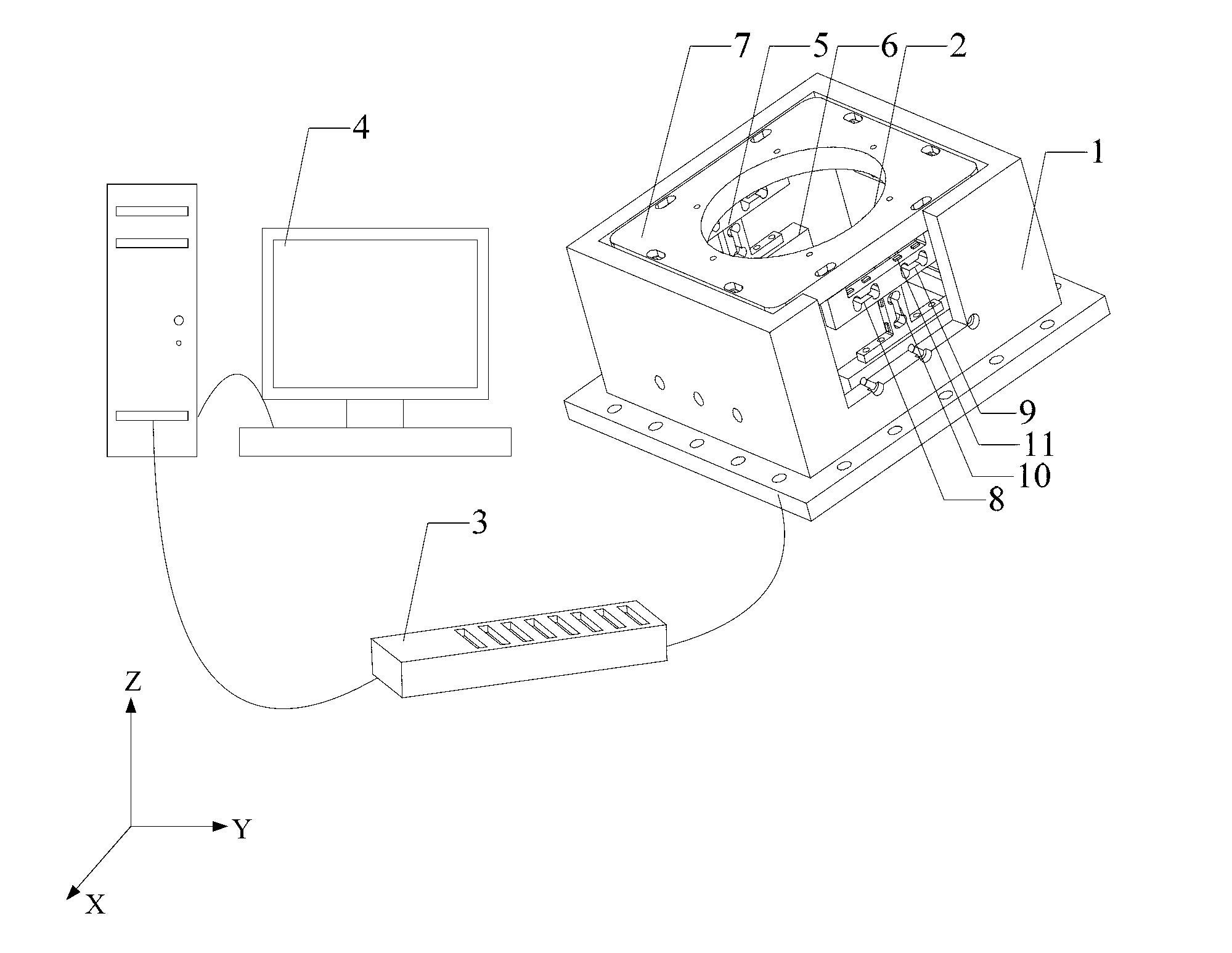

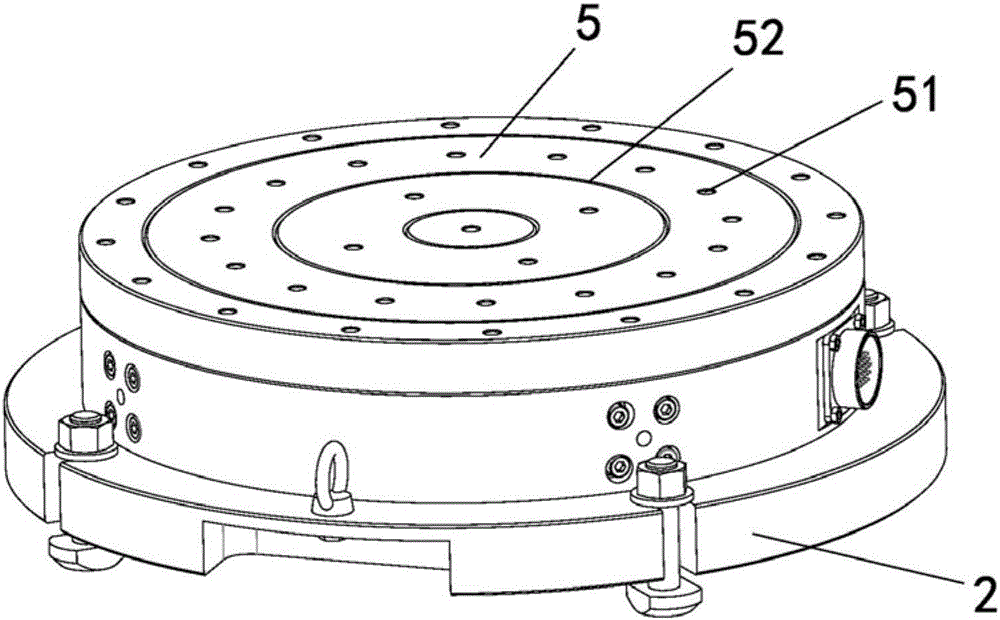

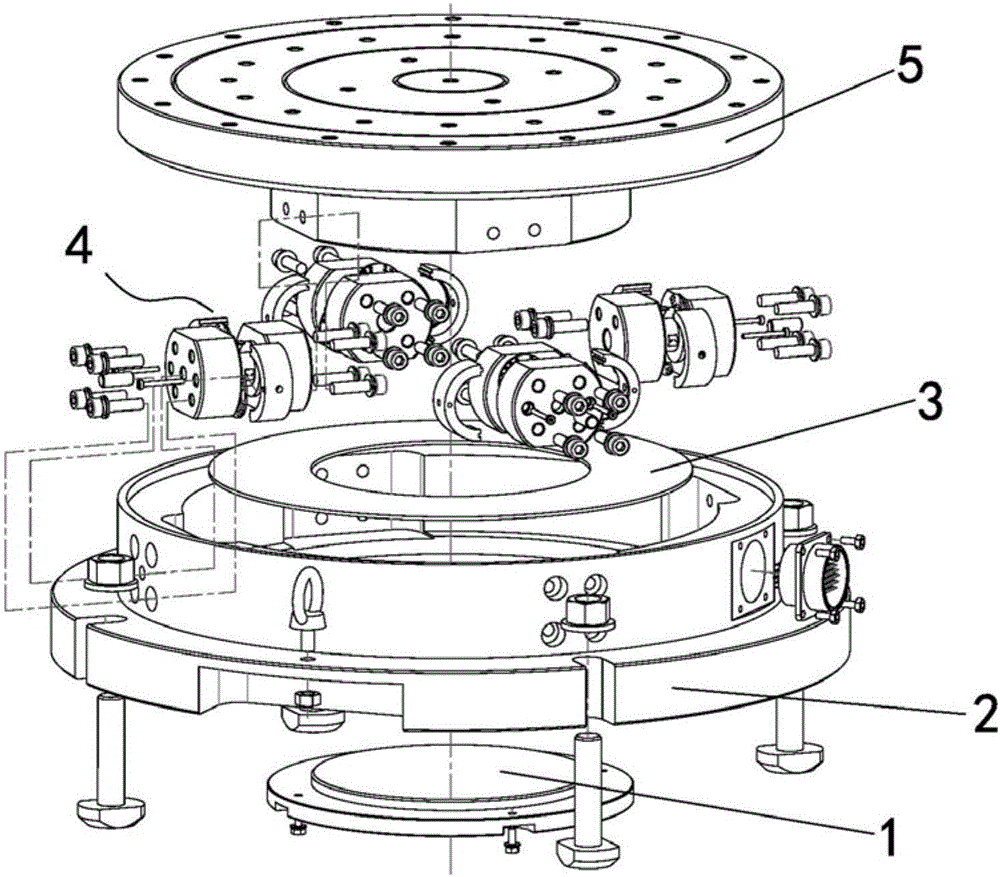

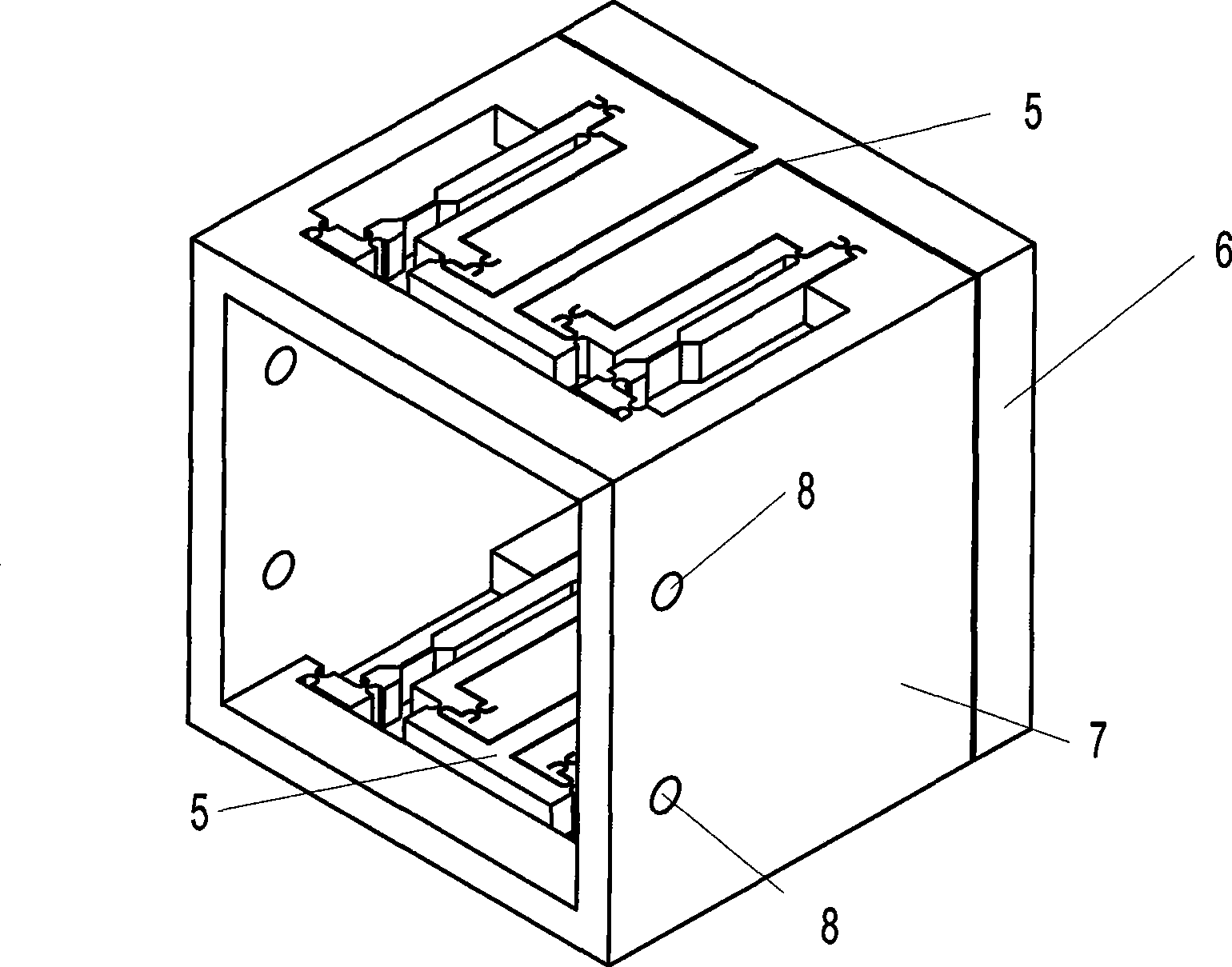

Ultra-low frequency high-accuracy micro-vibration measuring system

InactiveCN103323097AOvercoming the lack of a high-precision three-way sensorHigh measurement accuracySubsonic/sonic/ultrasonic wave measurementUsing electrical meansVibration measurementFull bridge

The invention discloses an ultra-low frequency high-accuracy micro-vibration measuring system which is composed of a base, four adapter blocks, four strain-type force sensors, a load disc, a dynamic strain indicator, 48 strain gages and a data collecting and processing system. The strain gages are pasted on the strain-type force sensors. The strain-type force sensors are located between the load disc and the adapter blocks and are connected between the load disc and the adapter blocks in a tightened mode through bolts. The adapter blocks are located on the side surface of the base and connected with the side surface of the base in a tightened mode through bolts. Three dynamic forces and three dynamic force moments of a disturbance source are measured through the fact that the strain gages pasted on the strain-type force sensors are reasonably combined and connected with the dynamic strain indicator to form 12 full bridge circuits. The disturbance source can be installed inside the measuring system and can also be installed outside the measuring system. The strain gages are connected with the dynamic strain indicator through wires. The dynamic strain indicator is connected with the data collecting and processing system through a wire. The ultra-low frequency high-accuracy micro-vibration measuring system can accurately measure the vibratory force and the vibratory force moment of a tiny disturbance source, the measured frequency range is accurate to 0Hz, and the measuring reliability is high.

Owner:BEIHANG UNIV

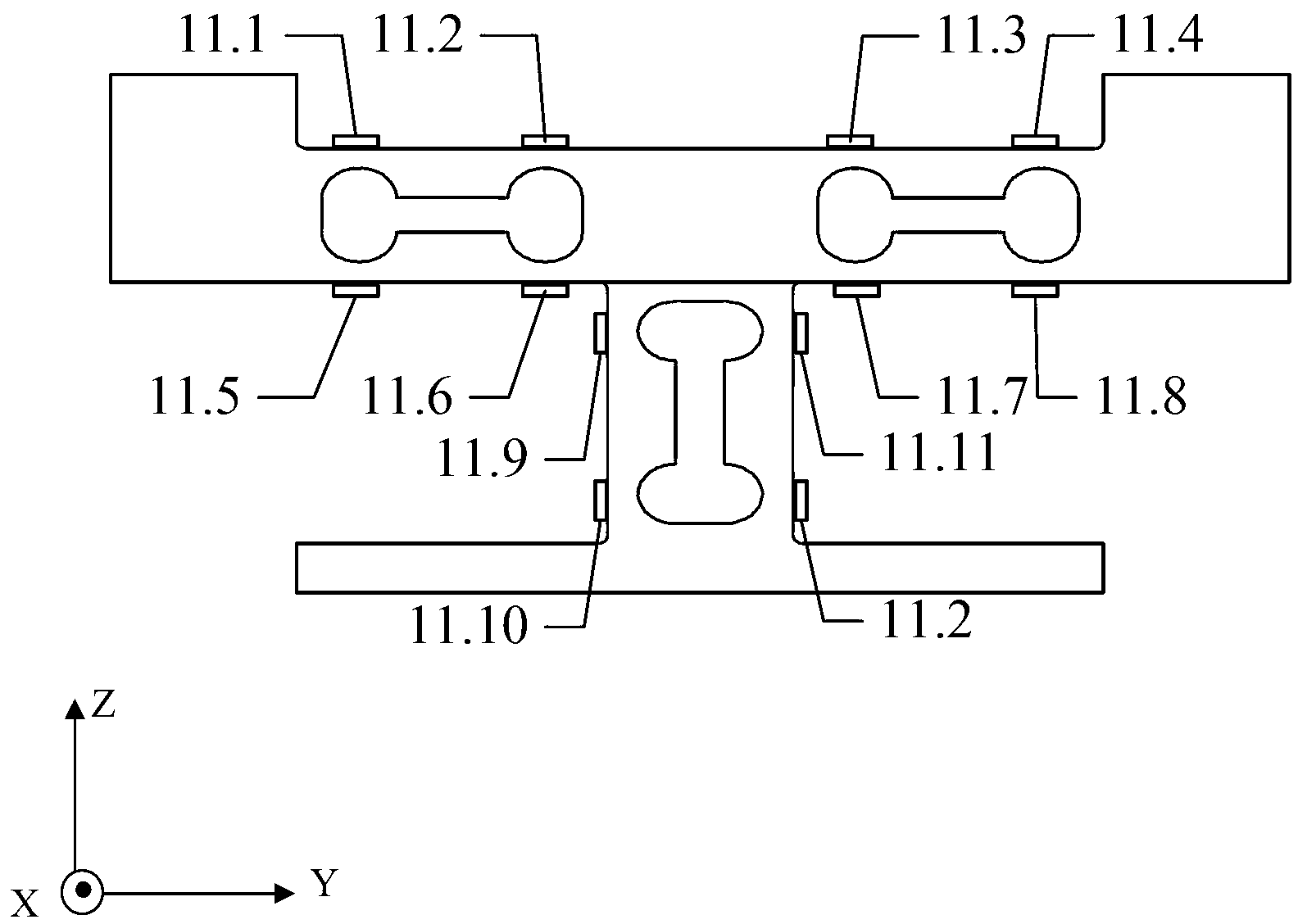

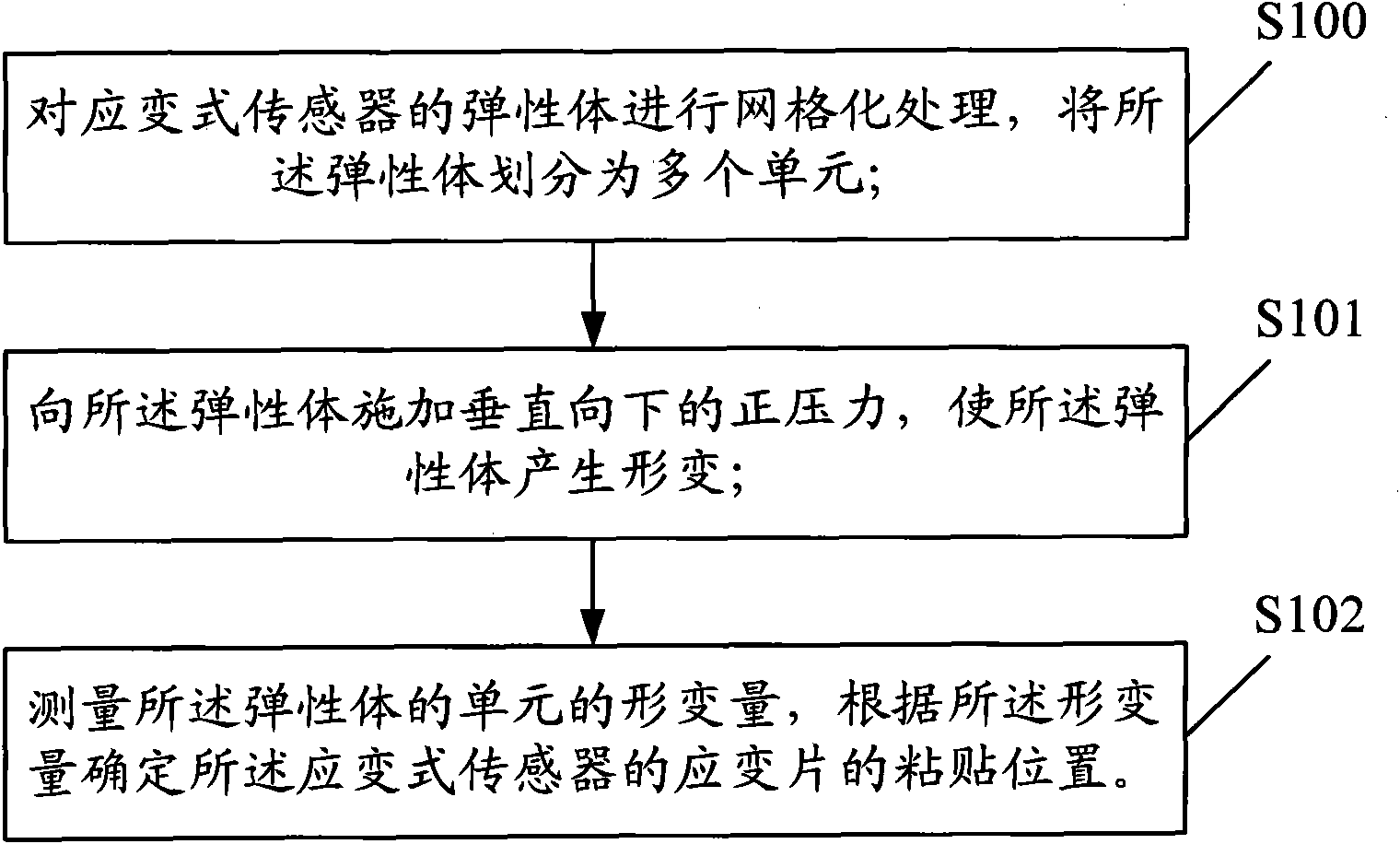

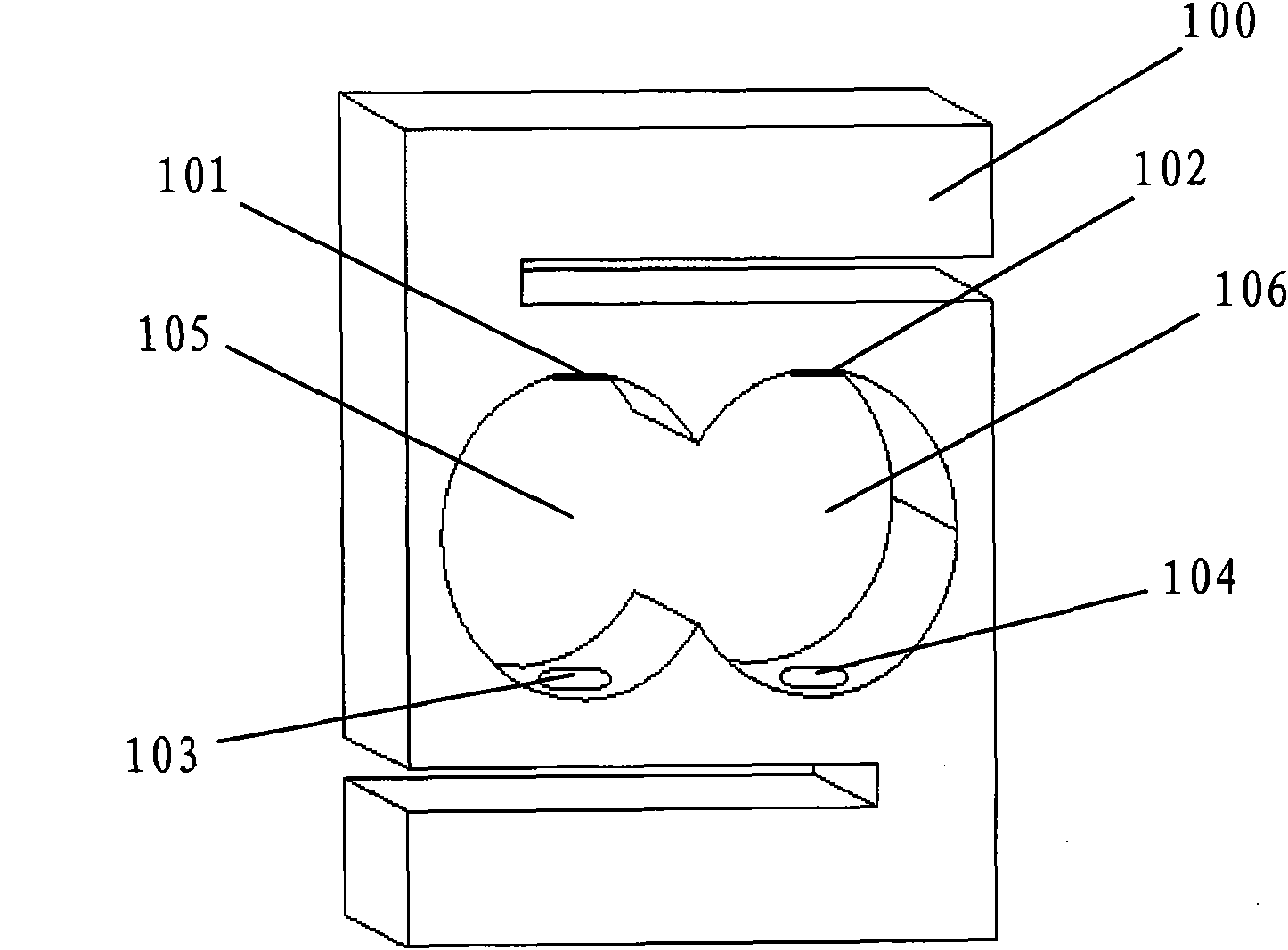

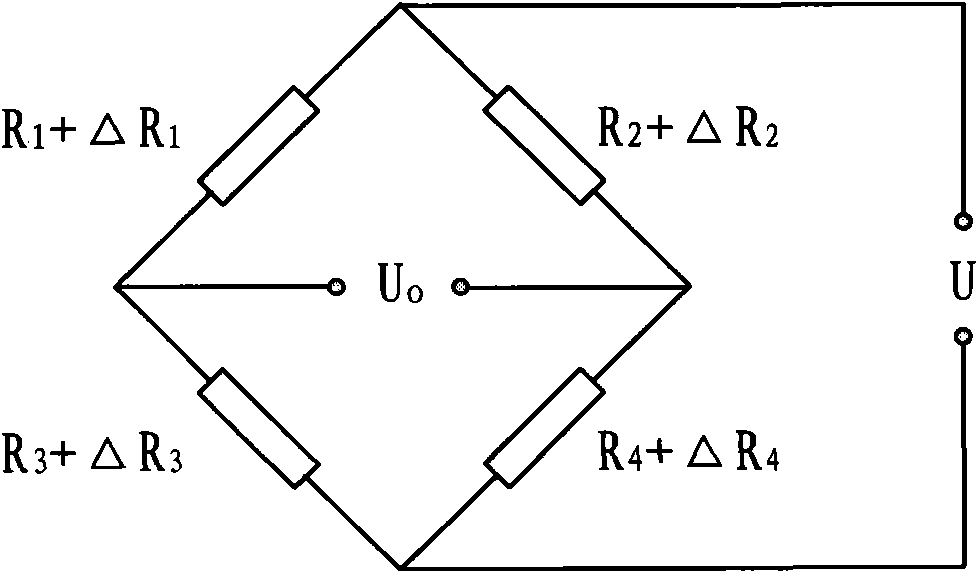

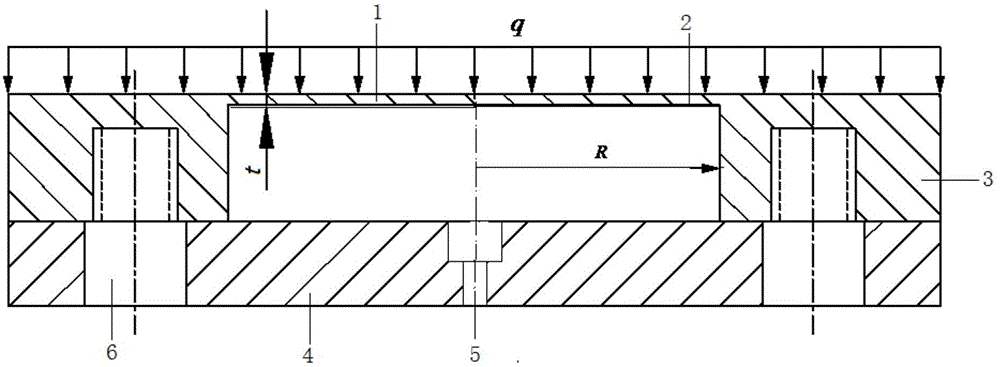

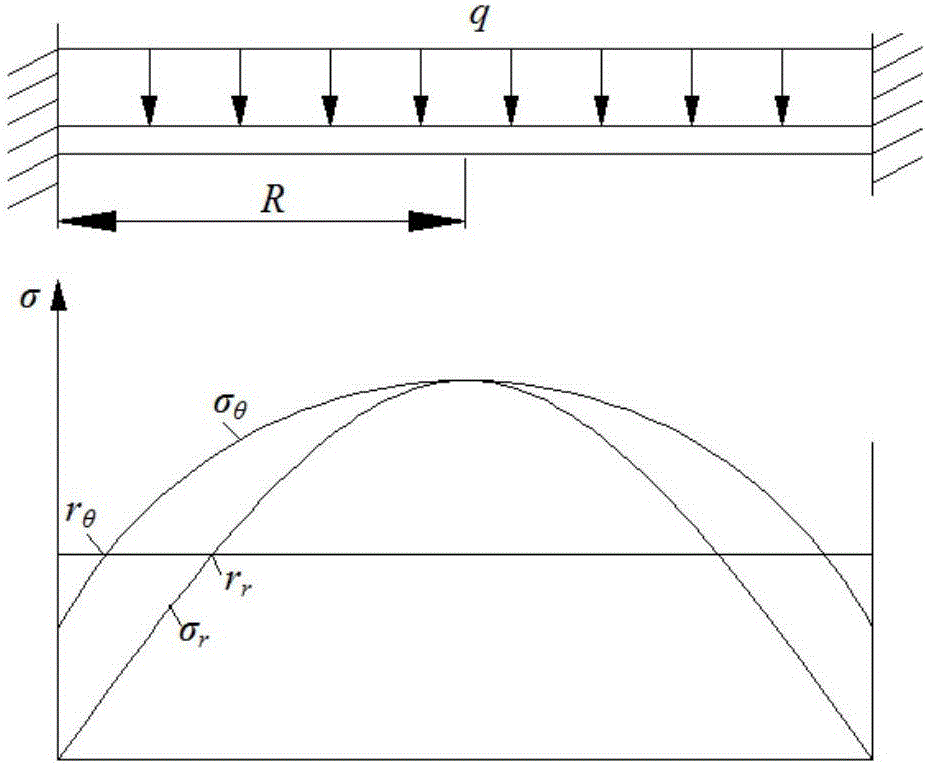

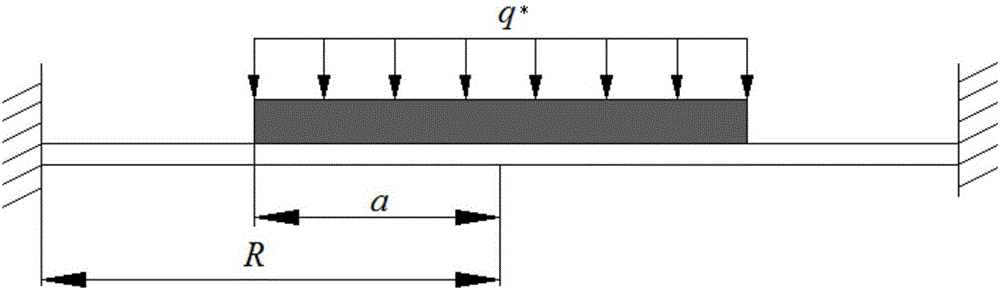

Method for determining paste position of strain gauge of sensor

ActiveCN101608960AReduce distractionsHigh measurement accuracyForce measurementWeighing apparatus for continuous material flowElastomerPositive pressure

The invention discloses a method for determining a paste position of a strain gauge of a sensor. The method comprises the following steps: carrying out gridding treatment on an elastomer of a strain type sensor to divide the elastomer into a plurality of units; applying a vertically downward positive pressure to the elastomer to cause the elastomer to deform; measuring the unit deformation amount of the elastomer; and determining the paste position of the strain gauge of the strain type sensor according to the deformation amount. By adopting the embodiment of the invention, the measurement precision of the strain type sensor can be improved.

Owner:广州粤能电力科技开发有限公司

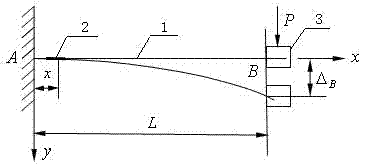

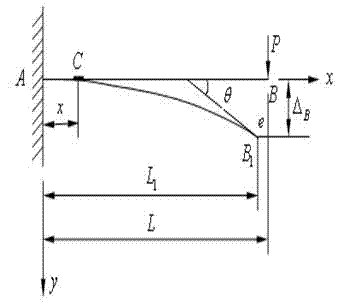

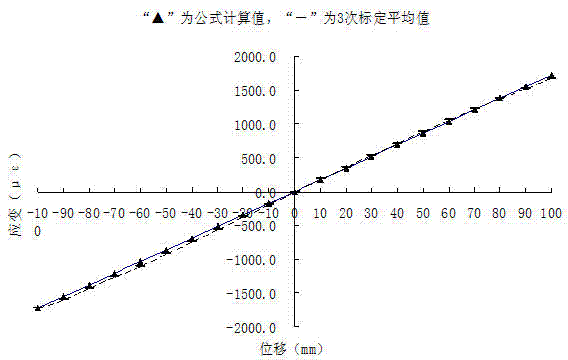

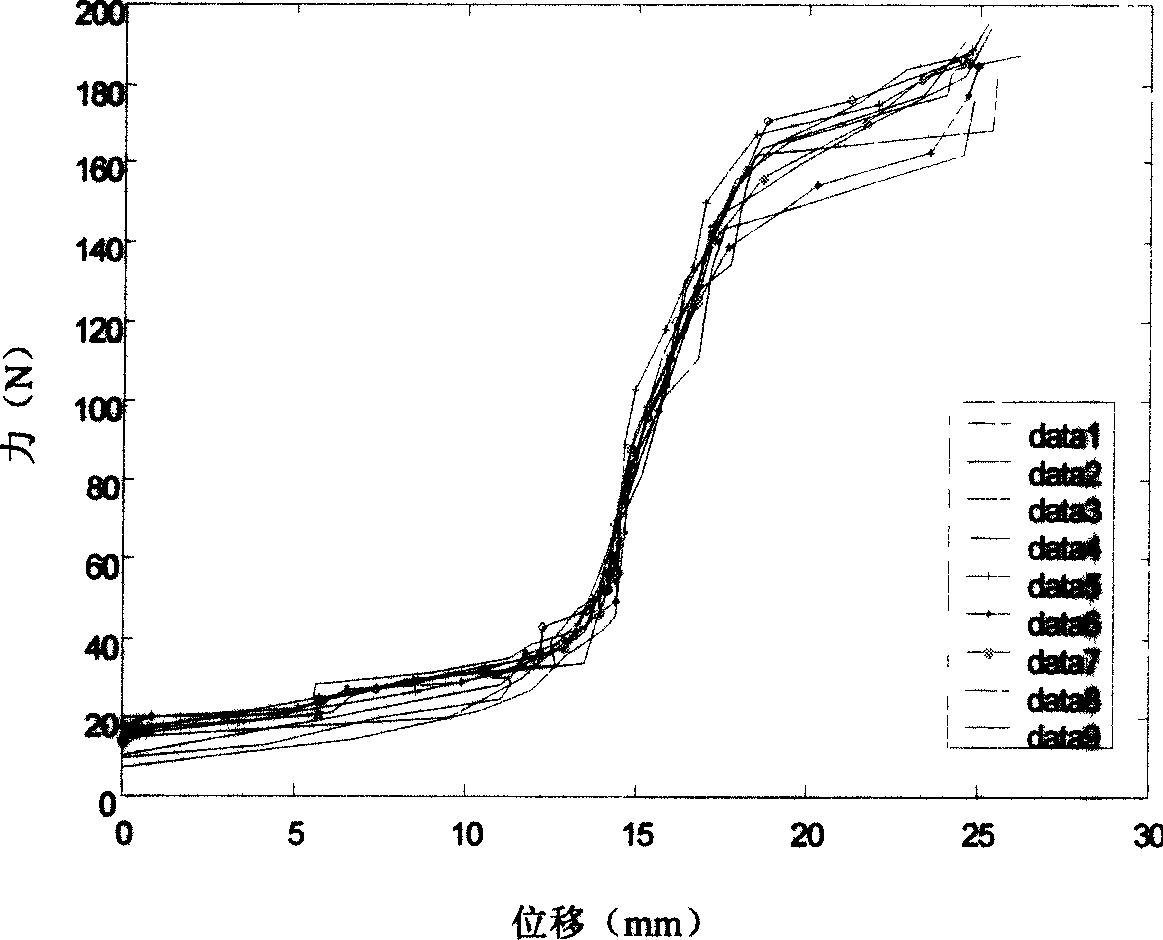

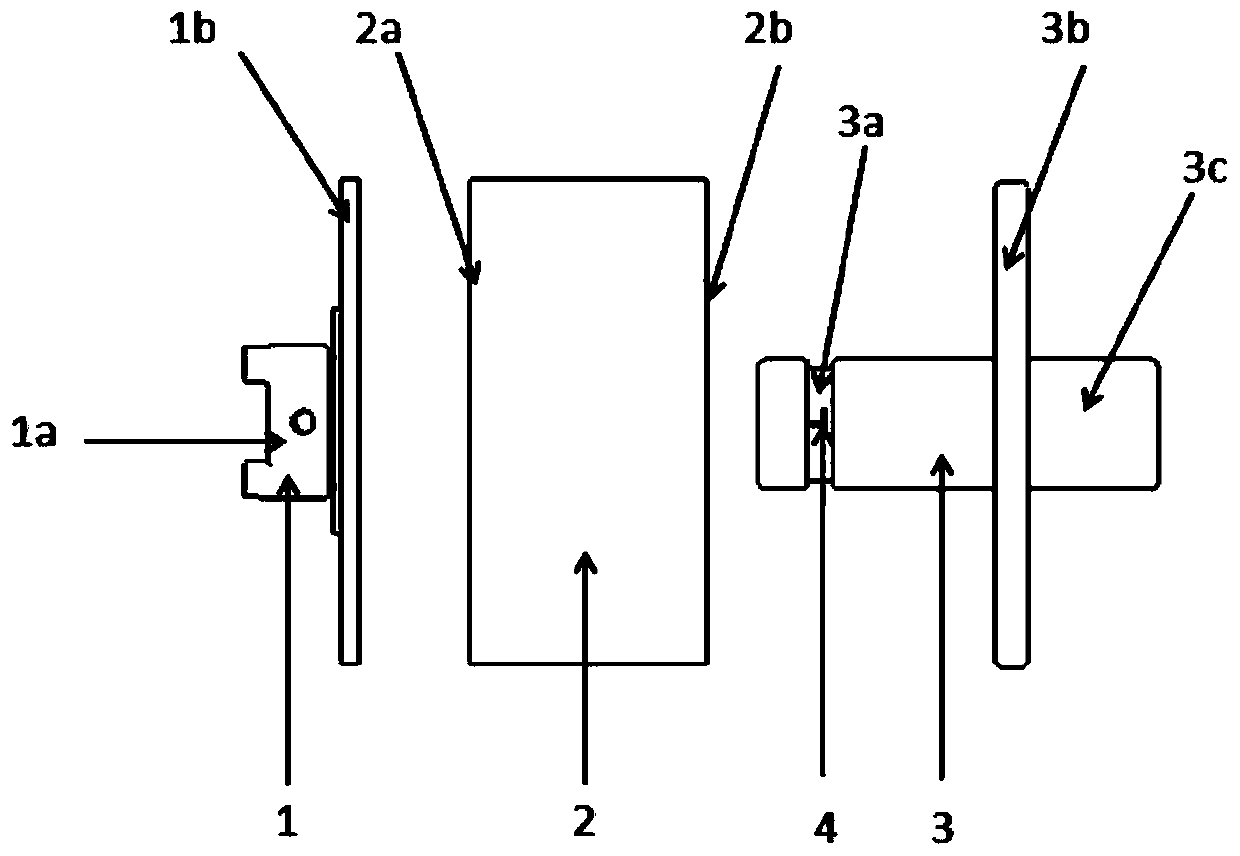

Strain type linear bidirectional large displacement sensor and detection method thereof

InactiveCN103090778ASolve the nonlinear problem of measuring large displacementSolve nonlinear problemsUsing electrical meansStrain typeEngineering structures

The invention discloses a strain type linear bidirectional large displacement sensor and a detection method of the strain type linear bidirectional large displacement sensor. According to the strain type linear bidirectional large displacement sensor, a strain sheet is arranged on a displacement strain conversion beam to form a bridge circuit which is connected with a strain gauge, a fixed end of the displacement strain conversion beam is fixed on a detection point, and a freed end of the displacement strain conversion beam is inserted into a rigid guide groove and fixed at a reference position. According to the detection method of the strain type linear bidirectional large displacement sensor, when the detection point moves, the displacement of the rigid guide groove is in linear relation with the strain at the position of the strain sheet on the displacement strain conversion beam, strain values during the movement of the detection point are recorded through the strain gauge, and the displacement value of the detection point is determined through the recorded strain values according to a marked relational expression between the strain and the displacement. The strain type linear bidirectional large displacement sensor is simple in structure, good in repeatability, high in sensitivity, convenient to manufacture and install, low in cost, and suitable for detection and tests in an engineering structure, especially the measurement of large displacement of the engineering structure and components of the engineering structure.

Owner:TAIYUAN UNIV OF TECH

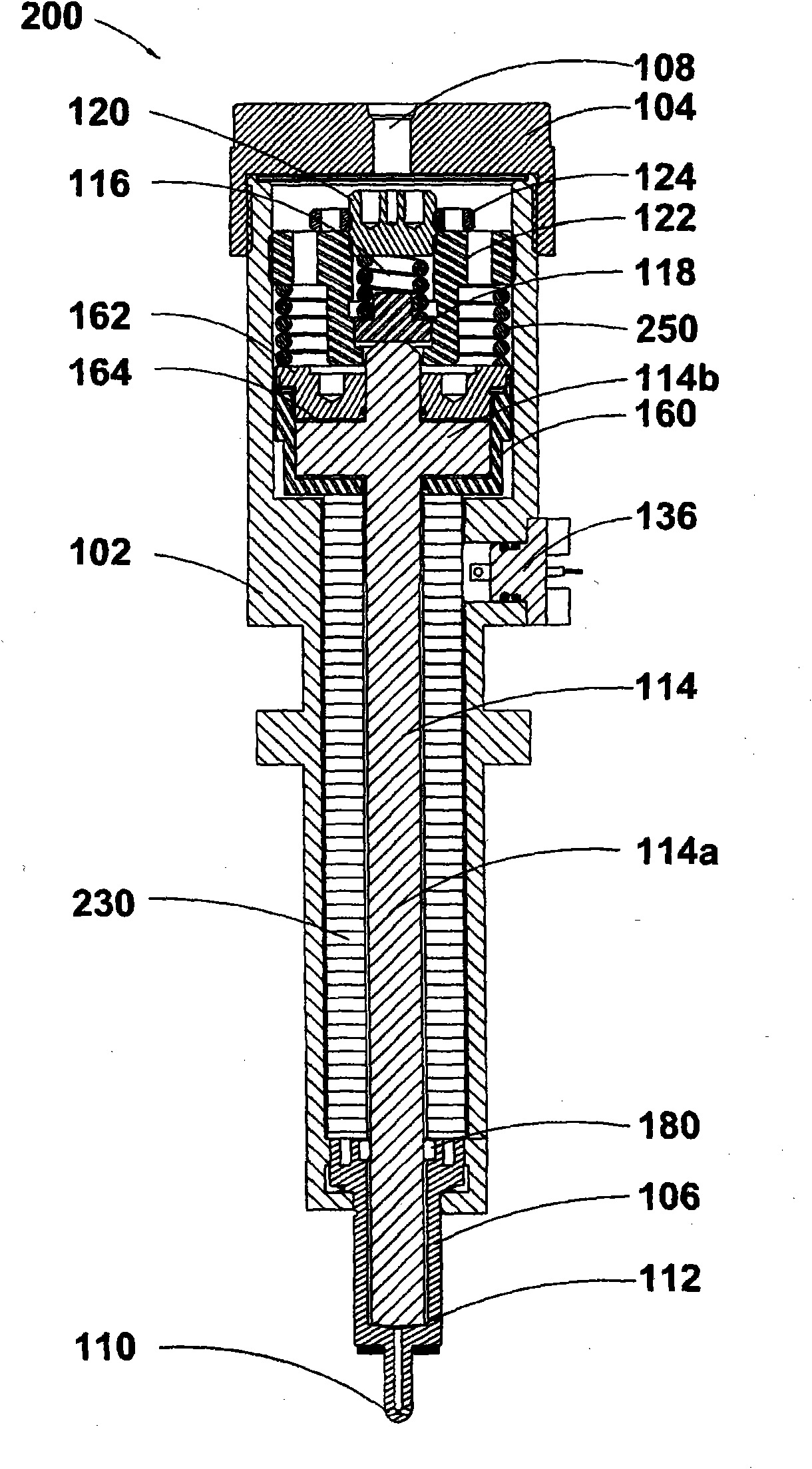

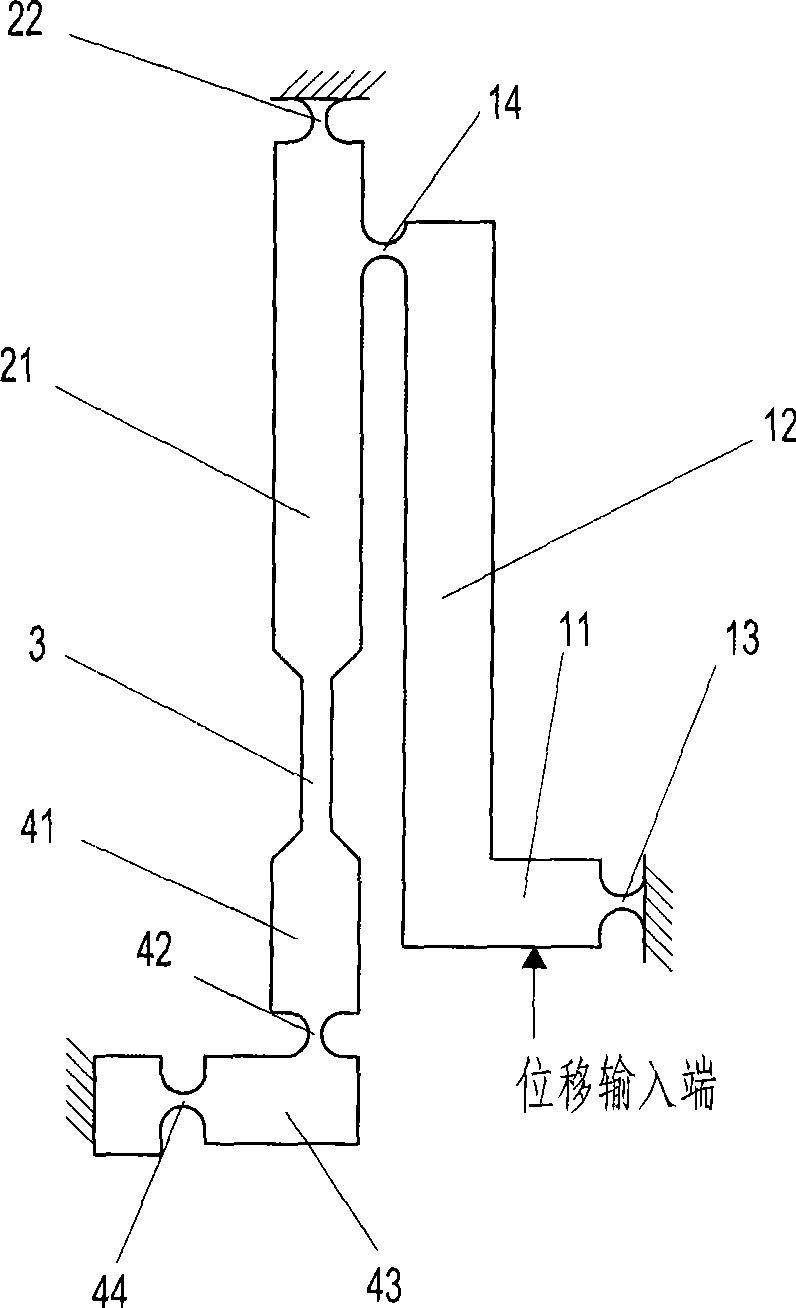

Directly actuated valve with a strain-type actuator and a method of operating same

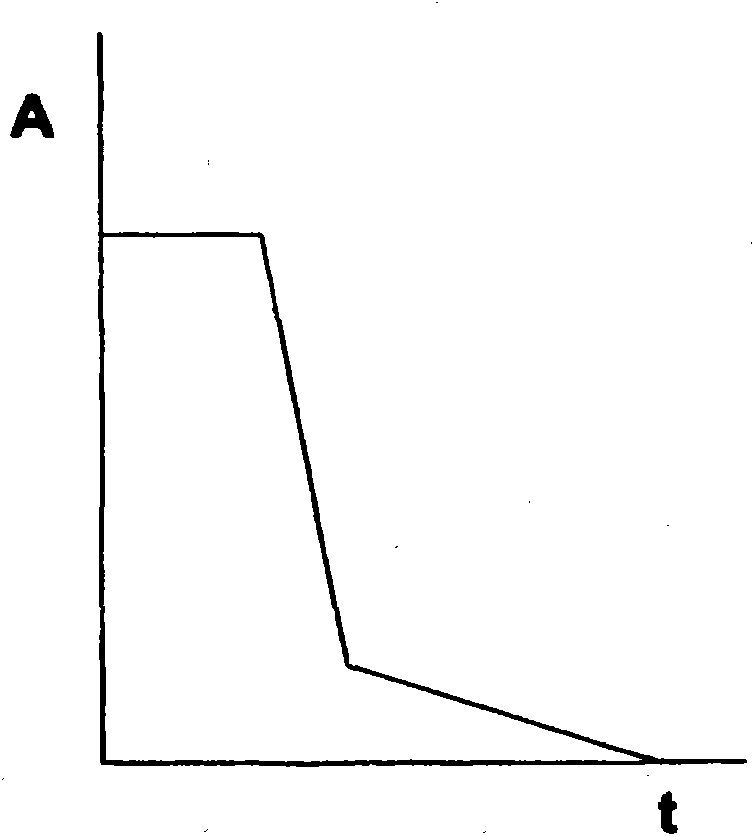

ActiveCN101861487AReduce the amplitudeElectrical controlOperating means/releasing devices for valvesEngineeringActuator

Disclosed is a method of operating a directly actuated valve that comprises a strain-type actuator to actuate a valve member to travel between a closed position and an open position, the method comprising transmitting displacements from the strain-type actuator to the valve member, maintaining a compressive stress on the actuator that is greater than a predetermined minimum stress by applying a pre-load compressive stress and limiting to less than predetermined limits at least one of: (a) acceleration and deceleration of the valve member when moving between open positions and the closed position; and (b) velocity of said valve member immediately before contacting the valve seat. One of the preferred techniques for limiting the velocity of the valve member while also reducing the amount offluid that flows through the valve during the closing time, comprises changing the closing rate of the valve member so that the valve member travels most of the closing distance quickly during the beginning of a closing movement, and then slowing down the closing rate of the valve member in a second portion of the closing movement, so that the velocity of the valve member is less than a predetermined limit immediately before contacting the valve seat.

Owner:WESTPORT POWER

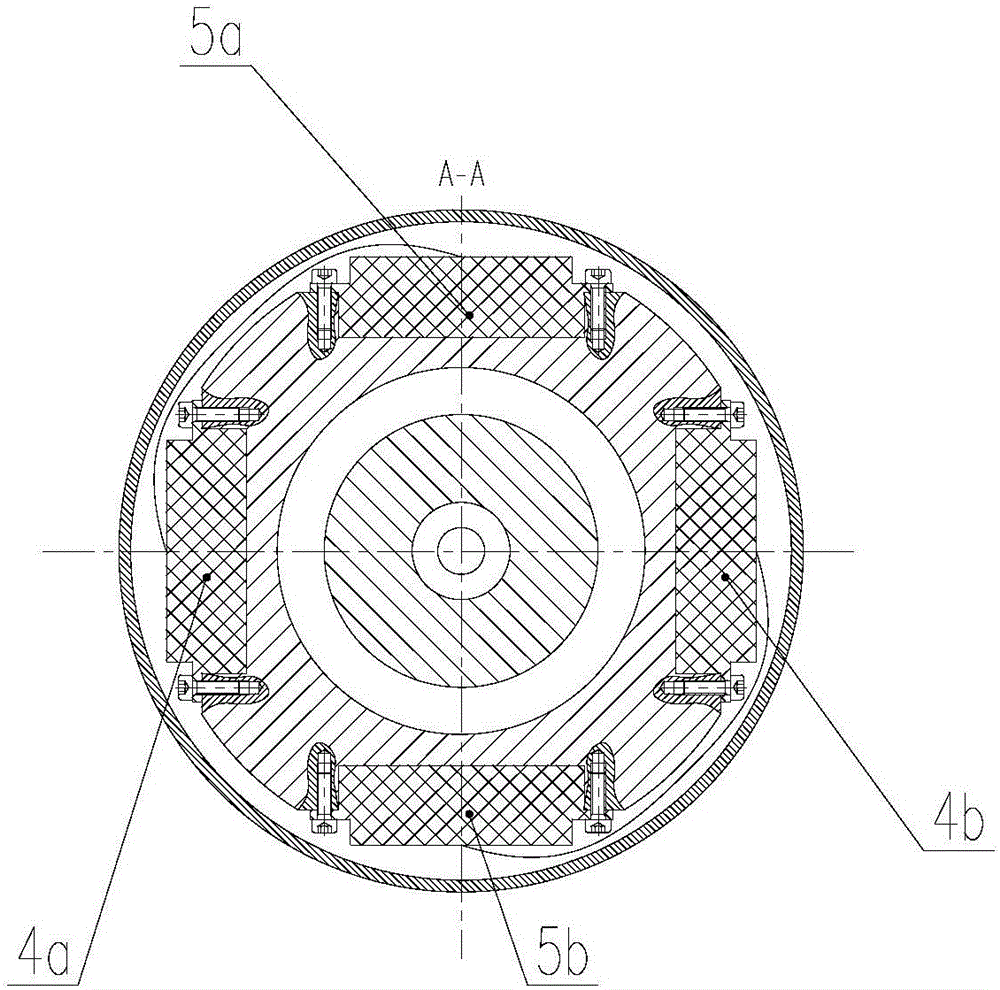

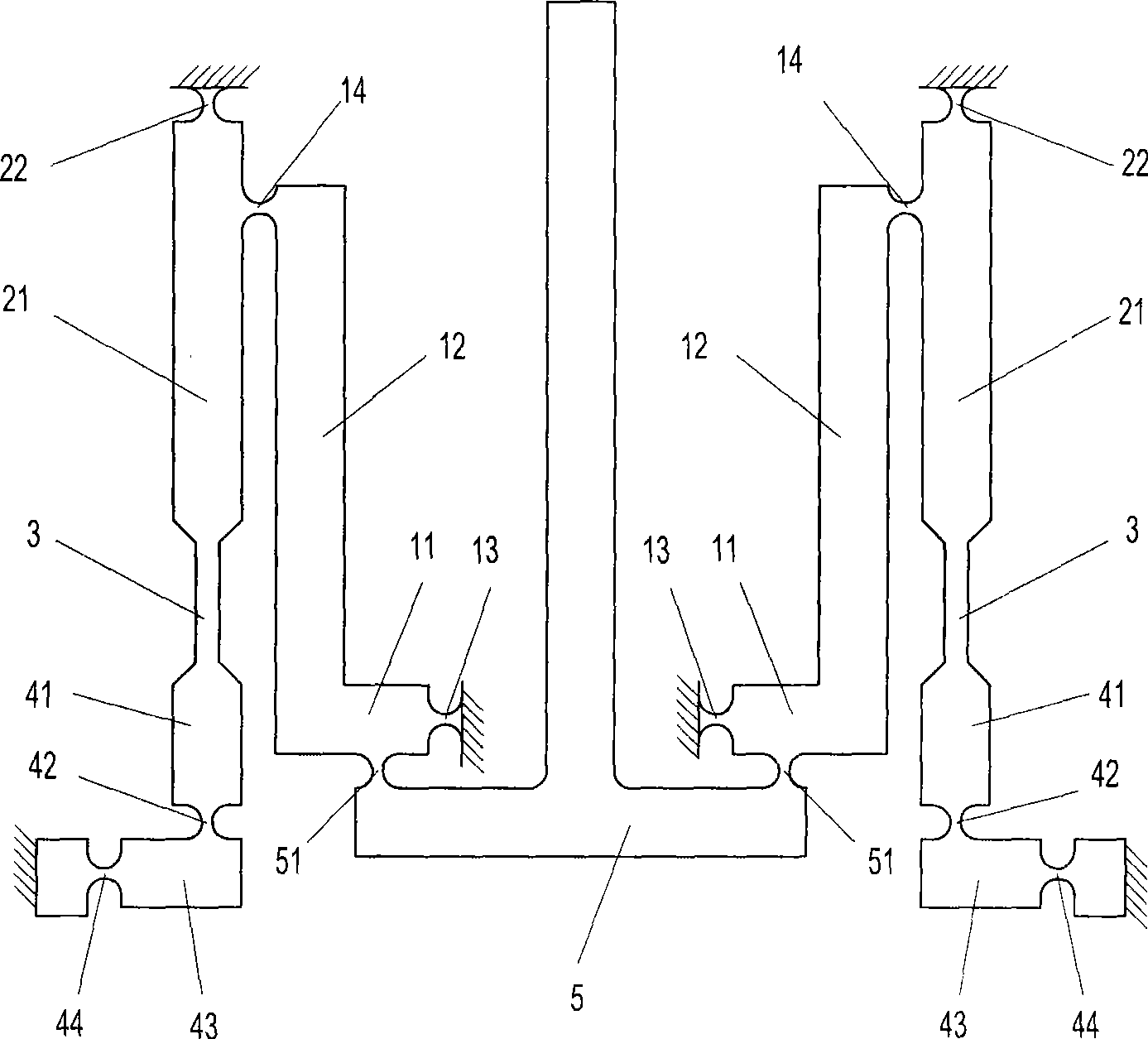

Strain type six-dimensional force transducer

ActiveCN106556488AIncrease stiffnessHigh sensitivityForce measurementMeasurement of force componentsElastomerCoupling

The invention discloses a strain type six-dimensional force transducer including a bottom cover, a base, a circuit board, elastic bodies, and a top cover. The bottom cover is connected with the bottom surface of the base, the circuit board is arranged inside the base, the four elastic bodies are uniformly distributed in the base, the outer side ends of the sensing elements of the elastic bodies are connected with the base, the inner side ends of the sensing elements of the elastic bodies are connected with the top cover, and the top cover is supported on the base through the elastic bodies. The strain type six-dimensional force transducer can better eliminate the inter-dimensional coupling due to the adoption of the plurality of elastic bodies and reasonable strain gauge bridge scheme design, and the strain type six-dimensional force transducer can have high rigidity and good sensitivity through the elastic bodies in a special structure.

Owner:TONGJI UNIV

Novel resistance strain type earth pressure cell sensor

A novel resistance strain type earth pressure cell sensor comprises an earth pressure cell side wall and an earth pressure cell end cover, wherein the earth pressure cell side wall is fixed to the earth pressure cell end cover, a stress film is arranged at one end of the earth pressure cell side wall, and an annular resistor strain gauge is arranged on the bottom surface of the stress film. The sensor further comprises an outer cover and a rubber force transmission block, wherein the earth pressure cell side wall is sleeved with the outer cover, and the rubber force transmission block is arranged between the bottom surface of the outer cover and the stress film. The novel resistance strain type earth pressure cell sensor is high in sensitivity and easy to calibrate.

Owner:ZHEJIANG UNIV OF TECH

Tecomperature compensation method for strain-type weighing sensor

InactiveCN1399122ALow reliabilityReduce manufacturing costWeighing apparatus using elastically-deformable membersDisplay deviceEngineering

The present invention relates to a temperature compensation method for strain-type weighing sensor. Inside or near the weighing sensor, a temperature sensor is installed, the temperature sensor is calibrated in zero point temperature-zero point output and temperature-elastic modulus, and zero point temperature-zero point output curve and temperature-elastic modulus curve are created in the weighing display. The operation includes first zero point temperature compensation based on the zero point temperature-zero point output curve in the weighing display, the elastic modulus compensation based on the temperature-elastic modulus curve, and final converting the measured weight into true weight based on the weight reference calibration value in the weighing sensor.

Owner:ZHENGZHOU HENGKE IND

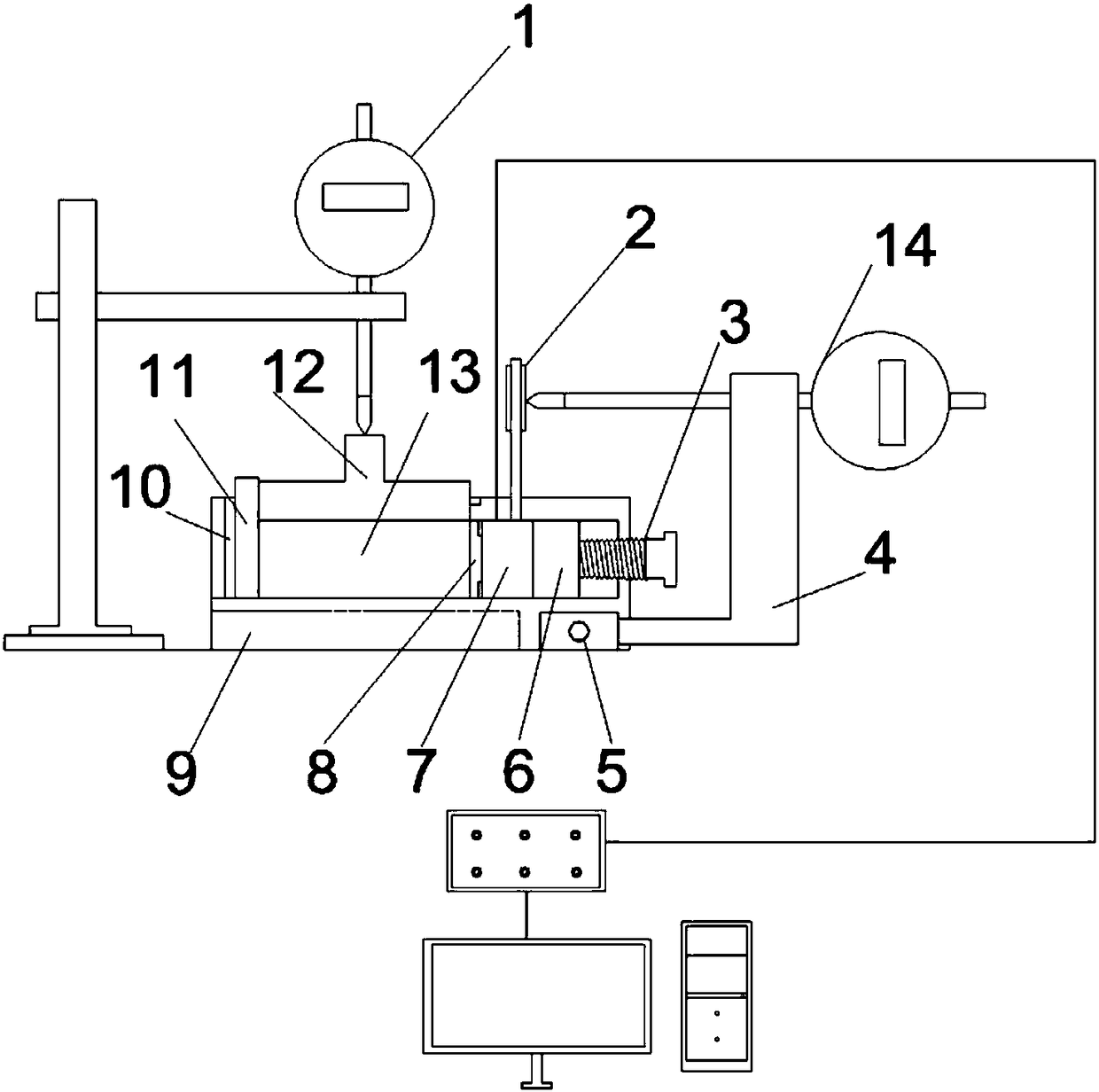

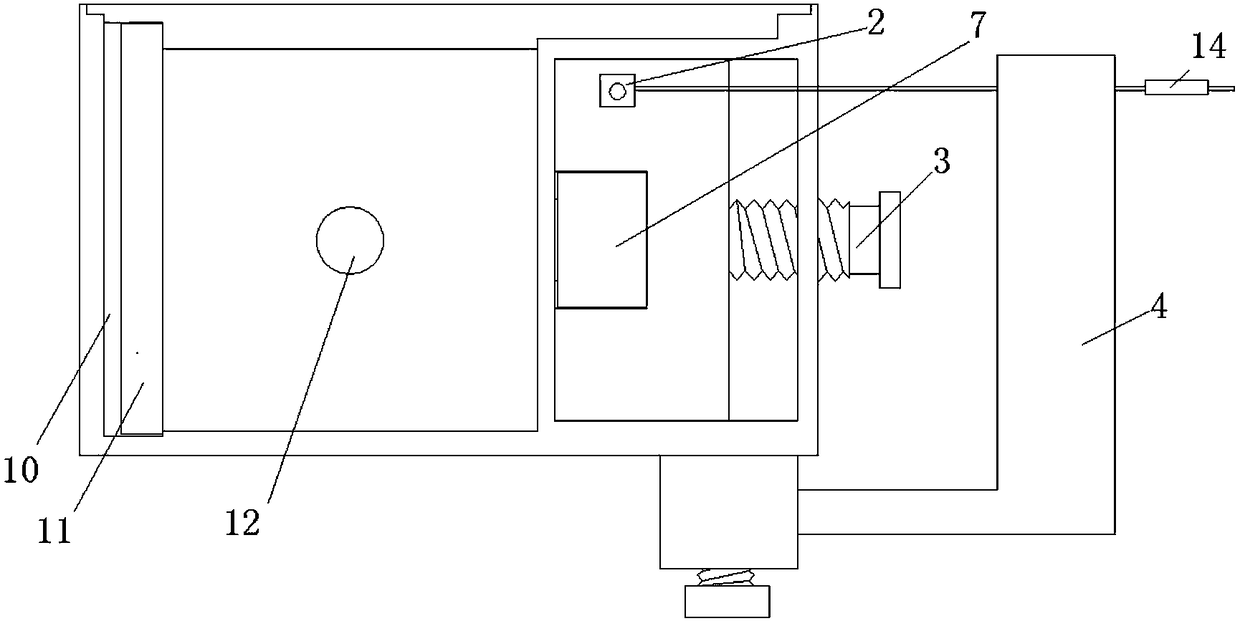

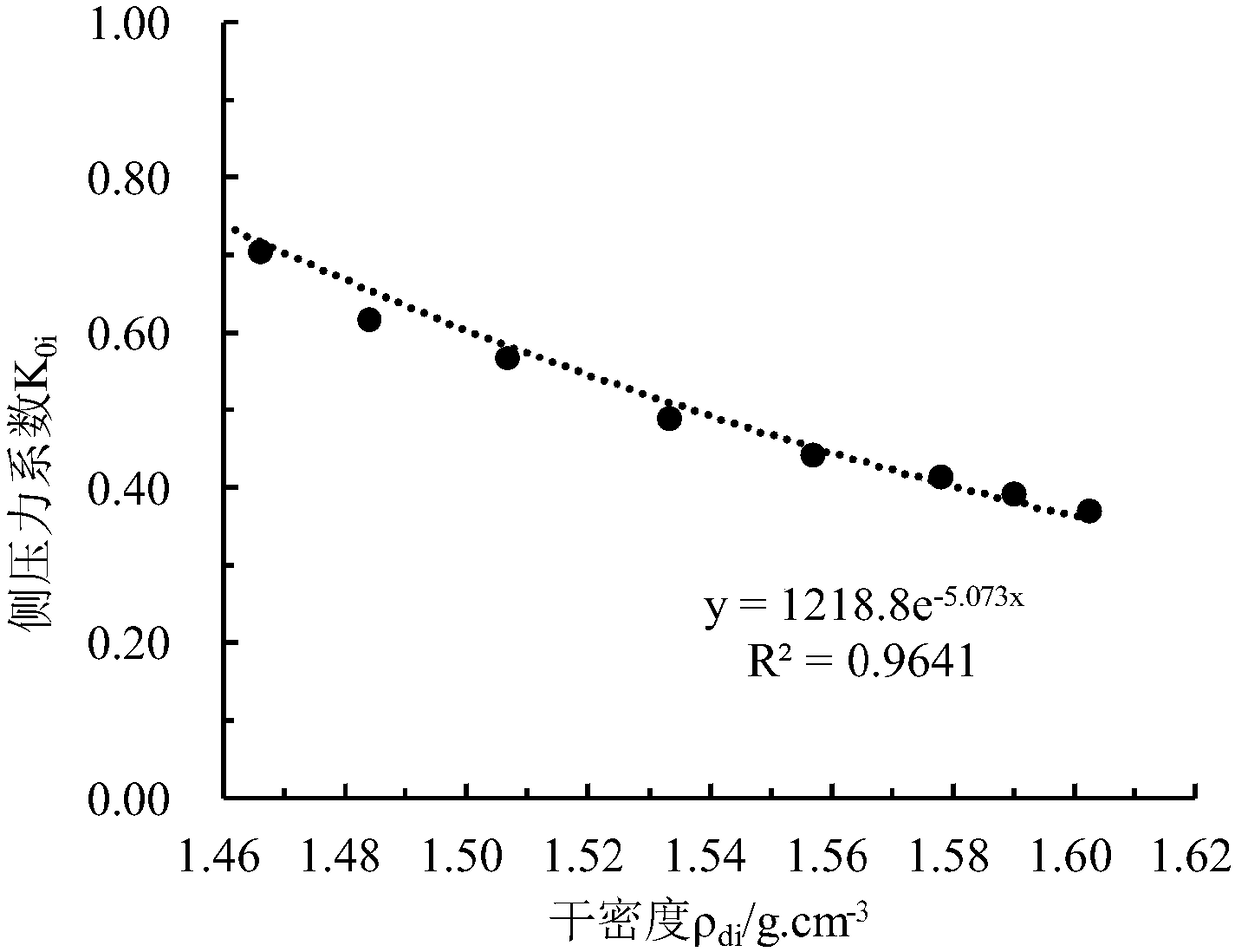

Strain type lateral expansion force testing device and measuring method

ActiveCN108593883AAchieve strippingIn line with actual working conditionsPreparing sample for investigationEarth material testingEngineeringSoil science

The invention relates to a strain type lateral expansion force testing device and a measuring method. The strain type lateral expansion force testing device comprises a measuring device, a data collecting device and a loading device. The measuring method comprises the following steps of performing water soaking expansion testing on specimens with same initial wet density states under non-load andnon-lateral strain conditions, and obtaining the expansion limit water content and corresponding dry density of the specimens with same initial wet density states under the condition of stable expansion; performing gradual loading type cementing testing on the specimens with same initial wet density states under the conditions of expansion limit water content and corresponding dry density, measuring the lateral pressure coefficient K0 at different dry densities, and stripping the lateral expansion force from the lateral resultant force. The strain type lateral expansion force testing device and the measuring method have the advantages that the testing method and the device are simple, the operation is convenient, the structure is reasonable, and the manufacturing cost is economical; the problem of stability of expanded soil edge slope after wetting expansion in the long-time expected precise evaluation process of the field is solved, the important design parameters are provided for thedesign of engineering structures and wall back buffer layers in the expanded soil area, and the device and the method are suitable for being popularized and applied in engineering.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Strain type rockburst early warning method based on acoustic signal waveform change characteristics

ActiveCN105676268AGuarantee personal safetySafe installation and operationSpeech analysisSeismologySmall amplitudeGraphics

The invention provides a strain type rockburst early warning method based on acoustic signal waveform change characteristics. The method includes the following steps: acoustic signals in a strain type rockburst destruction process are collected and transmitted to an acoustic signal processing system, the acoustic signal processing system performs denoising processing first, and then draws and analyzes an acoustic signal oscillogram, main forewarning information of occurrence of rockburst is that after small-amplitude fluctuation of the amplitude of the acoustic signals for a relatively long time, high-amplitude acoustic signals suddenly appear for a short period of time, and soon afterwards, a ''relative quiet period'' of continuous low-amplitude acoustic signals appear; a curve of a time fractal dimension value changing with time is drawn, another piece of forewarning information of occurrence of rockburst is that after continuously increasing to a relatively large value, the value of the time fractal dimensions D<t> continuously declines in a period of time and approaches a historical minimum value; and finally, an alarm is given in the form of sending out high-decibel sound or changing screen graphics. The strain type rockburst early warning method based on acoustic signal waveform change characteristics belongs to a non-contact monitoring means, and has the advantages that the installation operation is safe and the signals are reliable and stable.

Owner:GUANGXI UNIV

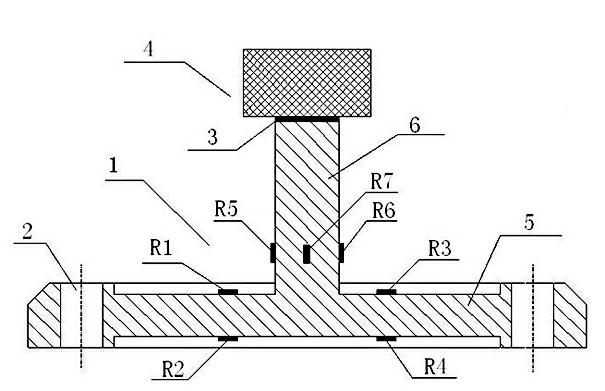

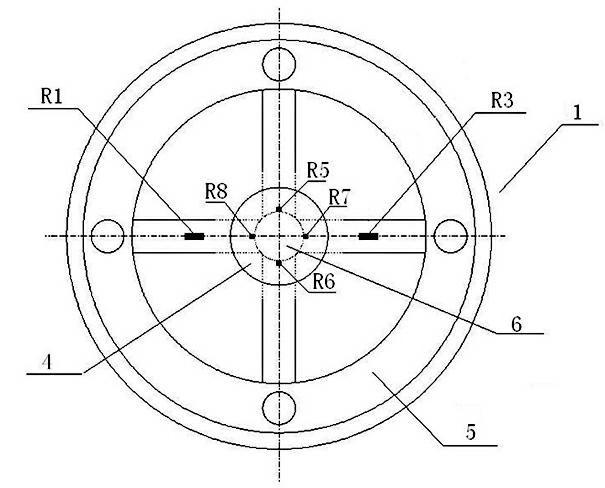

Strain type three-dimensional acceleration sensor

ActiveCN102435775ARealize three-dimensional vibration state detectionLow costAcceleration measurement using interia forcesAcceleration measurement in multiple dimensionsElastomerInverted-T shape

The invention discloses a strain type three-dimensional acceleration sensor and belongs to the field of a three-dimensional sensor. The sensor comprises an elastic body, fixing glue, a mass block and eight strain foils, wherein an axial cross section of the elastic body is inverted T-shaped; the lower end of the elastic body is of a spoke structure; the lower end is of a cylinder structure and anupper end face of the elastic body is fixedly connected to the mass block through the fixing glue; four strain foils are symmetrically arranged on a same spoke bar of a spoke, particularly, a first strain foil and a third strain foil are arranged on the upper surface of the spoke bar and a second strain foil and a fourth strain foil are arranged on the lower surface of the spoke bar; and four strain foils, namely, a fifth strain foil, a sixth strain foil, a seventh strain foil and an eighth strain foil, are uniformly arranged on a cylinder of the elastic body along a circumferential direction. The strain type three-dimensional acceleration sensor can be used for simultaneously detecting the three-dimensional vibration states of an object.

Owner:CHONGQING UNIV

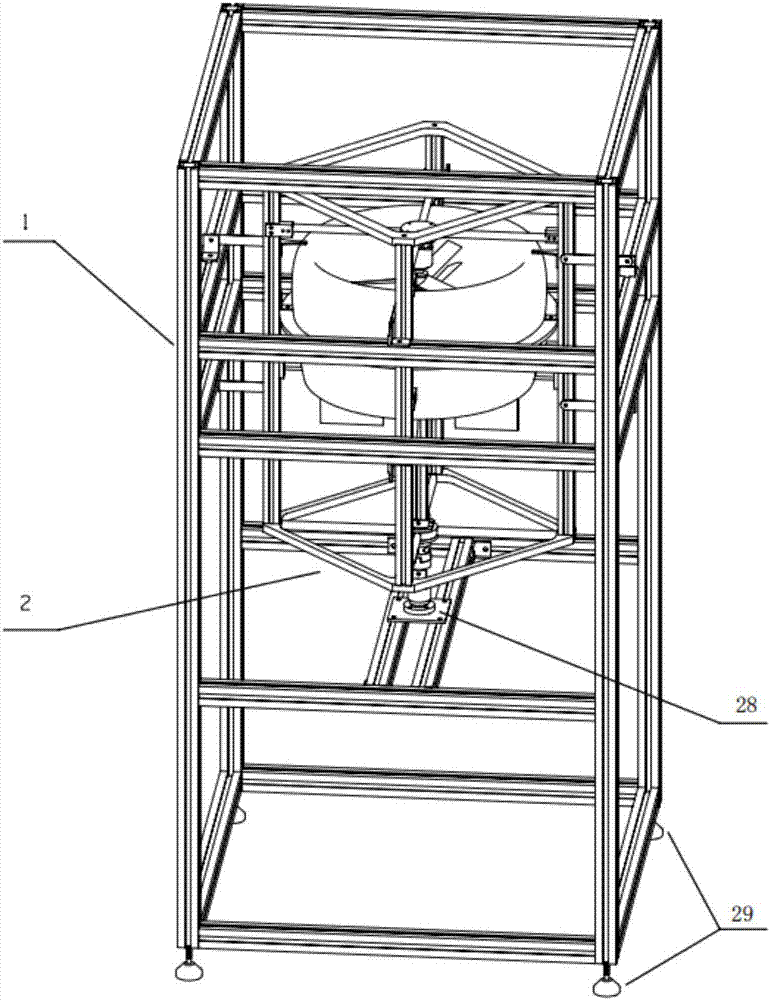

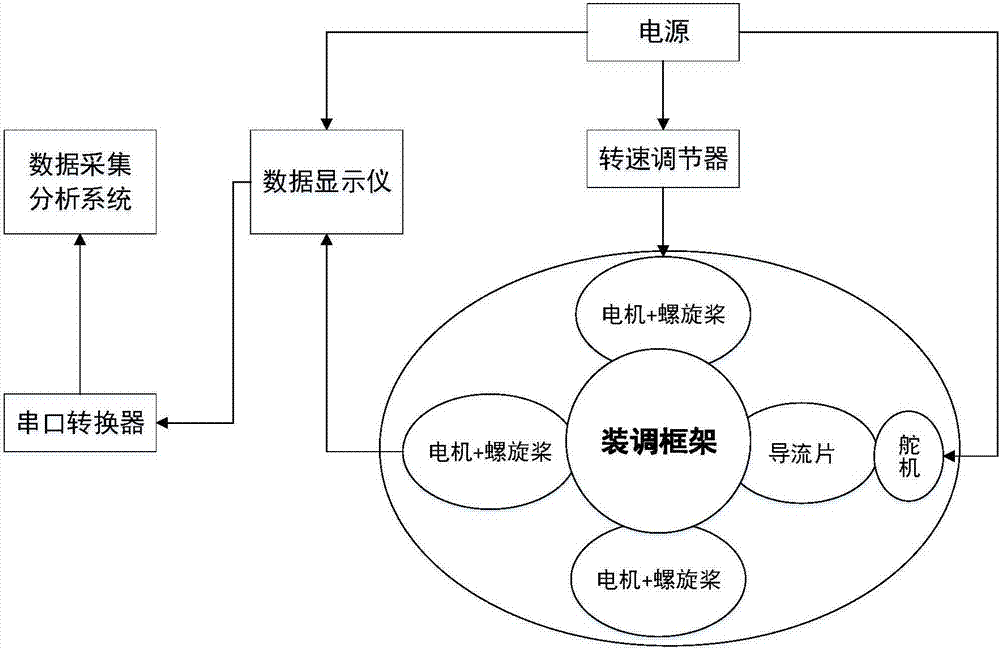

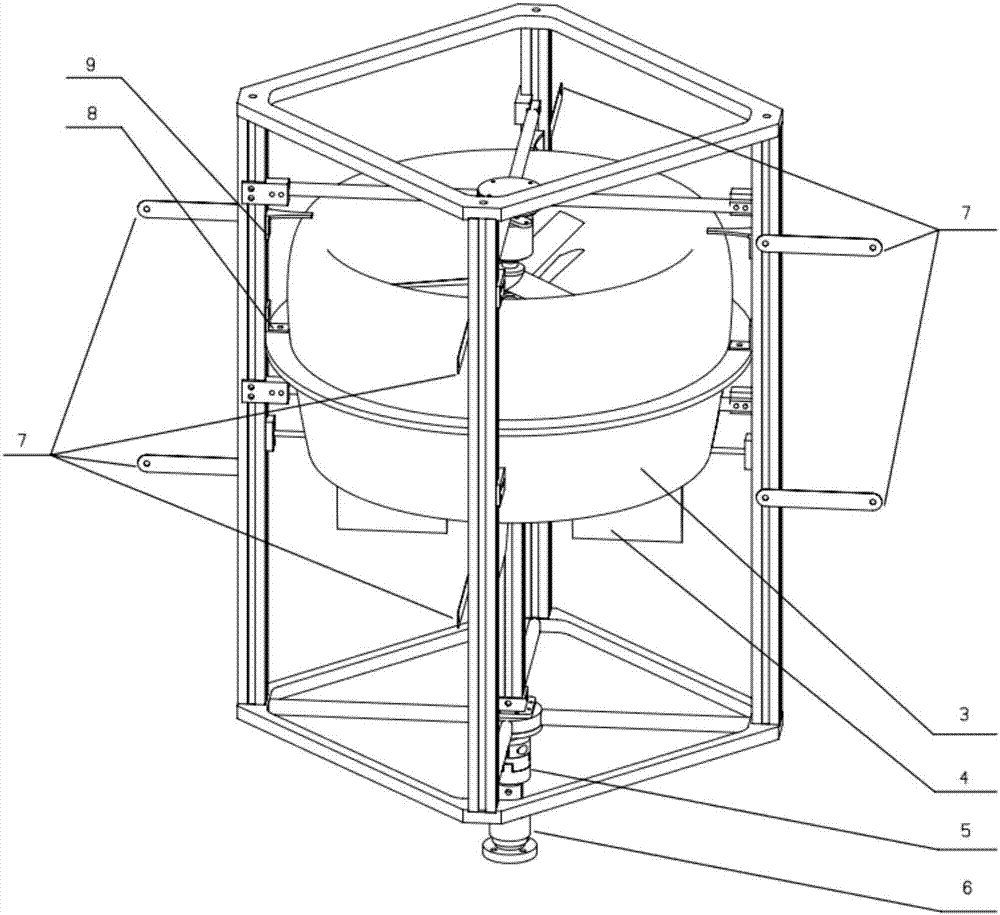

Aerodynamic characteristic testing stand for ducted coaxial dual-rotor unmanned aerial vehicle

ActiveCN107228720AReduce the effects of ground effectMeet different test needsWork measurementTorque measurementElectrical resistance and conductanceUncrewed vehicle

The invention, which relates to the field of hovering fore-measuring technology of the unmanned aerial vehicle, provides an aerodynamic characteristic testing stand for a ducted coaxial dual-rotor unmanned aerial vehicle, so that problems of the existing motor thrust testing technique are solved. The aerodynamic characteristic testing stand comprises an external testing platform bracket, an internal adjustment support, a ducted propeller system and a measurement display system. The external testing platform bracket and the internal adjustment support are three-dimensional frames; and the internal adjustment support is fixed inside the external testing platform bracket by flat springs. According to the invention, because straight cantilever type springs are arranged at the same direction, the minimum stiffness plane is easy to bend; with a resistance strain type transducer, displacement during testing is small; because of different flat spring installation and fixation ways, displacement at a certain direction can be restricted and the freedom degree of the sensor measuring direction can be kept; and to-be-measured information generated by the system is transmitted to the sensor and data reading and recording are carried out by a display system, so that different test objectives are achieved.

Owner:CHANGGUANG SATELLITE TECH CO LTD

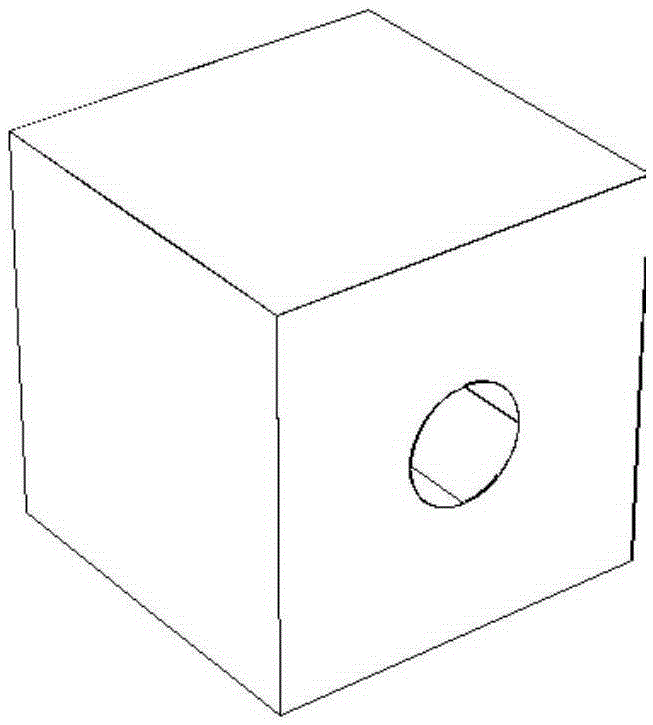

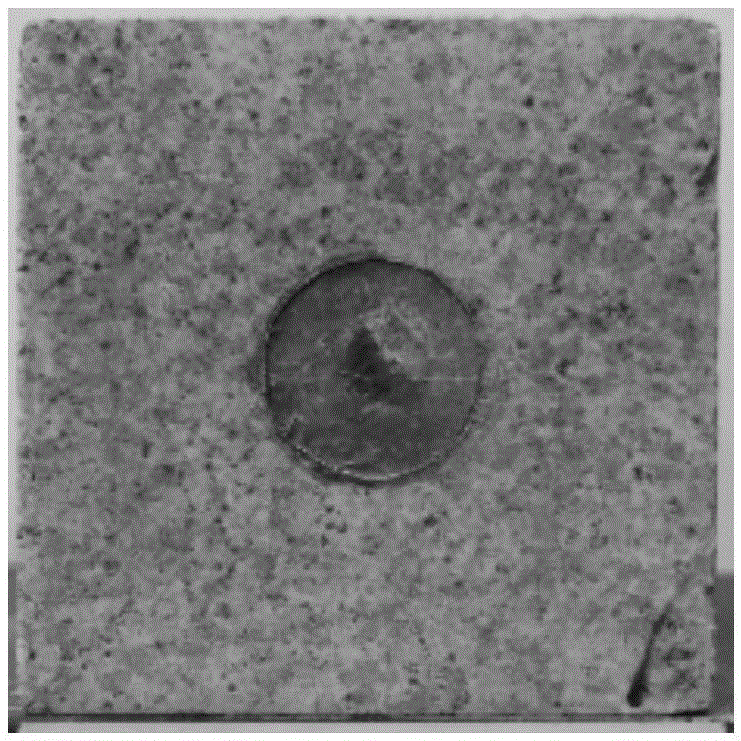

Achieving method for simulating situation that straining-type rock bursting of roadway is caused by excavating unloading effect

The invention discloses an achieving method for simulating the situation that straining-type rock bursting of a roadway is caused by the excavating unloading effect, and belongs to the field of geology simulating tests. The achieving method includes the following step that a hole is filled with a concrete column, wherein the cement-sand ratio is controlled, flocculating agents are added, the errors between the mechanical parameters and the roadway-surrounding-rock parameters of the concrete column are controlled to be lower than 10% by testing the mechanical parameters including the compressive strength, the extension strength, the poisson ratio and the elasticity modulus of the concrete column, and then the hole is filled with concrete after the concrete is evenly stirred. The achieving method has the advantages that by means of the achieving method for simulating the situation that straining-type rock bursting of the roadway is caused by the excavating unloading effect, the background of the combined effects of different self-weight stress fields and tectonic stress fields in a site can be fully considered, and the straining-type rock bursting process is generated in the roadway digging process in rock mass. In addition, other monitoring means are combined, the various physical-performance-change parameters in the rock bursting breeding process, the rock bursting occurring process and the rupturing process after rock bursting are collected, and reliability is high.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Resistance strained sensor with protector

InactiveCN1746635AGuaranteed to workAvoid installation errorsWeighing apparatus using elastically-deformable membersElastomerElectrical resistance and conductance

A transducer of resistance strain type with protective device is prepared as sticking resistance foil gauge on elastic body surface, fixing contact on free end of elastic body, setting cavity in protective sleeve, setting boss for fixing elastic body fixing end at one side of cavity bottom surface and setting bosses having spacing gap and corresponding to elastic body free end separately on top surface and bottom surface of cavity, and setting through hole on protective sleeve to let contact pass.

Owner:常熟市百灵天平仪器有限公司

Automobile door closing-force testing device

InactiveCN1710392ACorrectly evaluate the difficulty of closingSimple structureApparatus for force/torque/work measurementReal-time dataTransducer

A device for testing door close force of automobile is controlled by computer, it applies S-shape strain type of force test transducer and capacity type of displacement transducer to measure force and displacement as well as applies serial interface to input force displacement signal to portable computer for realizing real time data collection and communication . The device not only can realize test of door close force but also can realize test of door close displacement.

Owner:SHANGHAI JIAO TONG UNIV

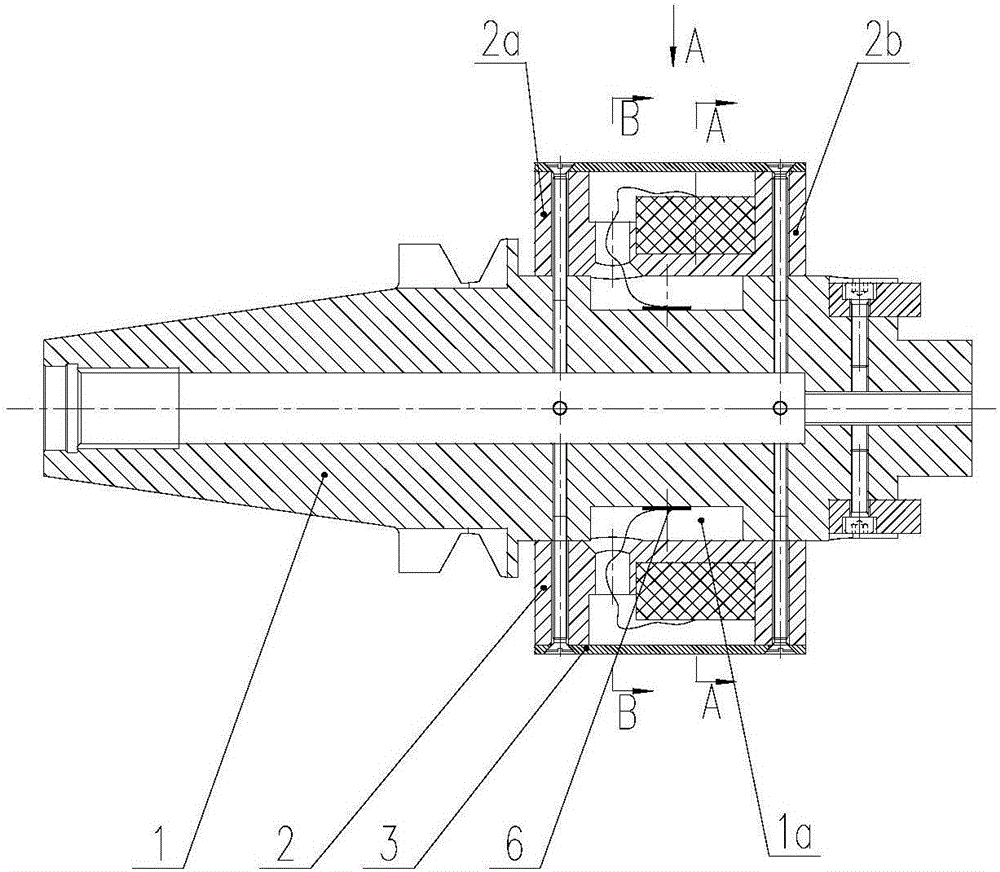

Strain type rotary two-component milling force sensor

ActiveCN103737430AImprove versatilityWide versatilityMeasurement/indication equipmentsMetal working apparatusInterference fitFull bridge

A strain type rotary two-component milling force sensor comprises a body structure. A binding cover is in interference fit with the central axis portion of the body structure, and is in threaded connection with the periphery of the body structure, and a front-end structure is in threaded connection with the binding cover. The front-end structure is formed by connecting a front HSK tool handle head and a rear disc, a force measuring sensor and a machine tool spindle are connected through the tool handle head, and the rear disc and the binding cover are in seamless connection. A thin-wall cylinder is arranged at one end of the body structure, a tool clamp is arranged at the other end of the body structure, a supporting disc is arranged in the middle of the body structure, the thin-wall cylinder is an elastic element of the whole sensor and is very high in sensitivity, and the overall structure rigidity and the sensitivity of the sensor are combined through the thin-wall cylinder. The supporting disc supports the modules of the sensor, and the tool clamp is used for mounting a tool. A metal strain sheet is pasted on the thin-wall cylinder, a Wheatstone full-bridge mode is formed in a connecting mode, and the sensor is used for measuring axial force Fz and spindle torque M, and has the advantages of being high in sensitivity, strong in anti-interference capacity, strong in universality and the like.

Owner:XIAN WINWAY TOOLS

Strain type micro-nano-scale micro-nano displacement sensor

The invention provides a strain type micro-nano class micro-nano displacement transducer. The micro-nano displacement transducer is characterized by having a detection unit which is formed by rigid rod bodies and flexible hinges and is provided with a lever type displacement first-level amplification mechanism and a displacement second-level amplification mechanism. Through multi-level amplification, the micro-nano displacement transducer allows a strain piece on an elastic body to detect the movement of a detecting object, and acquires detection results by external signal acquisition and processing equipment. The displacement transducer has the advantages of high integration, small volume, low energy consumption, high precision, low cost, simple structure, high sensitivity, easy labeling and good reliability.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

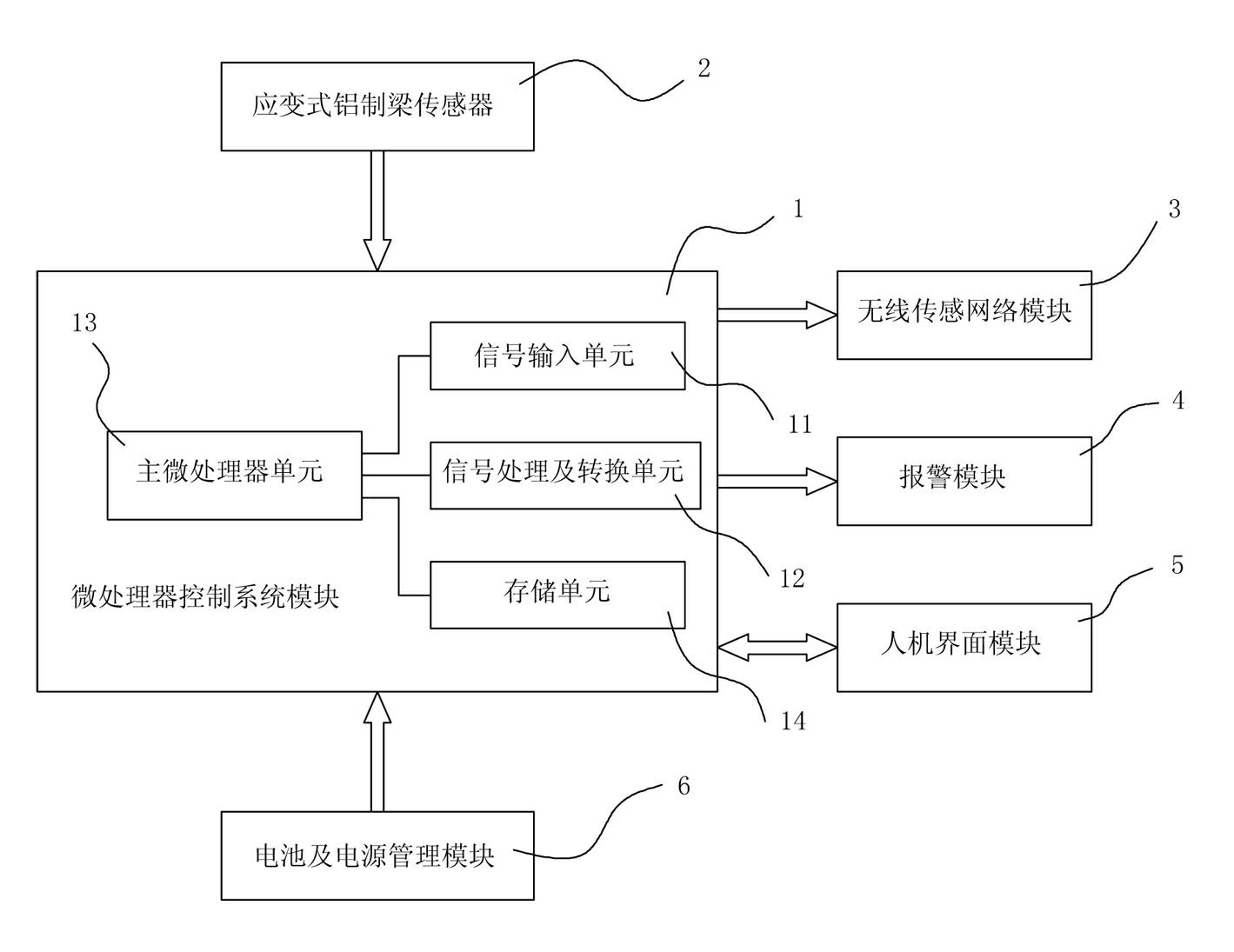

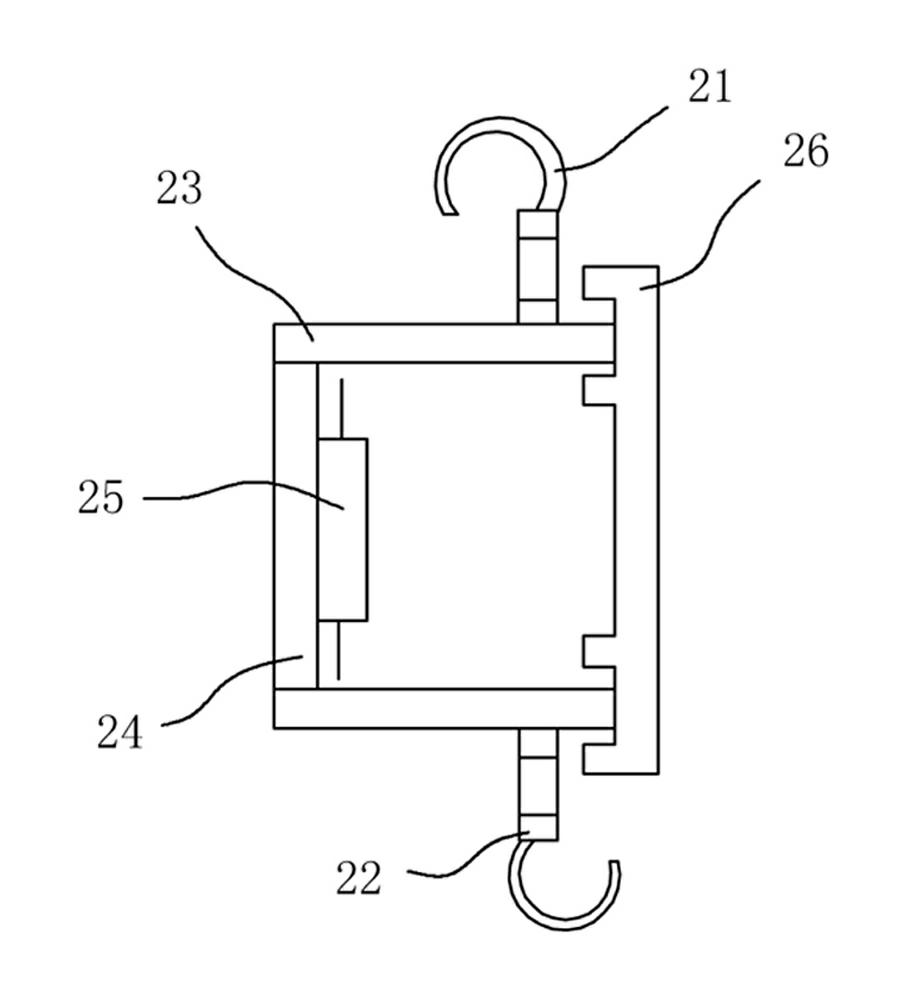

Hospital venous transfusion monitoring terminal

InactiveCN102114280AEasy to useEasy to work independentlyFlow controlHuman–machine interfaceSupply management

The invention disclose a hospital venous transfusion monitoring terminal which comprises a microprocessor control system module, a strain type aluminum beam sensor, a wireless sensing network module, an alarm module, a human-computer interface module and a battery and power supply management module, wherein a transfusion bag or a transfusion bottle for injection is hung on the strain type aluminum beam sensor, and the strain type aluminum beam sensor is used for sending detected weight change data of the transfusion bag or the transfusion bottle into the microprocessor control system module for analyzing and processing. Weight of liquid medicine is adopted as a detection index, and the transfusion speed, the residual amount of the liquid medicine and the abnormal status of the transfusionare monitored by detecting the weight of the liquid medicine in a real-time manner through the technology of the strain sensor, thereby solving the impacts of environmental factors on the detection, and having the advantages of being simple and practical, being convenient to operate, being safe and reliable, being low in cost, realizing complete wireless networking, being conductive to popularization and the like.

Owner:JIANGMEN POLYTECHNIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com