Slab caster two cold nozzle impact measuring system

A slab continuous casting machine and measuring system technology, applied in the direction of measuring force, measuring device, testing of machine/structural components, etc., can solve the problems of long time period, increased measurement cost, poor test accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

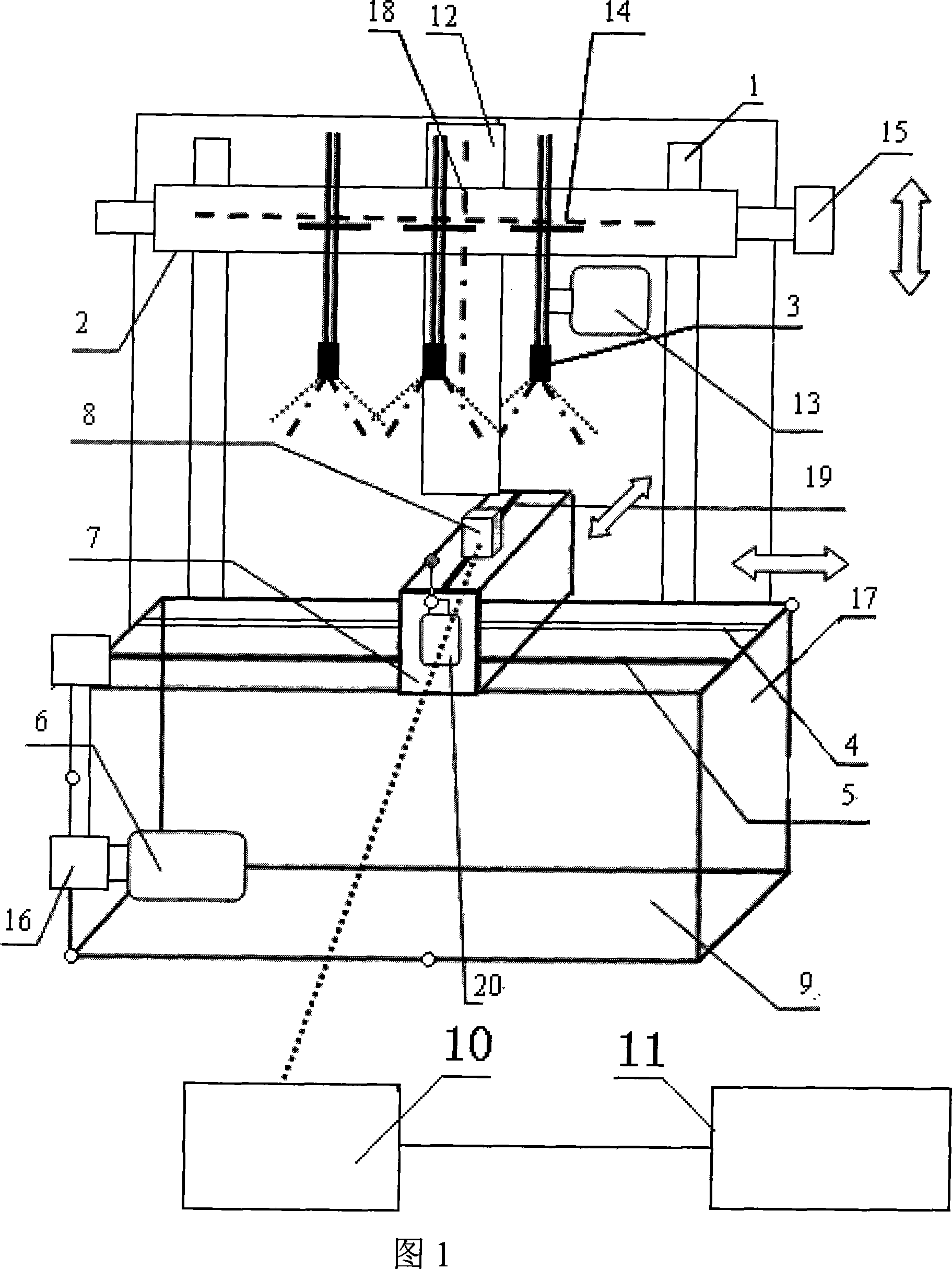

[0018] As shown in Figure 1, it includes nozzle moving mechanism, nozzle, signal conditioner 10, computer data acquisition and analysis unit 11, waterproof strain-type micro-force value sensor 8 and sensor moving mechanism, waterproof strain-type micro-force value sensor 8 is fixed on the transmission On the sensor moving mechanism, the waterproof strain-type micro-force value sensor 8 is moved to the detection position through the sensor-moving mechanism; the nozzle 3 is fixed on the nozzle moving mechanism, and the nozzle 3 is downward, and the nozzle 3 is moved to the waterproof strain-type micro-force value by the nozzle moving mechanism Above the sensor 8, the nozzle 3 sprays water, and the waterproof strain-type micro-force value sensor 8 is driven to different positions through the sensing movement mechanism. The electrical signal is passed through the signal conditioner 10 and the computer data acquisition and analysis unit 11 to provide a three-dimensional water spray ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com