Strain type micro-nano-scale micro-nano displacement sensor

A displacement sensor, micro-nano technology, applied in instruments, measuring devices, electrical devices, etc., can solve the problems of affecting the accuracy of the sensor, low response frequency, poor anti-interference ability, etc., and achieve simple structure, high sensitivity and good reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

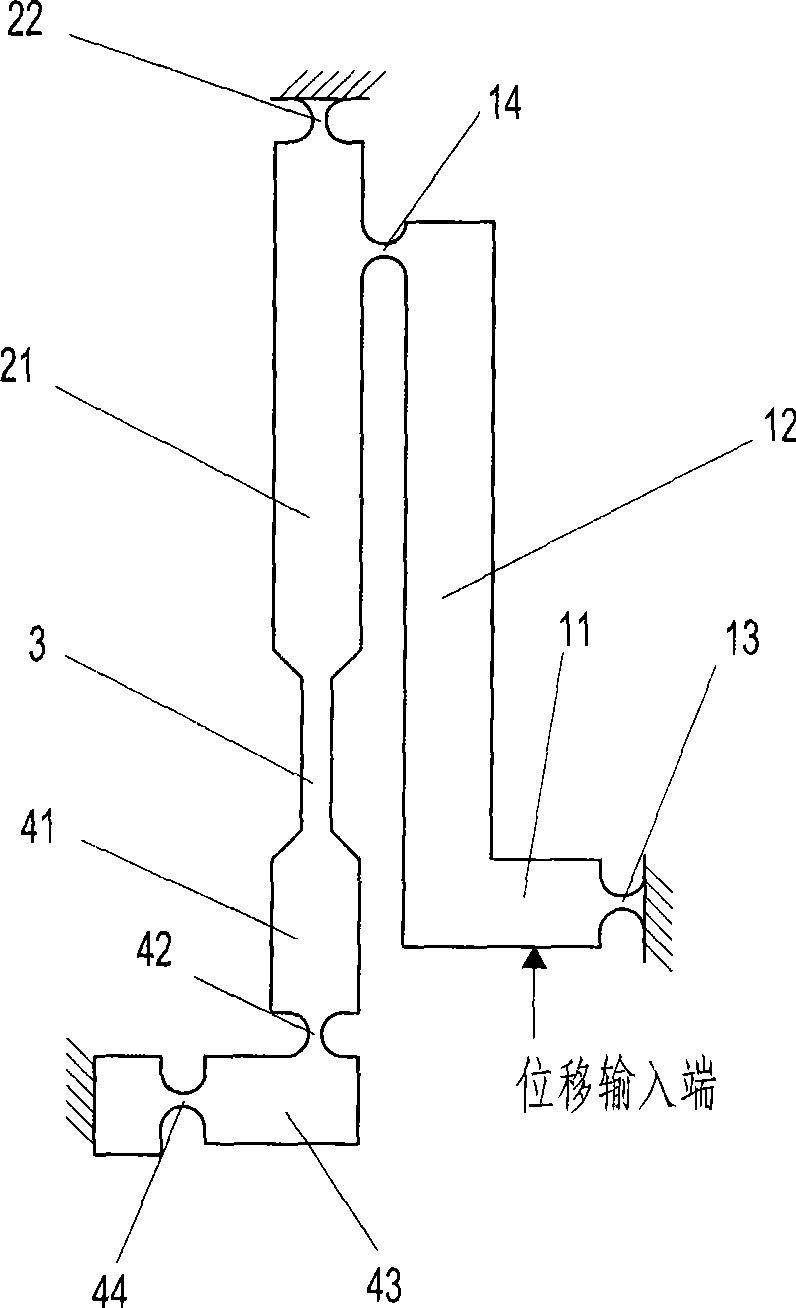

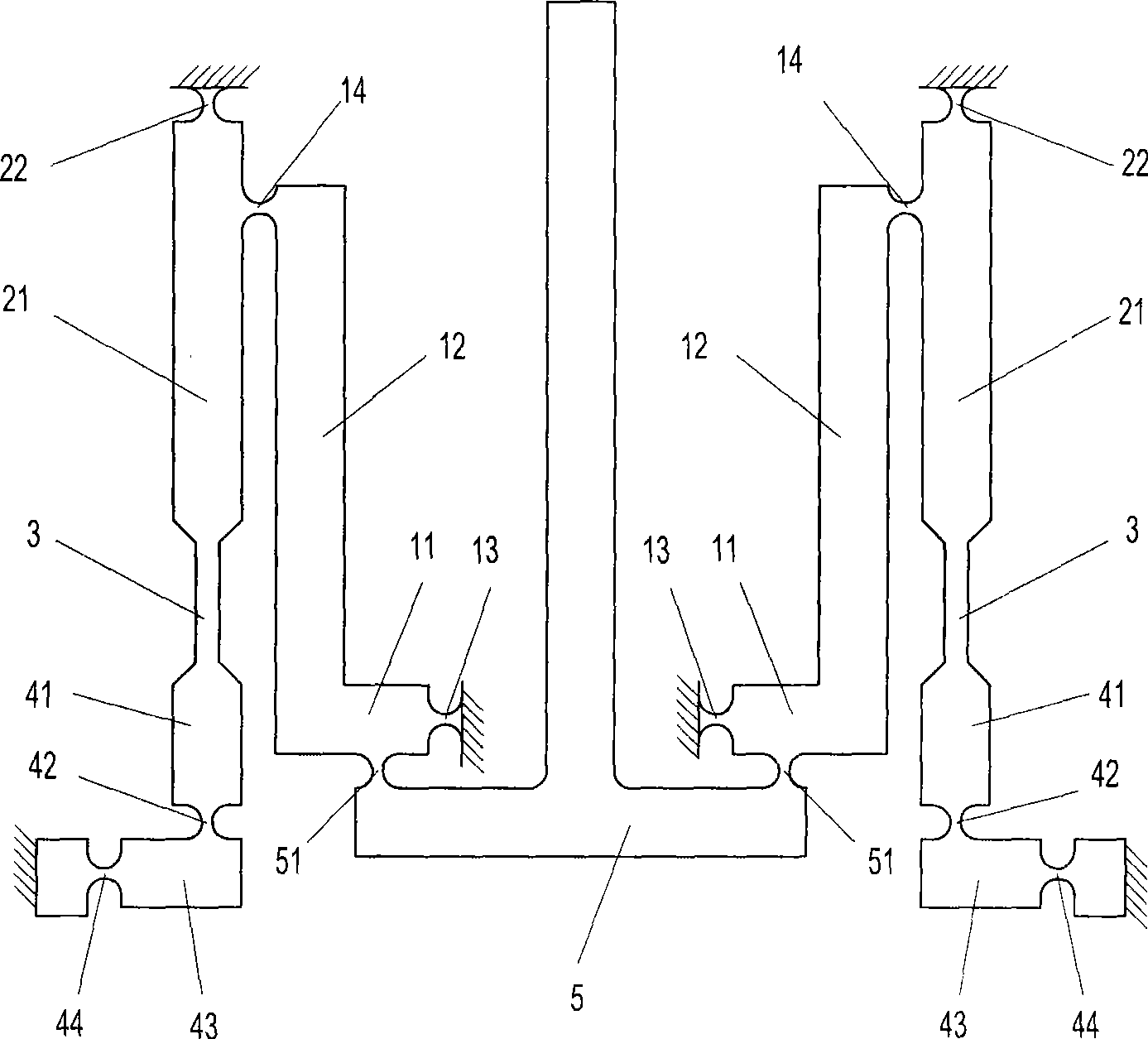

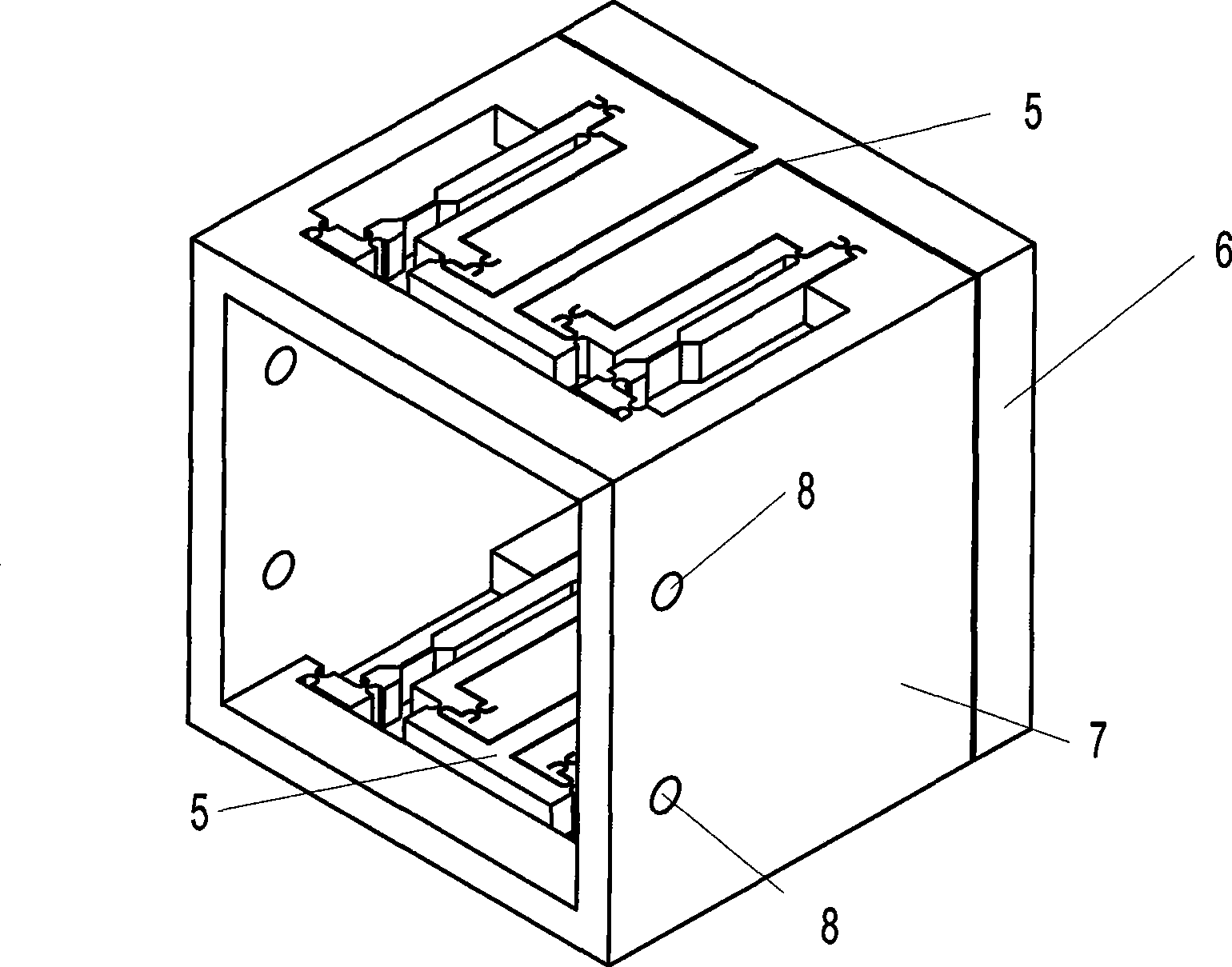

[0027] see figure 1 , in this embodiment, the specific structure of the detection unit composed of each rigid rod body and flexible hinge is set as:

[0028] The first-stage amplifying mechanism for displacement is provided with a first-stage lever arranged in an "L" shape, the first-stage short rod 11 is the input arm, and the first-stage long rod 12 is the output arm, and the end of the short rod connected to the fixed seat is flexible. The hinge 13 is a first-level fulcrum, the first-level measured displacement is formed on the short rod 11, and the long rod-end flexible hinge 14 connected to the second-level amplification mechanism is the first-level output end of the measured displacement;

[0029] The displacement amount is provided with a secondary amplification mechanism, which has a straight rod section lever 21, one end of which is connected to the fixed seat with a straight rod end flexible hinge 22, and the other end is an elastic body 3 connected with a multi-degr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com