Patents

Literature

42results about How to "Improved low cycle fatigue performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Precipitation-strengthened nickel-iron-chromium alloy

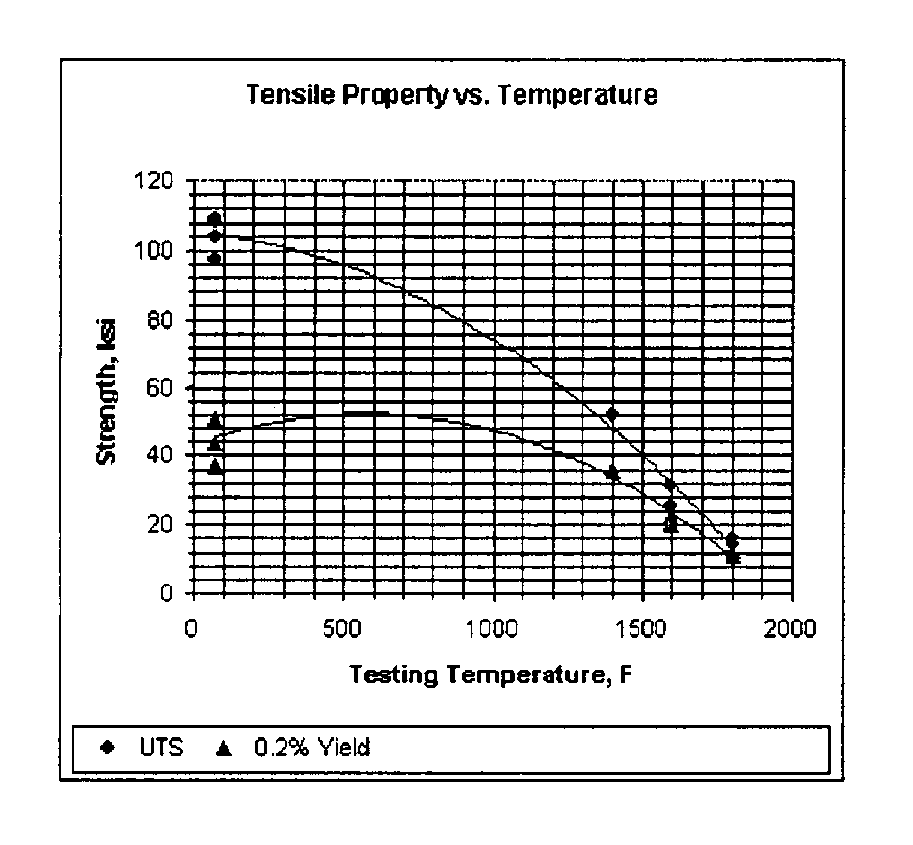

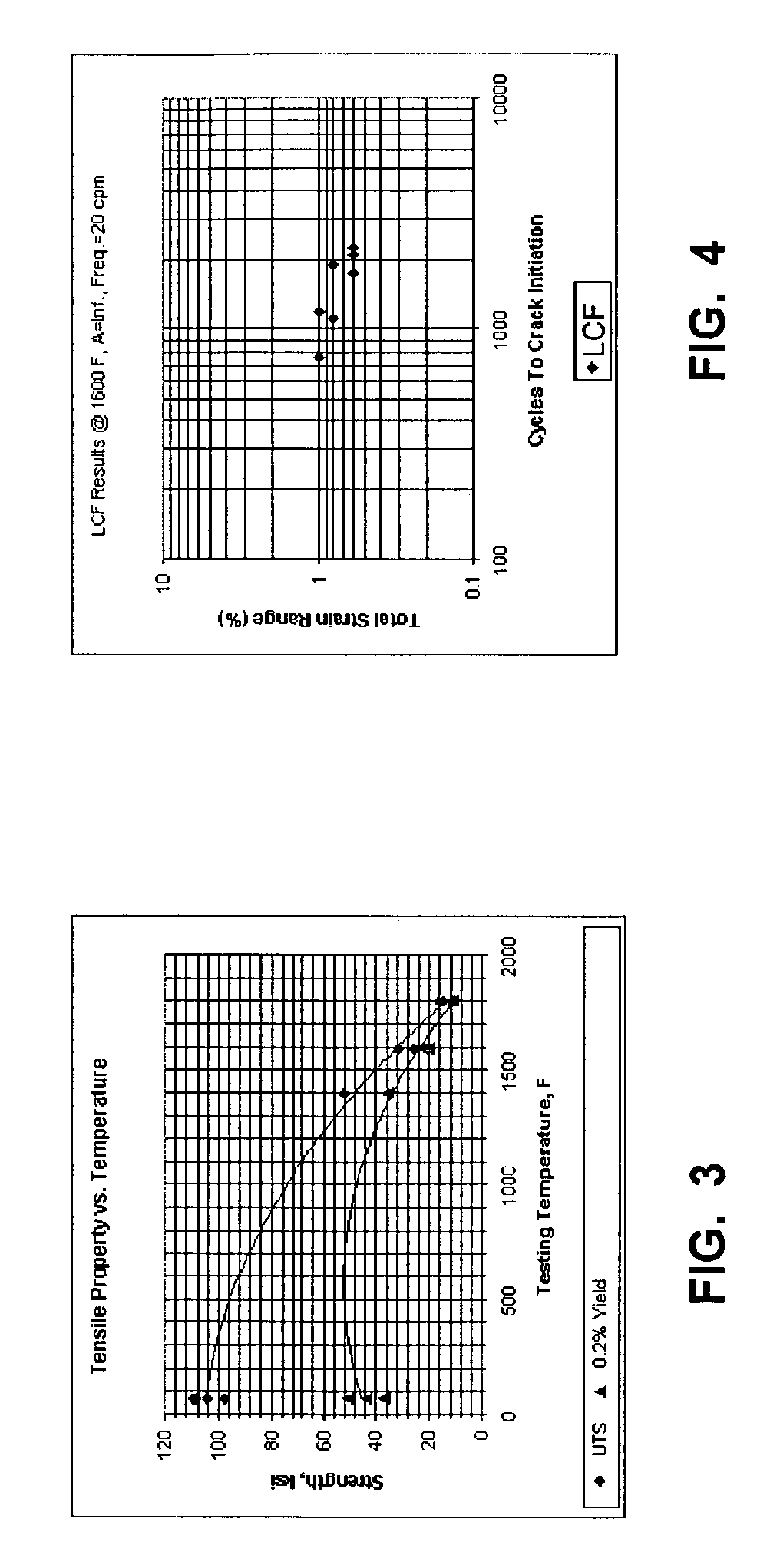

InactiveUS7118636B2Improved low cycle fatigue resistanceFine grain structureBlade accessoriesGas turbine plantsSolubilityAustenite grain

An Fe—Ni—Cr alloy formulated to contain a strengthening phase that is able to maintain a fine grain structure during forging and high temperature processing of the alloy. The alloy contains a sufficient amount of titanium, zirconium, carbon and nitrogen so that fine titanium and zirconium carbonitride precipitates formed thereby are near their solubility limit in the alloy when molten. In the production of an article from such an alloy by thermomechanical processing, a dispersion of the fine titanium and zirconium carbonitride precipitates form during solidification of the melt and remain present during subsequent elevated processing steps to prohibit austenitic grain growth.

Owner:GENERAL ELECTRIC CO

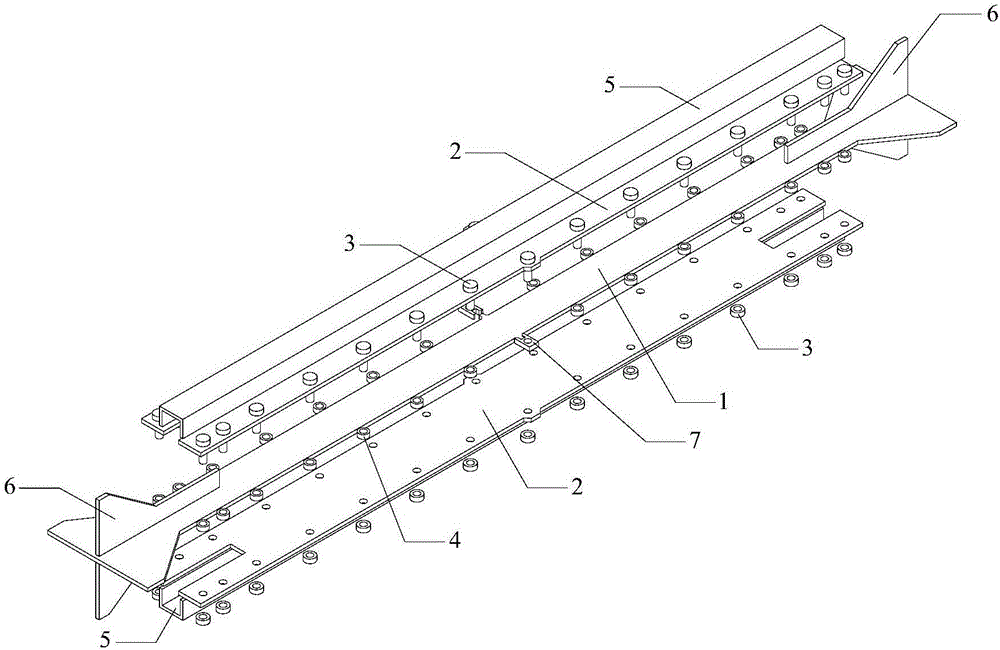

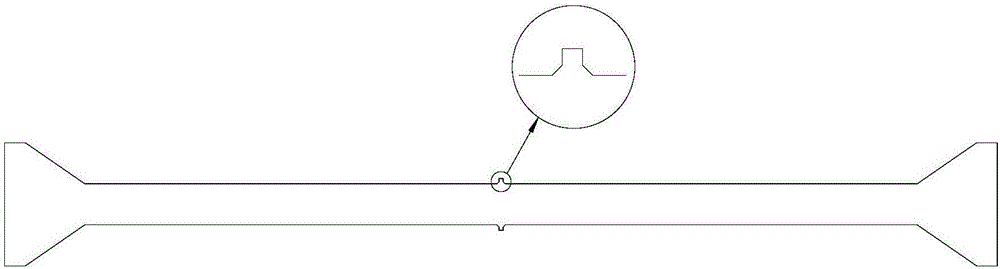

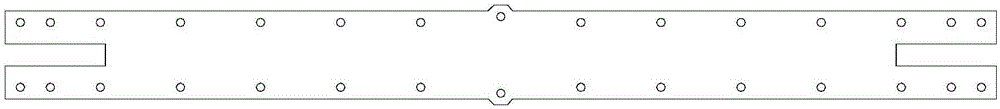

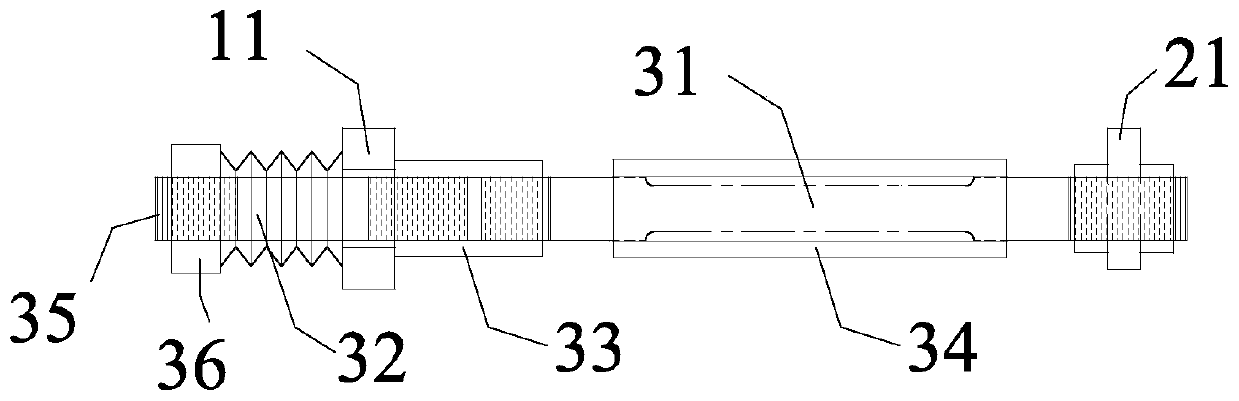

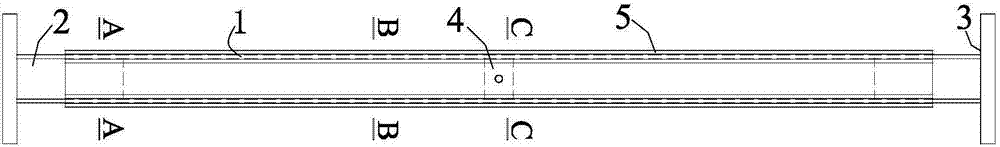

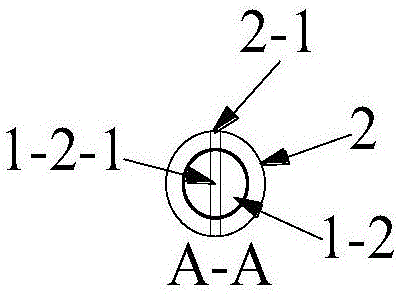

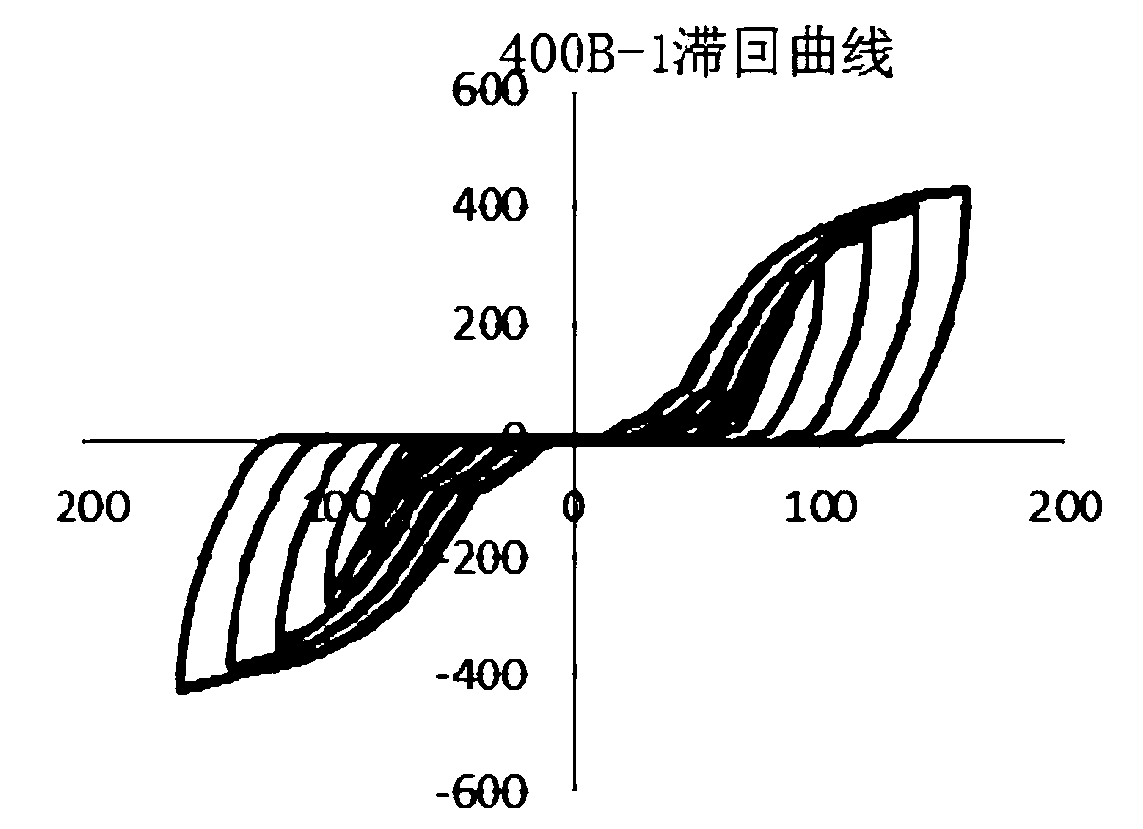

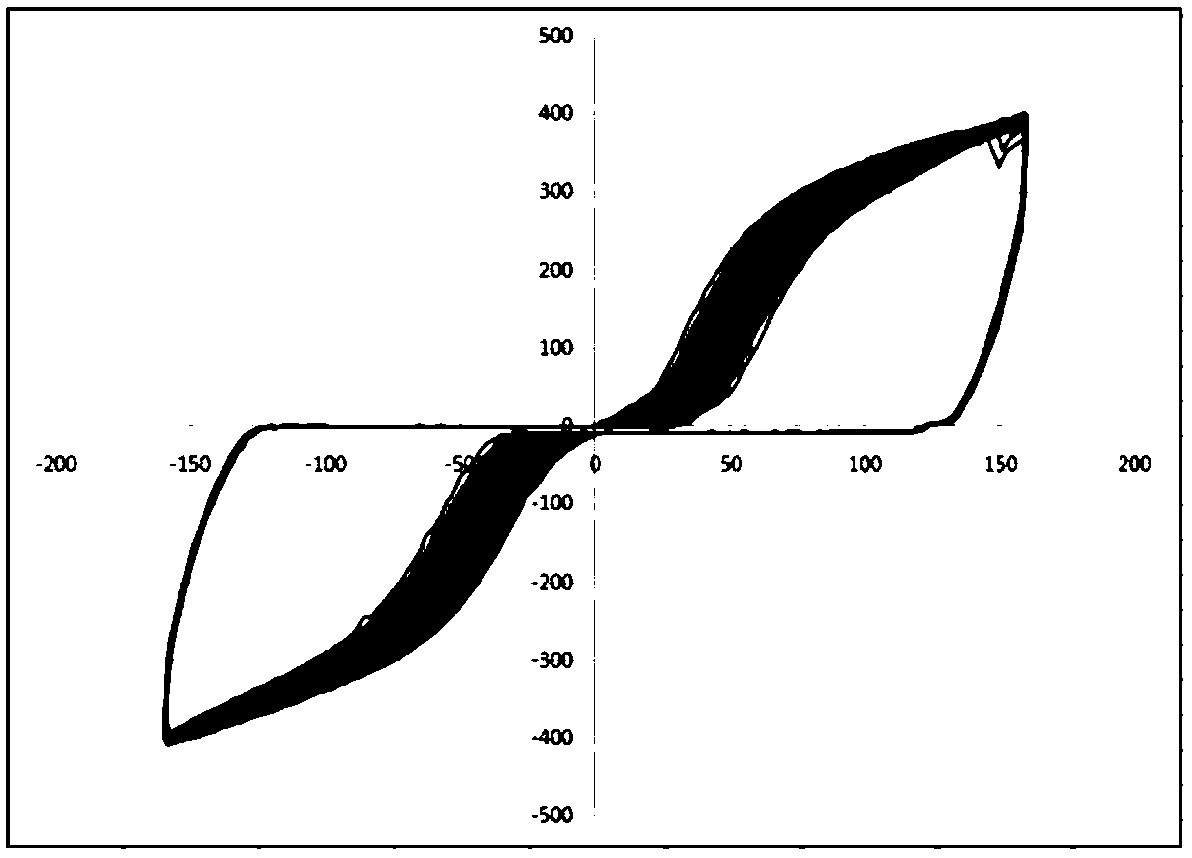

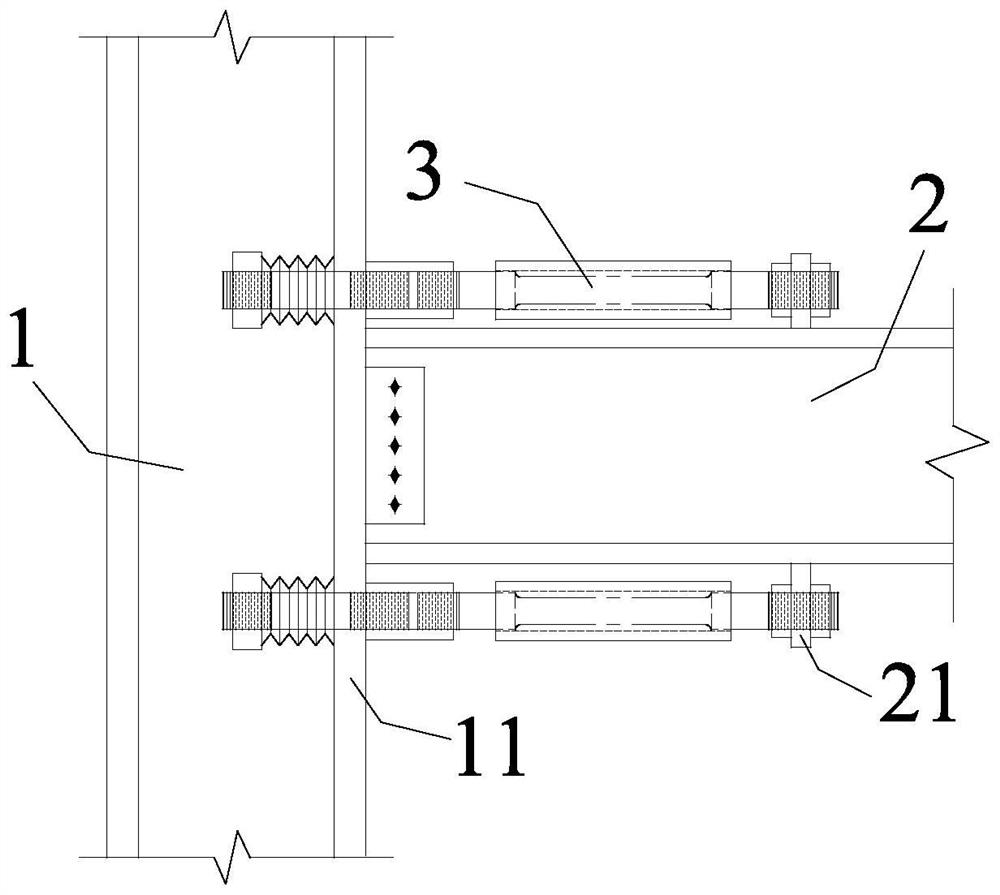

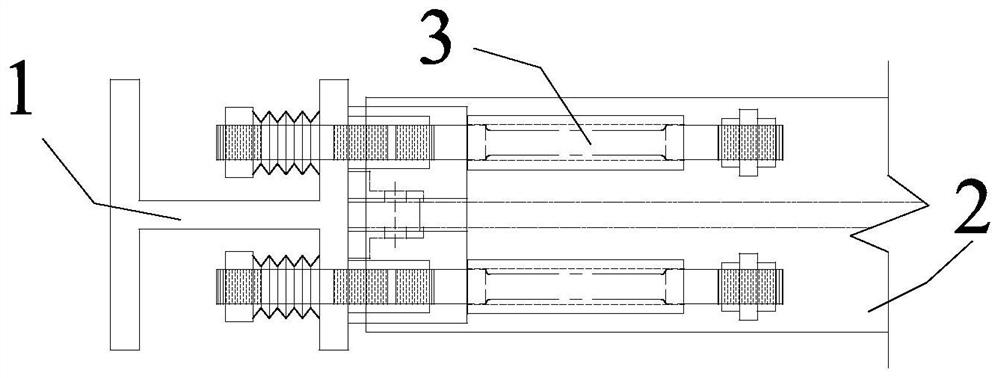

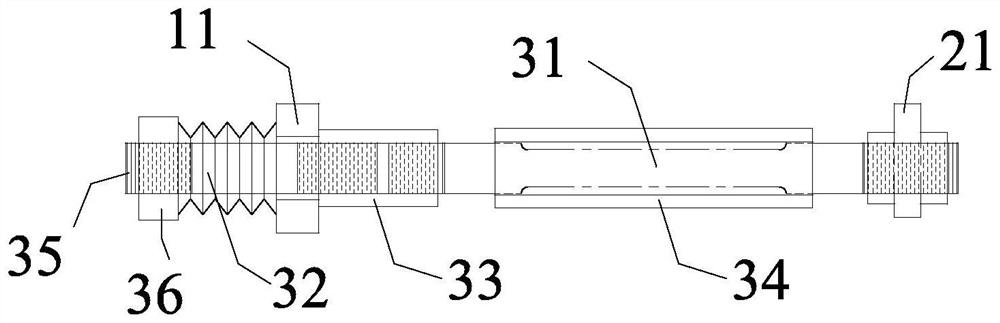

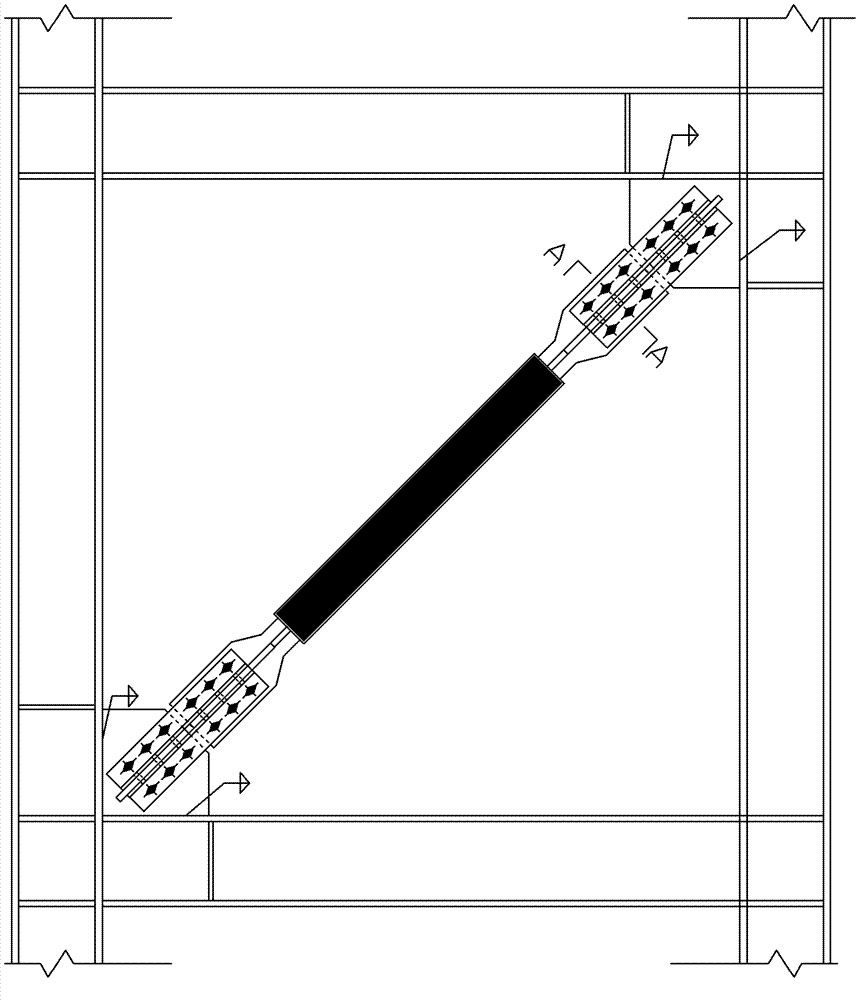

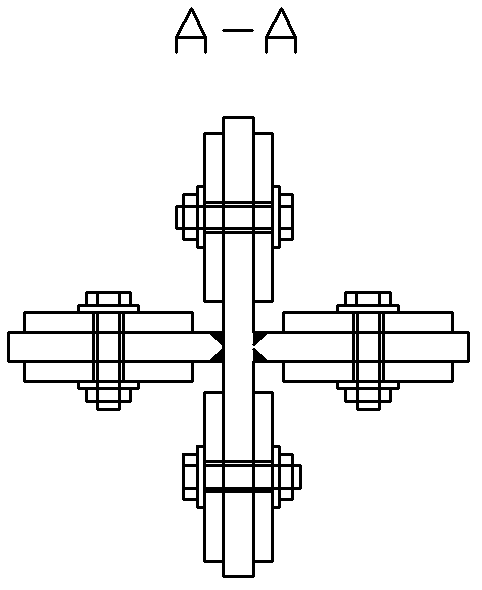

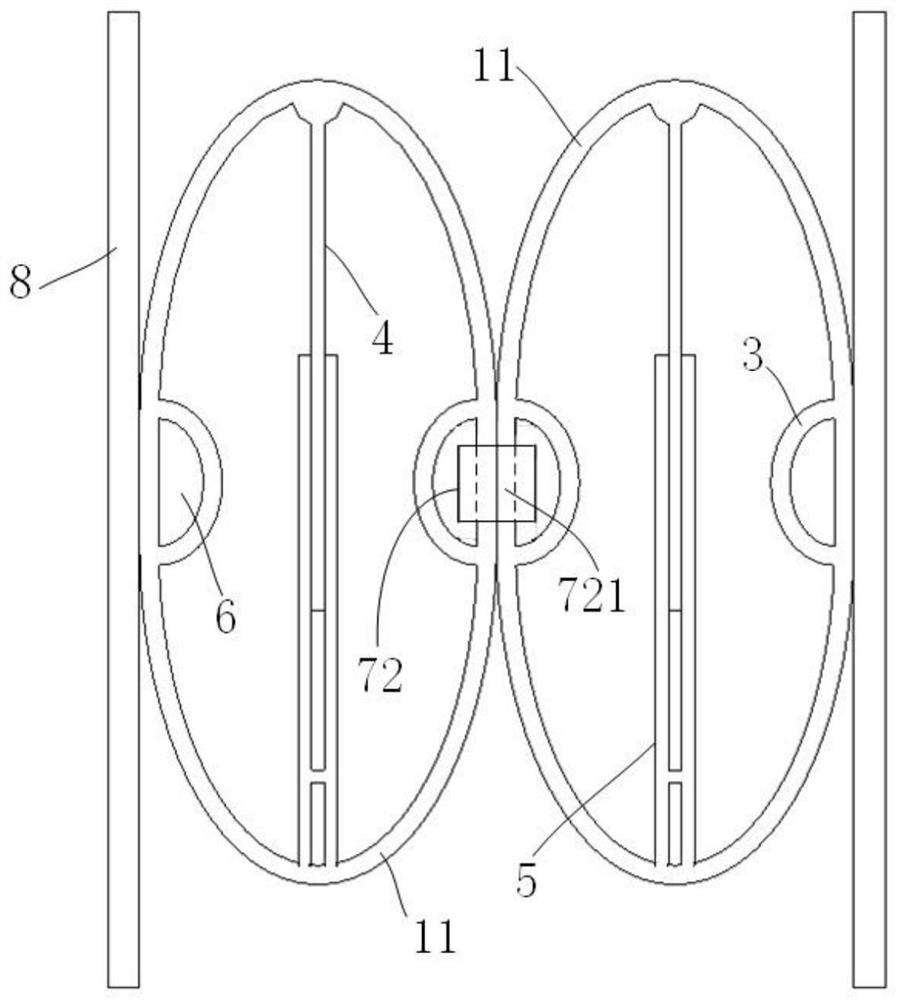

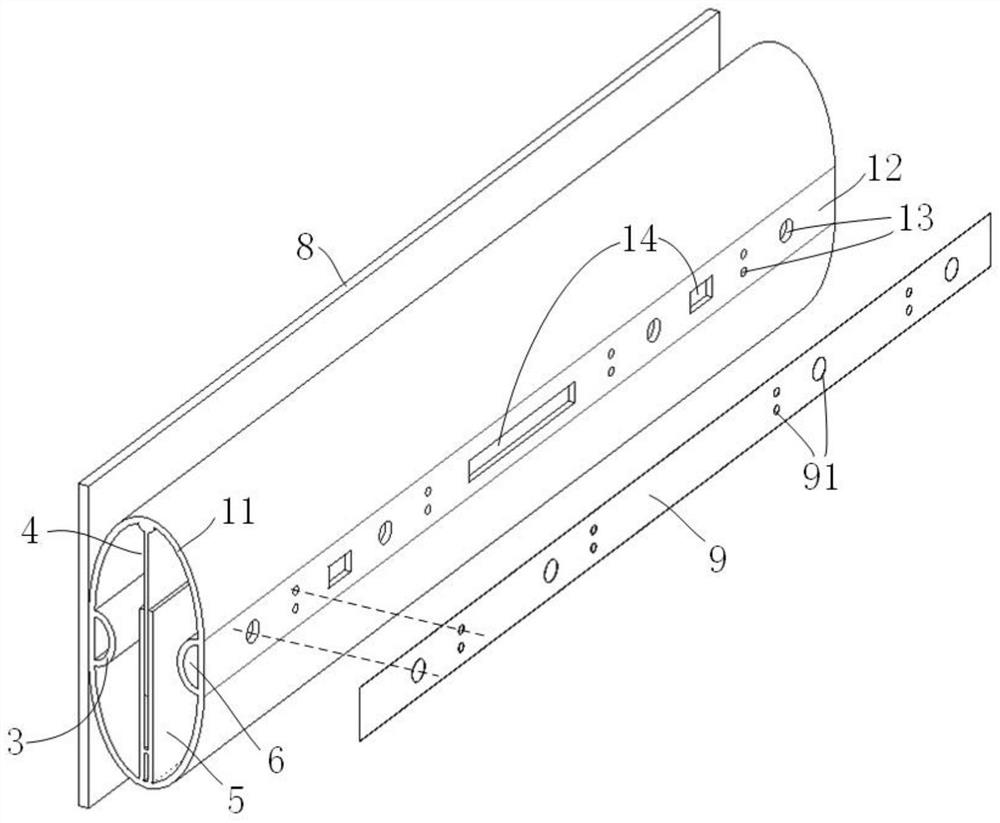

All-steel-assembled buckling restrained brace with lateral side capable of being inspected

InactiveCN106639029AEase of performance evaluationEasy to assembleProtective buildings/sheltersShock proofingBuckling-restrained braceEngineering

The invention provides an all-steel-assembled buckling restrained brace with the lateral side capable of being inspected. Welded joints at the ends of stiffening ribs are smoothed, the low-cycle fatigue performance of the brace is effectively improved, the plastic deformation capability of steel is adopted, and meanwhile the state of an inner core can be easily judged through the lateral side after a seism. The all-steel-assembled buckling restrained brace solves the problems that the deformation or damage state of the inner core cannot be conveniently evaluated rapidly after a seism, the welded joints at the ends of the stiffing ribs have quality defects, and the damaged inner core cannot be conveniently replaced. The buckling restrained brace achieves the aims that the deformation state of the inner core can be judged without detaching, and whether the inner core should be replaced or not can be rapidly evaluated after a seism; the welded joints at the ends of the stiffing ribs are processed, the middle cross section of the inner core is possibly damaged, and the low-cycle fatigue performance of the brace is improved; an assembled scheme is adopted, and the damaged inner core can be conveniently replaced. The all-steel-assembled buckling restrained brace comprises the inner core, the end stiffing ribs, two restrained face plates, gaskets, limiting grooves and high-strength bolts.

Owner:TONGJI UNIV

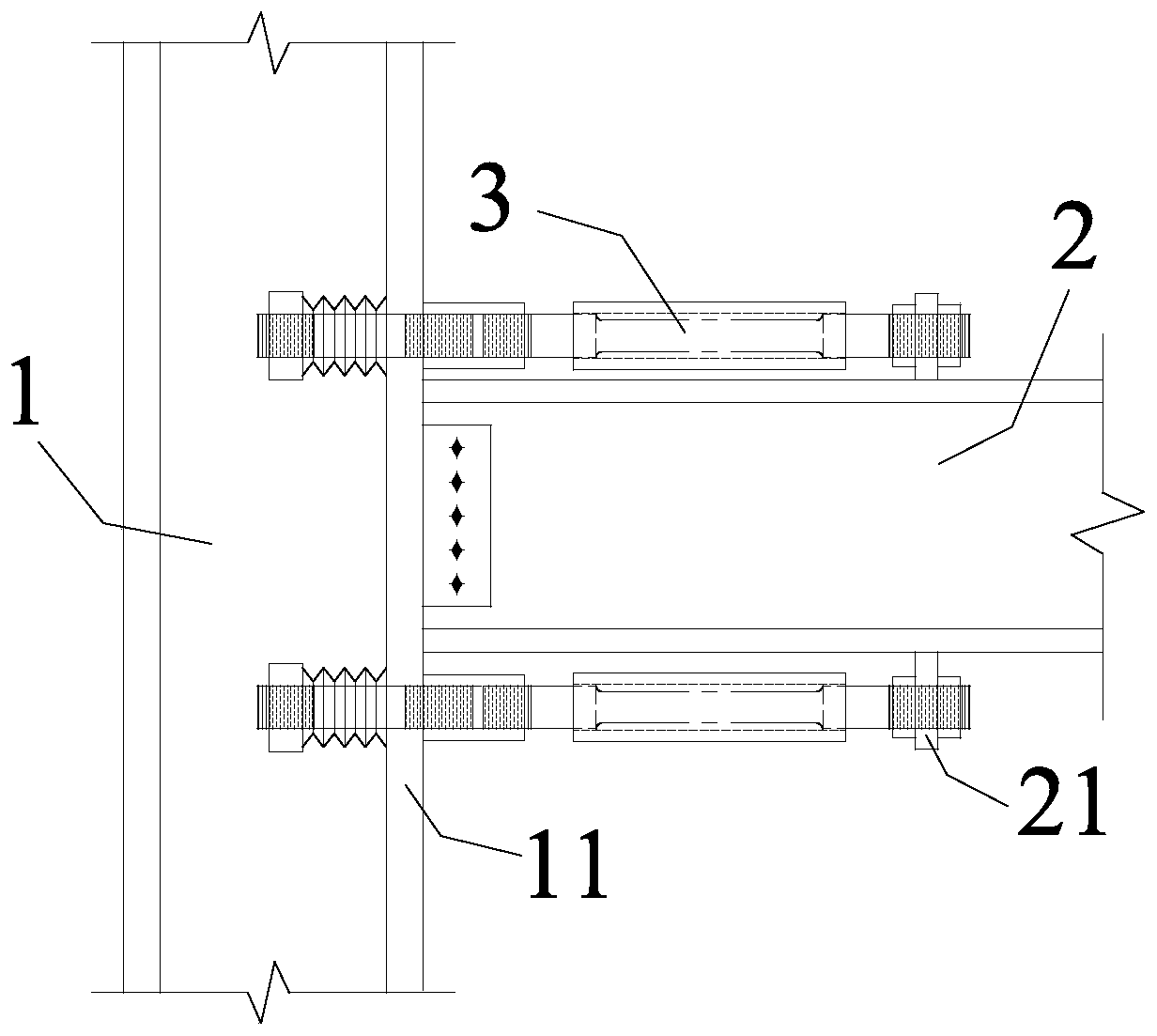

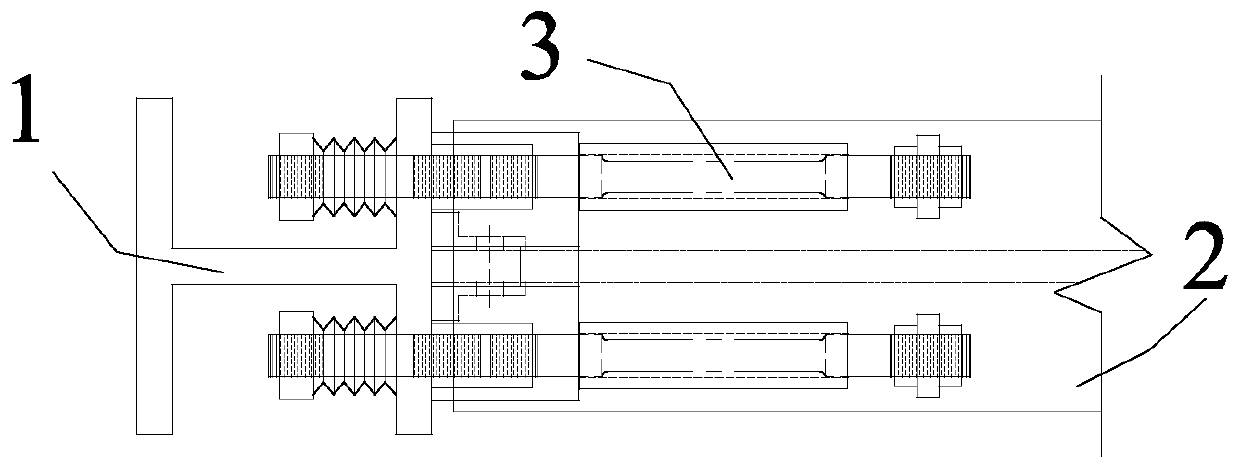

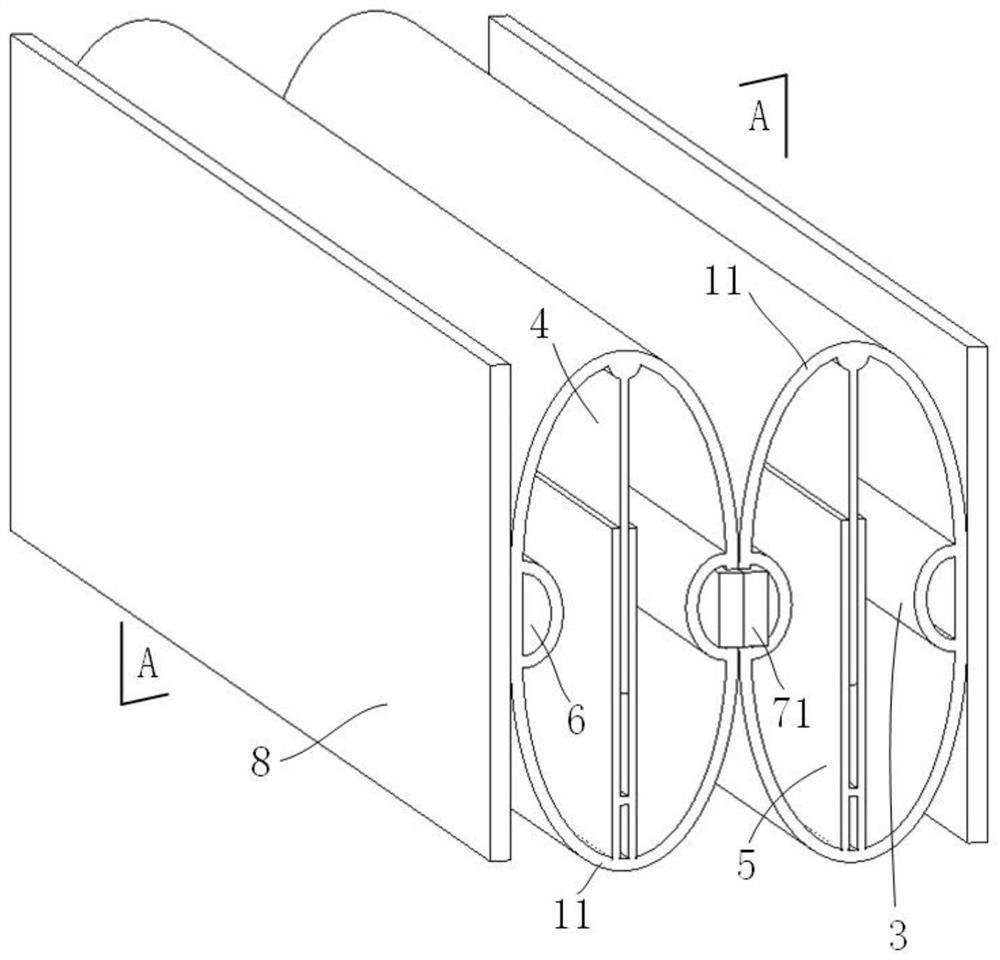

In-series disc spring large deformation energy consumption beam column node

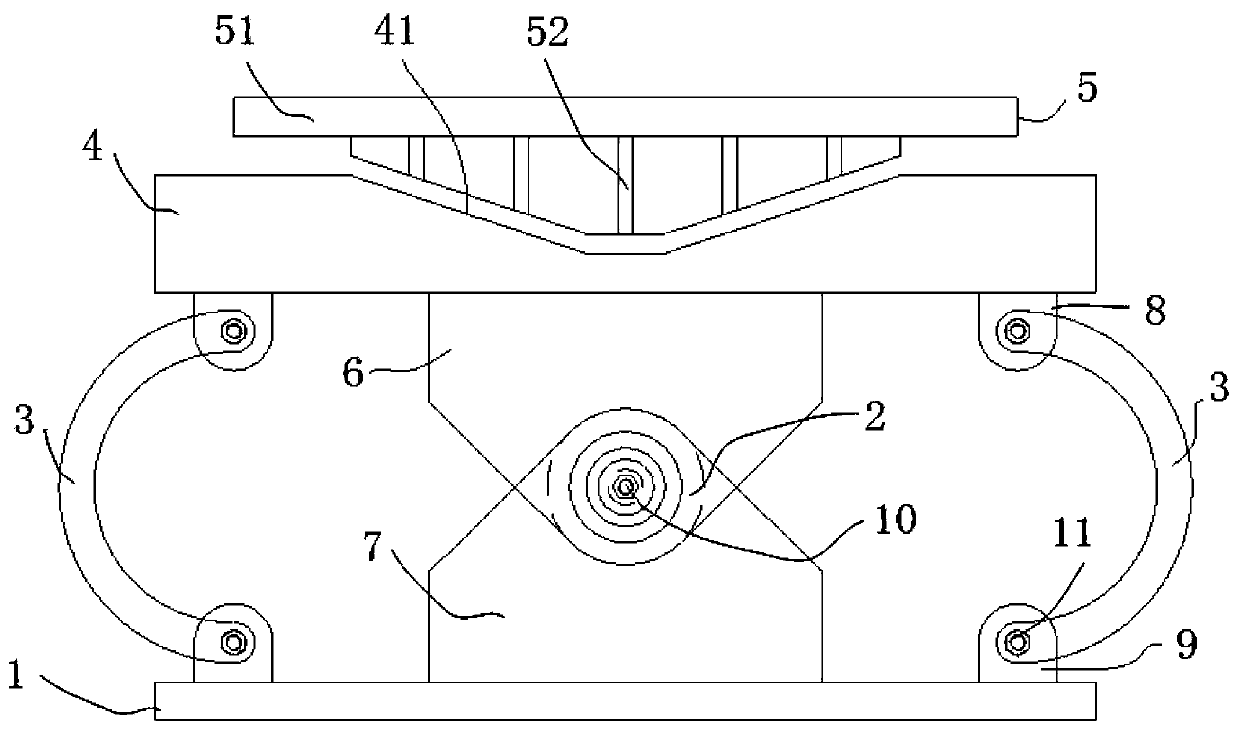

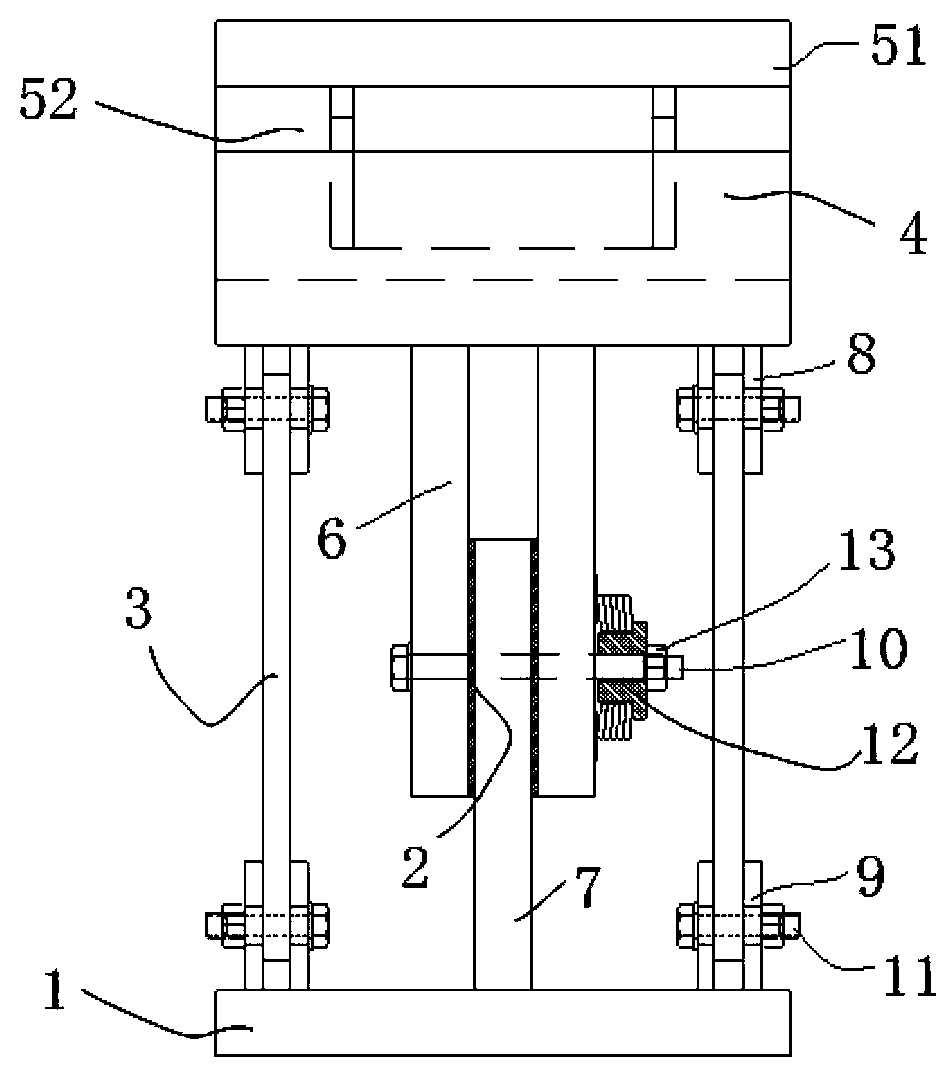

ActiveCN109798011AGive full play to energy consumption capacityImproved low cycle fatigue performanceProtective buildings/sheltersShock proofingEngineeringLarge deformation

The invention discloses an in-series disc spring large deformation energy consumption beam column node, which comprises an assembly type column, an assembly type beam and a disc spring combination type damper, wherein the disc spring combination type damper consists of an energy consumption rod, a disc spring set, an internal thread sleeve, an outer sleeve, a sliding guide rod and an extrusion nut, one end of the disc spring combination type damper is fixed on the fixed plate of a surface of the assembly type beam, and the other end passes through the flange plate of the assembly type column and presses tightly the flange plate. By adjusting the pressure of the extrusion nut, tensile deformation generated by the two ends of the disc spring combination type damper can be fully supplied by the energy consumption rod under the action of small and moderate earthquakes, the other part is supplied by the compressive deformation of the disc spring set, so that the disc spring combination typedamper has better deformability, and the fatigue performance of the disc spring combination type damper is conducive to being improved.

Owner:SOUTHEAST UNIV

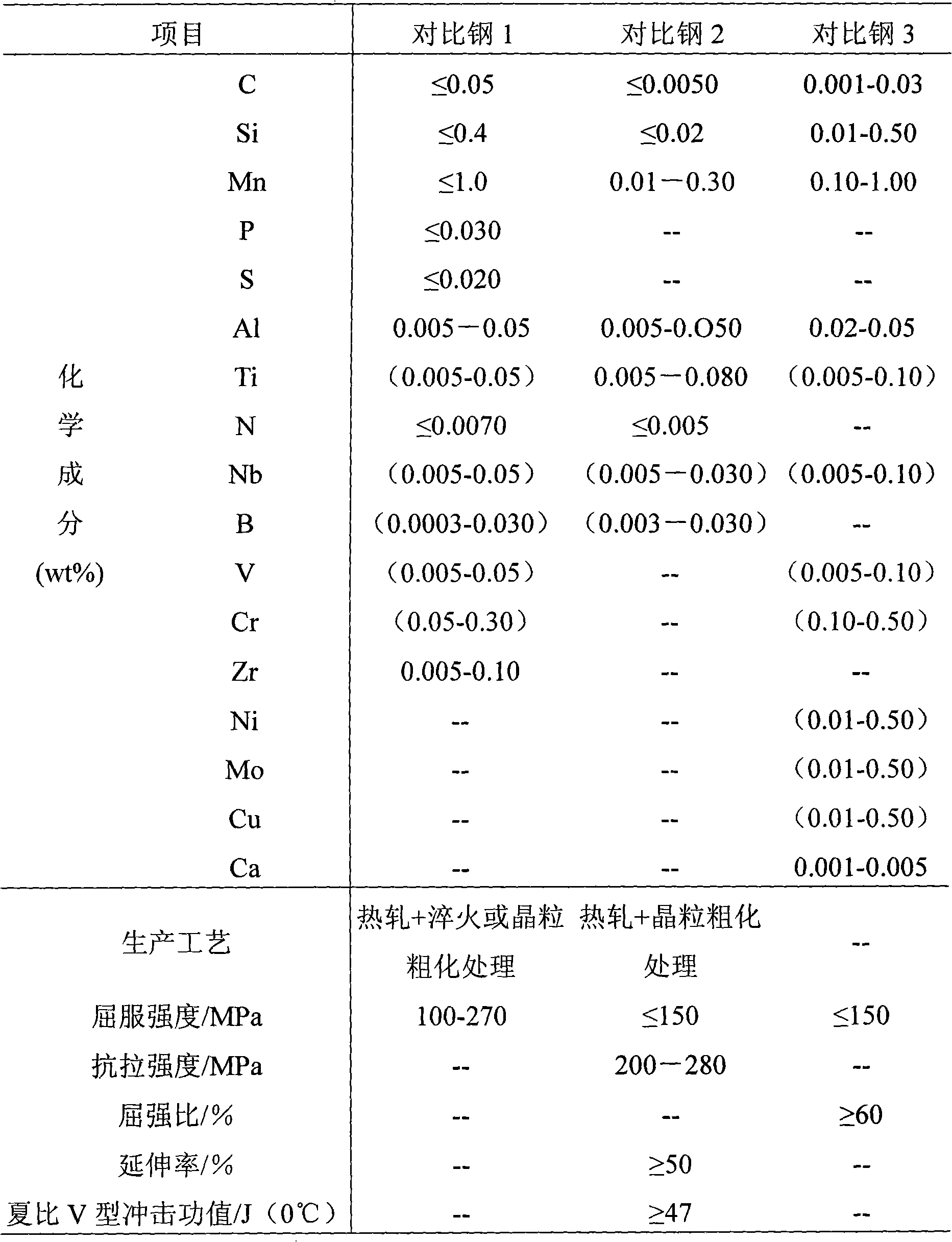

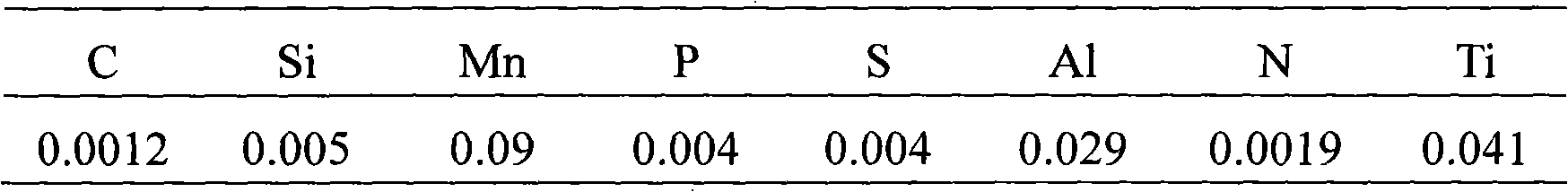

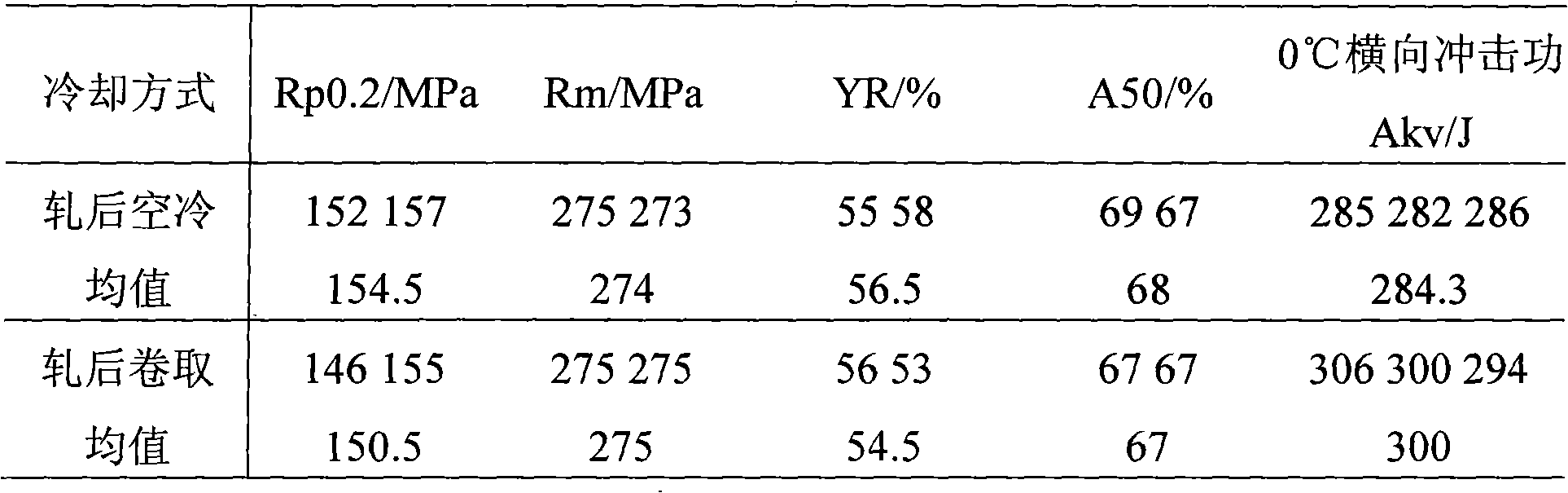

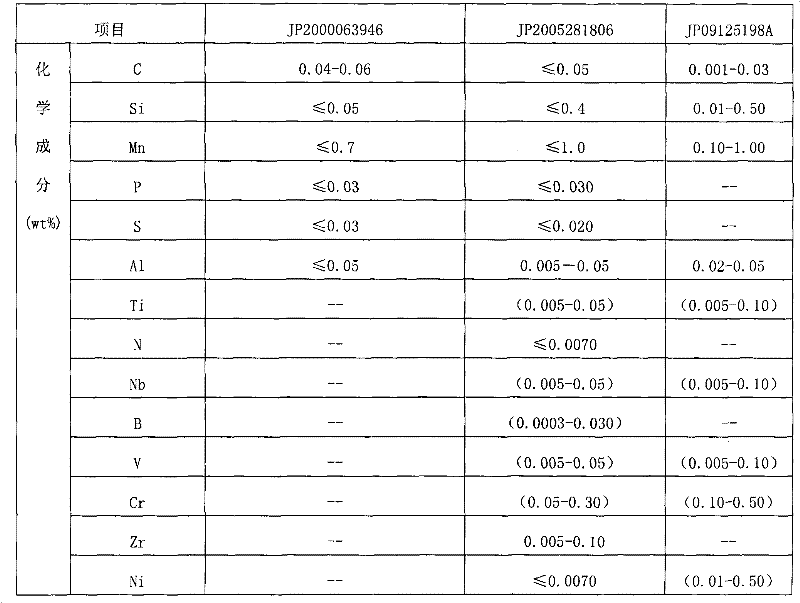

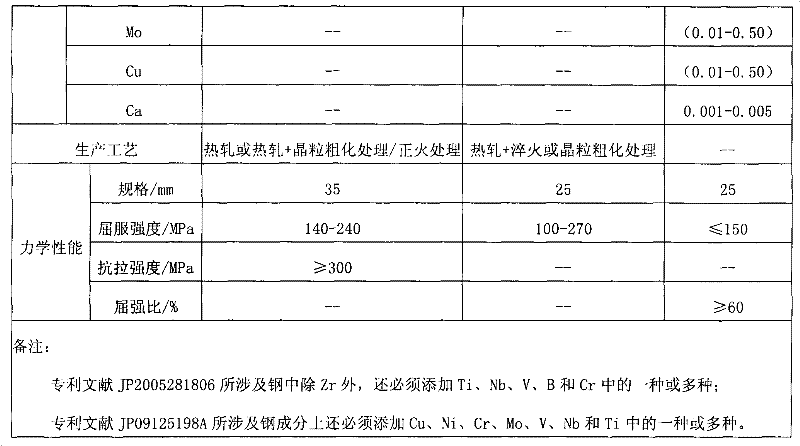

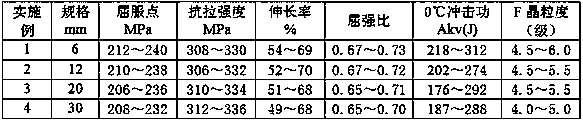

Yield strength 160MPa grade building earthquake-resistance low-yield strength steel and method for producing same

ActiveCN101514425AImprove mechanical propertiesExcellent 0℃ impact toughnessEarthquake resistanceChemical composition

The invention provides low-yield strength building earthquake-resistance steel, which comprises the following chemical components (in weight percentage): 0.01 to 0.05 percent of C, 0.02 percent of Si, 0.05 to 0.15 percent of Mn, less than or equal to 0.01 percent of P, less than or equal to 0.006 percent of S, 0.01 to 0.05 percent of Al, less than or equal to 0.005 percent of N, 0.01 to 0.10 percent of Ti, and the balance of Fe and inevitable impurity elements. The invention also provides a method for producing the earthquake-resistance steel. The earthquake-resistance steel has excellent comprehensive mechanical properties, a yield strength of 140 to 180MPa, an elongation of more than 50 percent, excellent plastic deformation capacity, excellent zero degree centigrade impact toughness, an excellent low cycle fatigue property and excellent welding performance, and is suitable to be used in building earthquake-resistance design to protect main buildings and is simple in production process, low in cost and suitable for large-scale production.

Owner:BAOSHAN IRON & STEEL CO LTD

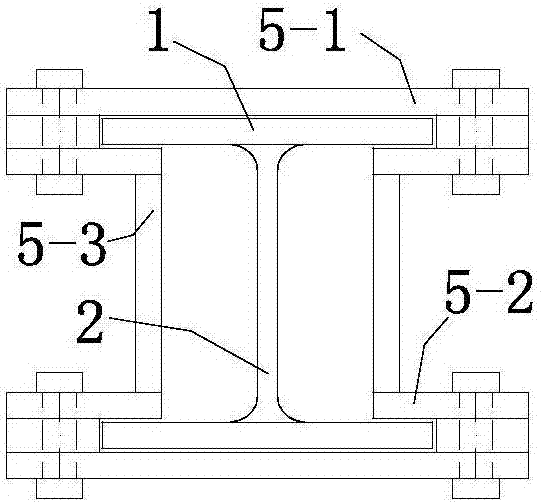

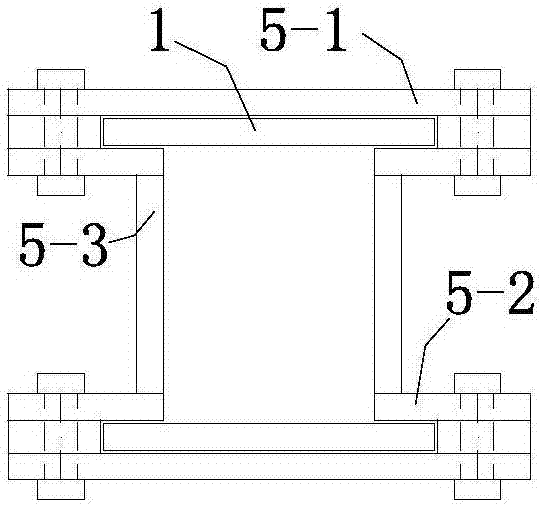

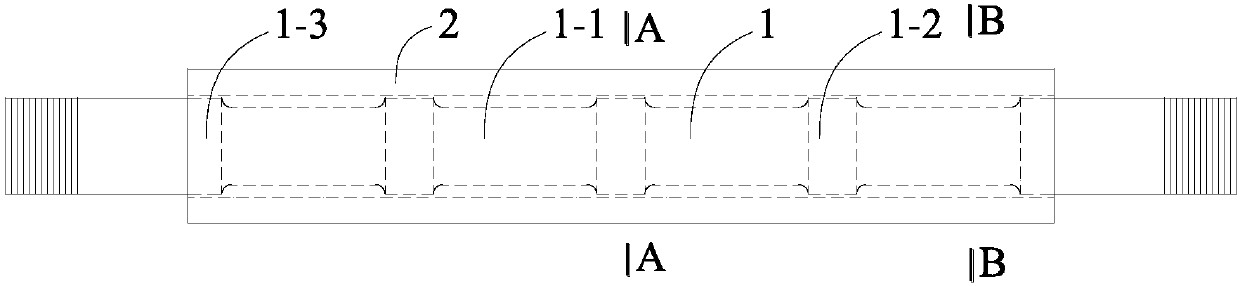

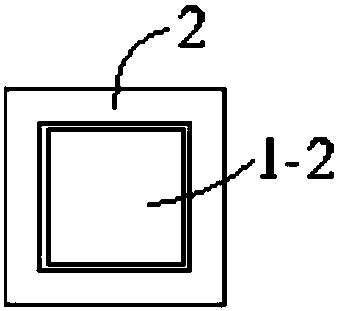

Dual-core visual inspection buckling restraint support

ActiveCN106869354AImproved low cycle fatigue performanceControllable bending stiffnessProtective buildings/sheltersShock proofingBuckling-restrained braceDual core

The invention discloses a dual-core visual inspection buckling restraint support. The dual-core visual inspection buckling restraint support comprises two energy consumption inner core panels, two sets of end stiffening plates, two end connecting plates, a plurality of sets of connecting positioning plates and a peripheral restraint component; the two energy consumption inner core panels are arranged in parallel in the panel thickness direction, the end stiffening plates are rectangular plates, the two opposite sides of each set of end stiffening plates are perpendicularly and fixedly connected with the parallelly-arranged energy consumption inner core panels, and the other sides of the end stiffening plates and the end sides of the energy consumption inner core panels are located in the same plane; the end connecting plates are fixedly connected with the end sides of the two energy consumption inner core panels and one sides of the end stiffening plates; and the connecting positioning plates are also rectangular plates, in the parallelly-arranged energy consumption inner core panels, the two opposite sides of the connecting positioning plates are perpendicularly and fixedly connected with the energy consumption inner core panels, and all the connecting positioning plates are located in the same plane and distributed at equal intervals.

Owner:SOUTHEAST UNIV

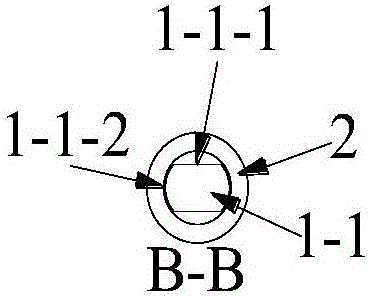

Vertical type bamboo-shaped round rod energy consumption rod

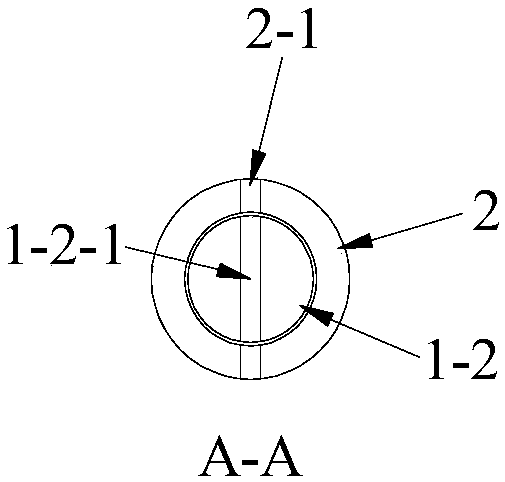

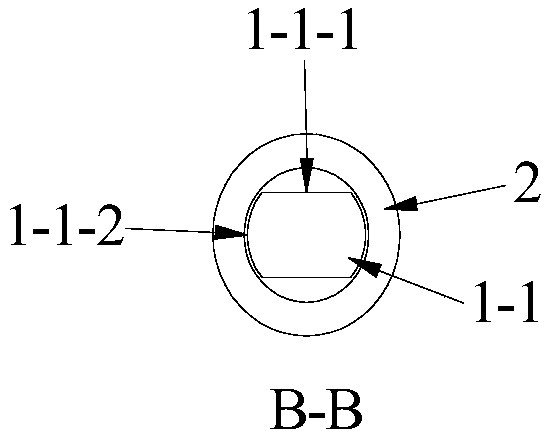

ActiveCN106760854AAvoid torsional deformationConstrained Lateral DeformationProtective buildings/sheltersShock proofingEnergy consumption

The invention discloses a vertical type bamboo-shaped round rod energy consumption rod comprising a core part, an outer restraint part and a locating pin. The core part is composed by connecting a plurality of mutually-perpendicular energy dissipation sections, intermediate limiting sections, bamboo sections and two-end connecting sections along the longitudinal coaxial axis. The intermediate limiting sections are located in the middle of the core part. The bamboo sections and the energy dissipation sections are distributed at intervals, arranged on the two sides of the intermediate limiting sections and form a whole together with the intermediate limiting sections, and the two ends of the outer sides of the bamboo sections and the energy dissipation sections are fixedly connected with the two-end connecting sections to form the core part. The cross sections of the intermediate limiting sections, the bamboo sections and the two-end connecting sections are all circular. First holes are formed in the middles of the intermediate limiting sections in the diameter direction. The energy dissipation sections are cut and manufactured in the length direction, so that the cross sections of the energy dissipation sections are two parallel opposite sides, the other two short sides are original arc lines, under the effect of the axial tensile pressure, the energy dissipation sections of the core part enter yielding through the formed new cross section areas, while the intermediate limiting sections, the bamboo sections and the two-end connecting sections always remain elastic.

Owner:SOUTHEAST UNIV

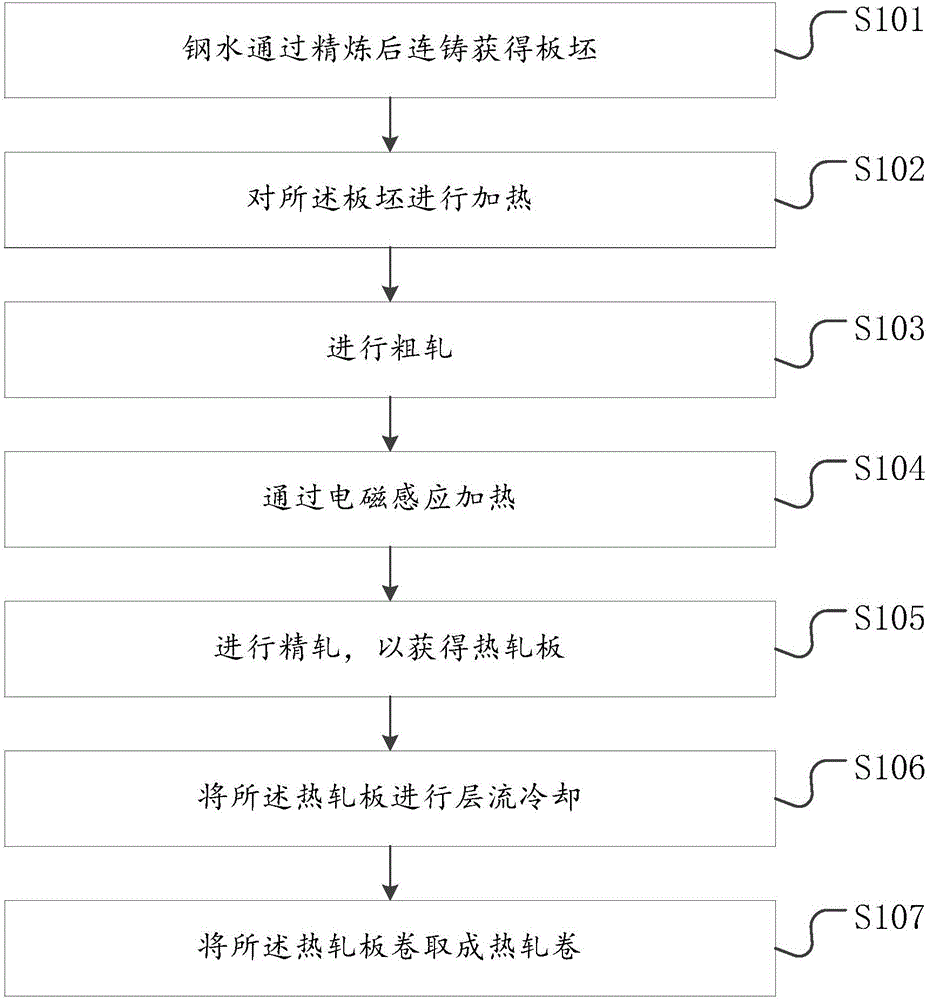

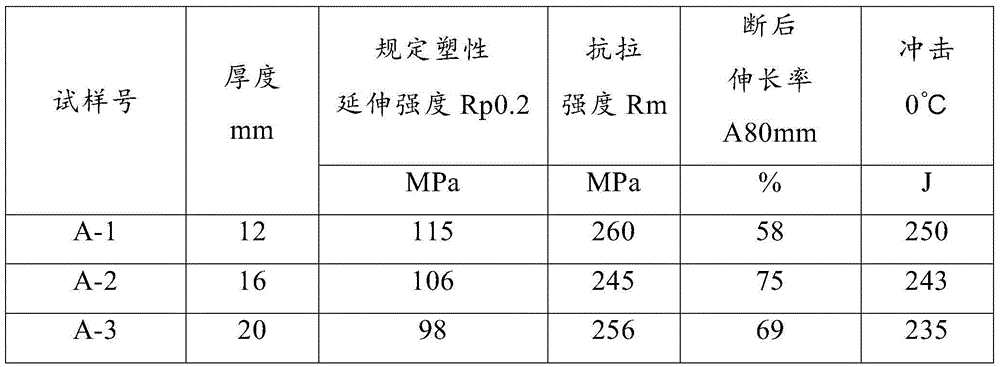

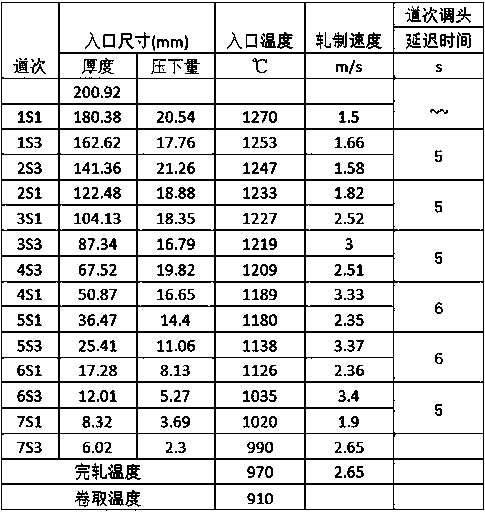

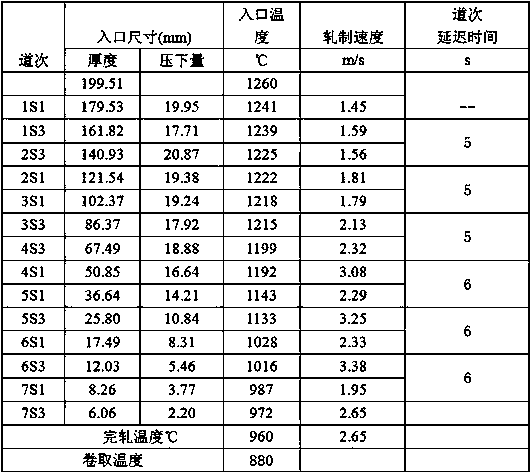

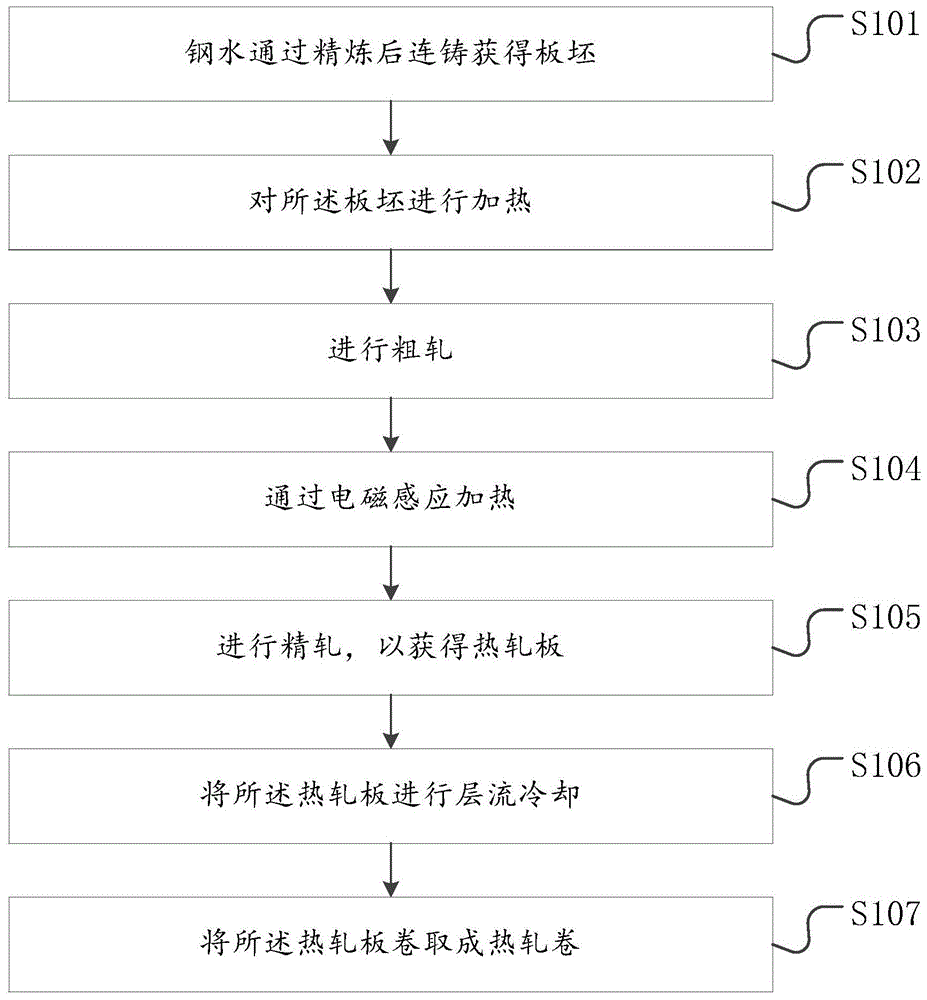

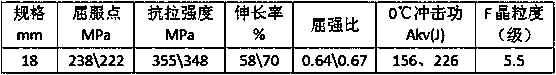

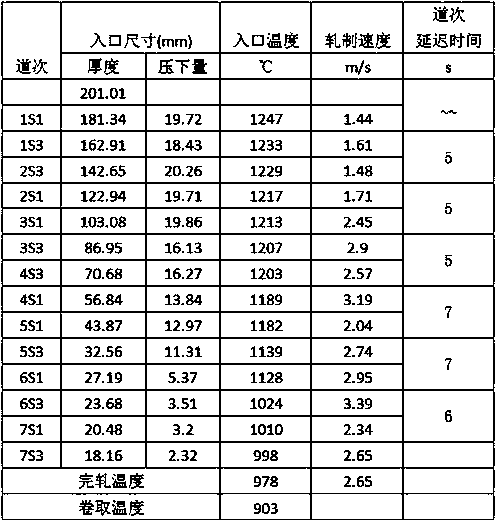

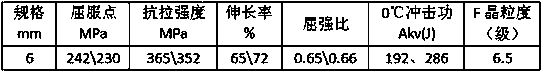

Manufacturing method of 100-MPa low-yield-point architectural antiseismic steel

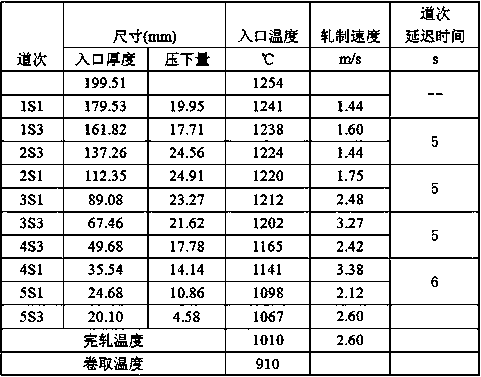

The invention discloses a manufacturing method of 100-MPa low-yield-point architectural antiseismic steel. The steel comprises the following chemical components in percentage by mass: at most 0.01% of C, at most 0.02% of Si, 0.05-0.1% of Mn, 0.01-0.06% of Al, at most 0.01% of P, at most 0.004% of S, at most 0.004% of N, 0.01-0.08% of Ti, and the balance of Fe and inevitable impurities. The method comprises the following steps: refining, continuous casting, heating, rough rolling, electromagnetic induction heating, finish rolling, laminar cooling, coiling and the like. The yield strength of the 100-MPa low-yield-point architectural antiseismic steel is up to 80-120 MPa, and the elongation percentage is greater than 50%; and the steel has the advantages of favorable plastic deformation, favorable impact toughness, lower alloy cost, practical technique, favorable weldability and favorable low cycle fatigue property.

Owner:SHOUGANG CORPORATION

Austenitic stainless steel continuous tube with low carbon and high strength and preparation method thereof

The invention discloses an austenitic stainless steel continuous tube with low carbon and high strength and a preparation method thereof. The austenitic stainless steel continuous tube comprises the components in percentage by mass: at most 0.03% of C, at most 1.00% of Si, 4.00-8.00% of Mn, at most 0.050% of P, at most 0.005% of S, 18-20% of Cr, 3-5.0% of Ni, 1.2-3.5% of Cu, 0.20-0.30% of N, at most 0.3% of Mo and the rest Fe and unavoidable impurities. The preparation method comprises the steps of (1) manufacturing a coil plate; (2) longitudinally shearing the coil plate and lengthening a steel band; and (3) forming the steel band, using laser welding, conducting rapid cooling after welding, and thus obtaining the stainless steel continuous tube. The produced continuous tube has high strength, low cost and good corrosion resistance by optimizing the alloy content and improving the manufacturing process.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

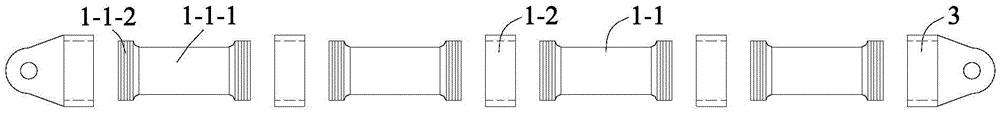

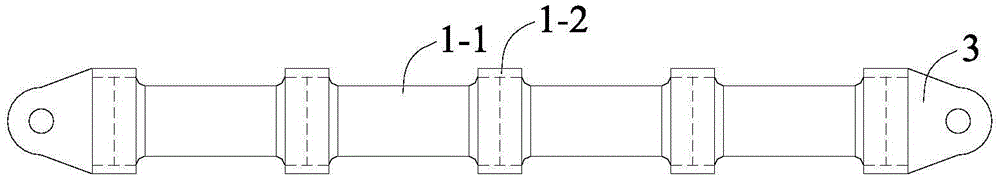

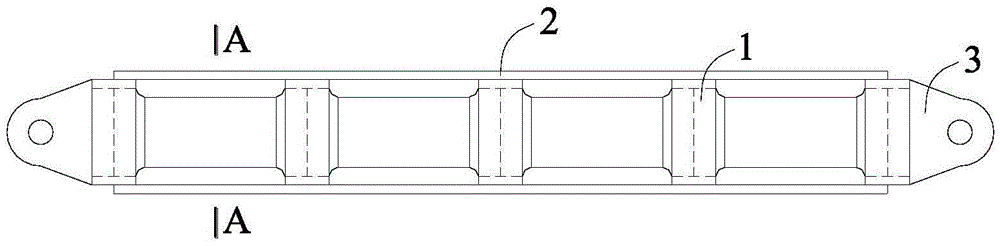

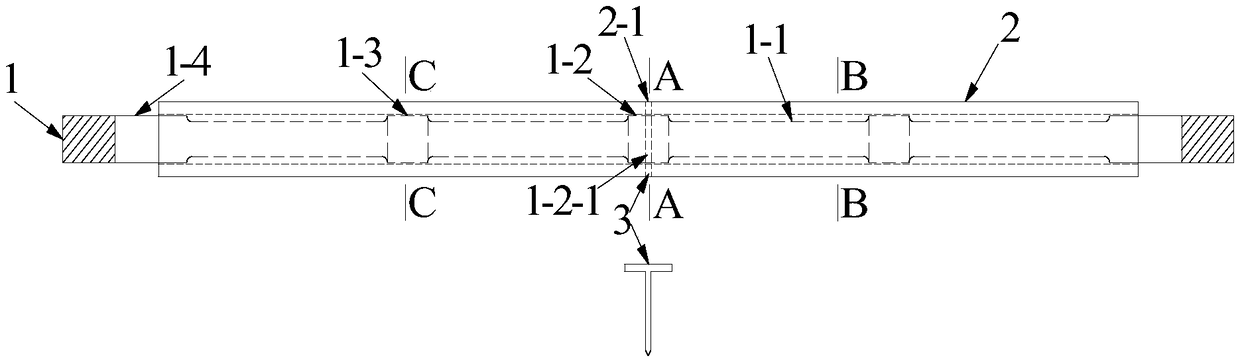

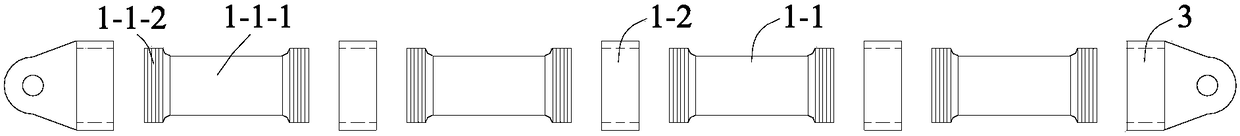

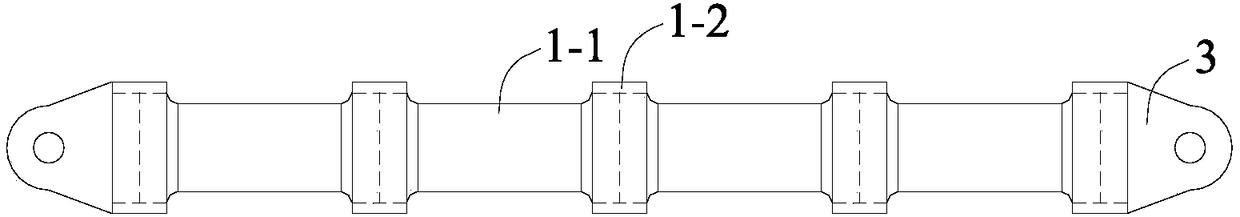

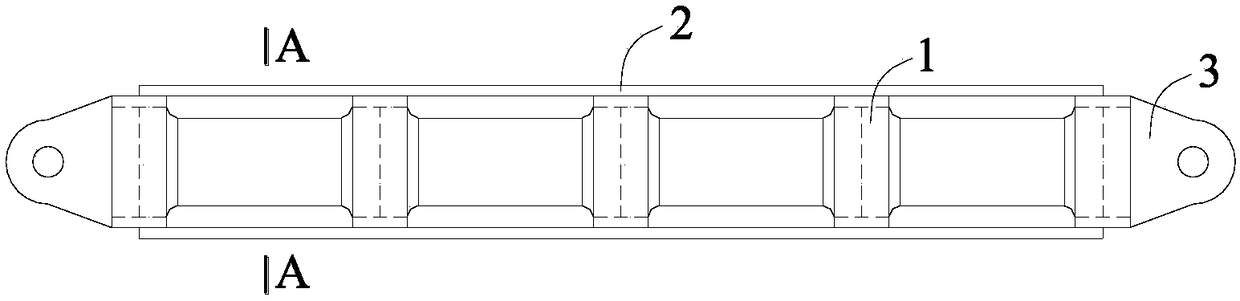

Modularized bamboo-shaped buckling restrained brace

ActiveCN105604205AIncrease production capacityRealize the designShock proofingBuckling-restrained braceEngineering

The invention discloses a modularized bamboo-shaped buckling restrained brace which comprises a core part, an outer restraining part and a structure connecting part. The core part comprises a plurality of circular energy dissipation sections and a plurality of elastic sleeves. Each circular energy dissipation section comprises a middle section and connecting sections at two ends. The core part is located inside the outer restraining part. The inner surface of the outer restraining part closely attaches to or is tangent to the outer surfaces of the elastic sleeves of the core part. One end of the structure connecting part extends into the outer restraining part, and the other end thereof extends out of the outer restraining part to be connected with a structure. The modularized bamboo-shaped buckling restrained brace has the advantages that the circular energy dissipation sections and elastic sleeves of the modularized bamboo-shaped buckling restrained brace can be produced in batch in factories, the circular energy dissipation sections and elastic sleeves can be selected and combined according to the length requirement of the buckling restrained brace, and accordingly the modularized production and design of the core part can be achieved.

Owner:CHINA JINGYE ENG TECH CO LTD +2

Bamboo-shaped round bar energy-dissipating rod

ActiveCN106760855BAvoid torsional deformationReduce surface strainProtective buildings/sheltersShock proofingRound barEnergy consumption

The invention discloses a bamboo-shaped round rod energy consumption rod comprising a core part, an outer restraint part and a locating pin. The core part is composed by connecting a plurality of energy dissipation sections, intermediate limiting sections, bamboo sections and two-end connecting sections along the longitudinal coaxial axis. The intermediate limiting sections are located in the middle of the core part. The bamboo sections and the energy dissipation sections are distributed at intervals, arranged on the two sides of the intermediate limiting sections and form a whole together with the intermediate limiting sections, and the two ends of the outer sides of the bamboo sections and the energy dissipation sections are fixedly connected with the two-end connecting sections to form the core part. The cross sections of the intermediate limiting sections, the bamboo sections and the two-end connecting sections are all circular. First holes are formed in the middles of the intermediate limiting sections in the diameter direction. The energy dissipation sections are manufactured by cutting of round rods in the length direction, so that the cross sections of the energy dissipation sections are two parallel opposite sides, the other two short sides are original arc lines, under the effect of the axial tensile pressure, the energy dissipation sections of the core part enter yielding through the formed new cross section areas, while the intermediate limiting sections, the bamboo sections and the two-end connecting sections always remain elastic.

Owner:SOUTHEAST UNIV

Preparation method of steel plate and steel strip for 160MPa grade weather-resistant low yield point damper

The invention discloses steel for a 160MPa grade weather-resistant low yield point damper and a a preparation method. The chemical components comprise 0.02-0.03wt% of C, 0.01-0.03wt% of Si, 0.10-0.25wt% of Mn, less than or equal to 0.015wt% of S, 0.030-0.050% of P, 0.025-0.045wt% of Als, 0.10-0.20wt% of Ni, 0.20-0.40wt% of Cr, 0.20-0.50wt% of Cu, 0.015-0.030wt% of Ti, 0.0010-0.0020wt% of B, less than or equal to 0.0040wt% of N, less than or equal to 0.0020wt% of O, less than or equal to 0.00015wt% of H, less than or equal to 0.25wt% of Ceq and the balance of Fe and inevitable impurities. A steel plate and a steel strip for the 160MPa grade weather-resistant low yield point damper are prepared by the following steps: pre-treatment desulfurization of blast furnace molten iron; converter smelting of molten iron; deoxidizing alloying of molten steel; LF furnace refining of molten steel; VD vacuum refining of molten steel; casting of molten steel; heating of a steel blank; descaling of the steel blank; controlled rolling and controlled cooling of the molten steel; finish rolling and cooling and the like. The steel disclosed by the invention overcomes the defect that existing steel for the low yield point damper is poor in weather resistance, so that the service life of the damper is prolonged, and the using and maintenance costs are lowered.

Owner:WUKUN STEEL

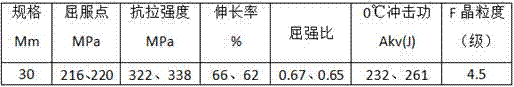

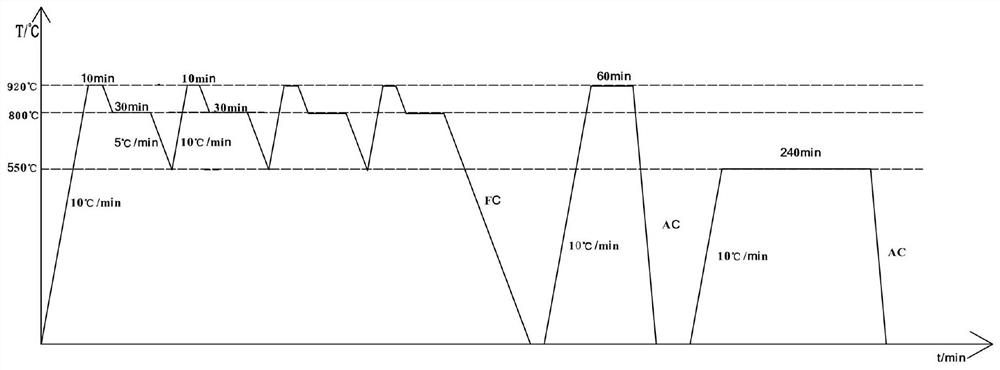

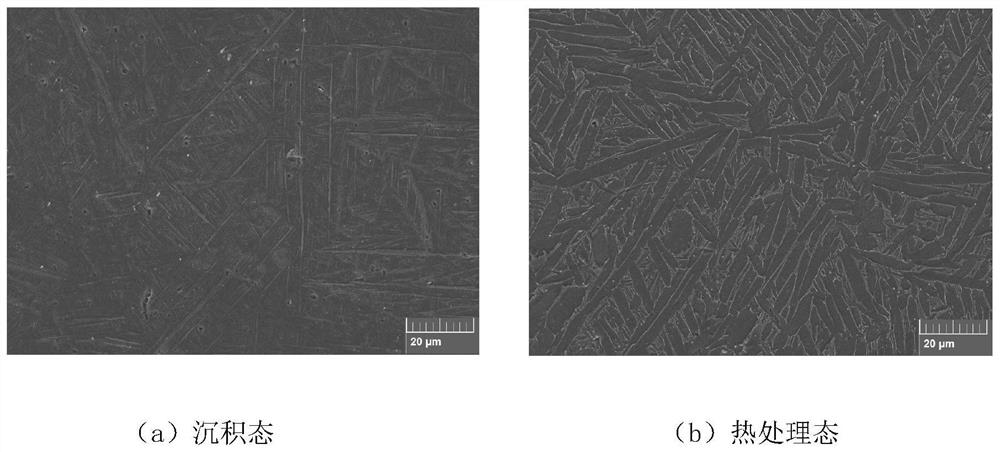

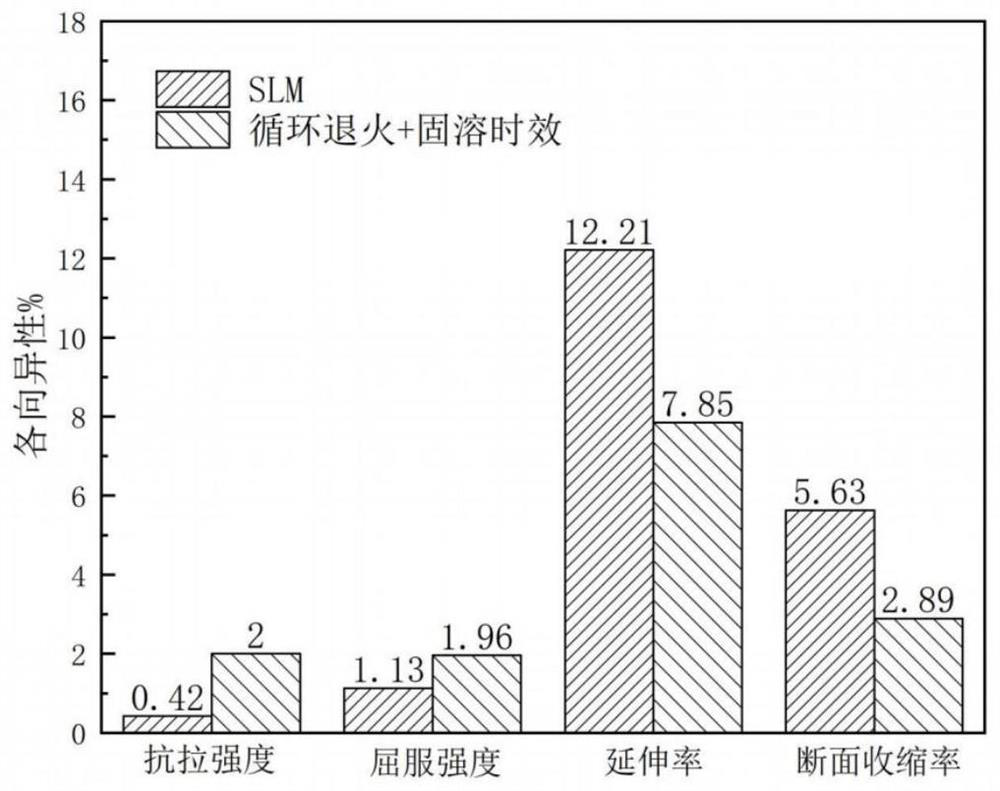

Heat treatment method for regulating and controlling static and dynamic load mechanical properties and anisotropy of SLM titanium alloy

ActiveCN112941439AImproved low cycle fatigue performanceLow cycle fatigue performanceAdditive manufacturing apparatusCrazingCrystal structure

The invention discloses a heat treatment method for regulating and controlling static and dynamic load mechanical properties and anisotropy of an SLM titanium alloy. The SLM forming manner enables a microstructure of a formed part to have an obvious thick columnar crystal structure, so that the mechanical properties of the formed part have obvious anisotropy. The SLM Ti-6Al-4V formed part is subjected to heat treatment including circulating spheroidizing annealing and solid solution aging, and a double-state structure is obtained. After heat treatment, the plasticity of a sample piece is greatly improved (the elongation reaches 18.35%), the mechanical properties exceed the forging standard, the sample stability is improved, and the anisotropy of plasticity is greatly reduced; after circulating spheroidizing annealing and solid solution aging heat treatment, the fracture toughness of the sample piece is 85.5 MPa, and the anisotropy is smaller than or equal to 15%; when the strain amplitude is larger than or equal to 0.9%, the low-cycle fatigue performance of the sample piece subjected to heat treatment is higher than that of a forged piece; the crack propagation path in the double-state structure is longer than that of the forged piece; when the strain amplitude is 0.7%-0.9%, the low-cycle fatigue performance is equivalent to that of the forged piece; and when the strain amplitude is smaller than or equal to 0.7%, the low-cycle fatigue performance is smaller than that of the forged piece.

Owner:XI AN JIAOTONG UNIV

Precipitation-strengthened nickel-iron-chromium alloy and process therefor

InactiveUS20070044872A1Increase resistanceMaintain good propertiesBlade accessoriesGas turbine plantsSolubilityAustenite grain

An Fe—Ni—Cr alloy formulated to contain a strengthening phase that is able to maintain a fine grain structure during forging and high temperature processing of the alloy. The alloy contains a sufficient amount of titanium, zirconium, carbon and nitrogen so that fine titanium and zirconium carbonitride precipitates formed thereby are near their solubility limit in the alloy when molten. In the production of an article from such an alloy by thermomechanical processing, a dispersion of the fine titanium and zirconium carbonitride precipitates form during solidification of the melt and remain present during subsequent elevated processing steps to prohibit austenitic grain growth.

Owner:GENERAL ELECTRIC CO

Yield strength 160MPa grade building earthquake-resistance low-yield strength steel and method for producing same

ActiveCN101514425BImprove mechanical propertiesExcellent 0℃ impact toughnessEarthquake resistanceChemical composition

The invention provides low-yield strength building earthquake-resistance steel, which comprises the following chemical components (in weight percentage): 0.01 to 0.05 percent of C, 0.02 percent of Si, 0.05 to 0.15 percent of Mn, less than or equal to 0.01 percent of P, less than or equal to 0.006 percent of S, 0.01 to 0.05 percent of Al, less than or equal to 0.005 percent of N, 0.01 to 0.10 percent of Ti, and the balance of Fe and inevitable impurity elements. The invention also provides a method for producing the earthquake-resistance steel. The earthquake-resistance steel has excellent comprehensive mechanical properties, a yield strength of 140 to 180MPa, an elongation of more than 50 percent, excellent plastic deformation capacity, excellent zero degree centigrade impact toughness, an excellent low cycle fatigue property and excellent welding performance, and is suitable to be used in building earthquake-resistance design to protect main buildings and is simple in production process, low in cost and suitable for large-scale production.

Owner:BAOSHAN IRON & STEEL CO LTD

Novel assembled buckling-restrained brace

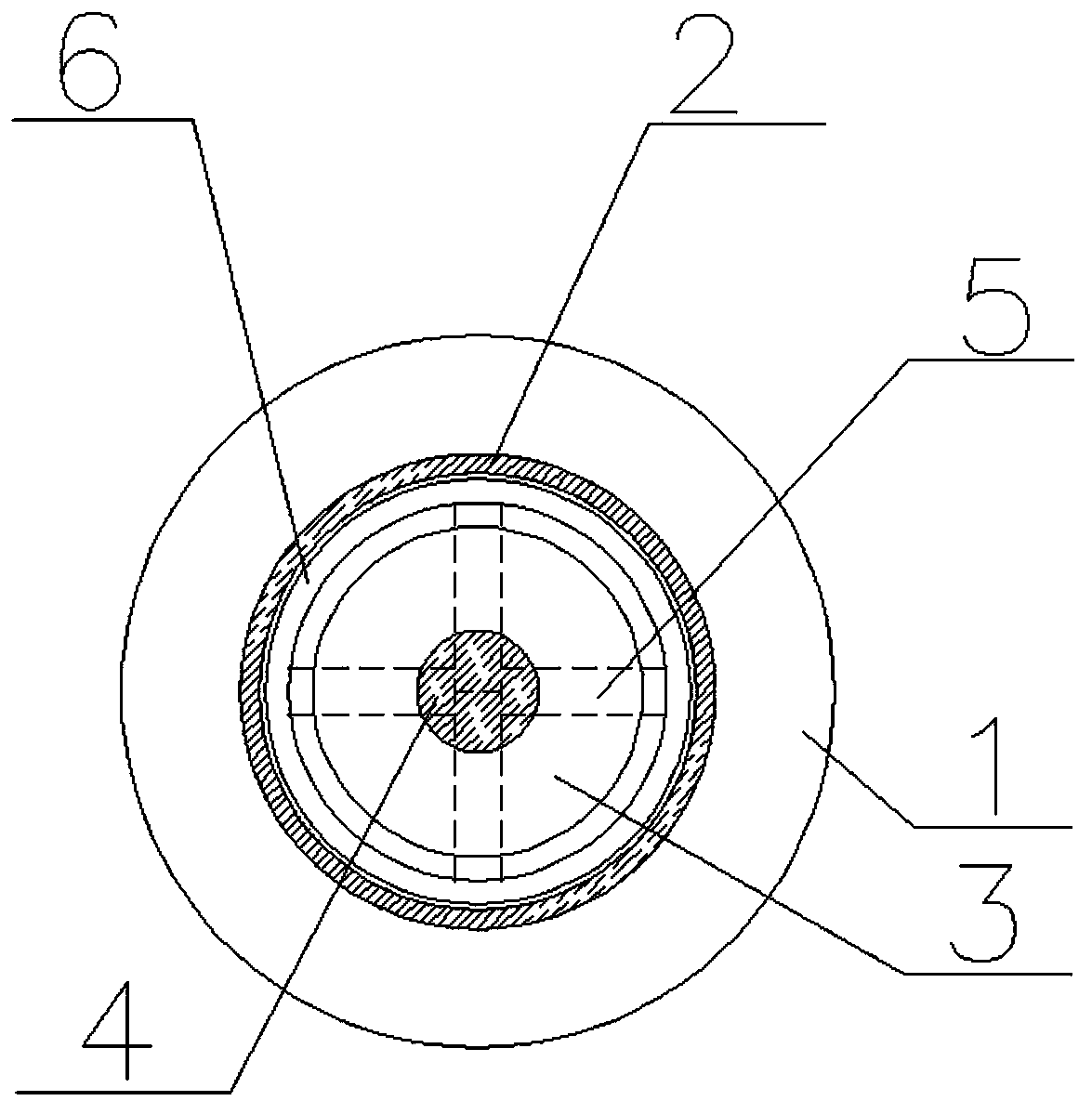

PendingCN111519784AQuite strongNo squeezeProtective buildings/sheltersShock proofingFriction weldingShock resistance

The invention discloses a novel assembled buckling-restrained brace. The novel assembled buckling-restrained brace comprises an outer connecting plate and an anti-instability steel pipe, the outer connecting plate is fixedly connected with a force transmission round pipe, the force transmission round pipe is nested in the anti-instability steel pipe, the end, away from the outer connecting plate,of the force transmission round pipe is connected with a round connecting end plate in a welded mode, and the other end of the round connecting end plate is connected with a dumbbell-shaped energy consumption cone steel bar in a friction welded mode, cross stiffening ribs are embedded in the ends, away from the connecting plates, of the force transmission round pipes, the circle centers of the force transmission outer connecting plates, the circle centers of the anti-instability steel pipes, the circle connecting end plates, the circle centers of the dumbbell-shaped energy dissipation cone steel bars, the circle centers of the cross stiffening ribs and the circle centers of the force transmission round pipes are located on the same axis, gaps of 2 mm are formed in the force transmission round pipes and the anti-instability steel pipes, and the cross stiffening rib is connected with the circular connecting end plate in a welding manner and is not fixedly connected with the force transfer circular pipe. The structure is convenient to machine, easy to install, environmentally friendly, capable of improving production efficiency, stable in structural form and capable of remarkably enhancing energy consumption capacity and improving shock resistance and shock absorption capacity of the structure.

Owner:山东天元建设机械有限公司 +1

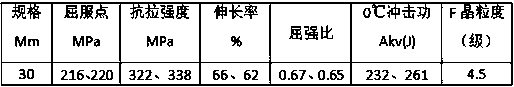

Yield strength 100MPa grade building earthquake-resistance low-yield strength steel and method for producing same

ActiveCN101514426BImprove mechanical propertiesImprove plastic deformation abilityLow-cycle fatigueChemistry

The invention provides low-yield strength building earthquake-resistance steel, which comprises the following chemical components (in weight percentage): less than or equal to 0.01 percent of C, less than or equal to 0.02 percent of Si, 0.05 to 0.10 percent of Mn, less than or equal to 0.01 percent of P, less than or equal to 0.006 percent of S, 0.01 to 0.05 percent of Al, less than or equal to 0.005 percent of N, 0.01 to 0.10 percent of Ti, and the balance of Fe and inevitable impurities. The invention also provides a method for producing the earthquake-resistance steel. The earthquake-resistance steel has excellent comprehensive mechanical properties, a yield strength of 80 to 120MPa, an elongation of more than 50 percent, excellent plastic deformation capacity, excellent zero degree centigrade impact toughness, an excellent low cycle fatigue property and excellent welding performance, and is suitable to be used in building earthquake-resistance design to protect main buildings and is simple in production process, low in cost and suitable for large-scale production.

Owner:BAOSHAN IRON & STEEL CO LTD

Damage-controllable energy dissipator

InactiveCN110670935AGive full play to the effect of energy dissipation and shock absorptionControl damage progressionProtective buildings/sheltersShock proofingClassical mechanicsEngineering

The invention discloses a damage-controllable energy dissipator. The energy dissipator comprises an extrusion rotating part, deformable connecting plates, a friction energy dissipation sheet and a base plate, a sliding groove is formed in the upper part of the extrusion rotating part, a sliding part is connected in the sliding groove, a first friction lug plate and first yield lug plates are connected to the lower part of the extrusion rotating part, a second friction lug plate and second yield lug plates are connected to the base plate, the first friction lug plate and the second friction lugplate are hinged through a first pin shaft, the end, which penetrates out of the first friction lug plate and the second friction lug plate, of the first pin shaft is provided with an elastic elementin a penetrating mode and then is locked by a locking nut, the friction energy dissipation sheet is clamped between the first friction lug plate and the second friction lug plate, one ends of the deformable connecting rods are hinged to the first yield lug plates through second pin shafts, and the other ends of the deformable connecting rods are also hinged to the second yield lug plates throughsecond pin shafts. The energy dissipator has the advantages that the energy dissipation and seismic mitigation effects can be fully exerted, in addition, the damage development degree of the energy dissipator can be effectively controlled, and the energy dissipation and seismic mitigation effects are guaranteed.

Owner:SHANGHAI BAOYE CONSTR INDAL FURNACE ENG TECH +1

Method for eliminating shrinkage defect of nickel-based turbine blade

The invention discloses a method for eliminating the shrinkage defect of a nickel-based turbine blade, and in particular relates to a method for eliminating the shrinkage defect of a M38 nickel-based alloy turbine blade through utilizing a hot isostatic pressing technology. The method is characterized by sequentially comprising the followings steps of: selecting a nickel-based turbine blade with the shrinkage defect under the internal quality standard as a treatment object, cleaning and drying the treatment object, putting the cleaned and dried nickel-based turbine blade into a graphite heating furnace, heating the graphite heating furnace while filling argon, then cooling along with the furnace, air cooling and the like. After the method is adopted, the service life of the turbine blade can be prolonged, moreover, waste products can be recycled, and the waste can be reduced.

Owner:无锡源创机械科技有限公司

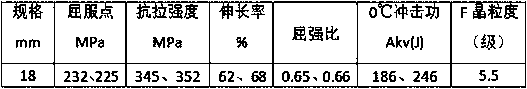

160MPa earthquake-proof low yield strength steel, steel plate and manufacturing method thereof

ActiveCN101775535BImproved low cycle fatigue performanceProtection securityEarthquake resistanceSheet steel

The invention provides earthquake-proof low yield strength steel and steel plate, characterized by containing the components in percentage by weight: at most 0.08 percent of C, at most 0.10 percent of Si, 0.1-1.2 percent of Mn, at most 0.015 percent of P, at most 0.010 percent of S, at most 0.05 percent of Al, at most 0.005 percent of N, at most 0.04 percent of Ti and the balance of Fe and unavoidable impurities. The invention also provides a manufacturing method of the steel plate, comprising the working procedures of heating steel billets, hot rolling and cooling after rolling. The steel isdesigned by adopting the component of low C-Si-Mn and being added with 0-0.04 percent of Ti, and has small fluctuation for the yield strength and excellent plastic deformation ability and 0-DEG C impact toughness. The invention adopts a processing technology of hot rolling at high temperature and air cooling or slowly cooling to the room temperature after hot rolling, has simple production process and lower cost, and is suitable for manufacturing earthquake-proof dampers for improving the earthquake resistance of buildings.

Owner:BAOSHAN IRON & STEEL CO LTD

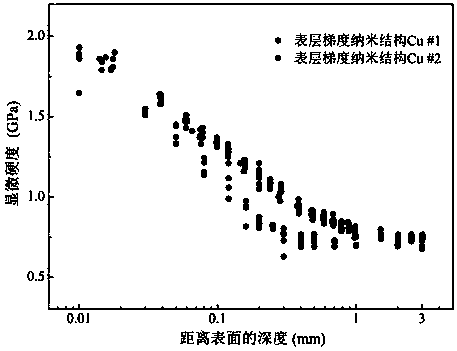

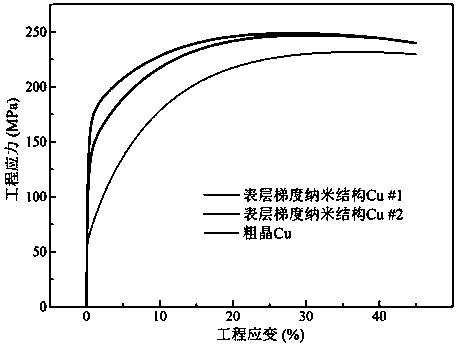

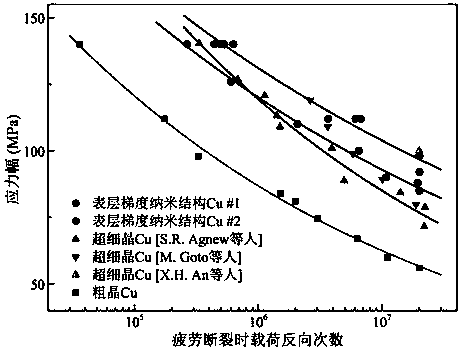

A Gradient Nanostructure with Excellent Comprehensive High-Cycle and Low-Cycle Fatigue Properties

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

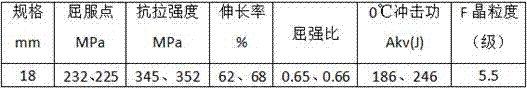

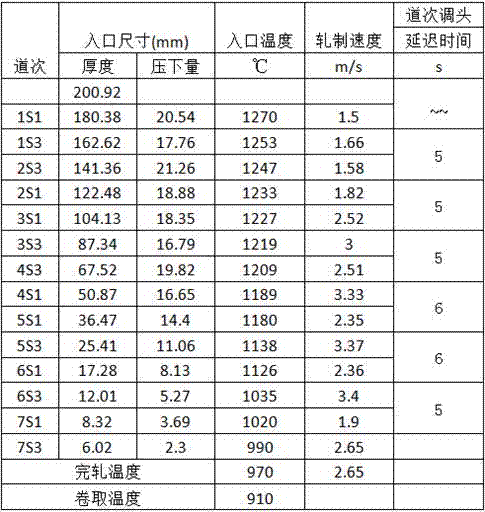

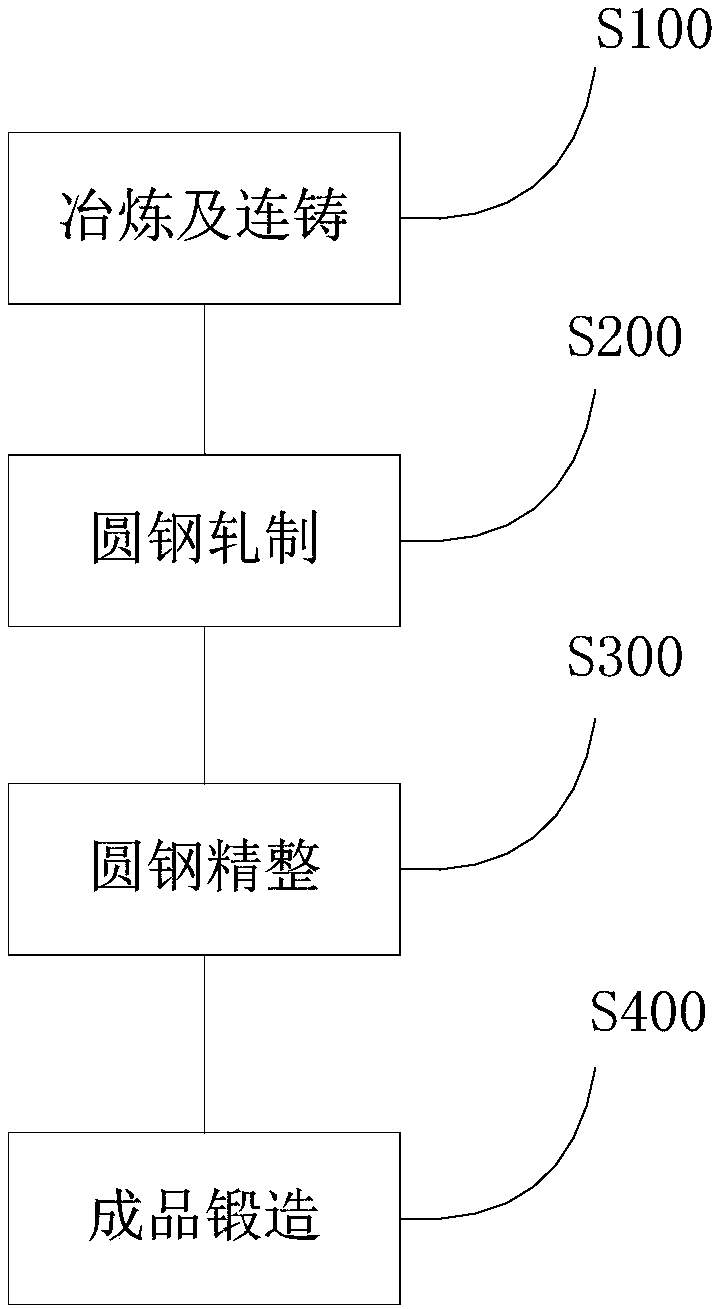

Design and manufacturing method ofsoft steel material with damping anti-seismic device for bridge

ActiveCN108286019AGuaranteed tensile strengthGuaranteed Yield StrengthChemical compositionEnergy absorption

The invention discloses a design and a manufacturing method of a soft steel material with a damping anti-seismic device for a bridge, and relates to a steel formula. The detailed ratio which is designed in a formulaaccording to the mass percentage ratio of a component element of a steel type refers to the claim. The manufacturing method comprises the steps of smelting, continuous casting, round steel rolling, round steel finishing and finished product forging. A low-carbon aluminum killed steel with a specified chemical component range is prepared according to the formula and the manufacturingmethod, and meanwhile, element contents of P and Swhich influence plastic performance are strictly controlled, and the residual element contentsare controlledand thennot only tensile strength and yield strength of the soft steel are guaranteed to be within a certain strength range, but also the specific value of the yield strength and the tensile strength is not greater than 0.72, and a manufactured anti-seismic isolation device is excellent in equivalent damping ratio and low-cycle fatigue performance, so that the use requirements of stress and energy absorption and seismic resistance of a railway bridge comprehensive working condition are met.

Owner:上海衍衡新材料科技有限公司 +2

Large-deformation energy-dissipating beam-column joints with series disc springs

ActiveCN109798011BGive full play to energy consumption capacityImproved low cycle fatigue performanceProtective buildings/sheltersShock proofingLarge deformationCompressive deformation

The invention discloses an in-series disc spring large deformation energy consumption beam column node, which comprises an assembly type column, an assembly type beam and a disc spring combination type damper, wherein the disc spring combination type damper consists of an energy consumption rod, a disc spring set, an internal thread sleeve, an outer sleeve, a sliding guide rod and an extrusion nut, one end of the disc spring combination type damper is fixed on the fixed plate of a surface of the assembly type beam, and the other end passes through the flange plate of the assembly type column and presses tightly the flange plate. By adjusting the pressure of the extrusion nut, tensile deformation generated by the two ends of the disc spring combination type damper can be fully supplied by the energy consumption rod under the action of small and moderate earthquakes, the other part is supplied by the compressive deformation of the disc spring set, so that the disc spring combination typedamper has better deformability, and the fatigue performance of the disc spring combination type damper is conducive to being improved.

Owner:SOUTHEAST UNIV

Buckling Constrained Braces of Rectangular Slubs

ActiveCN105735504BImproved low cycle fatigue performanceReduce surface strainShock proofingBuckling-restrained braceCoaxial line

The invention discloses a buckling constraint support of rectangular bamboo joints, which comprises a core component and an outer constraint component; the core component is connected along a longitudinal coaxial line by a plurality of circular energy dissipation sections, a plurality of rectangular elastic sections and end connection sections Composition, the circular energy dissipation section and the rectangular elastic section are arranged alternately, the cross-sectional diameter of the circular energy dissipation section is less than or equal to the minimum side length of the section of the rectangular elastic section, and the end connecting section is arranged between the circular energy dissipation section and the rectangular elastic section to form Both ends of the whole; the outer restraint part is a rectangular tube, the core part is located inside the outer restraint part, the rectangular elastic section of the core part is in close contact with the inner side of the outer restraint part, and there is a gap between the circular energy dissipation section and the outer restraint part . The invention can effectively limit the torsional deformation of the rectangular elastic section, thereby limiting the overall torsional deformation of the core component, reducing the surface strain of the circular energy dissipation section of the core component, and enhancing the low-cycle fatigue performance of the buckling-constrained support.

Owner:SOUTHEAST UNIV

Preparation method of steel plate and steel strip for 160mpa level weather-resistant low yield point damper

ActiveCN107475615BReduce manufacturing costNo heat treatment requiredChemical compositionSheet steel

The invention discloses steel for a 160MPa grade weather-resistant low yield point damper and a a preparation method. The chemical components comprise 0.02-0.03wt% of C, 0.01-0.03wt% of Si, 0.10-0.25wt% of Mn, less than or equal to 0.015wt% of S, 0.030-0.050% of P, 0.025-0.045wt% of Als, 0.10-0.20wt% of Ni, 0.20-0.40wt% of Cr, 0.20-0.50wt% of Cu, 0.015-0.030wt% of Ti, 0.0010-0.0020wt% of B, less than or equal to 0.0040wt% of N, less than or equal to 0.0020wt% of O, less than or equal to 0.00015wt% of H, less than or equal to 0.25wt% of Ceq and the balance of Fe and inevitable impurities. A steel plate and a steel strip for the 160MPa grade weather-resistant low yield point damper are prepared by the following steps: pre-treatment desulfurization of blast furnace molten iron; converter smelting of molten iron; deoxidizing alloying of molten steel; LF furnace refining of molten steel; VD vacuum refining of molten steel; casting of molten steel; heating of a steel blank; descaling of the steel blank; controlled rolling and controlled cooling of the molten steel; finish rolling and cooling and the like. The steel disclosed by the invention overcomes the defect that existing steel for the low yield point damper is poor in weather resistance, so that the service life of the damper is prolonged, and the using and maintenance costs are lowered.

Owner:WUKUN STEEL

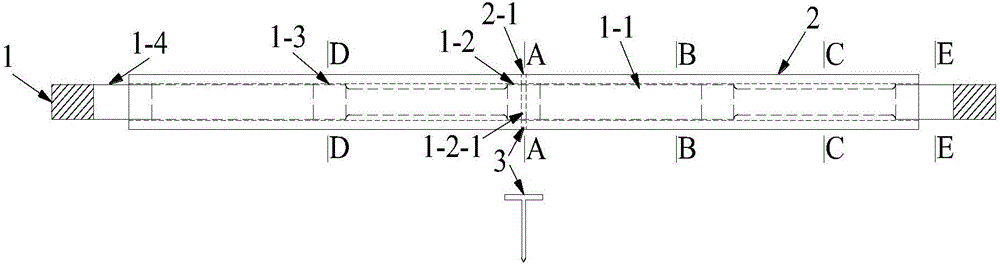

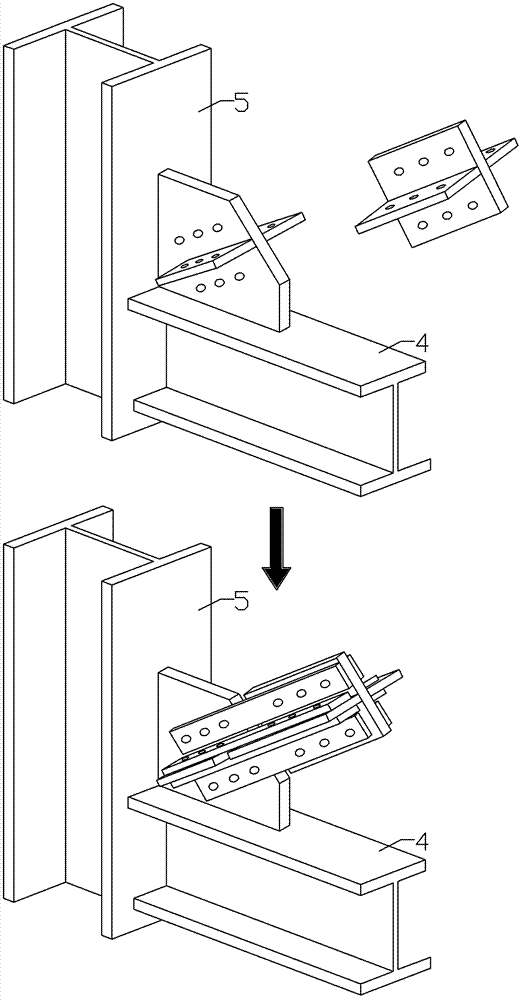

End part local elongation type anti-buckling support-beam-column connecting node

InactiveCN102296704BWith detachableNode link length is shortBuilding constructionsArchitectural engineeringSteel columns

The invention discloses an end part local elongation type anti-buckling support-beam-column connecting node and relates to an anti-buckling support-beam-column connecting node which is used for solving the problems in the aspects of anti-seismic performance of support and building structures, stability outside the plane of the node, seismic rehabilitation, construction, installation and the like caused by support-node plate bolted connection and node plate-beam column welded connection. An intermediate node plate of a framework node plate is plugged in an open slot on the end part local elongation type node, an intermediate core plate and a local elongation stiffening rib or a local elongation core plate are welded together with the intermediate node plate, the framework node plate is placed on the upper surface of the top flange of an I-shaped steel beam, vertical end plates of the framework node plate lean against each other and prop against the side flange of an H-shaped steel column, and the framework node plate is fixedly connected with the H-shaped steel column and the I-shaped steel beam respectively through a plurality of first and second high-strength bolts. The end part local elongation type anti-buckling support-beam-column connecting node is used for civil construction structures, especially in multi-storey and high-rise anti-seismic, energy-consuming and shock-absorption building structures.

Owner:HARBIN INST OF TECH

A self-restoring metal double-tube space shock-absorbing and energy-dissipating device with shock-proof damage

ActiveCN110725427BStable and continuous bending energy consumptionReduce tensile stressProtective buildings/sheltersShock proofingTube (structure)Engineering

The invention discloses an earthquake loss avoiding self-recovery type metal double-barrel space damping energy dissipation device, and belongs to the field of civil engineering structure energy dissipating and damping. An energy dissipation barrel A, an energy dissipation barrel B, a limiting ring plate, a limiting baffle, a limiting groove plate, a limiting ring cavity, a connecting piece, a positioning hanging plate and a thin rubber pad are included. The earthquake loss avoiding self-recovery type metal double-barrel space damping energy dissipation device is characterized in that the twoenergy dissipation barrels are adsorbed and fixed through a connecting piece magnet, meanwhile, the contact faces of the two energy dissipation barrels are matched and inset through grooves and flanges to form meshing, and accordingly double-barrel three-dimension relative deformation is restrained; each energy dissipation barrel is internally provided with a stretching and extrusion deformation limiting device, and the energy dissipation barrel deformation range can be controlled; when the relative stretching and deformation of the double barrels are too large, the adsorbed contact faces areseparated and recover from deformation, and when deformation is little, adsorbing and meshing can be conducted, and the double barrels recover into a whole. By means of the earthquake loss avoiding self-recovery type metal double-barrel space damping energy dissipation device, stable plastic energy consumption can be generated within a certain deformation range of the energy dissipation barrels, the earthquake loss avoiding self-recovery type metal double-barrel space damping energy dissipation device can adapt to space three-dimension deformation and large displacement, the initial state canbe automatically recovered, repairing after the earthquake is avoided, the structure is simple, and installation is convenient and fast.

Owner:XINGTAI POLYTECHNIC COLLEGE

A low-cost 225mpa grade low yield point damper steel plate and steel strip preparation method

The invention discloses a preparation method for steel plates and steel strips for low-cost 225 MPa-stage low-yield-point dampers. The preparation method comprises the following four steps of heatinga steel billet, descaling, rough rolling, finishing rolling and cooling, specifically, low-carbon aluminum killed steel billets are heated, high-pressure water sprays the high-temperature steel billets for descaling, then the steel billets are sent into a reversible double-rack furnace coiling rolling machine for reciprocating rough rolling and finishing rolling, the steel strips operate on cooling roller ways after rolling is completed and enter a laminar flow cooling section to be cooled, the finished plates are rolled or sheared on line, then stack cooling is conducted till the indoor temperature is reached, and thus steel with the thickening being 6-30 mm for the 225 MPa-stage low-yield-point dampers is obtained. According to the preparation method, expensive micro-alloying elements donot need to be added, smelting means such as furnace external refining and vacuum treatment are not needed, heat treatment does not need to be conducted after rolling, and thus the production cost islow. The steel plates and the steel strips obtained through the preparation method have low yield strength fluctuation, good plasticity and good toughness and have excellent impact and welding performance and low-cycle fatigue performance.

Owner:WUKUN STEEL

Modular Bamboo Buckling Constrained Braces

ActiveCN105604205BIncrease production capacityRealize the designShock proofingBuckling-restrained braceEngineering

Owner:CHINA JINGYE ENG TECH CO LTD +2

A kind of manufacturing method of 100mpa level low yield point building anti-seismic steel

The invention discloses a manufacturing method of 100-MPa low-yield-point architectural antiseismic steel. The steel comprises the following chemical components in percentage by mass: at most 0.01% of C, at most 0.02% of Si, 0.05-0.1% of Mn, 0.01-0.06% of Al, at most 0.01% of P, at most 0.004% of S, at most 0.004% of N, 0.01-0.08% of Ti, and the balance of Fe and inevitable impurities. The method comprises the following steps: refining, continuous casting, heating, rough rolling, electromagnetic induction heating, finish rolling, laminar cooling, coiling and the like. The yield strength of the 100-MPa low-yield-point architectural antiseismic steel is up to 80-120 MPa, and the elongation percentage is greater than 50%; and the steel has the advantages of favorable plastic deformation, favorable impact toughness, lower alloy cost, practical technique, favorable weldability and favorable low cycle fatigue property.

Owner:SHOUGANG CORPORATION

A kind of 225mpa level weather resistance low yield point damper steel plate and steel strip preparation method

The invention discloses 225MPa level weather resistance low-yield-point damper steel and a preparing method. The 225MPa level weather resistance low-yield-point damper steel comprises chemical components including 0.03 wt%-0.06 wt% of C, 0.01 wt%-0.03 wt% of Si, 0.15 wt%-0.25 wt% of Mn, smaller than or equal to 0.020 wt% of S, 0.040 wt%-0.065 wt% of P, 0.040 wt%-0.070 wt% of Als, 0.35 wt%-0.60 wt%of Cr, 0.25 wt%-0.45 wt% of Ni, 0.20 wt%-0.40 wt% of Cu, smaller than or equal to 0.0040 wt% of N, smaller than or equal to 0.0020 wt% of O, smaller than or equal to 0.0001 wt% of H and the balance Fe and inevitable impurities. A 225MPa level weather resistance low-yield-point damper steel plate and a steel strip are obtained through the steps of blast furnace molten iron pretreatment desulfuration, molten iron converter smelting, molten steel deoxygenation alloying, molten steel LF furnace refining, molten steel VD vacuum refining, molten steel pouring, steel blank heating, steel blank descaling, steel blank controlled rolling and controlled cooling, refined rolling, cooling and the like. The defect that existing low-yield-point damper steel is poor in weather resistance is overcome, accordingly, the service life of a damper is prolonged, and the using and maintaining cost is reduced.

Owner:WUKUN STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com