Test device and method for assessing non-smooth surface anti-drag effect

A non-smooth surface and smooth surface technology, which is applied to the test device and field of evaluating the drag reduction effect of non-smooth surfaces, can solve the problems of inapplicability and immaturity, and achieve the effects of easy operation, accurate testing and reliable test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in more detail below in conjunction with accompanying drawing example:

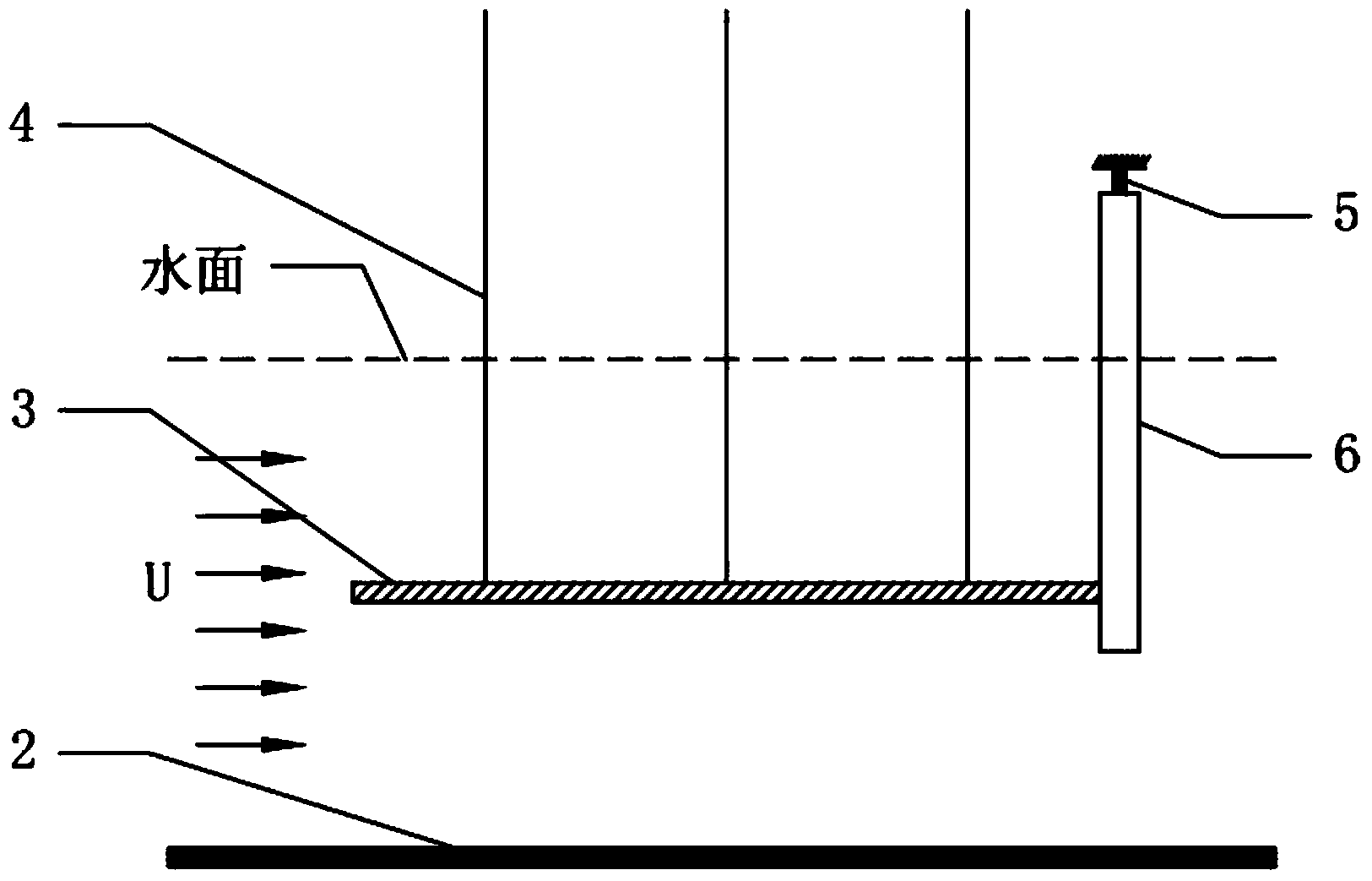

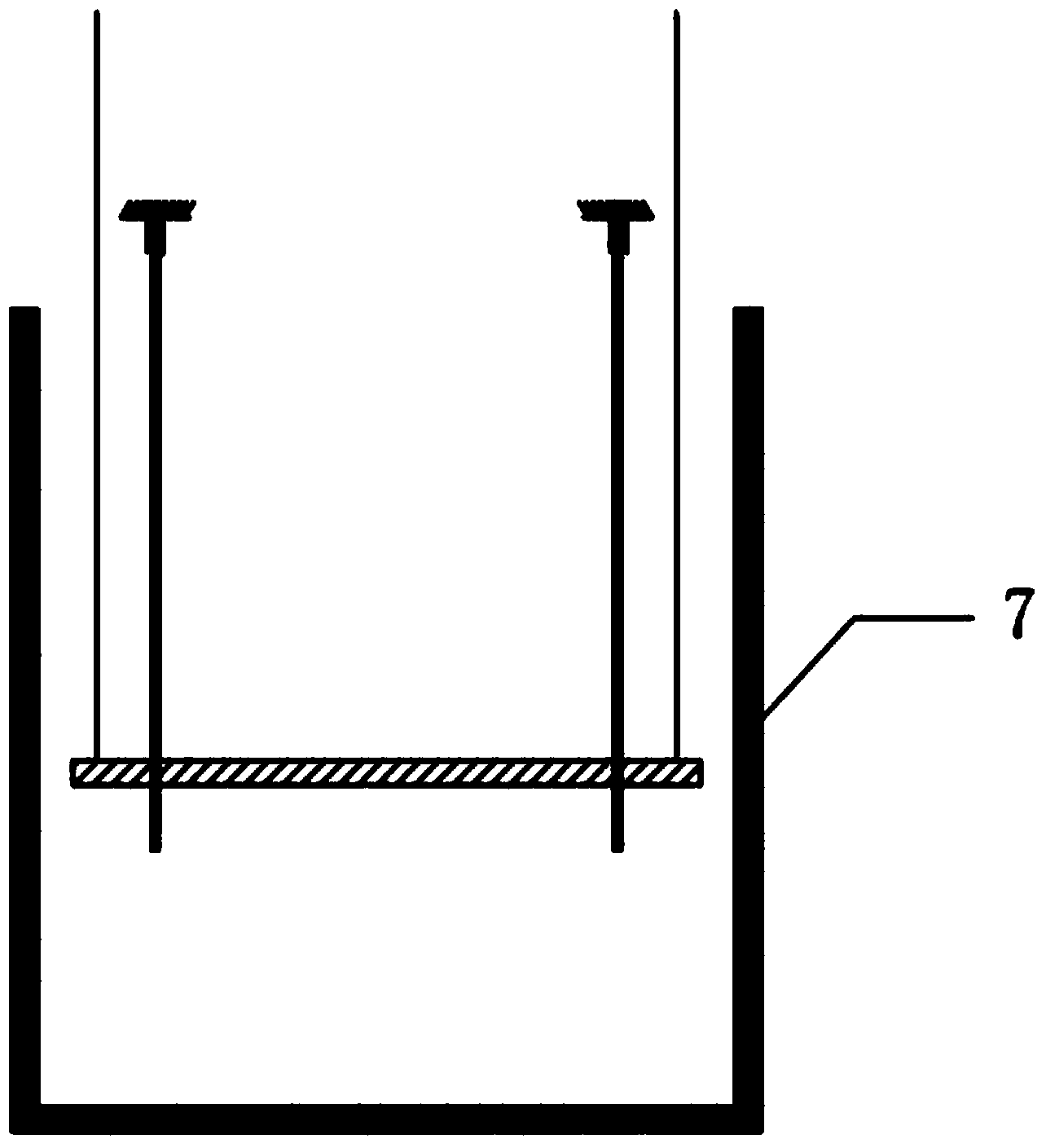

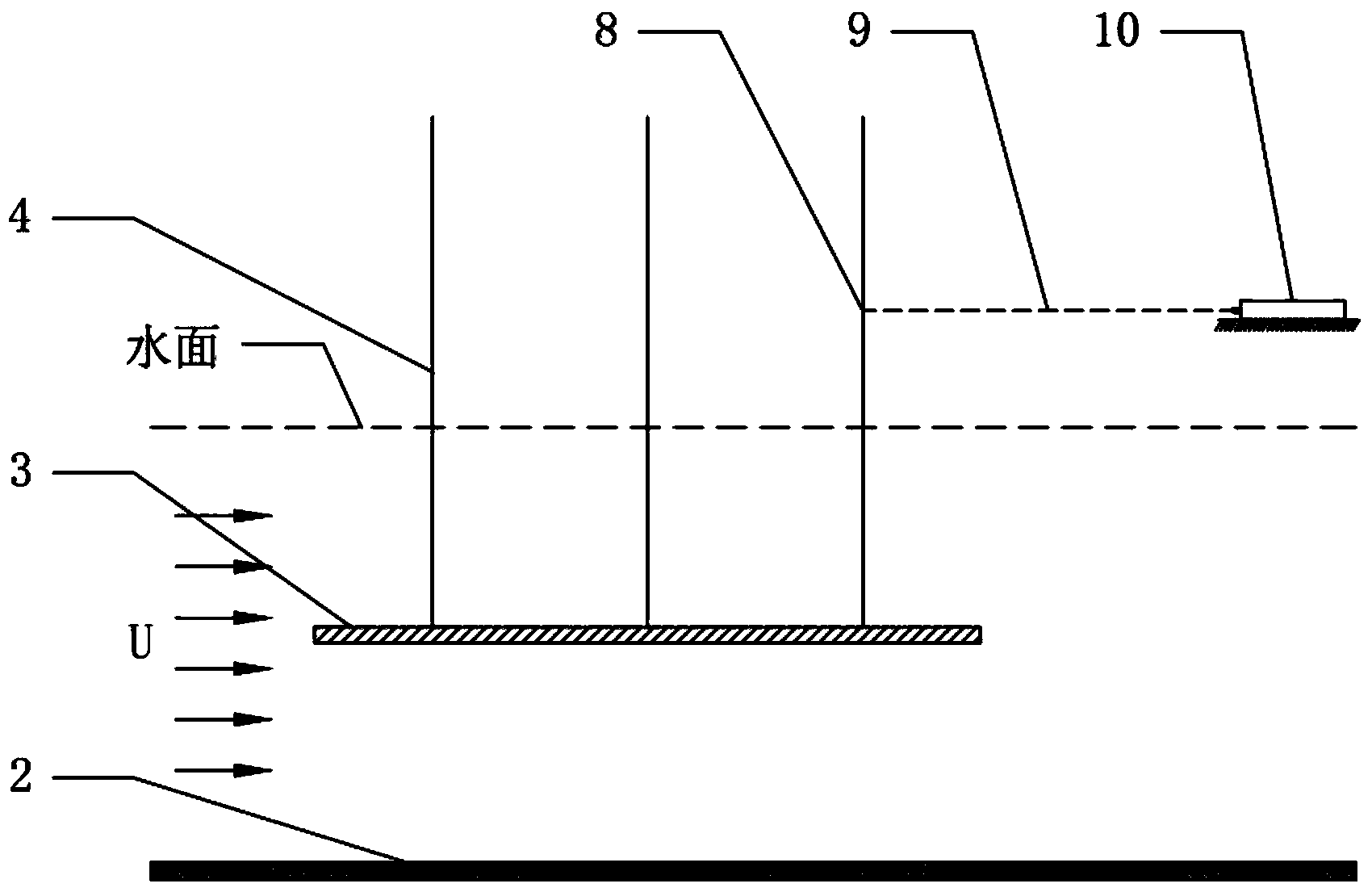

[0025] 1-2, the present invention includes a water hole (1), a non-smooth surface plate (3), a strain type balance support dowel bar (6), a force measuring element (5), a suspension steel wire (4) and a laser vibrometer instrument (10), the strain type balance support dowel bar (6) is connected to the force measuring element (5), and the suspension steel wire (4) is connected to the non-smooth surface plate (3).

[0026] When the water flow is still in the initial state, the angle between the hanging steel wire (4) and the vertical direction is 0, and the laser light path (9) of the laser vibrometer (10) is perpendicular to the hanging steel wire (4) at this time; the non-smooth surface plate (3) The static position is greater than half of the water depth, and the width of the flat plate is smaller than the width of the water tunnel, which reduces the influence of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com