Directly actuated valve with a strain-type actuator and a method of operating same

一种致动式、致动器的技术,应用在阀的操作/释放装置、具有减少磨损措施的燃料喷射装置、阀细节等方向,能够解决损坏致动器、关闭时间不是最佳等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

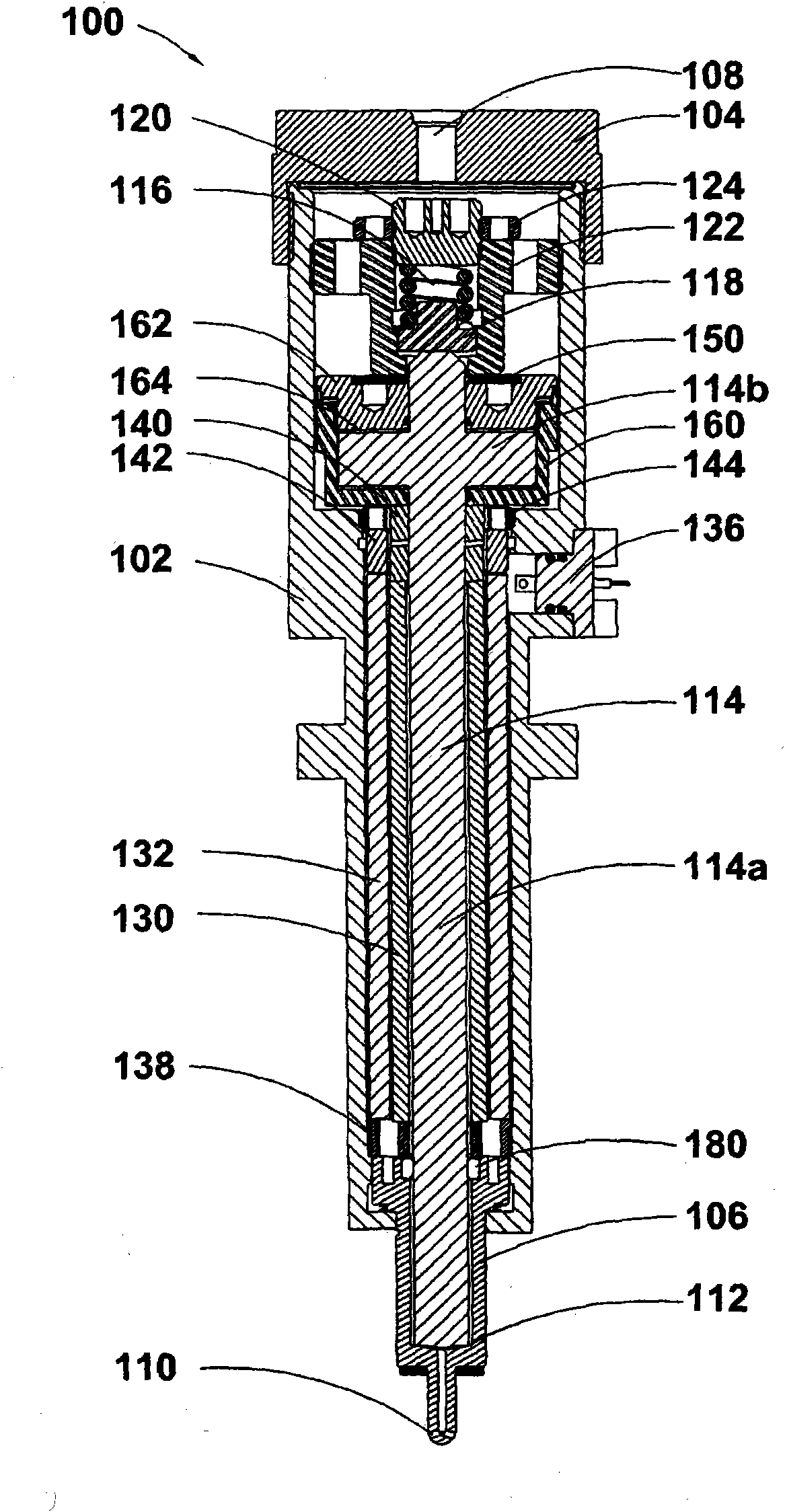

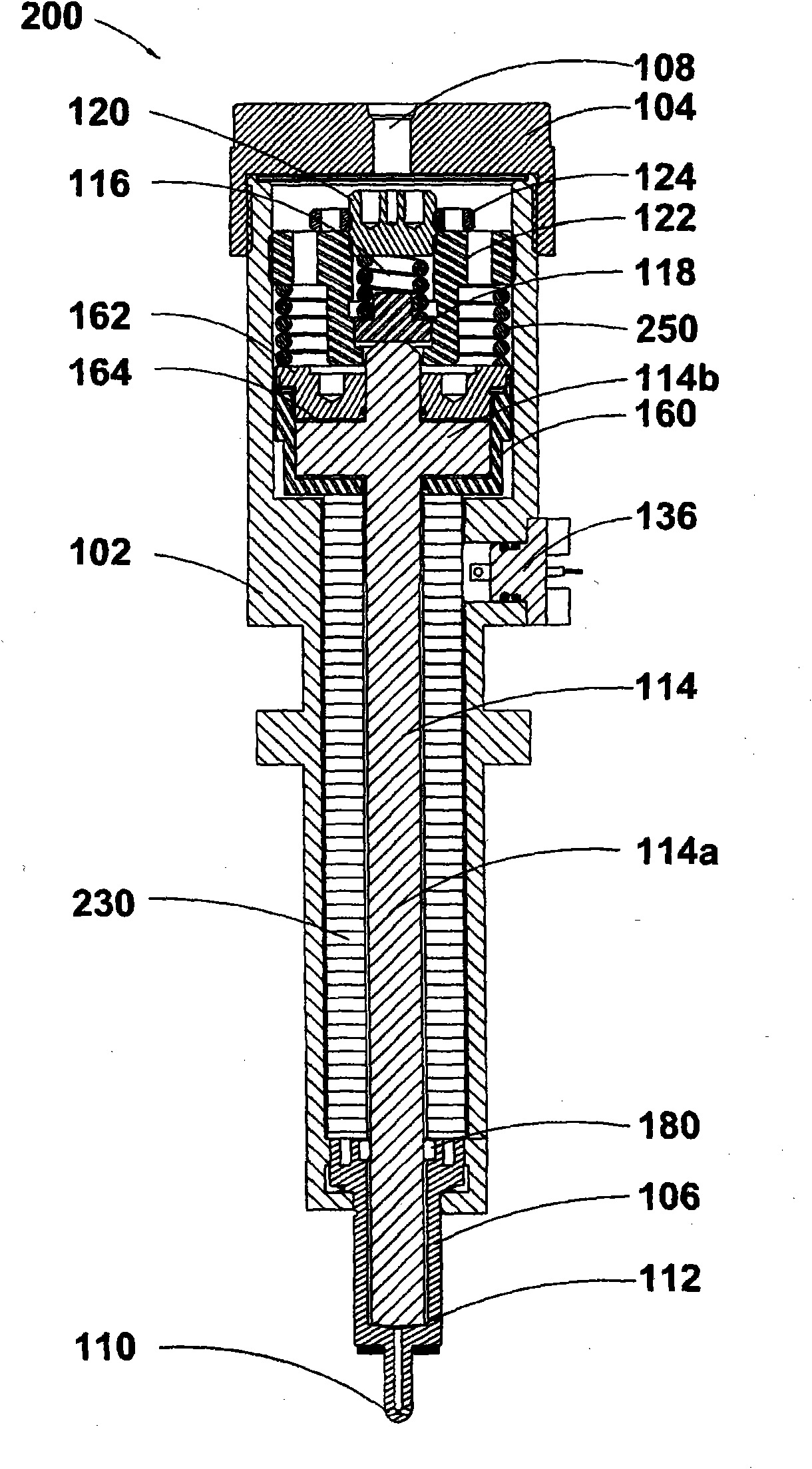

[0032] figure 1 and 2 Two preferred embodiments of directly actuated fuel injection valves 100 and 200 are shown, respectively, which can be used to inject fuel into the combustion chamber of an internal combustion engine. These examples of direct actuated injection valves with strain gauge actuators are described in detail to illustrate the differences between such injection valves and conventional electro-hydraulic actuated injection valves, which Actuated injection valves may use a strain gauge actuator to operate a hydraulically controlled valve. This distinction is important because currently disclosed methods of closing direct-actuated valves focus on the technical challenges associated with direct-actuated valves employing strain gauge actuators, and the disclosed methods are specific to this type of valve. valve. While injection of fuel into a combustion chamber is known to be one application for which the presently disclosed valve is particularly suitable, it is e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com