Strain type intelligent handle system for monitoring two-dimensional milling force

A milling force and strain type technology, applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., to achieve the effect of strong practicability, good economic and social benefits, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

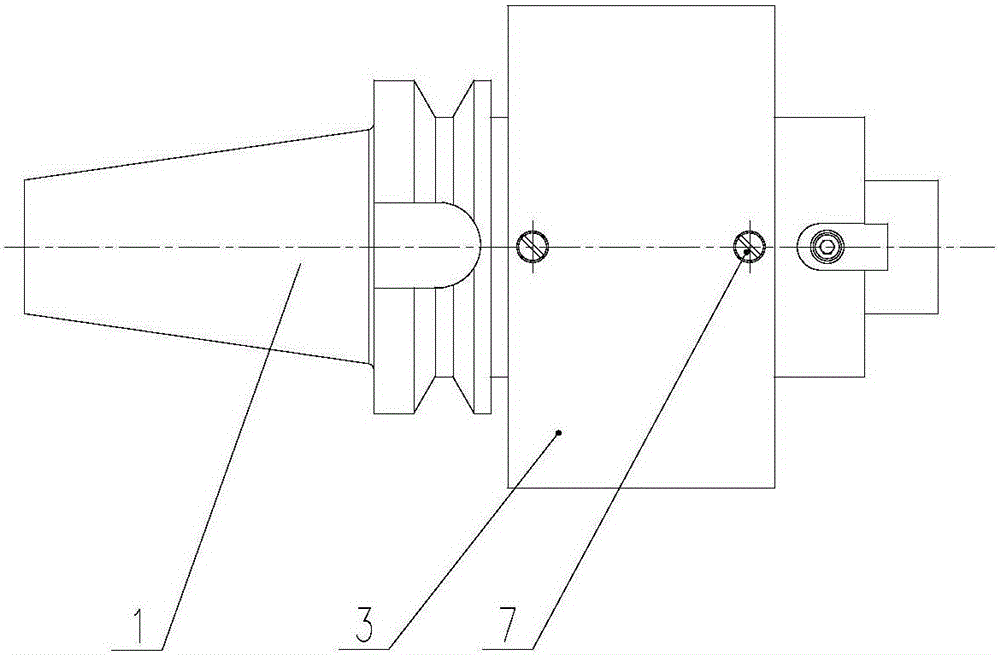

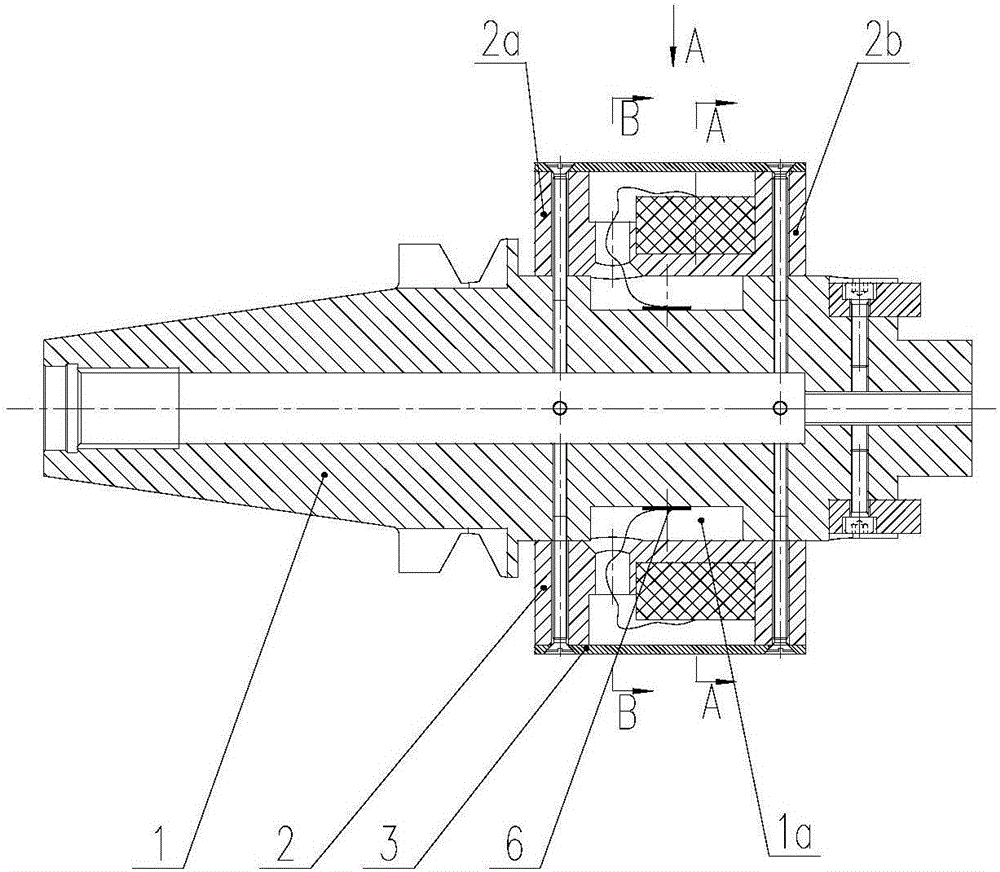

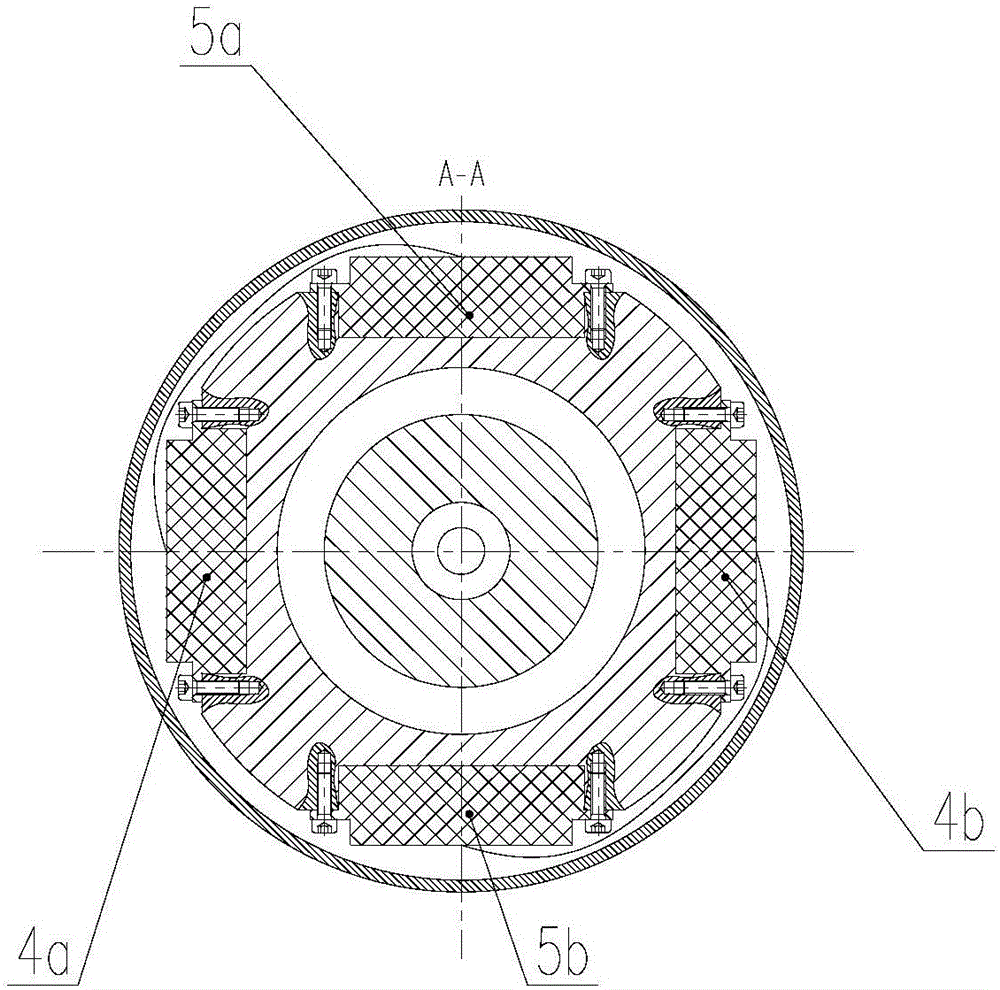

[0019] refer to Figure 1-5 , The strain-type intelligent tool handle system of the embodiment of the present invention is mainly composed of a standard tool handle 1, a circuit carrier 2, a sealing cover 3, a power supply module 4, an acquisition and emission module 5, a strain sensor 6, and the like. Wherein, the standard tool handle 1 is provided with an annular groove 1a, and a strain sensor 6 is pasted in the annular groove 1a. There are 8 threaded holes on both sides of the annular groove 1a, which are used for the cooperation of countersunk screws. The inner hole of the circuit carrier 2 is matched with the outer circle of the handle 1, and connected together by 8 countersunk head slotted screws. The two sides 2a and 2b of the circuit carrier 2 are cylindrical and have 8 through holes for passing the countersunk screws. The middle part 2c is compose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com