Multi-component force sensor

A force sensor, multi-component technology, applied in the field of component force devices, can solve the problems of poor isotropy of cross beam structure, unfavorable dynamic measurement, large number of strain gauges, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

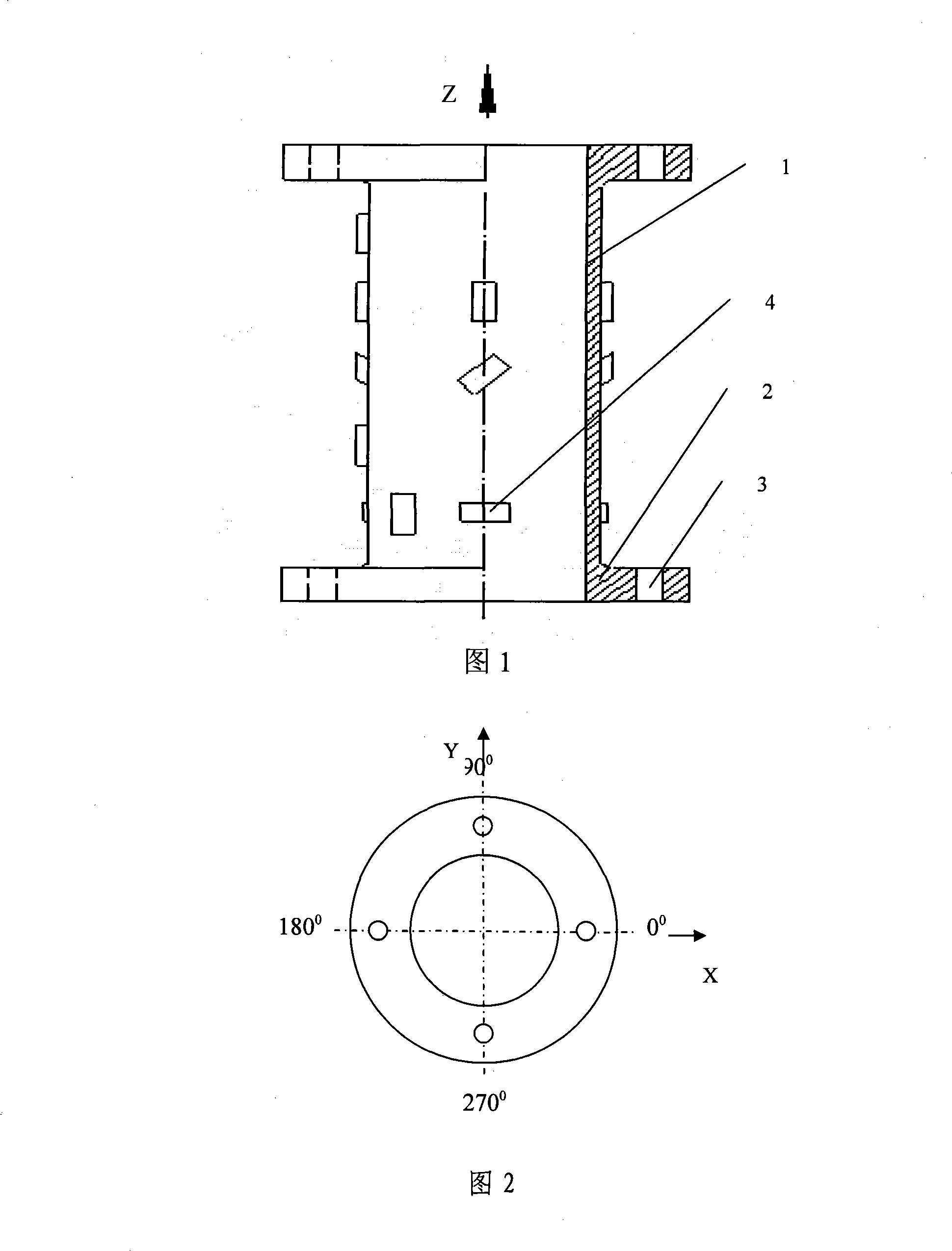

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings. Referring to Fig. 1 to Fig. 3, the present invention provides a multi-component force sensor with a thin-walled cylinder structure. There are flanges 2 at both ends of the thin-walled cylinder 1. The flange 2 and the thin-walled cylinder 1 can be integrated or connected in other ways. . Mounting holes 3 are provided on the flange 2 to facilitate assembly with other parts. The mounting holes 3 can be plain holes or threaded holes. There are at least four mounting holes 3 .

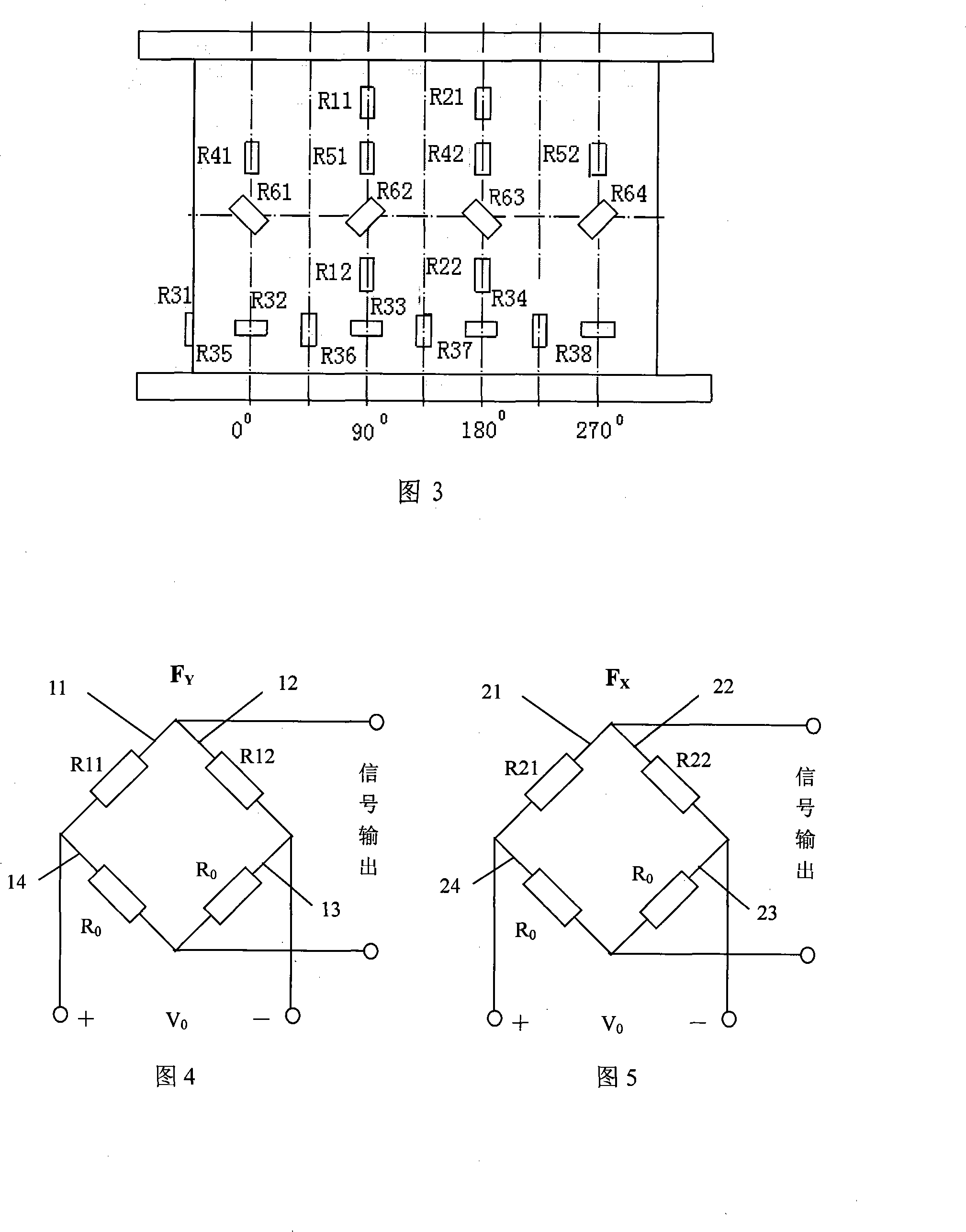

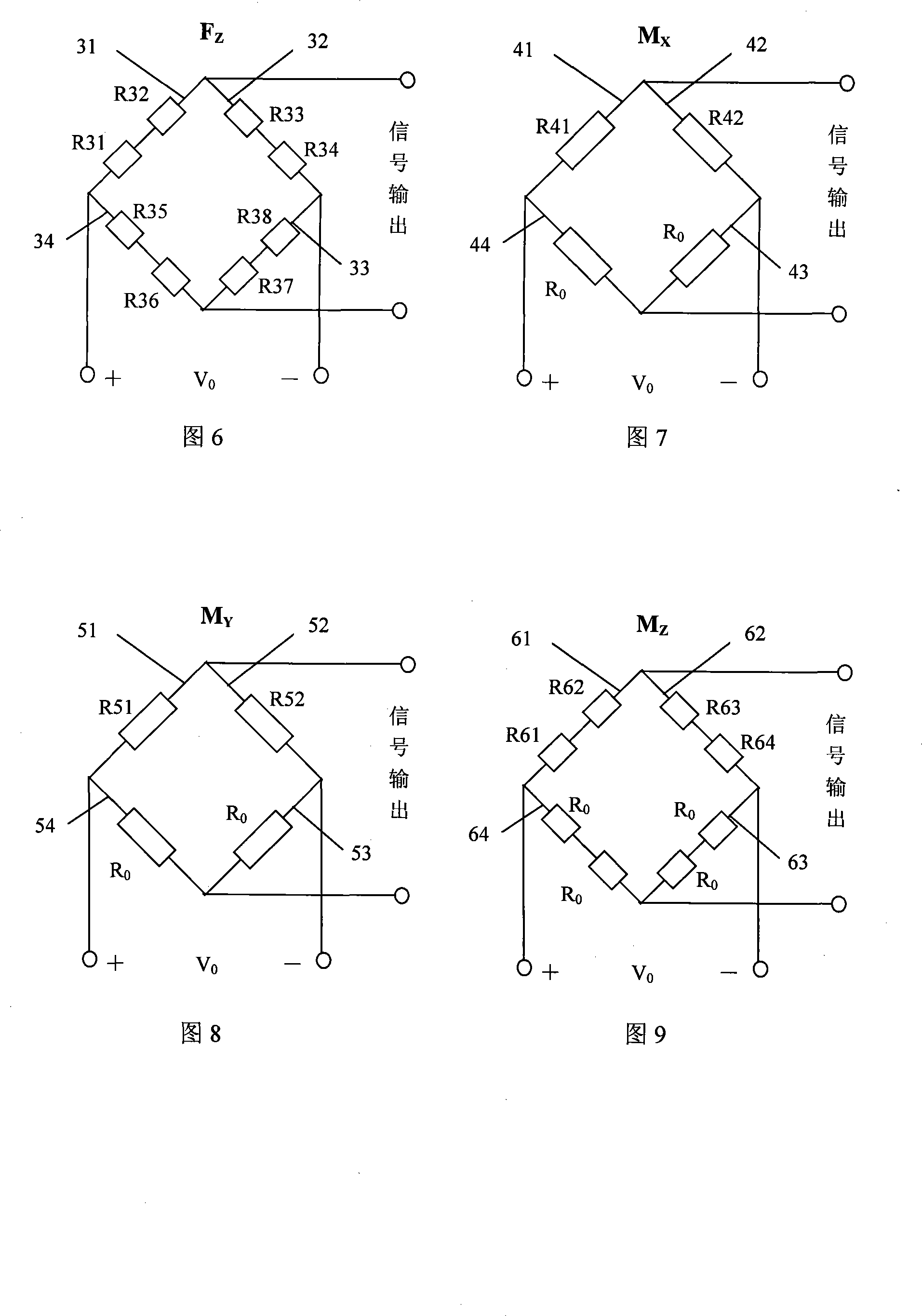

[0020] The wall of the thin-walled cylinder 1 is pasted with resistance strain gauges and temperature compensation strain gauges, R11, R12, R21, R22, R31, R32, R33, R34, R35, R36, R37, R38, R41, R42, R51, R52, R61, R62, R63, R64 are resistance strain gauges, R 0 for temperature compensating strain gauges. The position and method of attaching the strain gauges are as follows: divide the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com