Patents

Literature

120results about How to "Machining accuracy is easy to control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

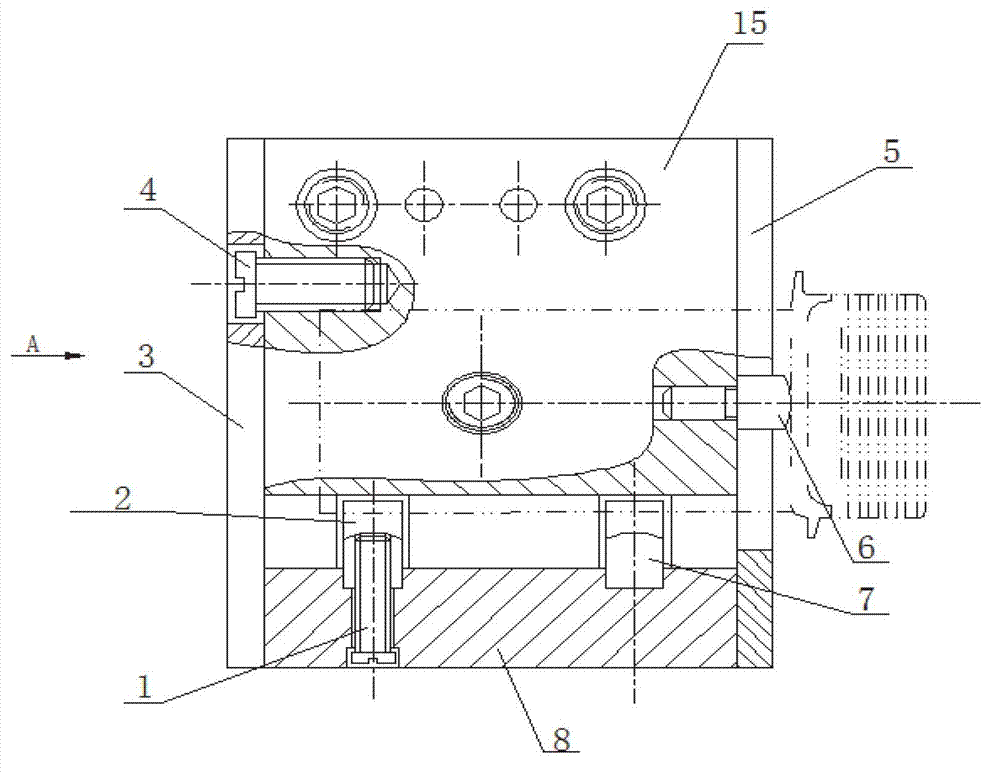

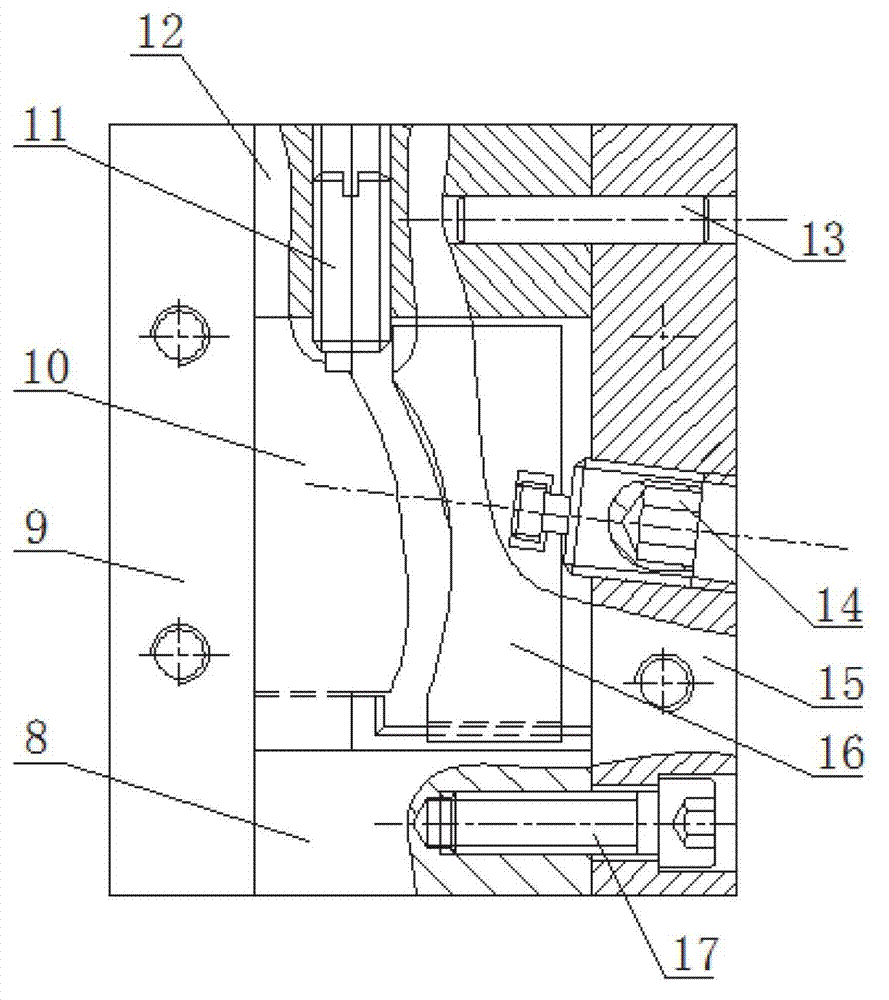

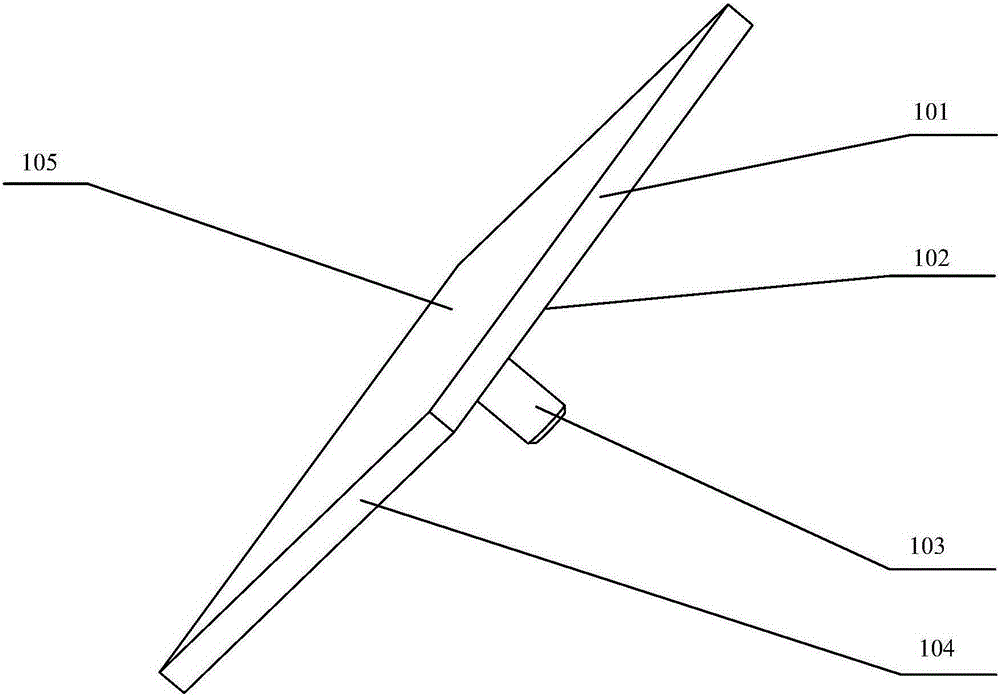

Clamping positioning device for finish machining aero-engine turbine blade

ActiveCN102962694AMachining accuracy is easy to controlCheap manufacturingPositioning apparatusMetal-working holdersTurbine bladeAlloy

The invention discloses a clamping positioning device for finish machining an aero-engine turbine blade, and the clamping positioning device comprises a framework consisting of a front cover plate, a rear cover plate, a left cover plate, a right cover plate, an upper cover plate and a lower cover plate through screws, a back surface positioning compression block which is arranged inside the framework and matched with the back molded surface of a blade body, a pelvic surface positioning compression block which is matched with a pelvic molded surface of the blade body, a positioning compression block which is matched with the blade body or an exhaust edge molded surface and a compression component which is used for compressing the other edge of the blade body, wherein one of the back surface positioning compression block and the pelvic surface positioning compression block is adjustably arranged on the front cover plate or the rear cover plate in the compression direction, the right cover plate or the left cover plate is provided with a blade body placing opening, and the cover plate is provided with a blade axial positioning component. Compared with the prior art, a fixing way for utilizing low-melting-point alloy to position the blade is adopted, so that the blade machining cost is greatly reduced, and problems caused by removing the low-melting-point alloy on the blade body can be avoided.

Owner:AECC AERO SCI & TECH CO LTD

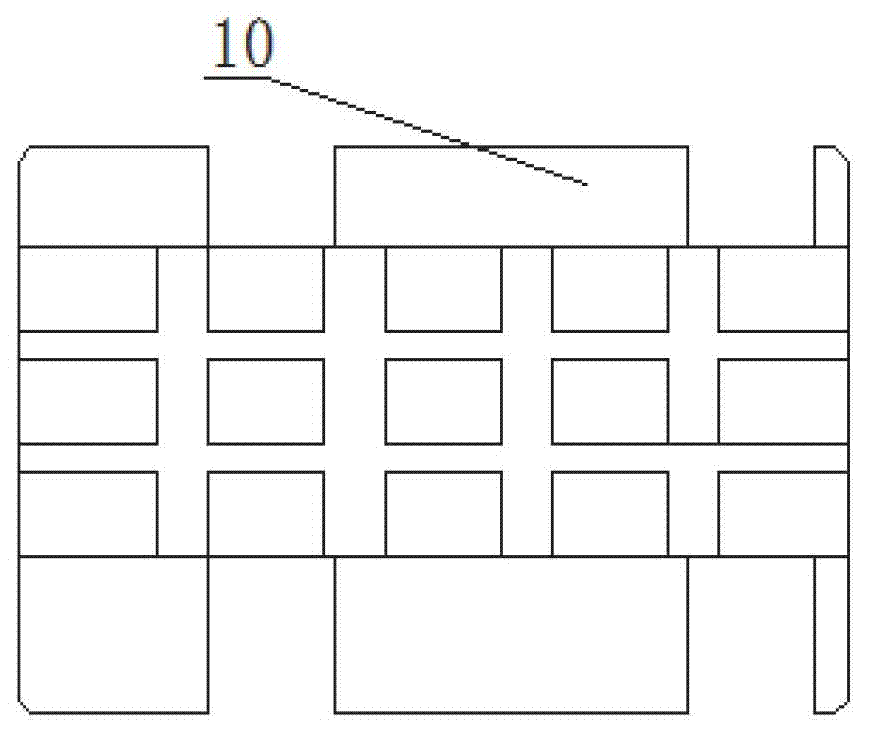

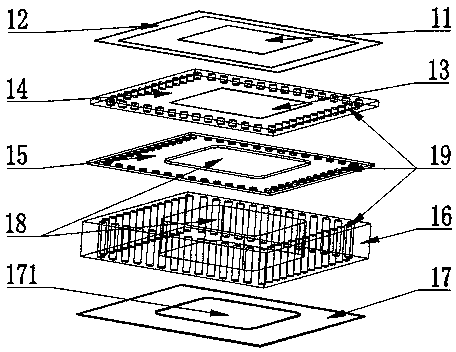

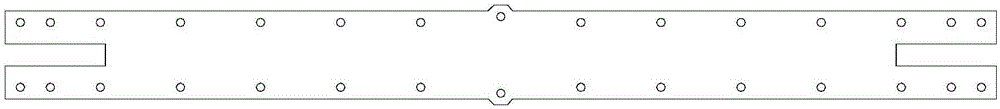

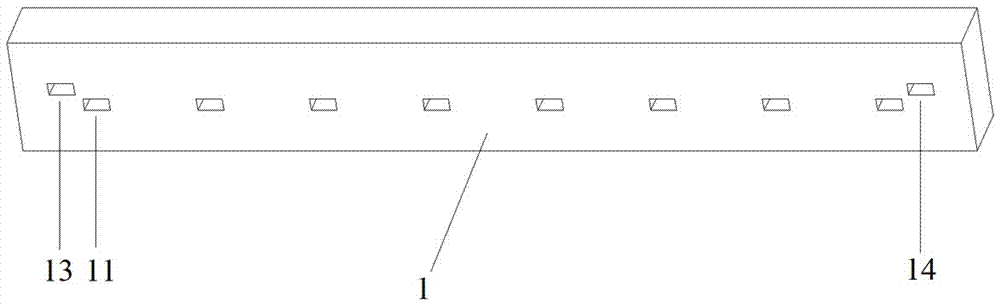

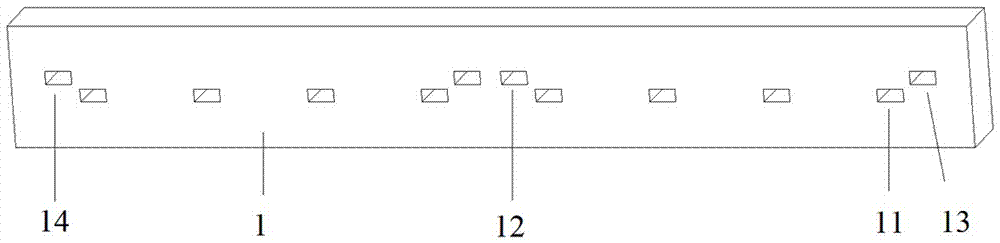

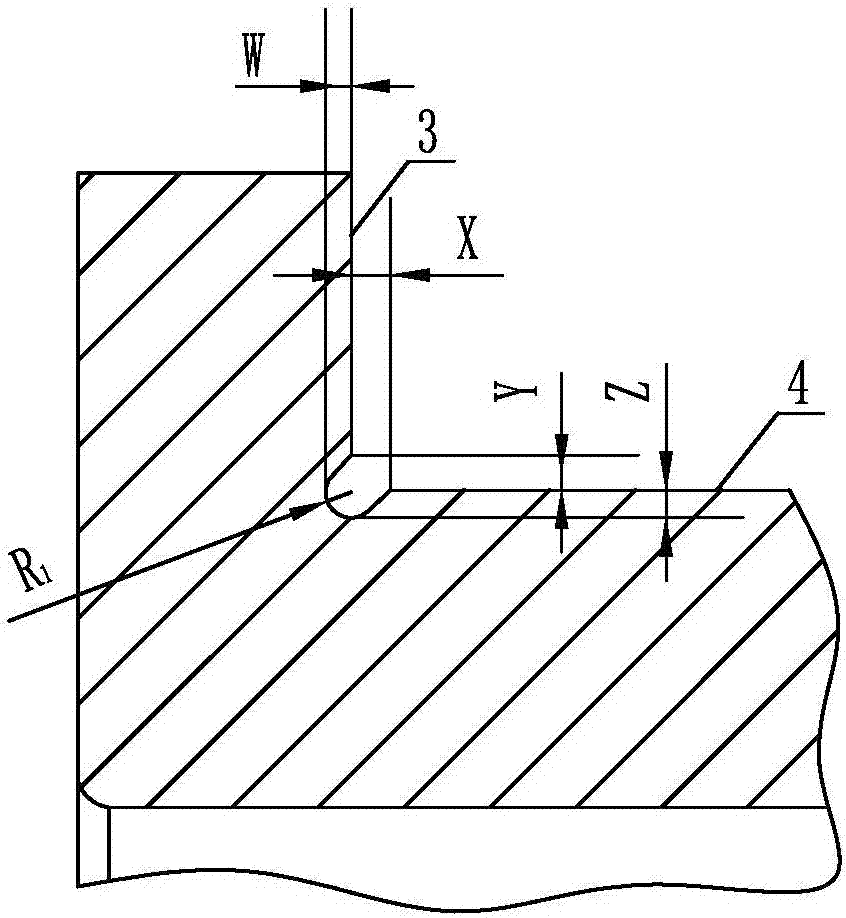

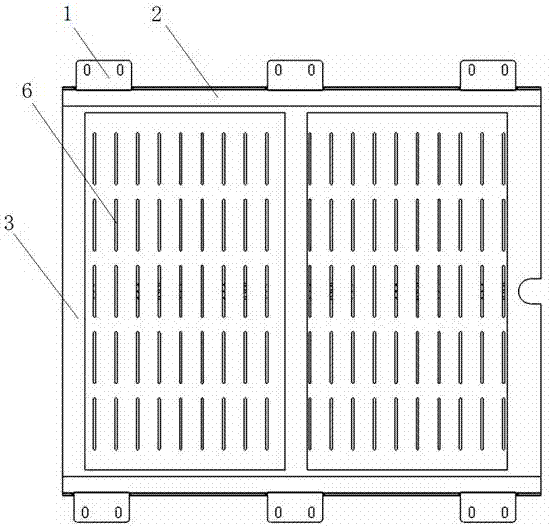

Broadband dual-polarized antenna unit based on coupled feeding

ActiveCN111525252ACompact structureEasy to processRadiating elements structural formsAntenna earthingsEngineeringBroadbanding

The invention discloses a broadband dual-polarized antenna unit based on coupled feeding. The broadband dual-polarized antenna unit comprises a radiation layer, a feeding layer, a metal substrate anda connecting structure which are connected layer by layer, wherein the radiation layer is coupled with the feed layer, the radiation layer comprises a first substrate integrated waveguide cavity structure and a main radiation patch and a parasitic radiation patch which are arranged on the end surface of the first substrate integrated waveguide cavity structure, the main radiation patch is matchedwith the parasitic radiation patch, the feed layer comprises a first slot feed and a second slot feed which are orthogonal to each other, and the connecting structure penetrates through the metal substrate and is connected to the first slot feed and the second slot feed respectively. The designed antenna unit has a wide standing wave bandwidth, the first slot feed and the second slot feed which are orthogonal to each other have a good cross polarization isolation effect, the designed antenna unit is compact in structure, and the designed hierarchical structure is good in machinability.

Owner:成都雷电微力科技股份有限公司

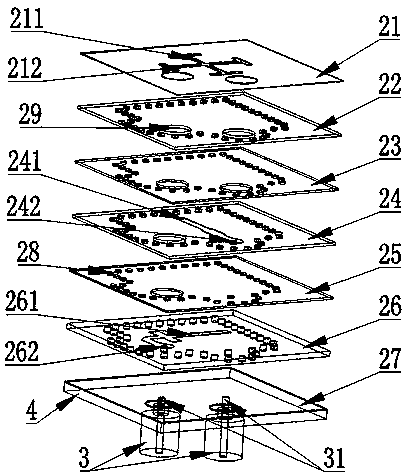

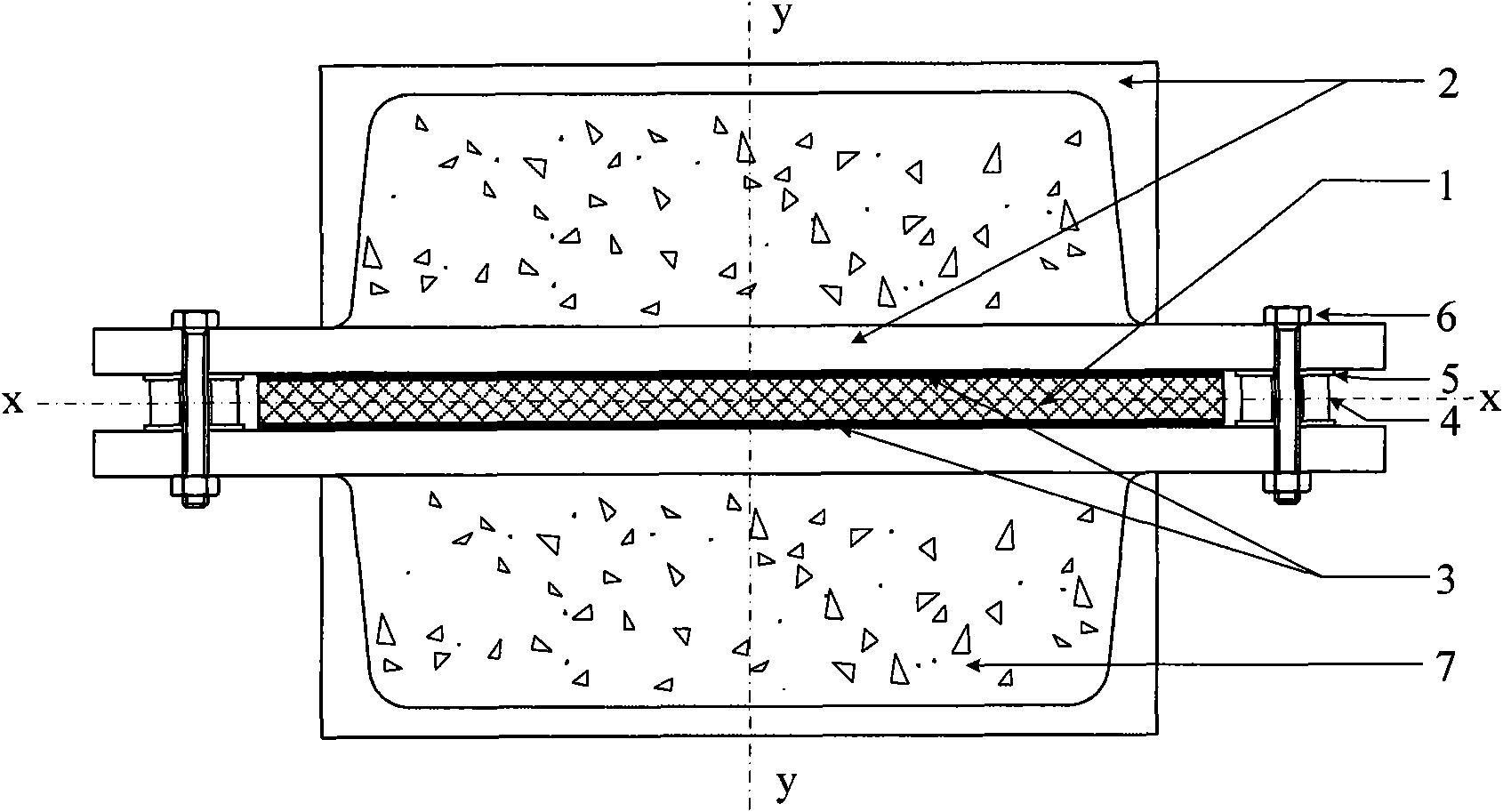

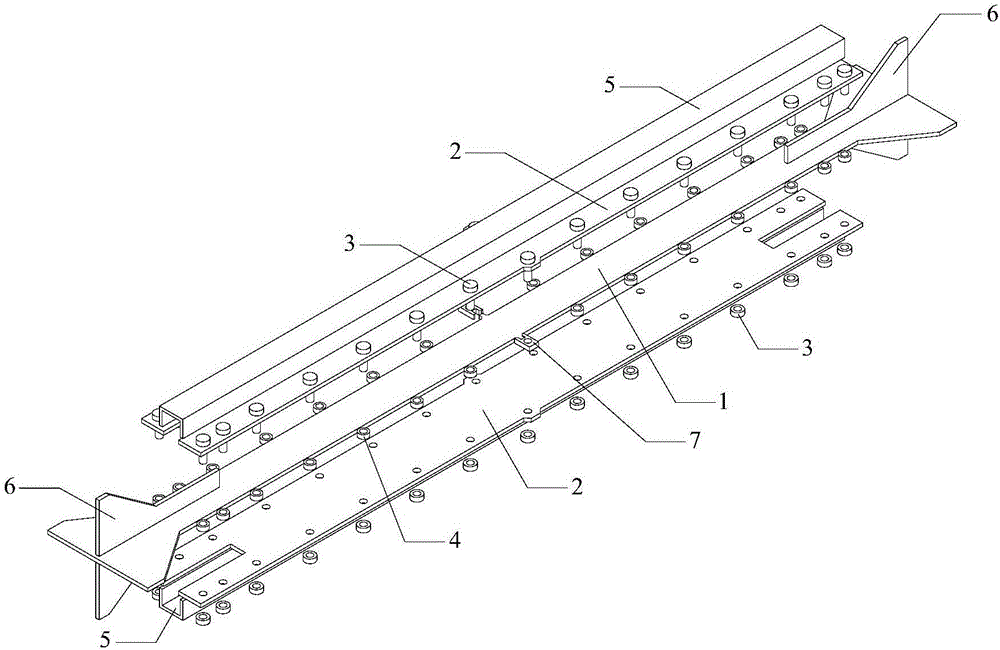

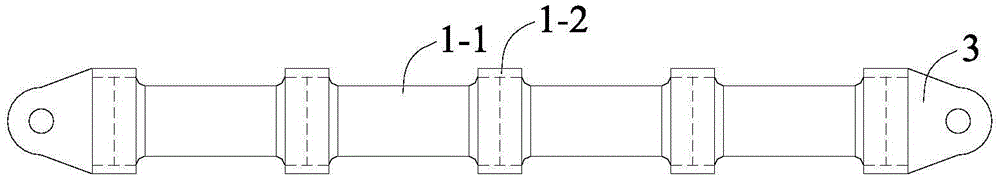

Buckling-resistant supporting element bound by four square pipes

InactiveCN101982624AImprove mechanical performanceEasy on-site assemblyShock proofingWhole bodyHigh intensity

The invention provides a buckling-resistant supporting element bound by four square pipes, belonging to the field of structural engineering. The supporting element consists of a cross-shaped internal core element and an external binding component. The cross-shaped internal core element is welded by three flat steel plates, and the surface of the cross-shaped internal core element is glued with hard rubber. The external binding component is bound by four square pipes with a plurality of extending steel plate bands, wherein each square pipe is oppositely welded by two equal angle irons with different sizes or four flat steel plates, and each square pipes is hollow or poured with the concrete. The binding effects among the square pipes are realized by the means that the extending steel plate bands are connected with each other by a plurality of high-strength bolts. The high-strength bolts are penetrated through the extending steel plate bands and a plurality of steel cushion plates and rubber spacers which are arranged among the extending steel plate bands, so that the four square pipes are connected with each other into a whole body. Meanwhile, a gap with 1mm-2mm is kept between the surface of the external binding component and the surface of the cross-shaped internal core element, and the gap is filled with the hard rubber which is glued at the surface of the cross-shaped internal core element, thereby meeting the requirement that the cross-shaped internal core element is pressed to be inflated.

Owner:TSINGHUA UNIV

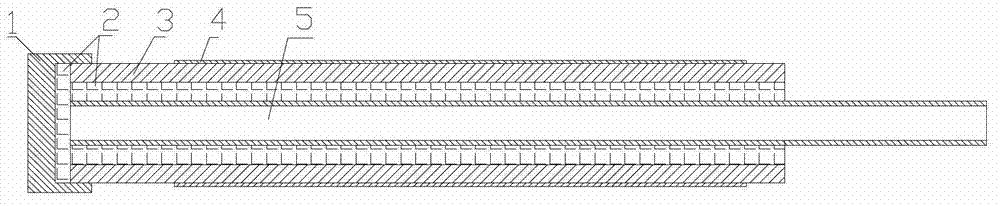

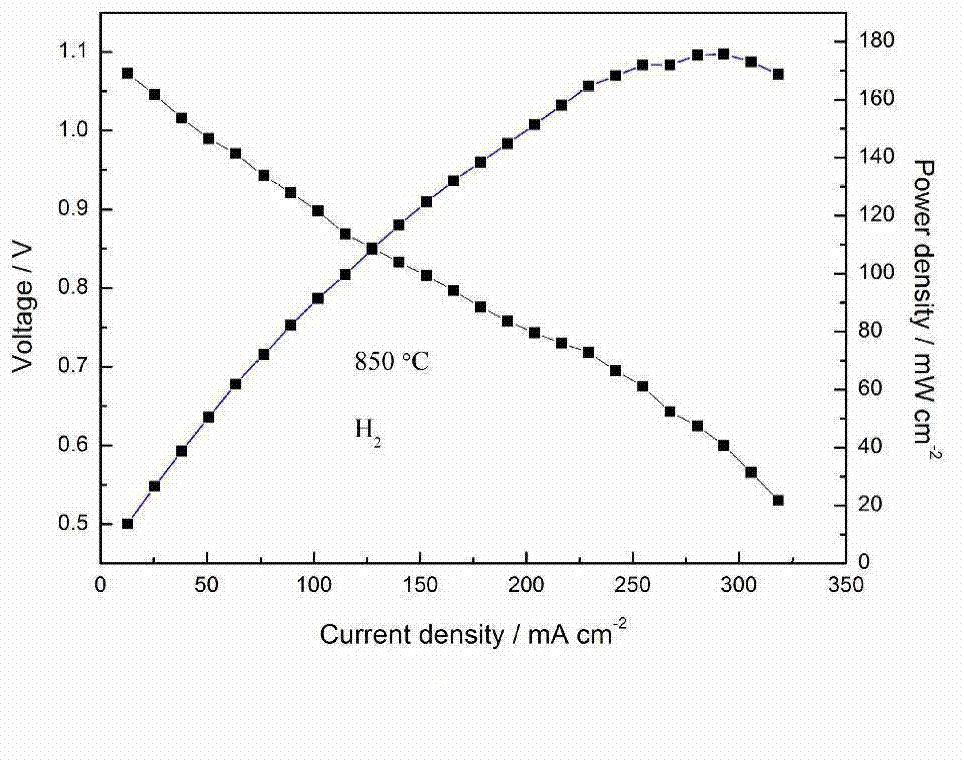

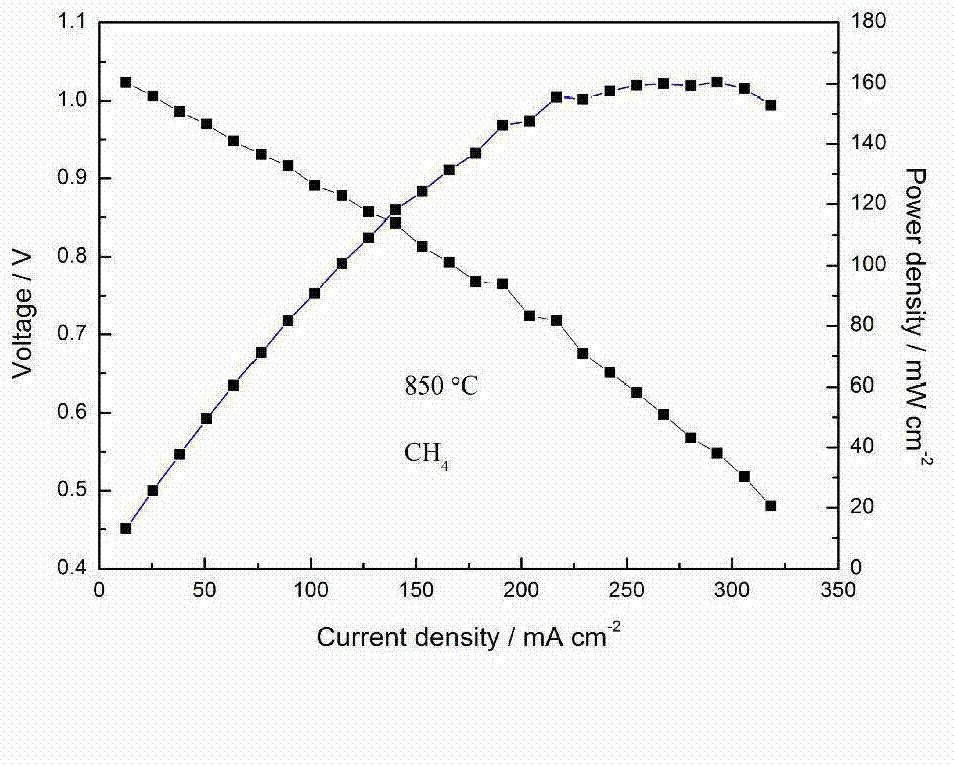

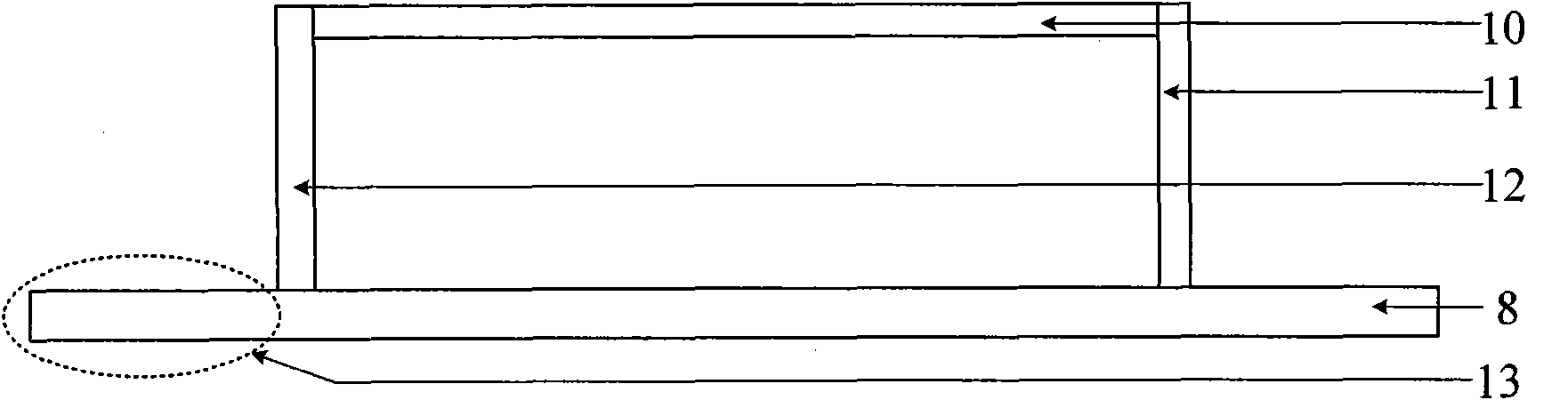

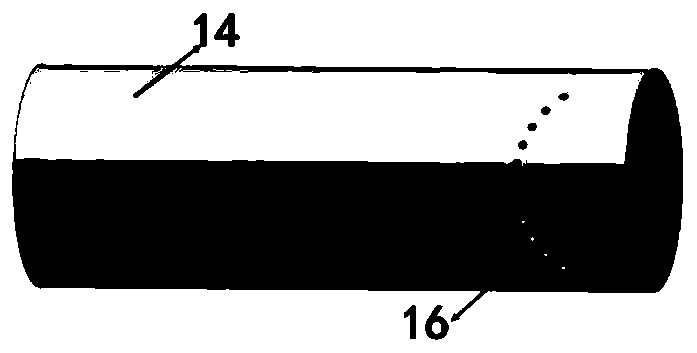

Anode support tube type solid oxide fuel cell and assembling method thereof

InactiveCN103094595AMachining accuracy is easy to controlLead to simpleCell electrodesSolid electrolyte fuel cellsSupporting electrolyteEngineering

The invention discloses an anode support tube type solid oxide fuel cell and an assembling method thereof, which relates to the cell application field. A metal connecting body shell cover of the cell is arranged on the top end of an anode support electrolyte tube, seals the gas of the end, and simultaneously exports the electric current of the anode. The electric current inside the anode is collected by porous Ni felt and guided to the closed end. At the other end of a cell tube, a heat-resisting ceramic tube or a heat-resisting alloy tube is used as a gas-guide tube, and the gas-guide tube preheats or reforms normal temperature fuel gas simultaneously when guiding the normal temperature fuel gas. When the gas is imported to the closed end, temperature and composition of the gas meet the requirement of power generation, so that power generation can be carried out during inverse flow of the gas. Remaining fuel tail gas after power generation combusts instantly when getting in touch with the air at the mouth of the tube, and the heat energy is recovered. Anode support tube type solid oxide fuel cell and assembling method thereof have the advantages that: the electric current collecting position is moved to the closed end from the inner side of the cell, and the structure of an assembled electric pile is simple and compact, and the value of the power can be adjusted.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

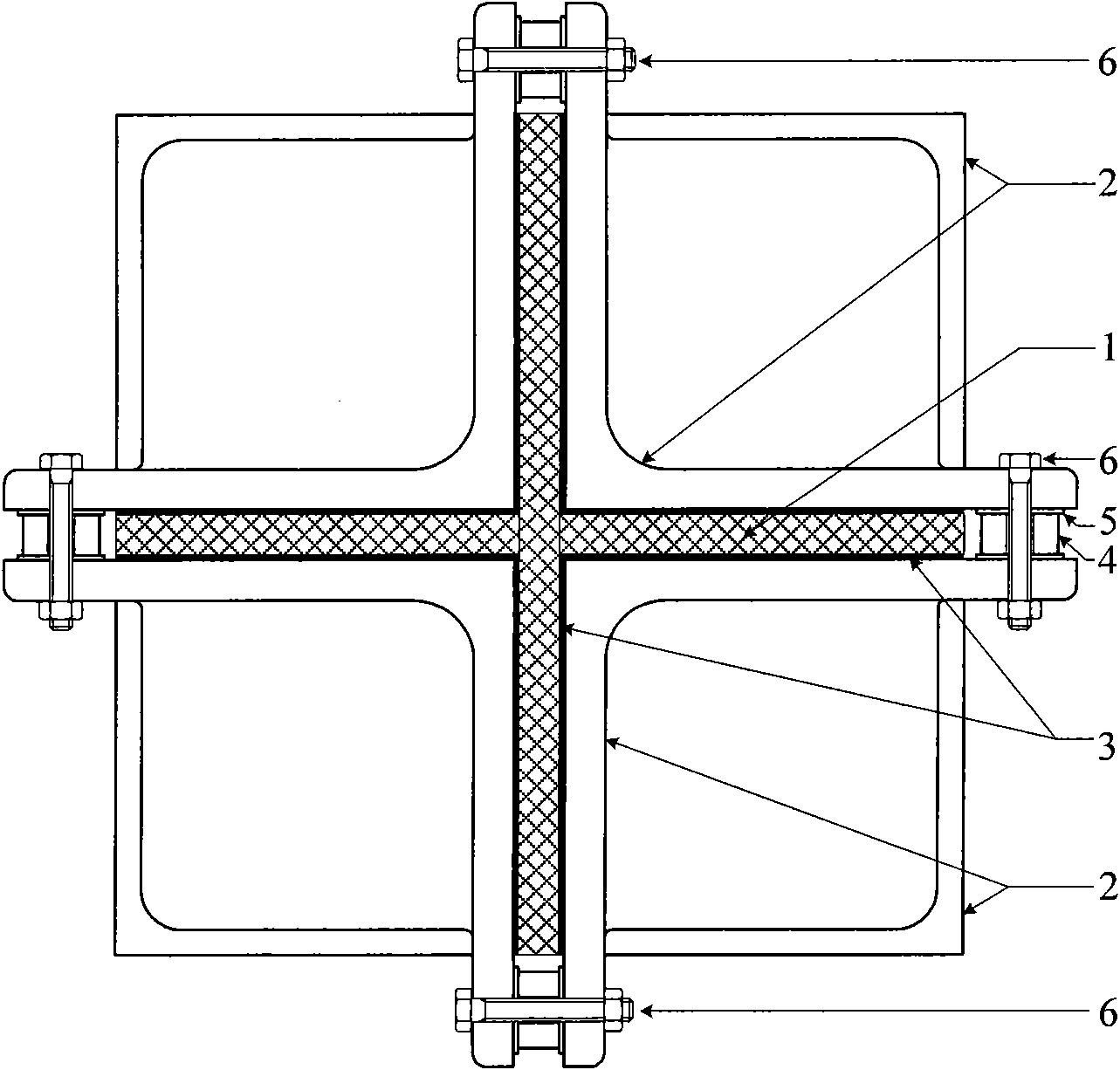

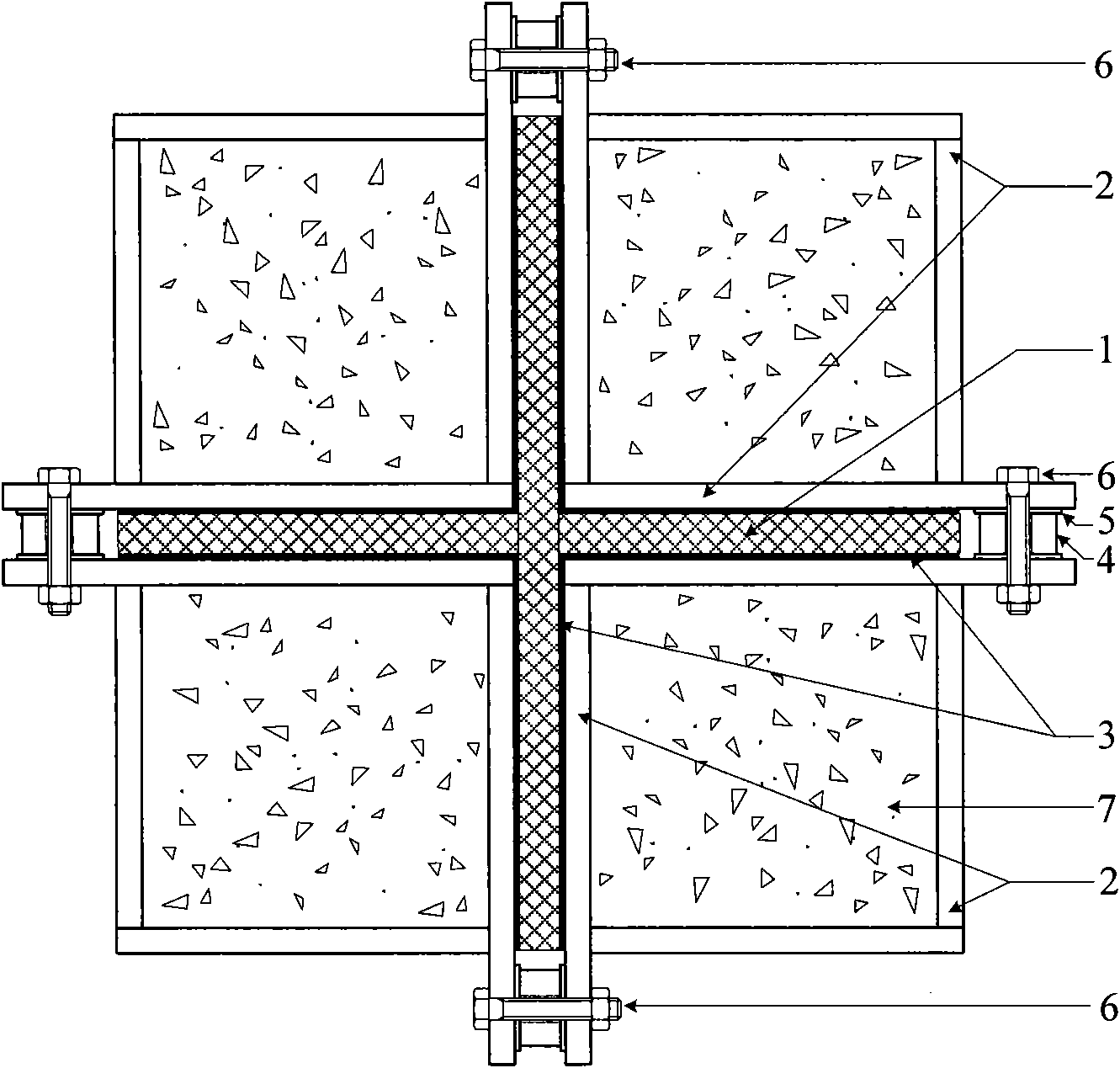

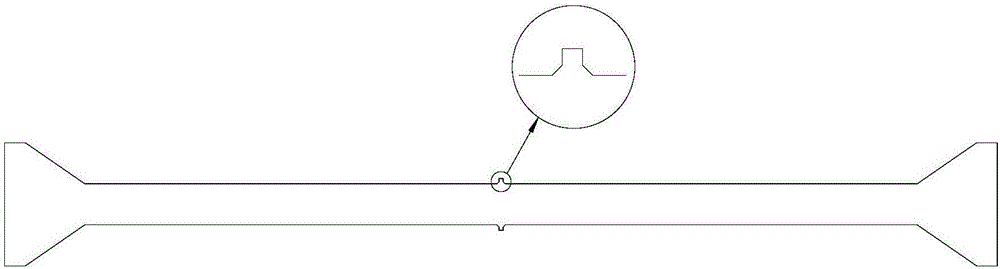

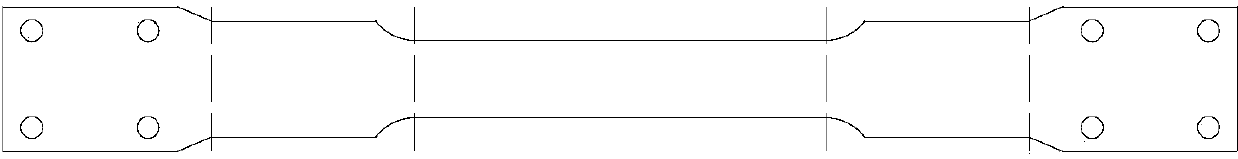

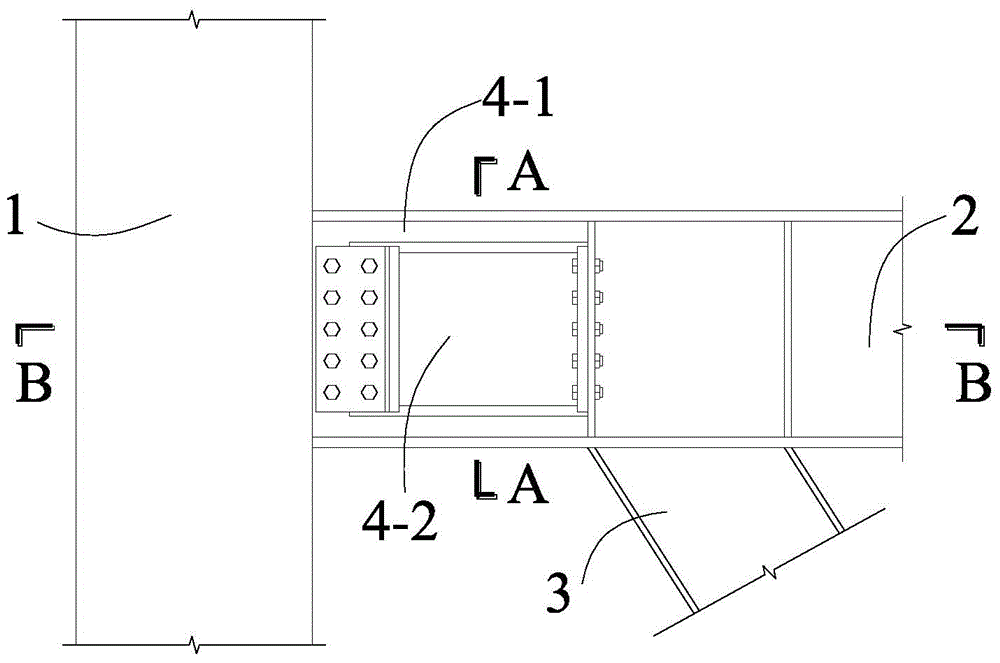

Double-rectangular tube buckled assembled buckling-restrained bracing member

InactiveCN101974948AEasy to replaceStable hysteresis performanceShock proofingBuckling-restrained braceEngineering

The invention discloses a double-rectangular tube buckled assembled buckling-restrained bracing member and belongs to the field of structural engineering. The bracing member consists of a linear inner core member and a peripheral restraining member, wherein the linear inner core member adopts a low-yield point high-ductility flat steel plate and hard rubber is adhered to the surface of the surface of the linear inner core member; the peripheral restraining member is bound by two restrained square steel tubes with extended steel plate strips; the binding function is realized by performing high-strength bolted connection on the square steel tubes; and a high-strength bolt passes through bolt holes on the extended steel plate strips of the square steel tubes, a steel plate arranged between the square steel tubes and a plurality of rubber gaskets so as to connect the two square steel tubes into a whole. The thickness of the steel plate is greater than that of the linear inner core member, and by adjusting the thickness of the rubber gaskets, a gap of 1-2mm is kept between the surface of the peripheral restraining member and the surface of the linear inner core member under the pretightening force of the high-strength bolt. The gap is filled by the hard rubber adhered to the surface of the linear inner core member so as to meet the requirement of expanding under pressure on the linear inner core member.

Owner:TSINGHUA UNIV

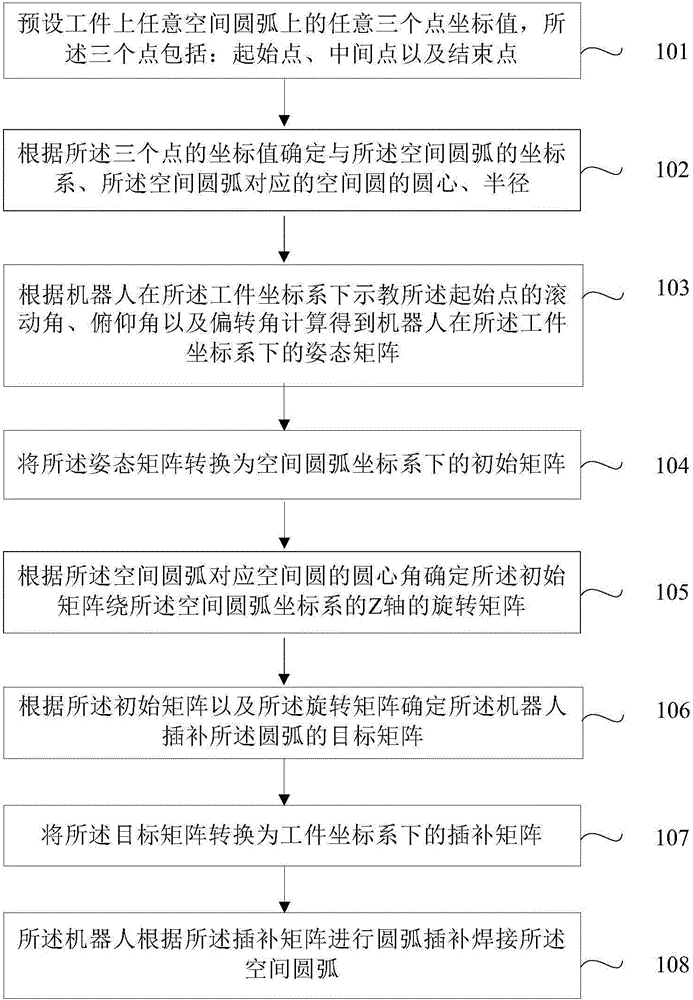

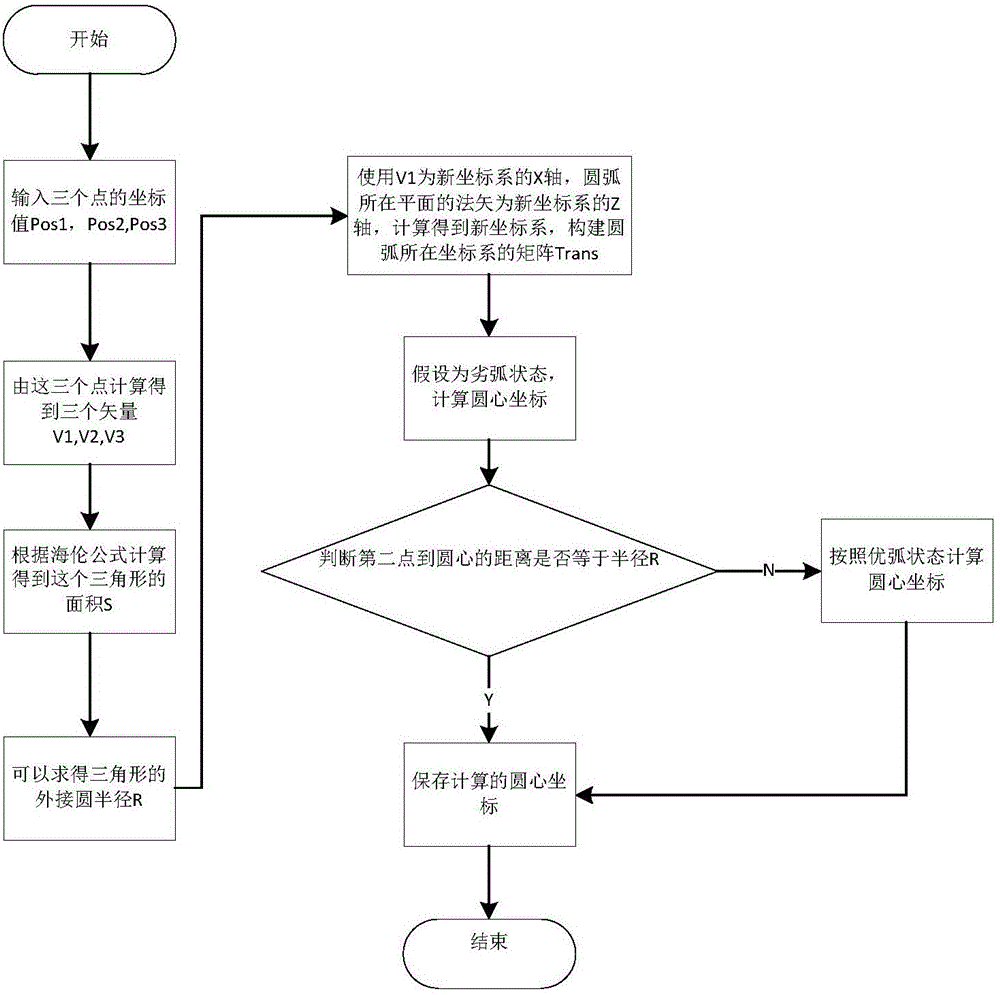

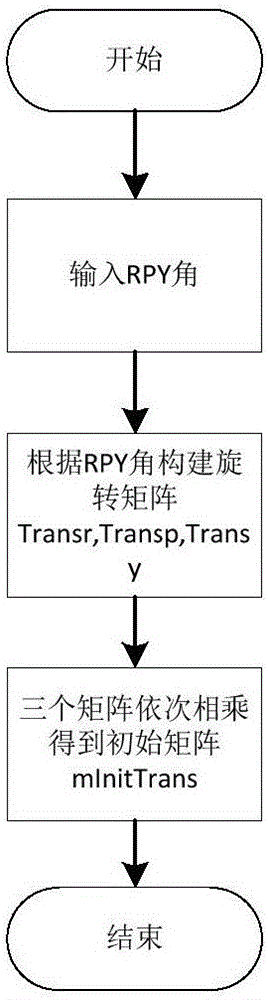

Space arc interpolation welding method based on teaching robot

ActiveCN105855672AImprove deficienciesEasy to operateWelding/cutting auxillary devicesArc welding apparatusComputer scienceRolling angle

The invention provides a space arc interpolation welding method based on a teaching robot. The space circular interpolation welding method includes the steps that coordinate values of any three points on an any space arc on a workpiece are preset; the circle center and the radius of a space circle corresponding to a space arc coordinate system and the space arc are determined according to the coordinate values of the three points; an attitude matrix of the robot under a workpiece coordinate system is obtained through calculation of the rolling angle, the pitch angle and the deflection angle of the robot at a teaching starting point under the workpiece coordinate system; the attitude matrix is converted into an initial matrix under the space arc coordinate system; a rotating matrix of the initial matrix around the Z axis of the space arc coordinate system is determined according to the circle center angle of the space circle corresponding to the space arc; a target matrix of a robot interpolation arc is determined according to the initial matrix and the rotating matrix; the target matrix is converted into an interpolation matrix under the workpiece coordinate system; and the robot conducts arc interpolation according to the interpolation matrix so as to weld the space arc. The operation method is simple, the machining precision is controllable, and the machining efficiency is high.

Owner:KEDE NUMERICAL CONTROL CO LTD

All-steel-assembled buckling restrained brace with lateral side capable of being inspected

InactiveCN106639029AEase of performance evaluationEasy to assembleProtective buildings/sheltersShock proofingBuckling-restrained braceEngineering

The invention provides an all-steel-assembled buckling restrained brace with the lateral side capable of being inspected. Welded joints at the ends of stiffening ribs are smoothed, the low-cycle fatigue performance of the brace is effectively improved, the plastic deformation capability of steel is adopted, and meanwhile the state of an inner core can be easily judged through the lateral side after a seism. The all-steel-assembled buckling restrained brace solves the problems that the deformation or damage state of the inner core cannot be conveniently evaluated rapidly after a seism, the welded joints at the ends of the stiffing ribs have quality defects, and the damaged inner core cannot be conveniently replaced. The buckling restrained brace achieves the aims that the deformation state of the inner core can be judged without detaching, and whether the inner core should be replaced or not can be rapidly evaluated after a seism; the welded joints at the ends of the stiffing ribs are processed, the middle cross section of the inner core is possibly damaged, and the low-cycle fatigue performance of the brace is improved; an assembled scheme is adopted, and the damaged inner core can be conveniently replaced. The all-steel-assembled buckling restrained brace comprises the inner core, the end stiffing ribs, two restrained face plates, gaskets, limiting grooves and high-strength bolts.

Owner:TONGJI UNIV

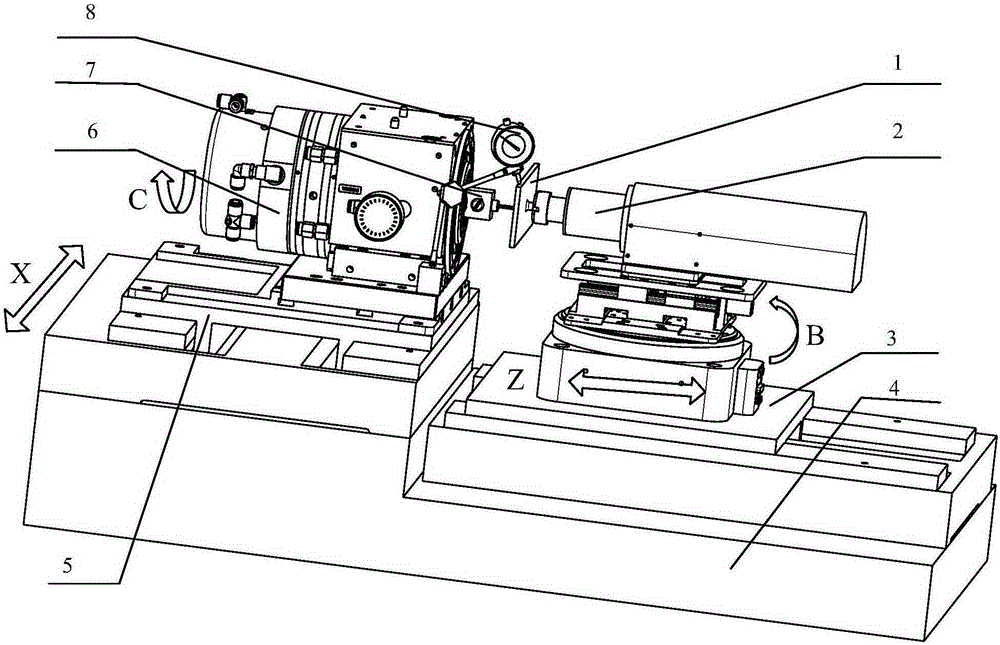

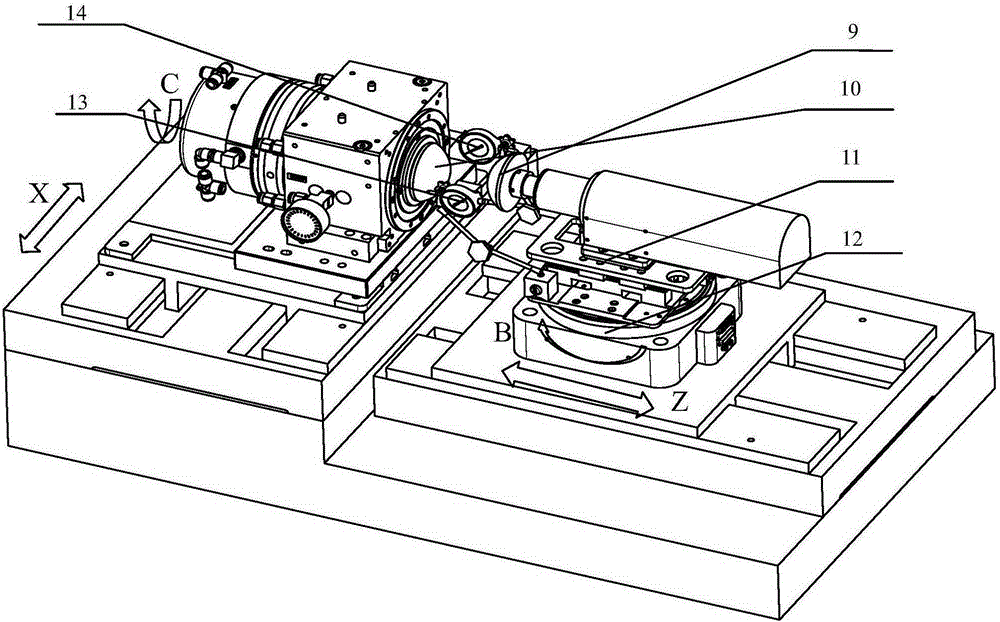

Horizontal precise polishing machine tool workpiece main shaft and tool system centering method

ActiveCN105290968AReduce processing difficultyMachining accuracy is easy to controlGrinding feed controlEngineeringOperability

The invention discloses a horizontal precise polishing machine tool workpiece main shaft and tool system centering method, and belongs to the field of mechanical manufacturing. The method comprises calibration adjustment in vertical and horizontal directions; in the vertical direction, a center punch scoring calibration plate eccentrically arranged relativeto a revolving center of a workpiece main shaft is adopted; and a coordinate of the workpiece main shaft relativeto an X-axis reference point of a machine tool in a specific position is mainly obtained through horizontal centering. The calibration plate and a calibration semisphere used in the whole centering process consist of simple geometries, so that the machining difficulty is low, the machining is precise and easy to be controlled, the manual clamping adjustment requirement is low, the repeated operability is good, and the error can be gradually reduced through multiple times of operations; a common dial indicator and a laser precise amesdial are adopted in measurement; the installation and the adjustment are flexible; the influence from machine layout is low; the generality is good; and the measurement precision is high. Compared with the use of a tool setting gauge or other special equipment, the method has the advantages of simple operation, convenience for installation and debugging and low manufacturing cost.

Owner:JILIN UNIV

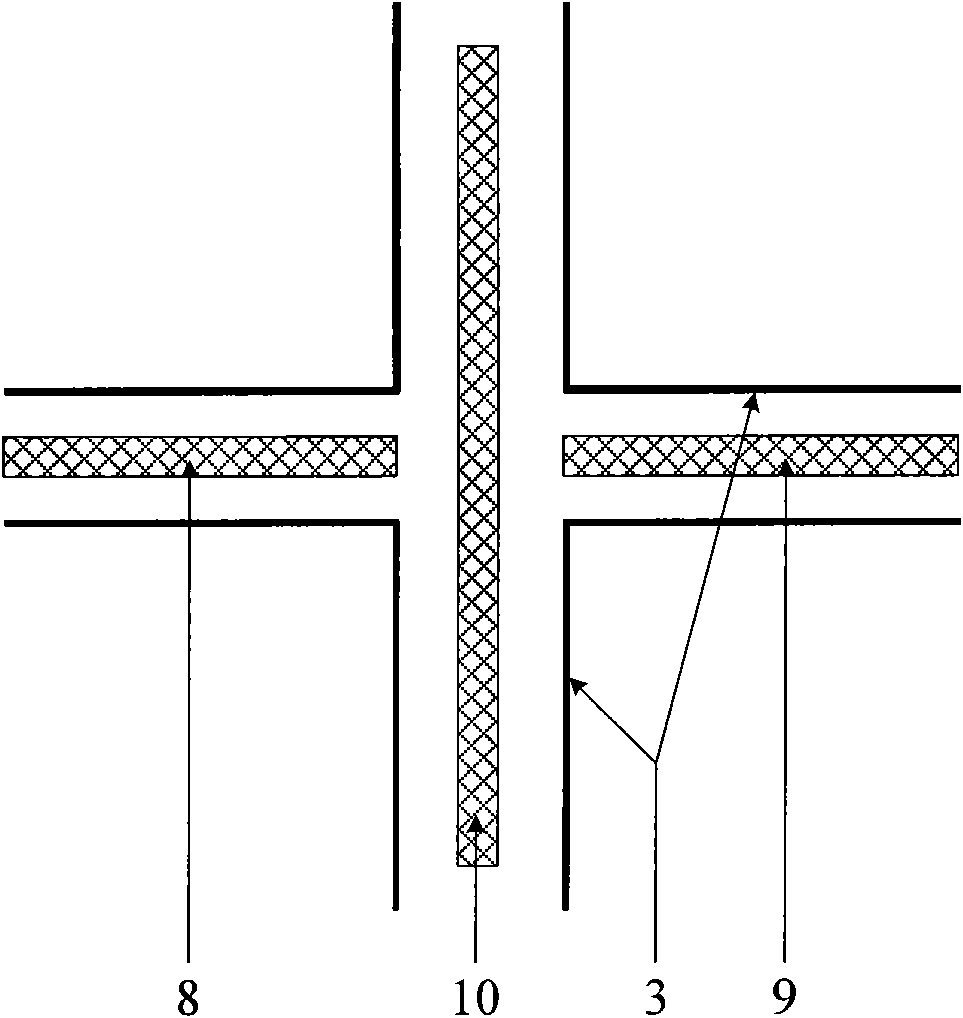

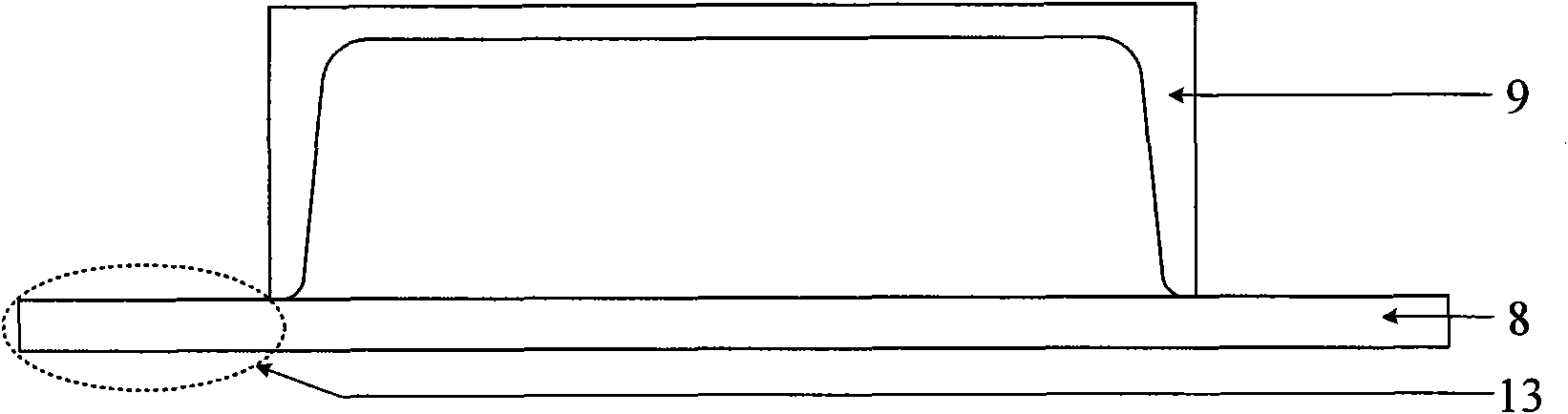

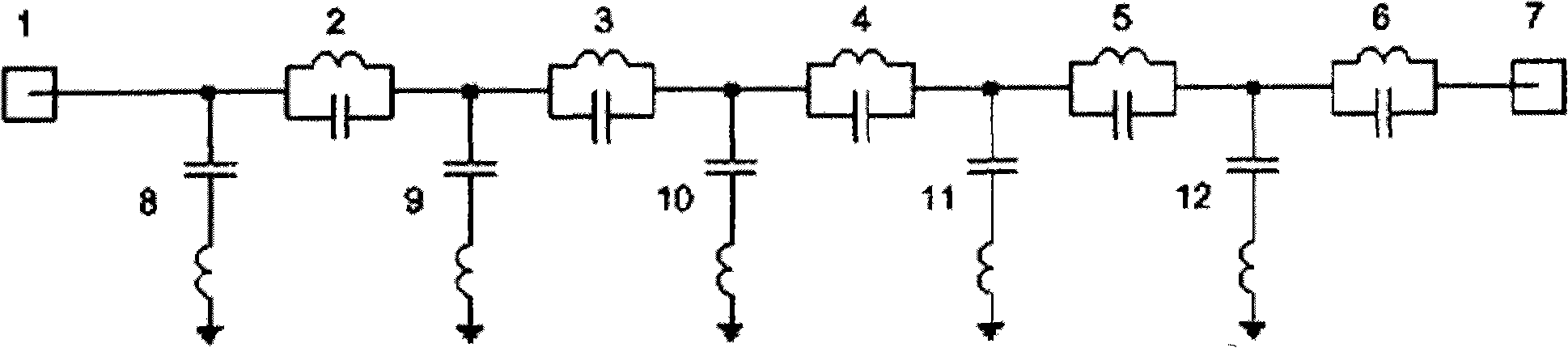

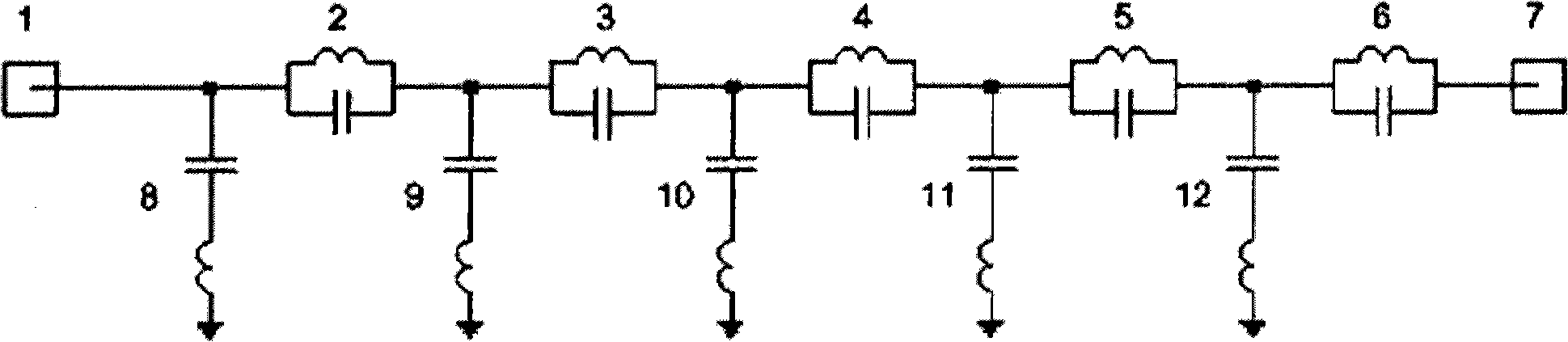

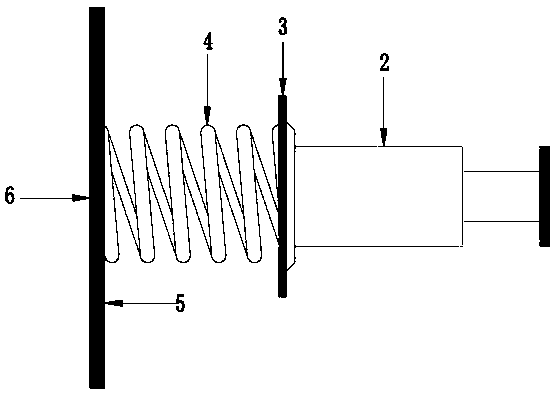

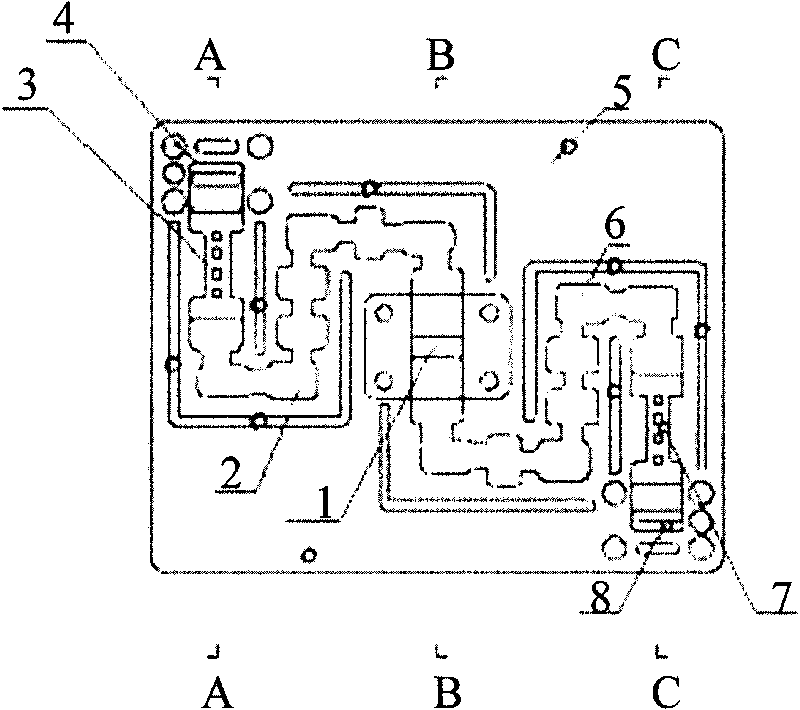

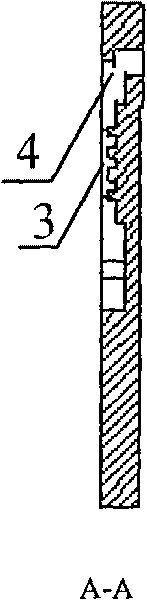

Adjustable band elimination filter

InactiveCN101938022AMachining accuracy is easy to controlSimple structureWaveguide type devicesElectronic communicationBand-stop filter

The invention relates to an adjustable band elimination filter, relating to the field of electronic communication and aiming at solving the technical problems of single realization mode, complex structure, large size, difficult assembly, low reliability and the like existing in the traditional band elimination filter. The adjustable band elimination filter comprises an input port, an output port, adjustable resonators and micro-band coupled transmission lines, wherein the input port (1) is connected with a plurality of sections of the micro-band coupled transmission lines in sequence in series and then is connected with the output port (7); one end of one adjustable resonator (8) is connected between the input port (1) and the adjacent micro-band coupled transmission line (2), and the other end is grounded; one adjustable resonator is connected between any two adjacent micro-band coupled transmission lines, one end of the adjustable resonator is connected between the adjacent micro-band coupled transmission lines, and the other end is grounded. The invention is applicable to the design of the adjustable band elimination filter.

Owner:DFINE TECH

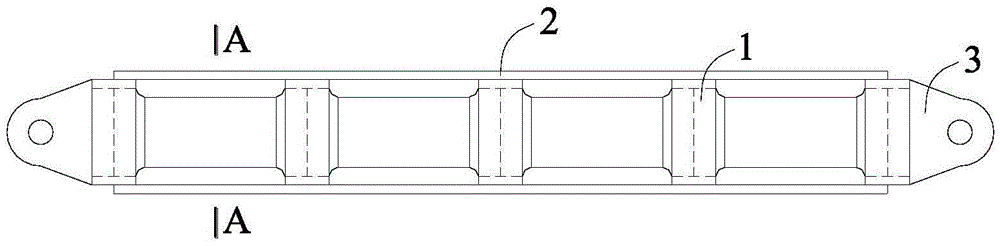

Bamboo-shaped buckling-restrained brace

ActiveCN105714952AShorten the lengthDestabilization will not happenShock proofingBuckling-restrained braceCoaxial line

The invention discloses a bamboo-shaped buckling-restrained brace, comprising a core component, an external restrained component and reinforced connecting components, wherein the core component is formed by alternately arranging a plurality of circular energy dissipation sections and a plurality of circular elastic sections along a longitudinal coaxial line; each circular elastic section comprises a plurality of middle elastic sections and two end elastic sections; the cross sectional area of each circular energy dissipation section is smaller than that of the corresponding circular elastic section; the core component is positioned in the external restrained component; each reinforced connecting component is composed of a node section, a connecting section and a reinforcing barrel. The bamboo-shaped buckling-restrained brace disclosed by the invention has the advantages that all the circular energy dissipation sections are shorter, and only yield without buckling under the action of an axial force, so that mortar is unnecessarily added or additional parts are unnecessarily arranged for restraining the circular energy dissipation sections, the cross sectional area of each circular energy dissipation section is smaller than that of each circular elastic section, the yielding force is less, and the rigidity requirement on the external restrained component is lower, therefore the external restrained component can be a simple circular casing, and the effects of simple structure, convenience in processing and lighter dead-weight are achieved.

Owner:SOUTHEAST UNIV

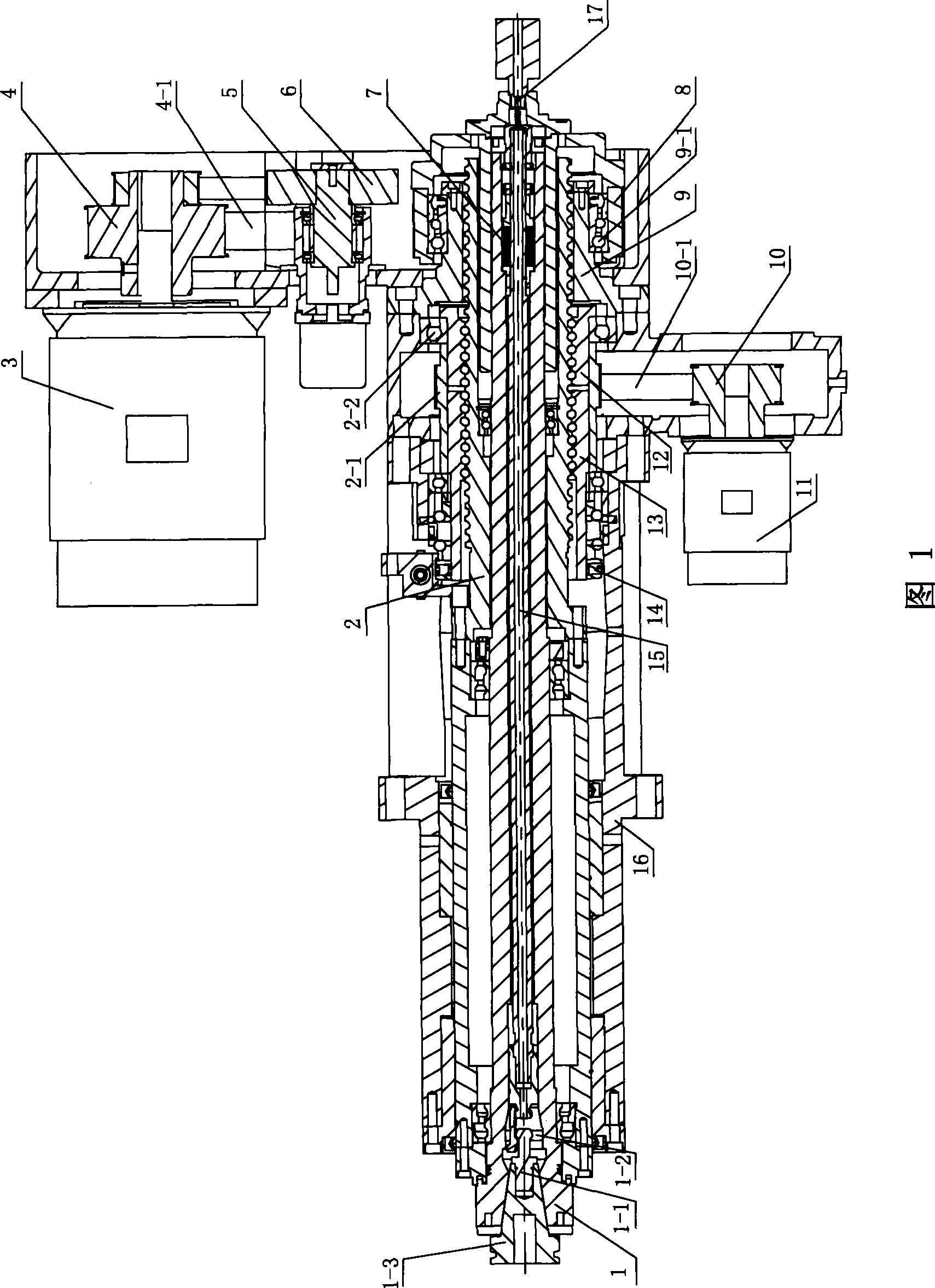

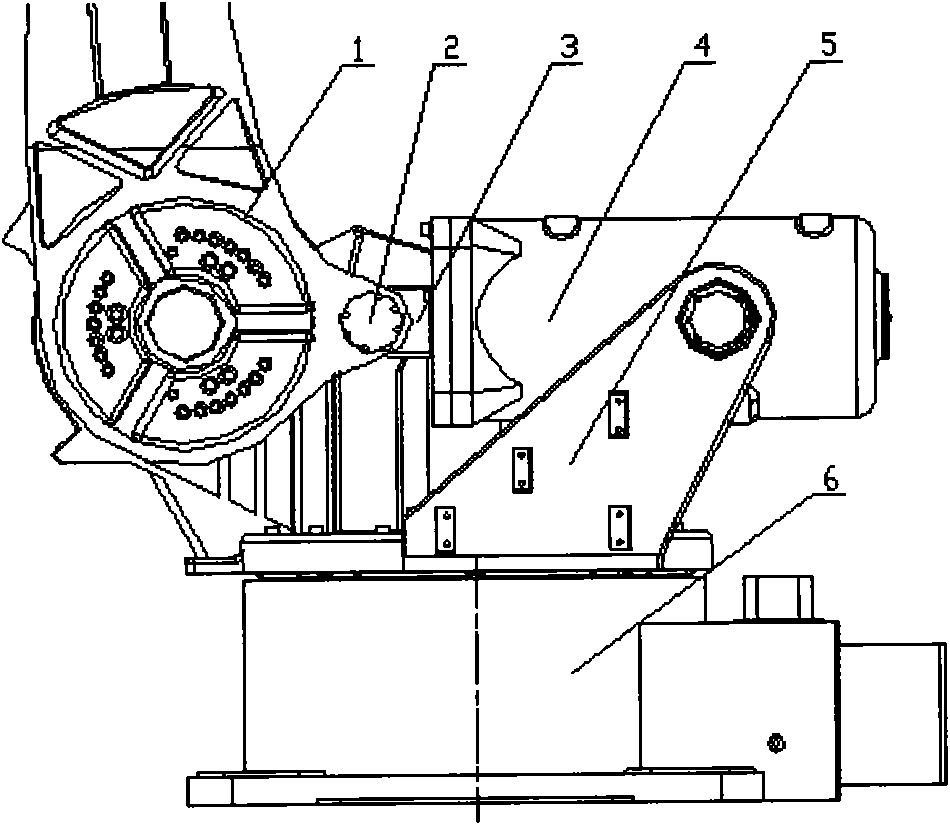

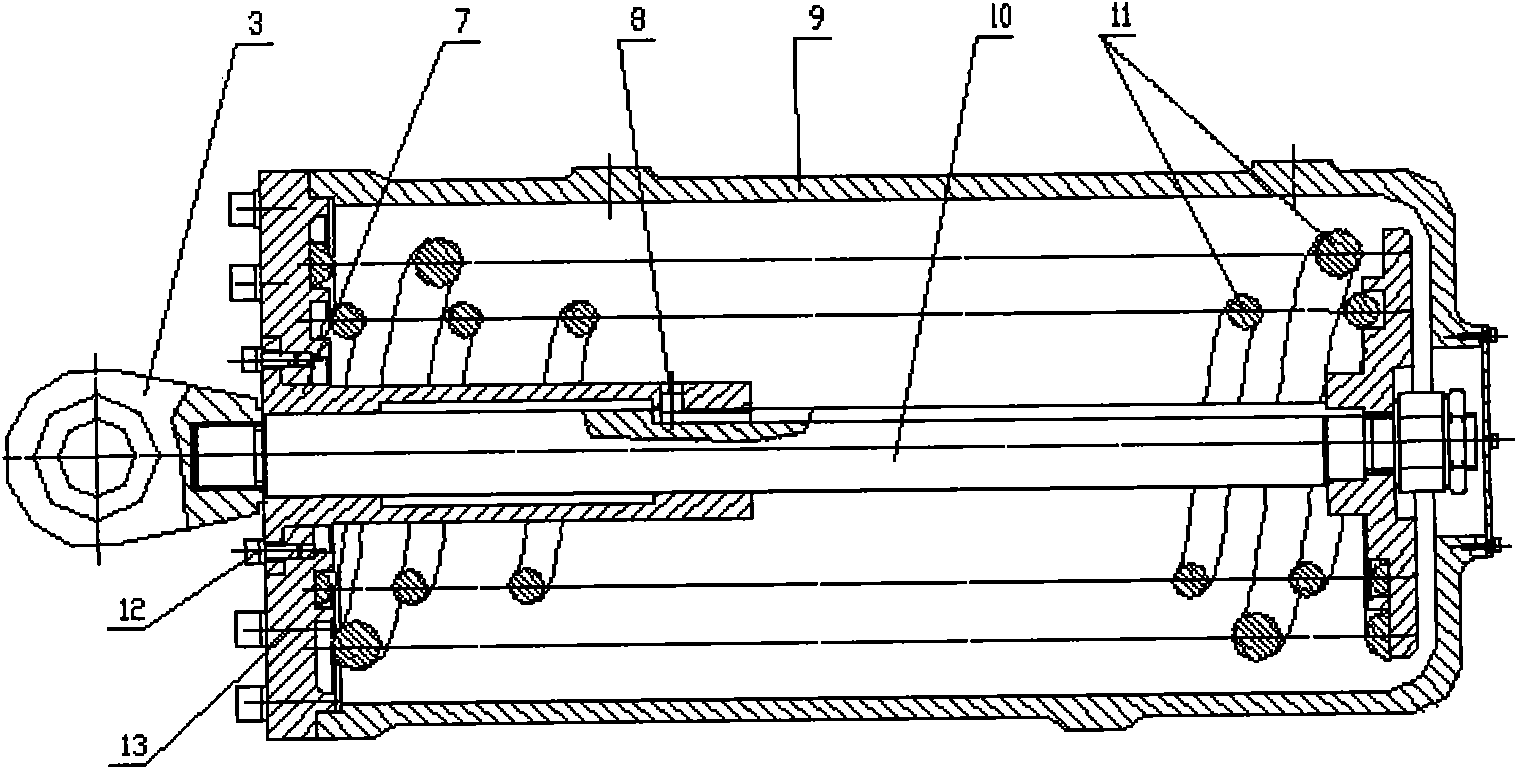

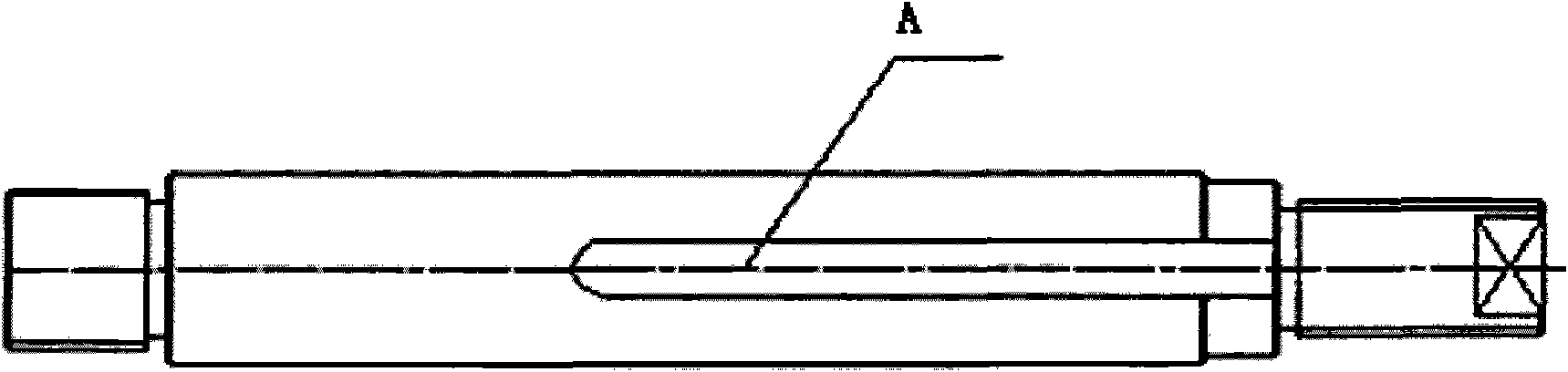

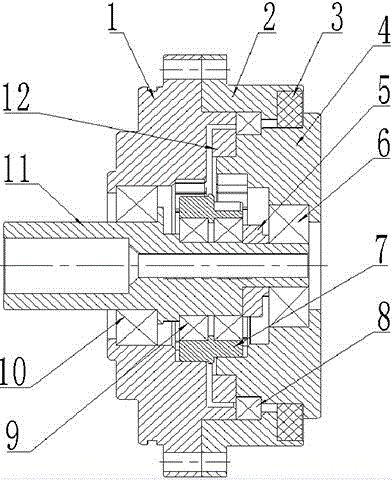

Numerical control main axle unit

The invention relates to the field of a machining main shaft unit, in particular to a numerical control main shaft unit, which comprises a main shaft for bearing a machining tool, a hollow pull rod, a main shaft feed driving device for driving the main shaft to slide axially, a main shaft rotation driving device for driving the main shaft to rotate radially, and a box body. Compared with the prior art, the numerical control main shaft unit is mainly arranged on a machining device to perform machining operations of drilling, reaming, boring, tapping, and the like, the feeding speed of the main shaft is easy to control, the vibration is smaller when the machining is in place, the precision of the axial dimension in the process of machining a workpiece is easy to control, the surface finish quality of a machined workpiece is high, and wearing parts are easy to replace, thus the numerical control main shaft unit sufficiently meets the requirements of the modern machining.

Owner:洪清德

Buckling restrained brace with staggered intersecting plates

ActiveCN103741830AAvoid damageIncrease the force sectionShock proofingBuckling-restrained braceCore component

The invention discloses a buckling restrained brace with staggered intersecting plates. The buckling restrained brace comprises a dissipating core component, a first reinforcing plate group, a second reinforcing plate group, and a uniform-section buckling restraint part. The first reinforcing plate group is fixedly connected to outer surfaces of two flanges of two tail ends of the dissipating core component. The uniform-section buckling restraint part is disposed outside the middle of the dissipating core component. The second reinforcing plate group is fixedly connected between the flanges and webs of the dissipating core component. The buckling restrained brace with staggered intersecting plates has the advantages that the middle of the dissipating core component can yield first and the ends of the dissipating core component can be in the elastic phase under the action of high external force, with no need of cutting a dissipating core plate, and accordingly damage of the dissipating core component caused by cutting is avoided; only the flanges or web edges of the dissipating core component are restrained, overall and local buckling of the dissipating core component is effectively guaranteed, conflict between the buckling restraint part and the two reinforcing plate groups is avoided, the section of the buckling restraint part in the length-wise direction is equal, and manufacturing difficulty is significantly reduced.

Owner:SOUTHEAST UNIV

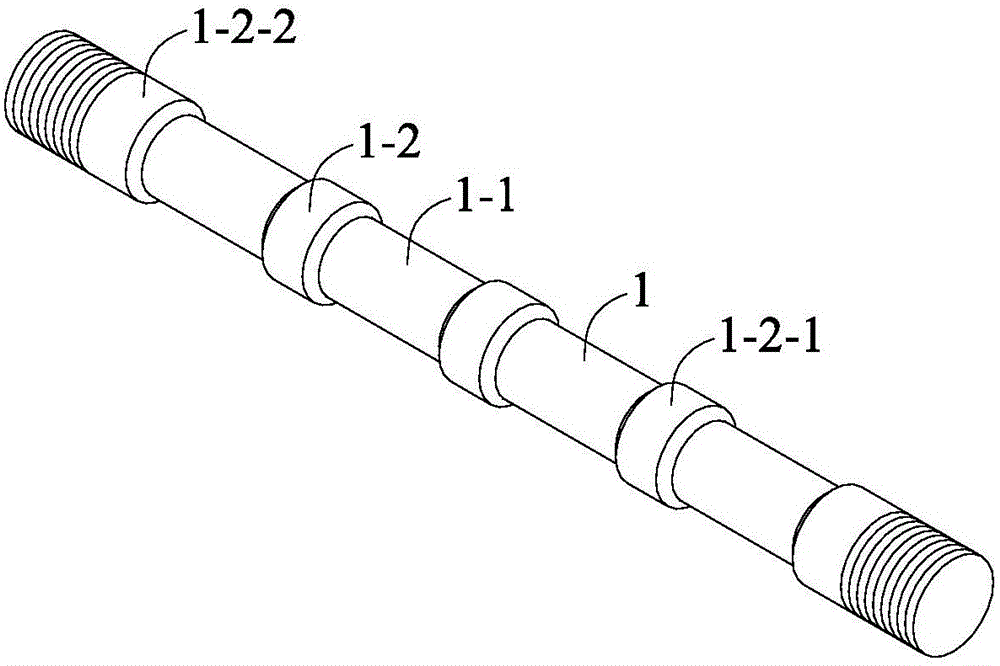

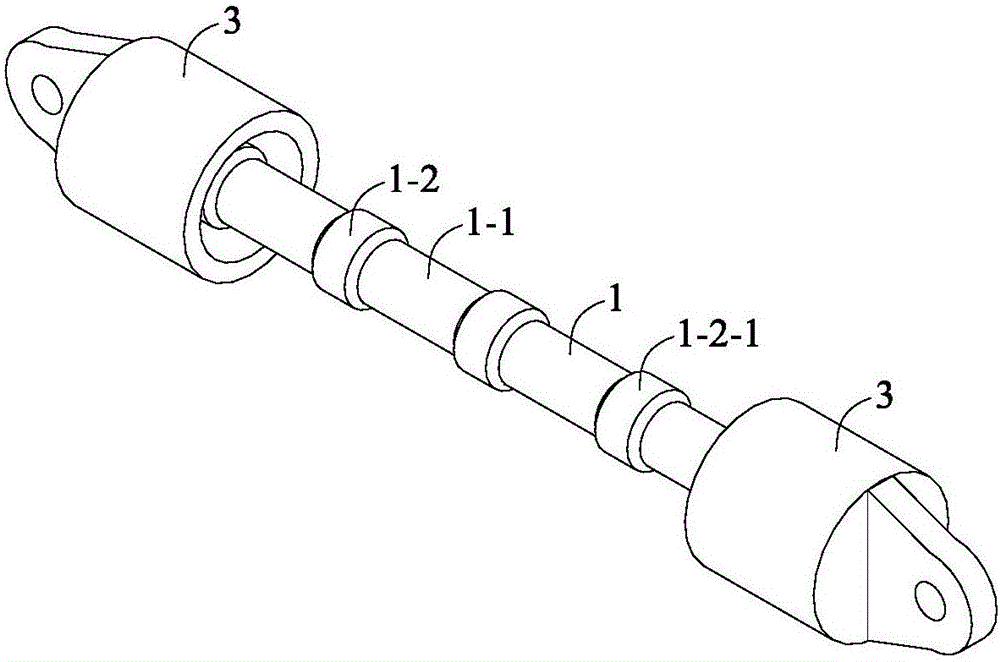

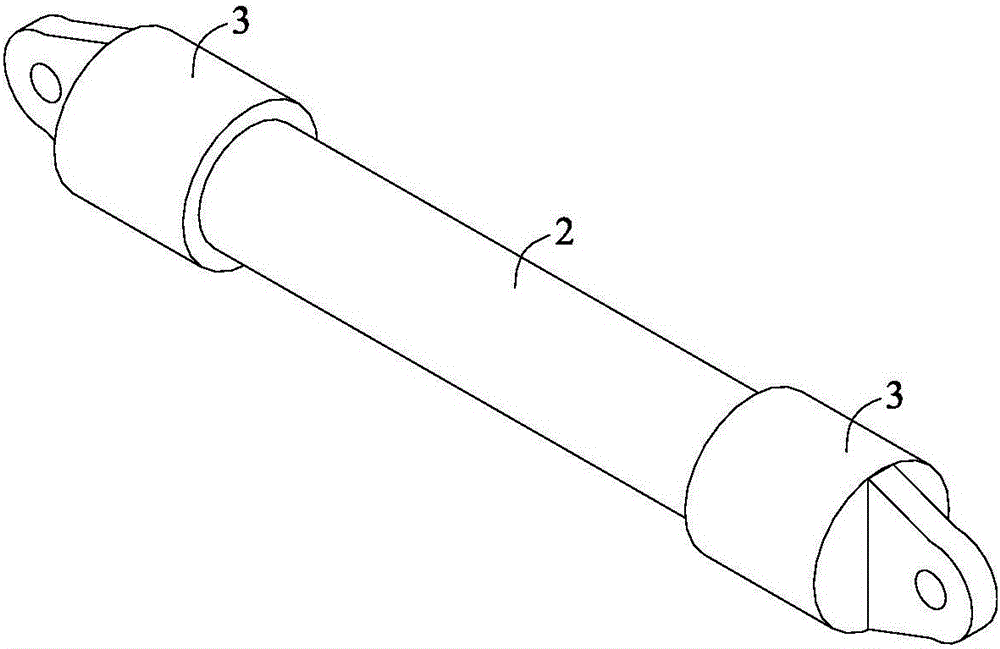

Balancer of welding robot and constructing method thereof

ActiveCN101863037AExtended service lifeSimple structureJointsWelding/cutting auxillary devicesEngineeringMechanical engineering

The invention relates to a balancer of a welding robot, and a construction method thereof; the balancer comprises a balancer shaft (10), a balancer guide bushing (7), a fixed pin and a joint bearing (3); the shaft end of the balancer shaft (10) is connected with the joint bearing (3); the balancer shaft (10) can be arranged in the balancer guide bushing (7) in a sliding way; and the fixed pin is inlaid on the balancer guide bushing (7) and can slide relative to the balancer shaft (10).

Owner:CHERY AUTOMOBILE CO LTD

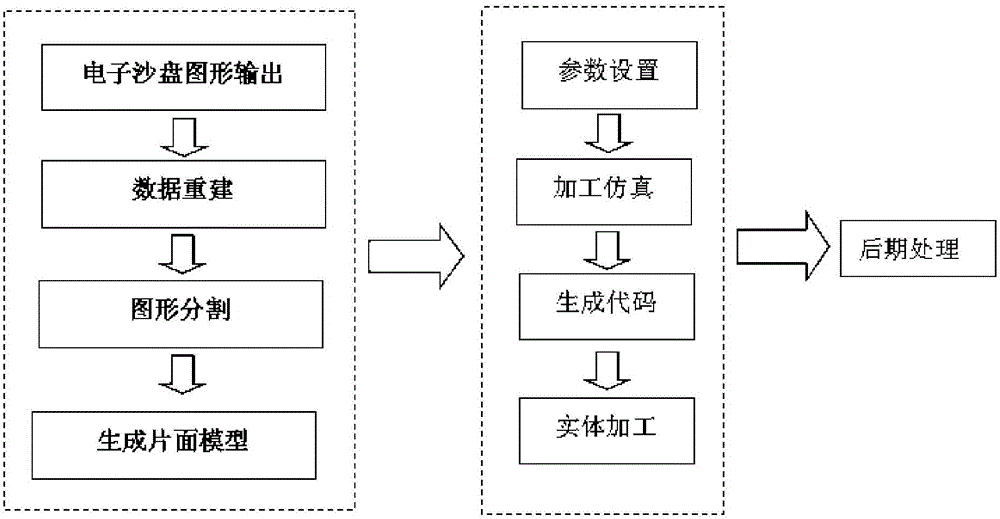

Processing method of 3D real-scene topographic map sand table

The invention discloses a processing method of a 3D real-scene topographic map sand table. Data reconstruction and graph segmentation are carried out on electronic sand table data of an OBJ format to obtain a one-sided model, according to the one-sided model, processing parameters are set and a cutter track is generated, processing simulation is carried out according to the processing parameters and the cutter track, and equipment of a processing center is provided for entity processing. According to the invention, the proportion can be controlled, a landform sand table model is not distorted, processing can be carried out needless of substantiating the one-sided model, a tedious one-sided model substantiating processing is omitted, labor and time cost is saved, the processing equipment is universal equipment, the processing precision is adjustable and controllable, the fineness processing precision can reach 0.05mm according to different processing precisions, labor cost and time are reduced, the processing efficiency is improved, and the production benefit is improved.

Owner:XIAN TECHNOLOGICAL UNIV

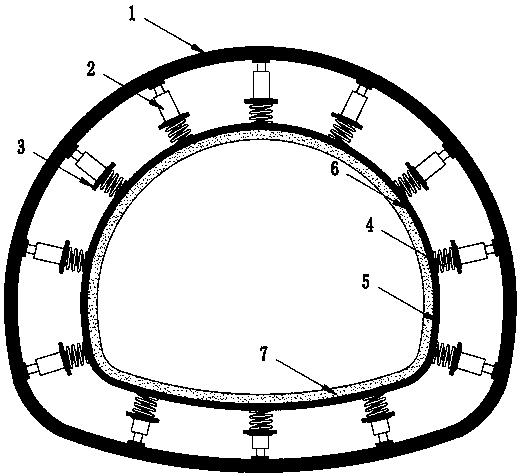

Multifunctional testing device used for lining structure

InactiveCN107941594AEven by forceReflect formation resistanceMaterial strength using tensile/compressive forcesCounterforceLine structure

The invention discloses a multifunctional testing device used for a lining structure. The multifunctional testing device is composed of a counterforce apparatus and a loading module. The counterforceapparatus is produced by bending and welding steel plates. The loading module is composed of a hydraulic jack, a force-transmission steel plate, a stratum spring, a steel base plate, and a rubber baselayer. One end of the jack is connected with the counterforce steel plate, the other end is connected with the stratum spring through the force-transmission steel plate, and the other end of the stratum spring is connected with the steel base plate and the rubber base layer. The multifunctional testing device has the advantages of simple processing production, good integral stability, and convenient operation, and has integral and local loading function. The multifunctional testing device can be widely used for the lining structure tests of tunnels under various conditions such as bias, relaxground pressure and lining backside cavity.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

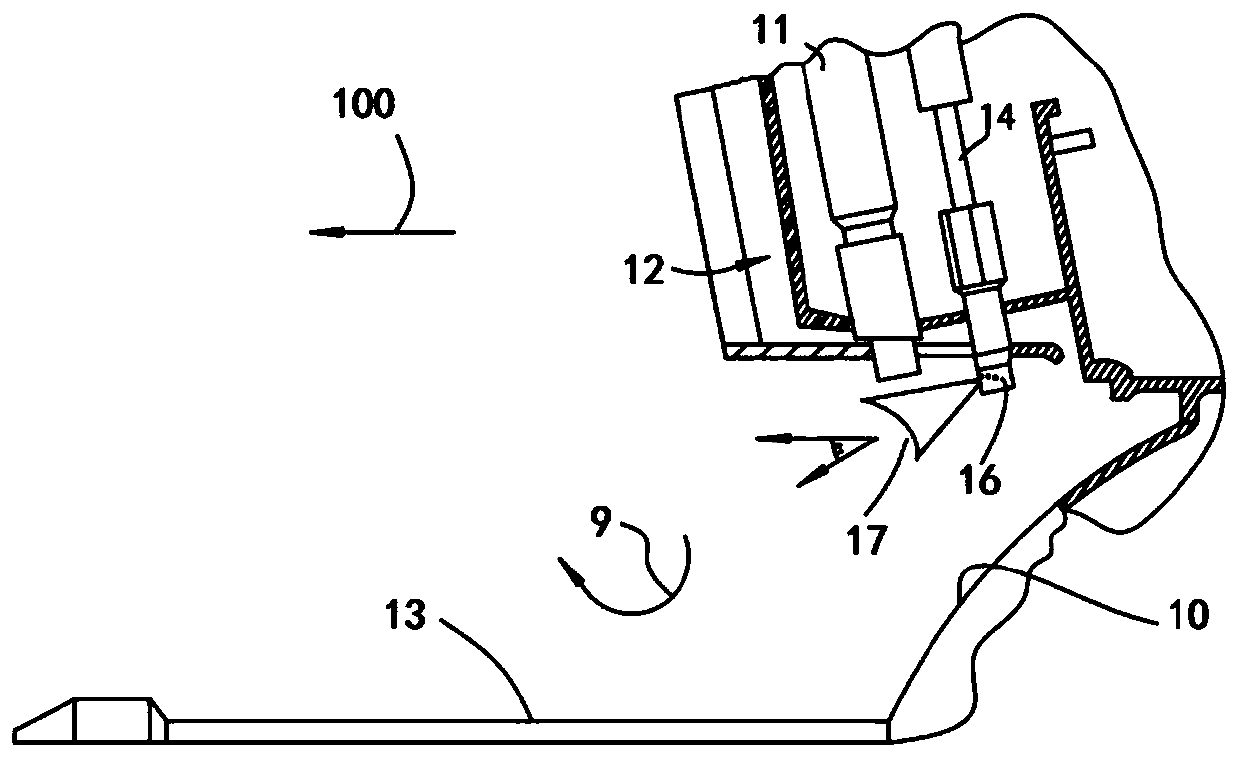

Modularized waveguide correction network applied to highly integrated phased array system

ActiveCN107465467AImprove consistencyMachining accuracy is easy to controlTransmitters monitoringWaveguidesModularityEngineering

The invention relates to a modularized waveguide correction network applied to a highly integrated phased array system. The network comprises an expansion installation plate and more than two correction modules, wherein the correction module is formed by coupling more than two main waveguides with a correction waveguide, wherein interfaces at one ends of the main waveguides on the same sides of the more than two correction modules, bend openings at two ends of the correction waveguide, more than four main waveguide installation holes on an expansion installation plate and more than four correction waveguide installation holes are connected in a cooperative manner; when in use, interfaces on the other side of the expansion installation plate are connected with a transmitting-receiving component, a load and a correction receiver or a correction transmitter; interfaces at the other ends of the main waveguides on the same sides of the more than two correction modules are connected with an antenna array. According to the network provided by the invention, the correction module is used as a basic unit, and machining accuracy is controllable; short waveguide sections are spliced to replace a long waveguide section, and thus machining and assembly problems of the long waveguide section are avoided. The expansion installation plate is smoother than the long waveguide section, and installation accuracy of the antenna array is enhanced.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 38 RES INST

Machining method of narrow and small grinding undercuts of roller bearing

InactiveCN107984172AReduce residual stressMachining accuracy is easy to controlBearing componentsPulp and paper industryMachining process

The invention relates to the technical field of machining, in particular to a machining method of narrow and small grinding undercuts of a roller bearing. According to the machining method, the problems that in the machining process of existing narrow and small grinding undercuts of a roller bearing, tools are worn severely, the large size dispersion of the grinding undercuts is prone to being caused, consequently, dimension deviation of the grinding undercuts is caused, and the percent of pass of finished products is low are solved. The method comprises the following steps that firstly, a tool-by-tool cutting method is adopted, the first plane, the second plane, the sleeve ring outer diameter and the sleeve ring inner diameter of a roller bearing sleeve ring are sequentially subjected tofinish lathing machining through two tools; then, flanges, roller ways and the grinding undercuts of the roller bearing sleeve ring are sequentially subjected to finish lathing machining; the first end face and the second end face of the sleeve ring are subjected to soft grinding, and after the flanges and the roller ways of the bearing sleeve ring are subjected to rough lathing machining, the roller ways continue to be subjected to finish grinding; and finally, the grinding undercuts are finally checked, and the bearing sleeve ring is subjected to heat treatment. The machining method is usedfor machining the narrow and small grinding undercuts of the roller bearing.

Owner:AVIC HARBIN BEARING

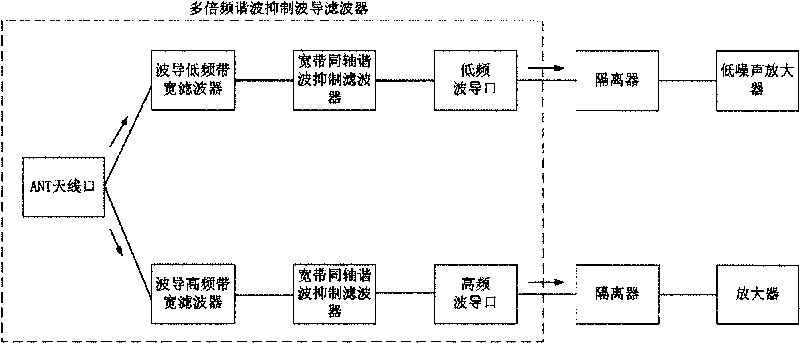

Multi-doubling frequency harmonic inhibiting waveguide wave filter

InactiveCN101694901AIncrease acceptanceMachining accuracy is easy to controlWaveguide type devicesWaveguideElectron

The invention discloses a multi-doubling frequency harmonic inhibiting waveguide wave filter which relates to the technical field of electronic communication and aims to solve the technical problems of complicated structure, large volume, difficult assembly, low reliability, and the like in the traditional multi-doubling frequency harmonic inhibiting product in a waveguide way. In the multi-doubling frequency harmonic inhibiting waveguide wave filter, a three-port structure comprises a high-frequency output end, a low-frequency output end and a public input end, and a signal source from the public input end of an antenna opening is divided into two paths, wherein one path is outwards output by a low-frequency waveguide opening of the low-frequency output end after passing through a waveguide bandpass wave filter A and a harmonic inhibiting wave filter, and the other path is outwards output by a high-frequency waveguide opening of the high-frequency output end after passing through a waveguide bandpass wave filter B and the harmonic inhibiting wave filter. The invention is suitable for the fields of microwave communication, satellite communication, electronic equipment, and the like.

Owner:DFINE TECH

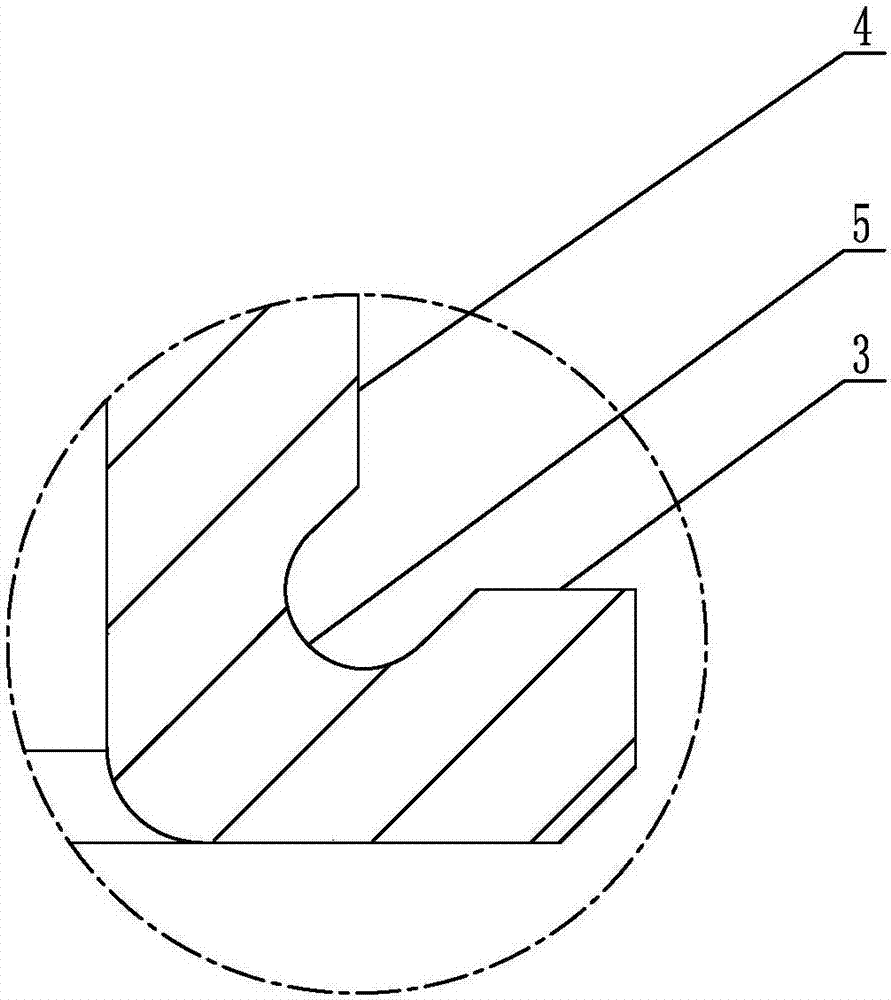

Single-eccentric short transmission chain speed reducer

The invention discloses a single-eccentric short transmission chain speed reducer. The single-eccentric short transmission chain speed reducer comprises a fixed main body, a bearing sleeve, a power input shaft, a power output shaft and a duplicate gear; the power input shaft comprises positive axis parts at the two ends and an off-axis part in the middle, the axes of the positive axis parts and the off-axis part do not coincide, the duplicate gear is arranged on the off-axis part of the power input shaft in a sleeving mode through a third bearing, and the duplicate gear comprises a first external gear and a second external gear; a first inner gear ring is arranged on the portion, corresponding to the first external gear, of the fixed main body, a second inner gear ring is arranged on the portion, corresponding to the second external gear, of the power output shaft, the first external gear and the first inner gear ring are in internal meshed transmission, and the second external gear and the second inner gear ring are in internal meshed transmission. The single-eccentric short transmission chain speed reducer has the advantages of being simple in structure, short in transmission chain, high in transmission efficiency, stable in transmission, large in transmission moment, wide in speed reducing ratio range and the like.

Owner:XUCHANG UNIV

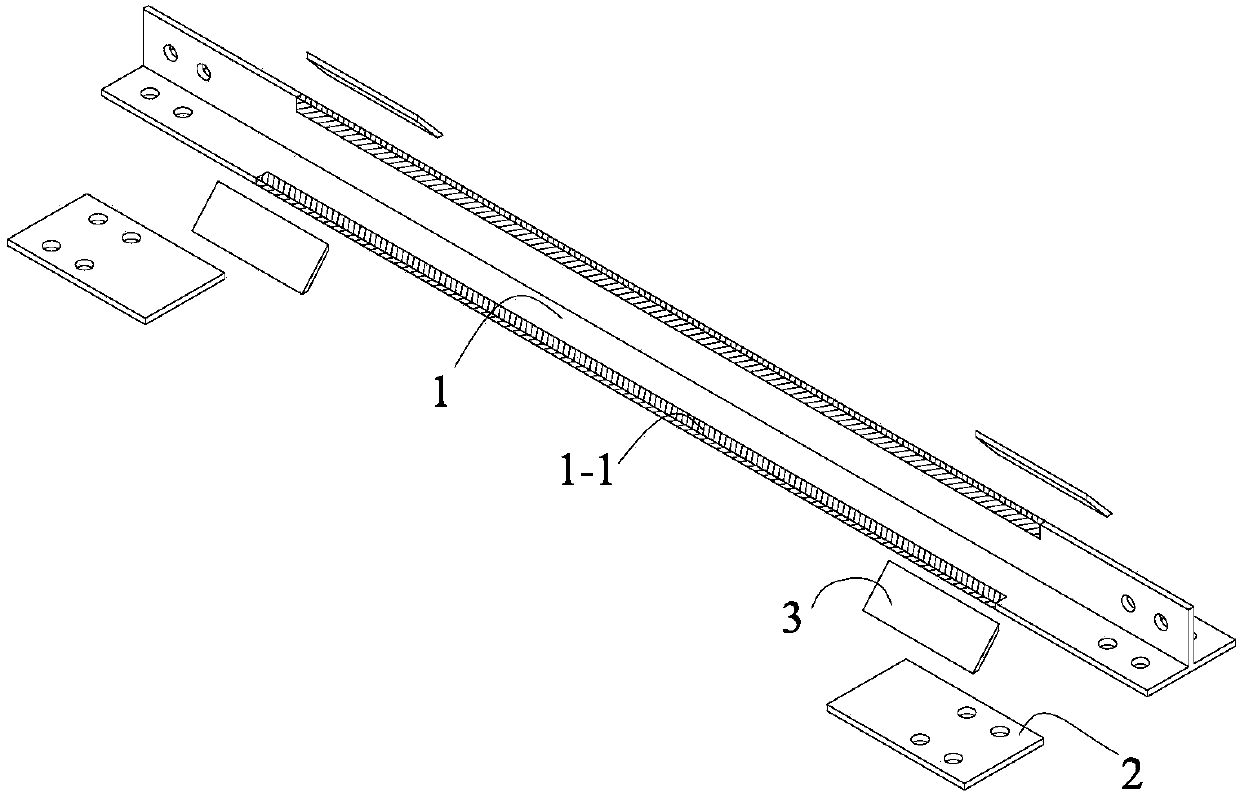

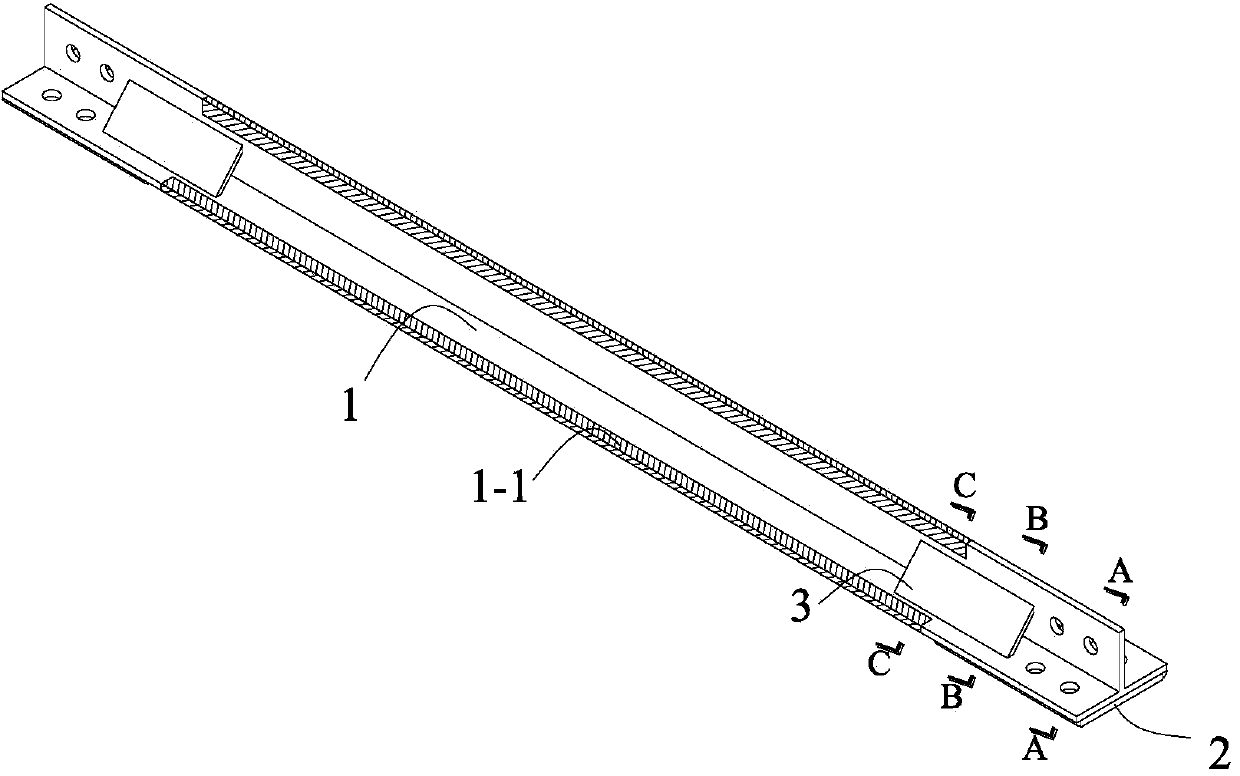

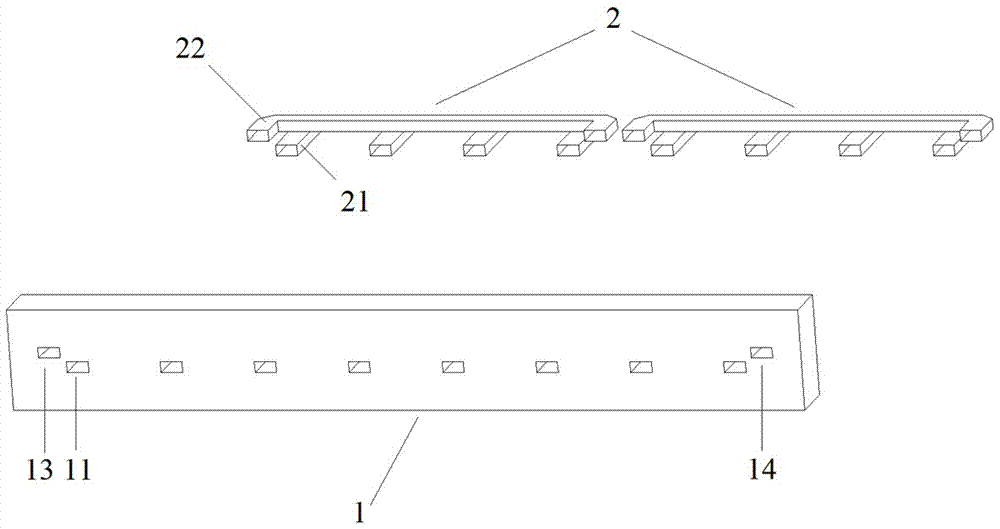

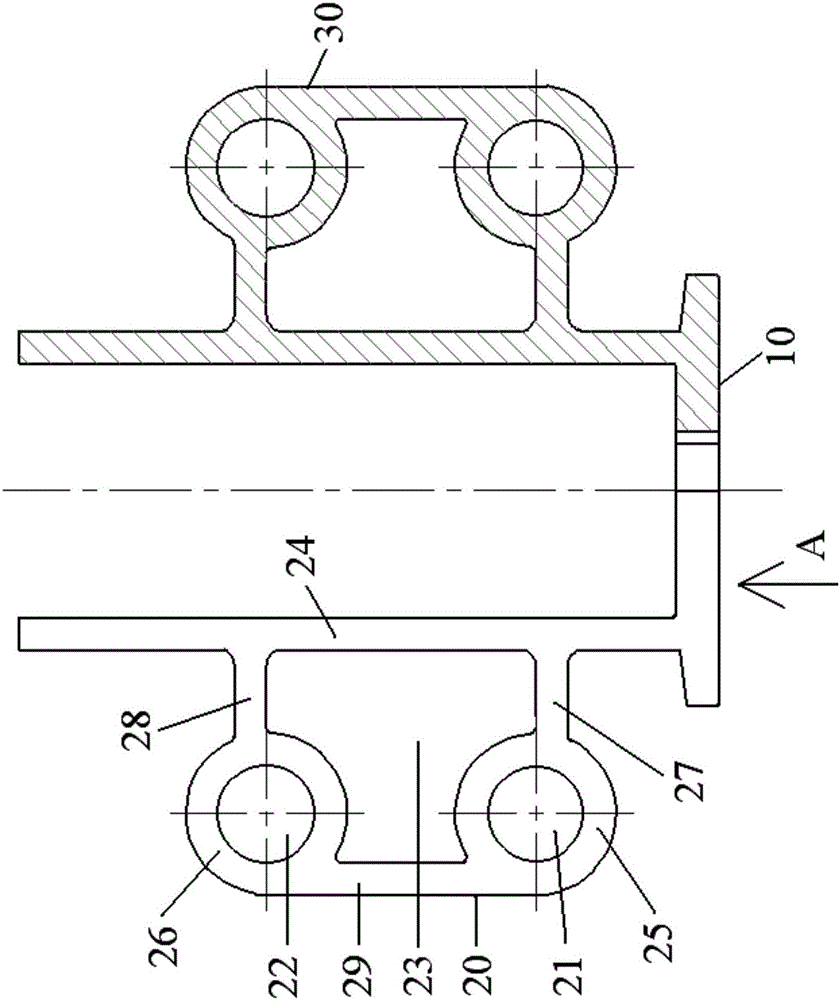

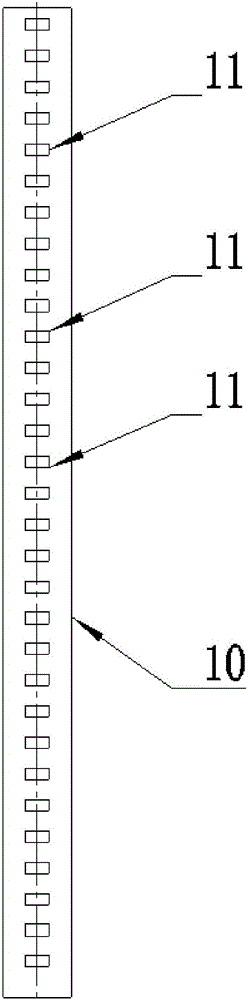

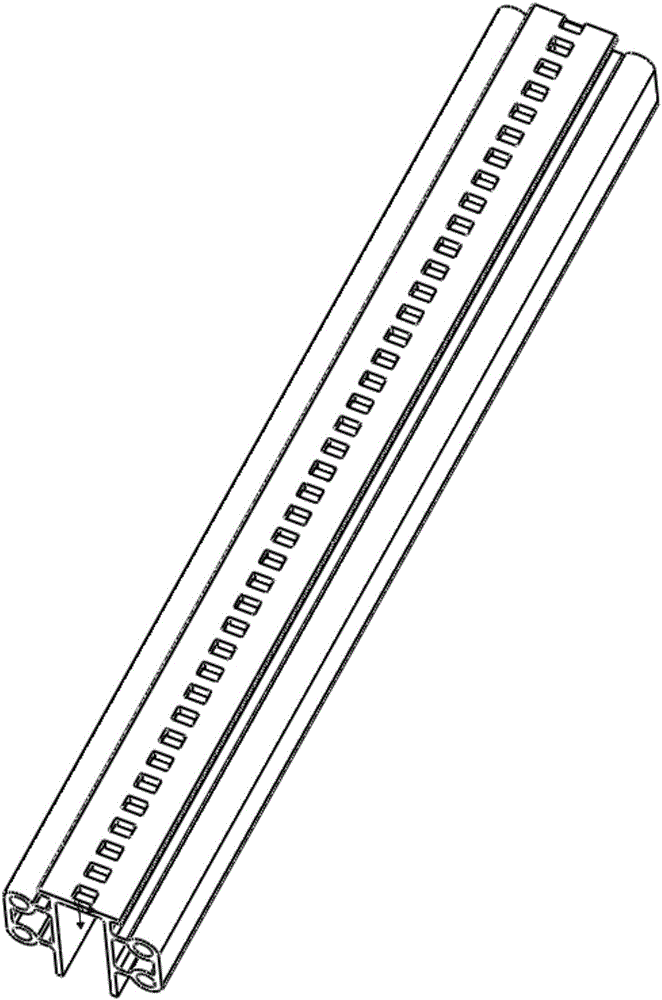

Guide rail unit used on transmission tower and guide rail

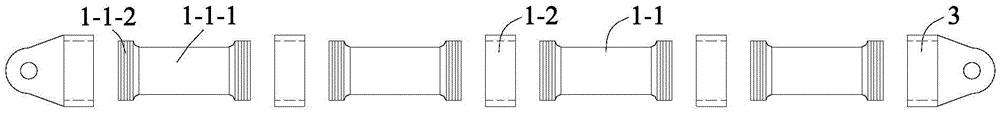

ActiveCN105819304ASmall wind blocking coefficientImprove lack of strengthElevatorsTransmission towerEngineering

The invention provides a guide rail unit used on a transmission tower and a guide rail. The guide rail unit is of a profile structure, and the guide rail unit used on the transmission tower comprises a rack (10), a left guide rod (20) and a right guide rod (30); the left guide rod (20) and the right guide rod (30) are mutual mirror images, a first inserting hole (21) and a second left side inserting hole (22) are formed in the left guide rod (20), and a first sealed cavity (23) is further contained in the left guide rod (20); and according to the guide rail unit used on the transmission tower and the guide rail, the guide rods and the rack are designed to be of an integrated profile structure, the problem that strength of the connecting position of an existing guide rail unit steel framework is insufficient is well solved, assembly errors are reduced, a whole frame body has no obvious weak points, the whole strength is higher, machining precision of the fixed-length guide rail unit is easily controlled, and scale production is facilitated.

Owner:BEIJING GUOWANG FUDA SCI & TECH DEV

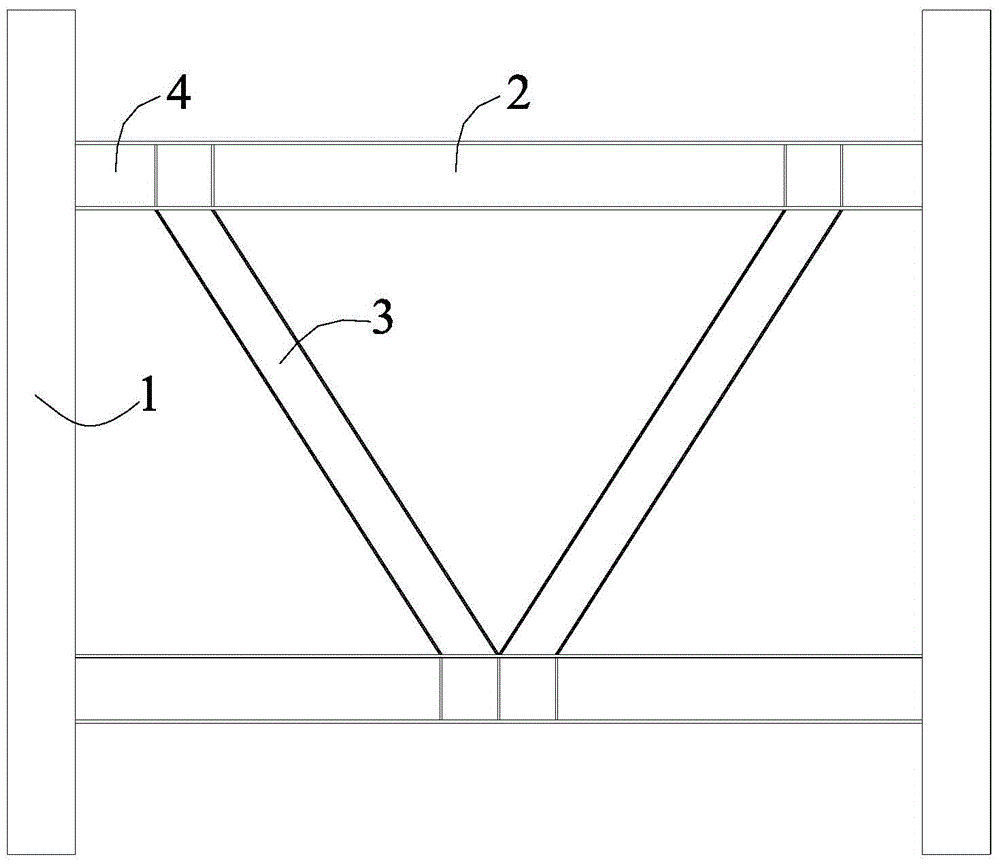

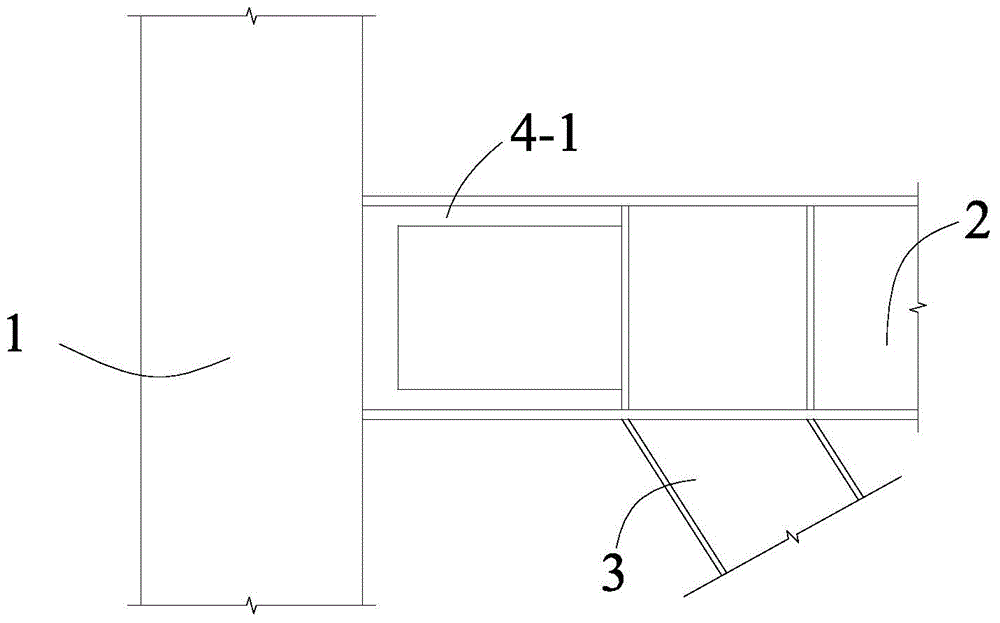

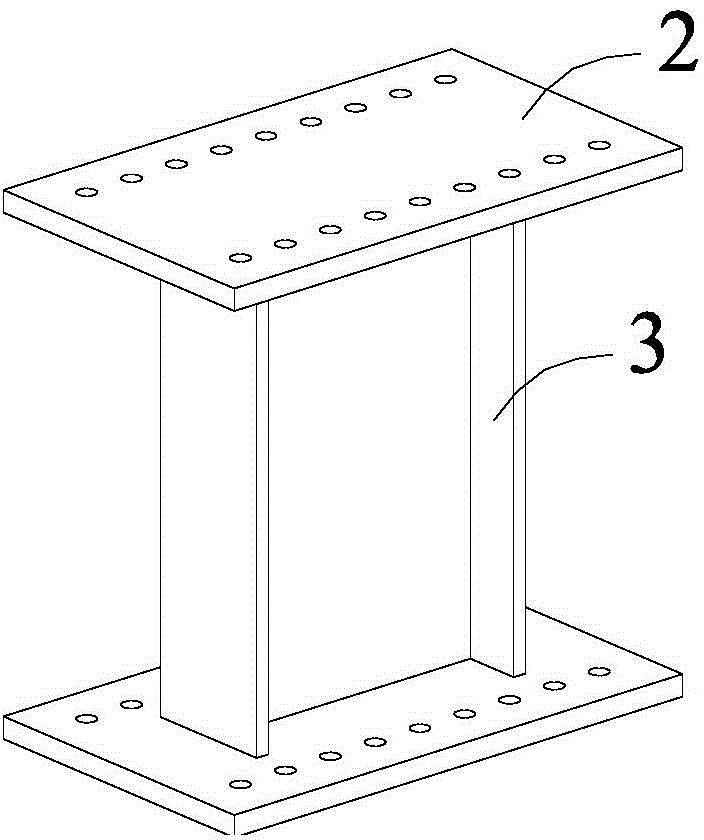

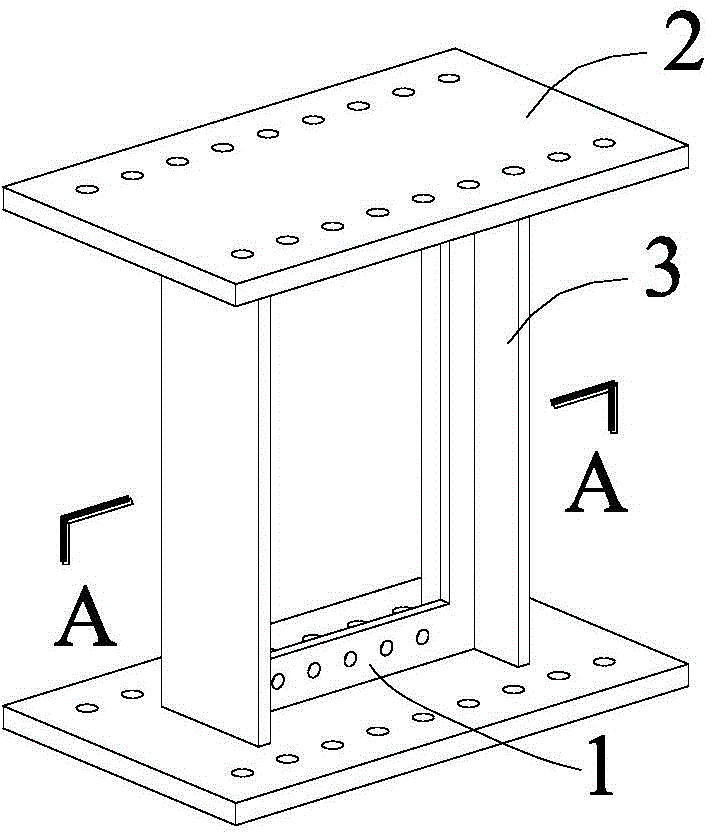

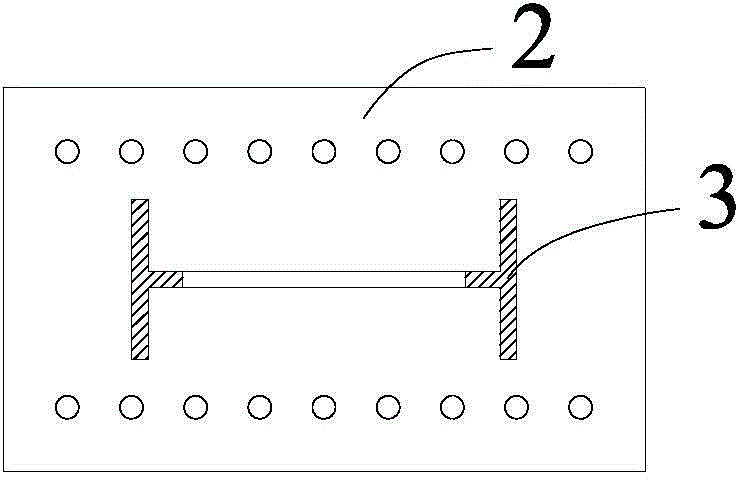

Eccentric support frame system easy to repair

ActiveCN104100017AReduce construction difficultyEasy to replaceShock proofingBraced frameEngineering

The invention discloses an eccentric support frame system easy to repair. The eccentric support frame easy to repair comprises frame columns, a non-energy-dissipation frame beam section, supports and energy-dissipation frame beam sections, wherein each energy-dissipation frame beam section comprises an elastic beam portion and an energy-dissipation portion, each elastic beam portion comprises beam flanges and a residue web obtained after an integral beam web is removed, and each energy-dissipation portion is mounted at the empty position obtained after the corresponding beam web is moved and comprises an energy-dissipation plate, a connection plate and a connection rib. The eccentric support frame system easy to repair has the advantages that under a function of strong shock, the energy-dissipation portions of the energy-dissipation frame beam sections can perform plastic energy dissipation firstly due to reasonable design, the elastic beam portions of the energy-dissipation frame beam sections are always kept within an elastic range, the energy-dissipation portions can be replaced conveniently and quickly after shock since the energy-dissipation portions are connected with the elastic beam portions via bolts, repairing of the elastic beam portions is not need, the difficulty in repairing the eccentric support frame system after shocking is lowered remarkably, and quick repairing of the current eccentric support frame system is achieved.

Owner:ARCHITECTURAL DESIGN & RES INST OF SOUTHEAST UNIV CO LTD

Function-restorable soft steel damper

The invention discloses a function-restorable soft steel damper. The function-restorable soft steel damper comprises a web, a structural anchor plate, flange plates and an energy dissipation component, wherein the end faces of both sides of the web are fixedly connected with the flange plates respectively; the upper and lower end faces of the web are fixedly connected with the structural anchor plate respectively; the web is a residual web formed by removing a portion from a complete web; the energy dissipation component is arranged at a vacated position on which the web is removed; the two ends of the energy dissipation component along the height direction of the soft steel damper are fixedly connected with the web respectively. An energy dissipation plate of the energy dissipation component enters plastic energy dissipation through reasonable design under the action of strong vibration, the web, the structural anchor plate and the flange plates always keep within an elastic range, and the energy dissipation component is fixedly connected with the web through a bolt, thereby realizing convenient and rapid replacement of the energy dissipation component after vibration, avoiding repairing other components of the soft steel damper, remarkably lowering the difficulty in replacing the entire soft steel damper after vibration, and realizing rapid recovery of the use functions of the current structure and member.

Owner:ARCHITECTURAL DESIGN & RES INST OF SOUTHEAST UNIV CO LTD

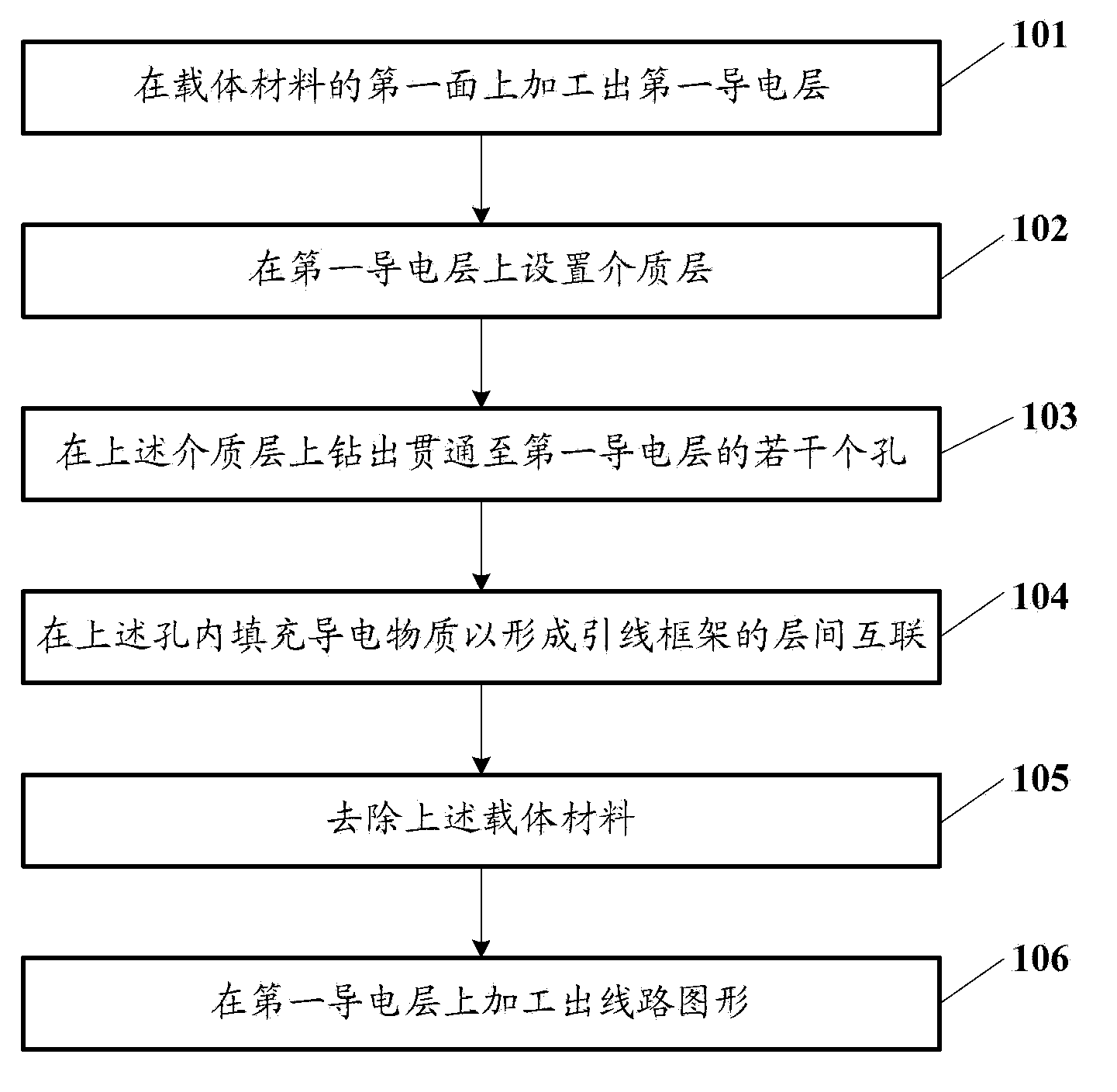

Leading wire framework processing method

ActiveCN103887179AImprove manufacturing precisionMachining accuracy is easy to controlSemiconductor/solid-state device manufacturingMedia layerCarrier material

The invention discloses a leading wire framework processing method. The leading wire framework processing method comprises steps that: a first face of a carrier material is processed to form a first conductive layer; the first conductive layer is provided with a medium layer; multiple holes are formed on the medium layer through drilling and penetrate through the first conductive layer; a first film is pasted on the medium layer on which the multiple holes are formed through drilling; exposure development processing on the first film is carried out to expose the holes; a conductive substance is filled in the holes; the carrier material is removed; the first conductive layer is processed to form a line graph. The leading wire framework processing method facilitates to improve manufacturing precision of a leading wire framework.

Owner:SHENNAN CIRCUITS

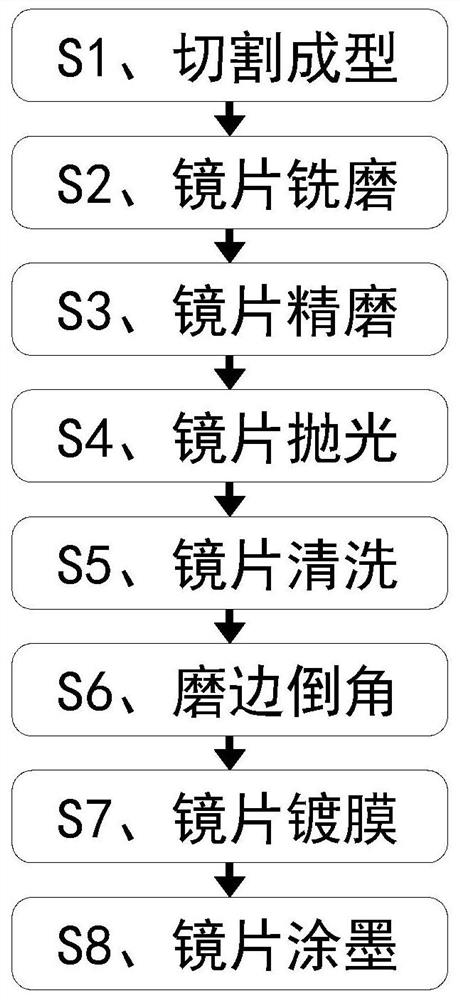

High-precision optical lens manufacturing and machining method

ActiveCN112276720AReduce labor costsImprove processing efficiencyEdge grinding machinesGrinding carriagesEngineeringOptic lens

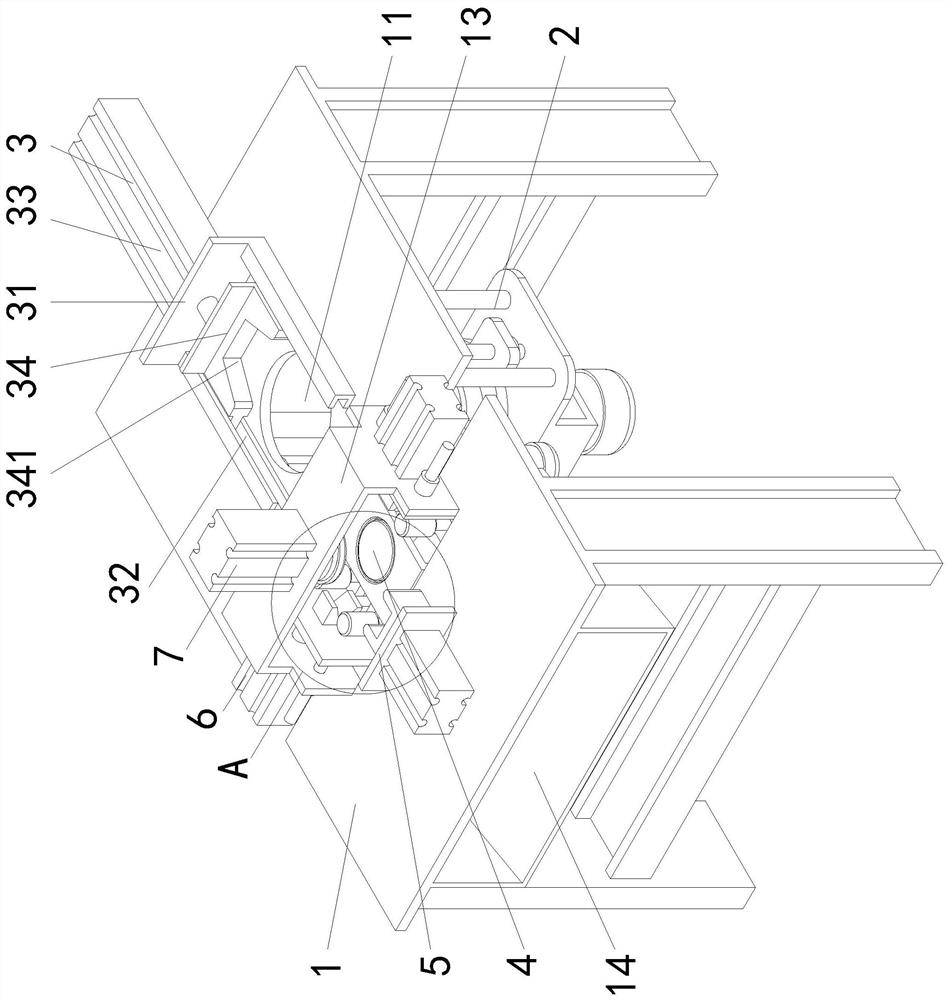

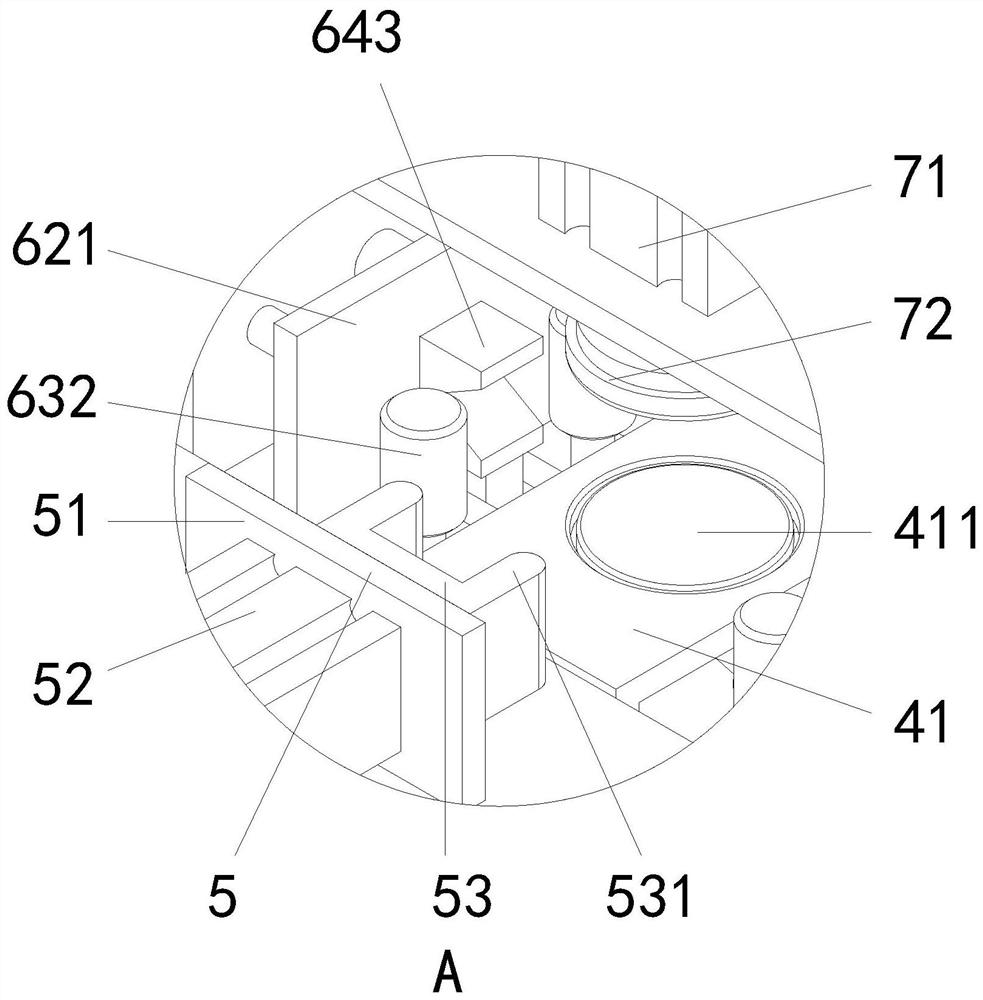

The invention relates to a high-precision optical lens manufacturing and machining method, in particular to an automatic chamfering device for high-precision optical lens manufacturing and machining.The automatic chamfering device comprises a machine table, an automatic conveying mechanism used for vertically conveying round lenses, a pushing mechanism used for horizontally pushing the round lenses, a discharging supporting plate mechanism, a front blocking positioning assembly, a chamfering mechanism and a pressing mechanism. According to the device related to the method provided by the invention, a series of continuous automatic machining operations of automatic upward conveying, automatic horizontal pushing, automatic chamfering positioning, automatic chamfering machining and automaticdischarging of the lenses can be completed through mutual cooperation of the arranged mechanisms, a traditional manual machining mode is replaced, the labor cost is reduced, the machining efficiencyis greatly improved, the machining precision is controllable and unified, and the overall machining quality is greatly improved.

Owner:湖南振添光学玻璃科技有限公司

Curve hole machining guide device

PendingCN109014466AMachining accuracy is easy to controlOrientation is accurateHydraulic cylinderEngineering

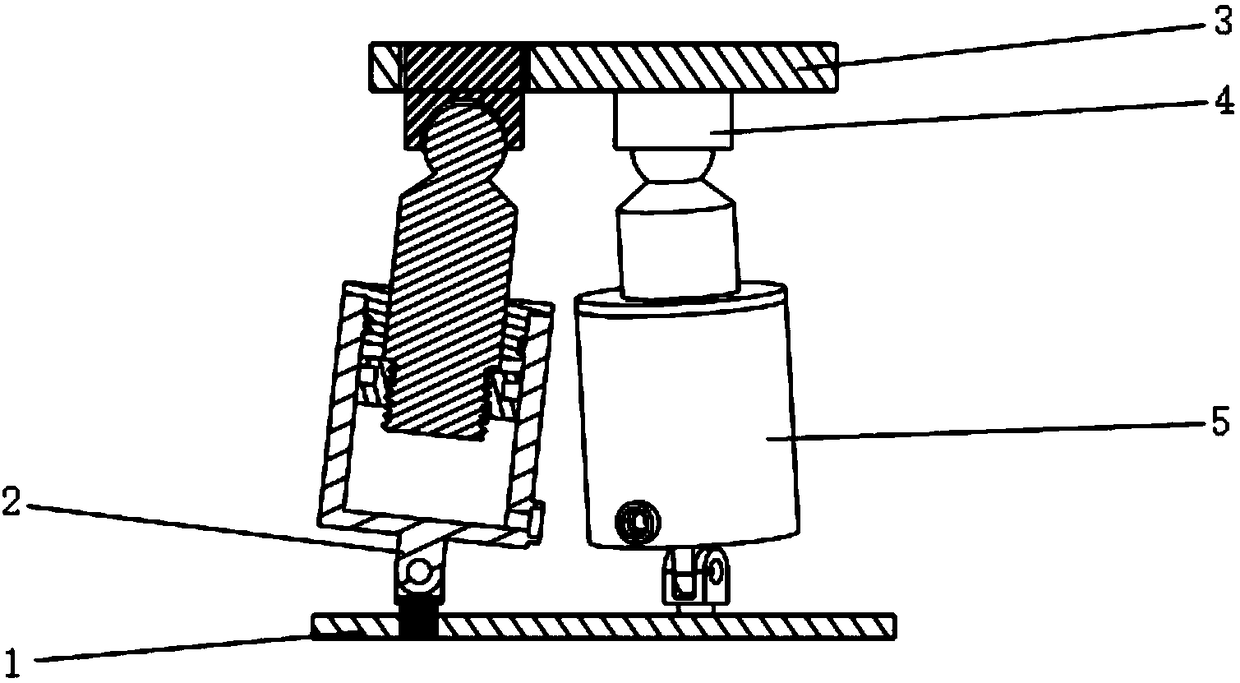

The invention discloses a curve hole machining guide device. The curve hole machining guide device is mainly composed of miniature hydraulic cylinders, upper and lower platforms, and connecting joints. According to the working principle of the curve hole machining guide device, the upper and lower platforms are connected by the three miniature hydraulic cylinders of the same model, initially, theupper and lower platforms are in a horizontal state, when one or two hydraulic cylinders are elongated, the upper platform can be made to change from the horizontal state to produce a certain includedangle state with the horizontal plane, and the included angle can be changed according to the elongation of piston rods of hydraulic cylinders. By controlling stretching and contracting amount of thepiston rods of three hydraulic cylinders, the angle size can be controlled, and then the control of the curvature radius of the operation track is controlled; and the device is precise in guide, themachining precision of a curve hole is easy to control, compared with an existing curve hole machining method, the stiffness of the guide device is high, the stability performance is high, and the structure and operation method are simple.

Owner:QILU UNIV OF TECH

Modularized bamboo-shaped buckling restrained brace

ActiveCN105604205AIncrease production capacityRealize the designShock proofingBuckling-restrained braceEngineering

The invention discloses a modularized bamboo-shaped buckling restrained brace which comprises a core part, an outer restraining part and a structure connecting part. The core part comprises a plurality of circular energy dissipation sections and a plurality of elastic sleeves. Each circular energy dissipation section comprises a middle section and connecting sections at two ends. The core part is located inside the outer restraining part. The inner surface of the outer restraining part closely attaches to or is tangent to the outer surfaces of the elastic sleeves of the core part. One end of the structure connecting part extends into the outer restraining part, and the other end thereof extends out of the outer restraining part to be connected with a structure. The modularized bamboo-shaped buckling restrained brace has the advantages that the circular energy dissipation sections and elastic sleeves of the modularized bamboo-shaped buckling restrained brace can be produced in batch in factories, the circular energy dissipation sections and elastic sleeves can be selected and combined according to the length requirement of the buckling restrained brace, and accordingly the modularized production and design of the core part can be achieved.

Owner:CHINA JINGYE ENG TECH CO LTD +2

Three-leg jacket building technology

ActiveCN109137964AHigh precisionGood build qualityFoundation engineeringMechanical engineeringEngineering

The invention relates to a three-leg jacket building technology which comprises the following steps: at first, dividing a support seat into three segments distributed from top to bottom, then, manufacturing pipe bodies required by assembling of all components, taking the pipe bodies with different sizes and required by assembling to assemble an X-shaped connecting seat and a connecting sleeve, assembling the X-shaped connecting seat and the pipe bodies to form an X-shaped connecting piece, mounting the connecting sleeve on steel pipe pile segments formed by straight pipe bodies in a sleeving manner, assembling the steel pipe pile segments with the X-shaped connecting piece to form segment support seats, then, manufacturing an upper platform, folding the upper platform and the vertical typeplane of the segment support seat at the uppermost end to form an assembly part A, then, folding the horizontal planes of the rest two segment support seats to form an assembly part B, and finally, folding the assembly part A and the assembly part B to form the three-leg jacket. The three-leg jacket building technology has the following advantages: the support seat is divided to three segments, so that the processing size precision of each segment is conveniently controlled to enable the overall precision to be higher.

Owner:NANTONG BLUE ISLAND OFFSHORE CO LTD

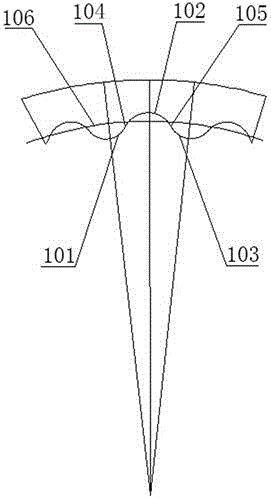

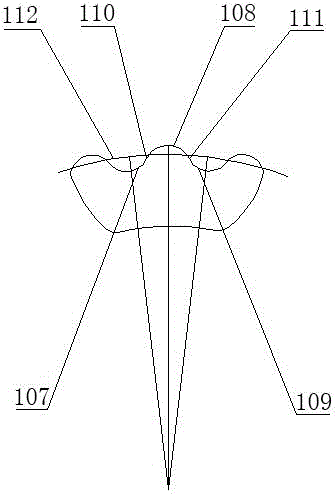

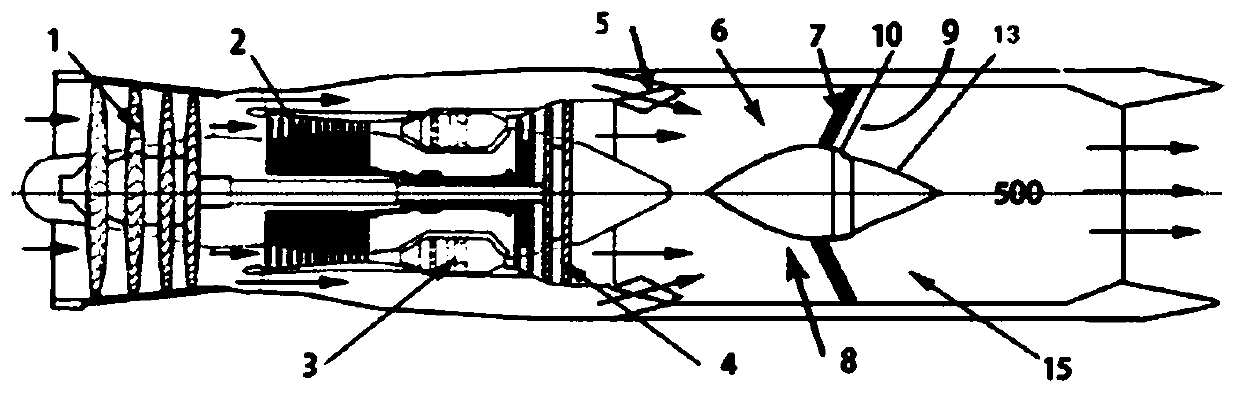

Direct-injection type fan-shaped nozzle applied to cavity structure of afterburner

ActiveCN111306577AImproved circumferential cross-fire performanceImprove combustion stabilityContinuous combustion chamberCombustion chamberAerosolize

The invention discloses a direct-injection type fan-shaped nozzle applied to a cavity structure of an afterburner, relates to the direct-injection type fan-shaped nozzle which is installed in the cavity of the afterburner and used for enhancing fire stabilization performance and flame connection performance, and belongs to the field of aeroengines. According to the direct-injection type fan-shapednozzle applied to the cavity structure of the afterburner, a plurality of direct-injection type spray holes distributed in a certain shape are formed in the bottom end of each oil injection rod and used for spraying fuel into the cavity structure in the afterburner, the fuel forms a fan-shaped oil mist annular surface after being sprayed and atomized through the shape of the holes, the fan-shapedoil mist surfaces of every two adjacent oil injection rods intersect, and an oil mist ring concentric with a casing is formed in the cavity structure. The fuel atomization effect is enhanced, the circumferential flame connection performance is enhanced, and the combustion efficiency is improved. The direct injection type fan-shaped nozzle is small in machining difficulty, high in machining precision and small in nozzle hole diameter, so that the fuel atomization effect is good, and the overall performance of the afterburner is greatly improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

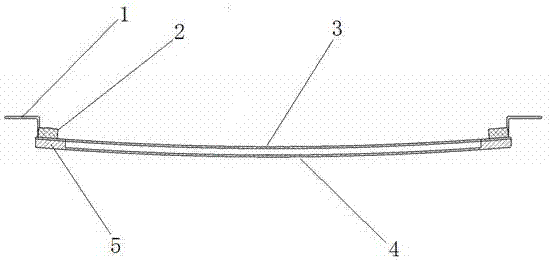

Integrated structure of air duct and internally-installed middle top plate

InactiveCN107415966ASave internal spaceReduce weightRailway roofsRailway heating/coolingEngineeringMaintainability

The invention discloses an integrated structure of an air duct and an internally-installed middle top plate. An upper layer air conditioner air inlet plate and a lower air conditioner air outlet plate are of arc-shaped structures. A gap is formed between the upper layer air conditioner air inlet plate and the lower air conditioner air outlet plate. A rubber sealing strip and an aluminium alloy installing bracket are arranged in the position, connected with the edge of a vehicle roof, of the upper layer air conditioner air inlet plate. Compared with the prior art, according to the integrated structure of the air duct and the internally-installed middle top plate, the internally-installed middle top plate of a vehicle is turned into an air duct bottom plate, the functions of the air conditioner air duct and the internally-installed middle top plate are integrated, two parts are combined into one part, the vehicle inner space is greatly saved, weight is reduced, the structure is mainly composed of whole glass steel, the aluminium alloy installing bracket and the rubber sealing strip, the integration level is high, and the maintainability is high.

Owner:CRRC NANJING PUZHEN CO LTD

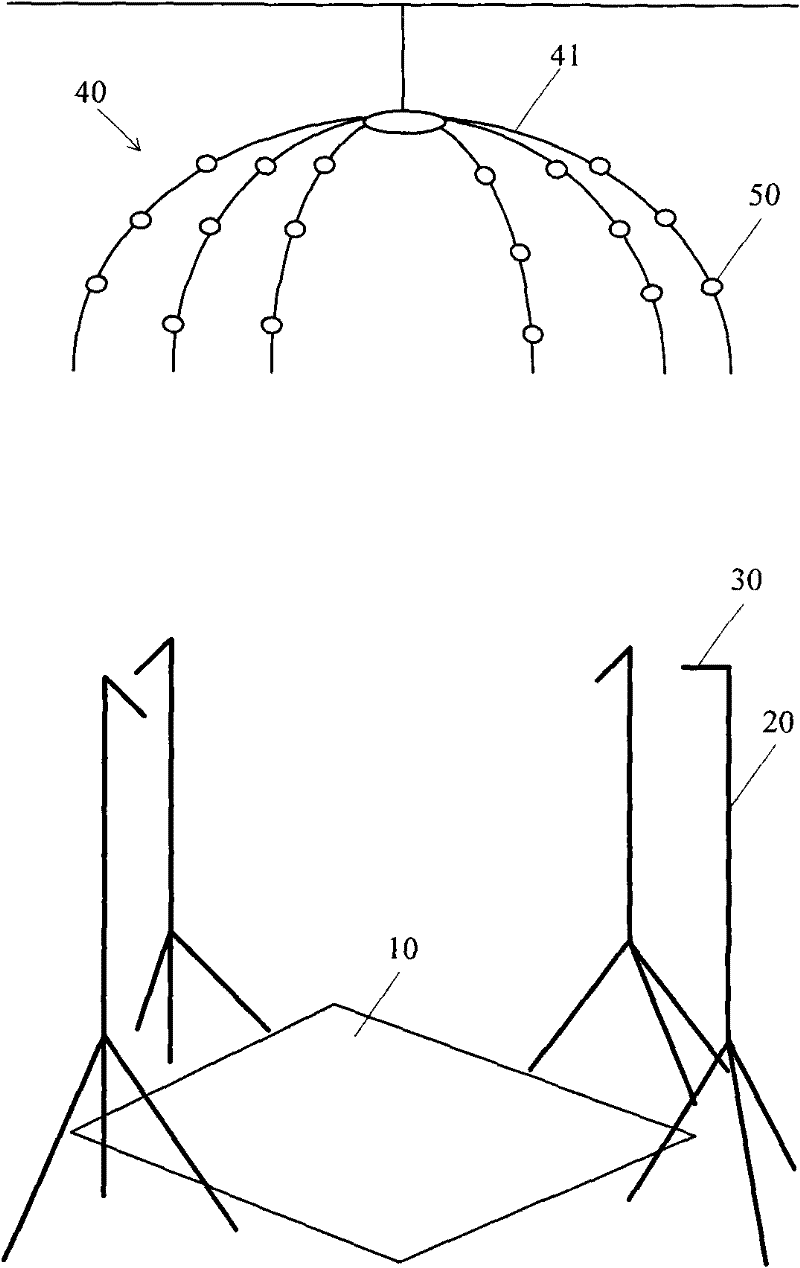

Acoustic power measuring frame

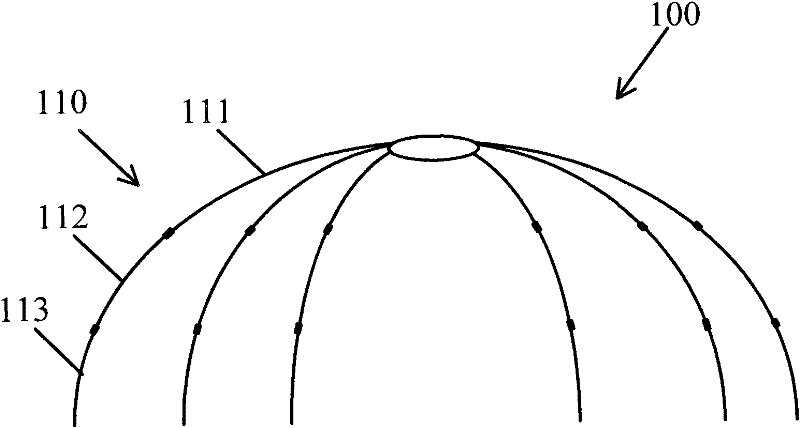

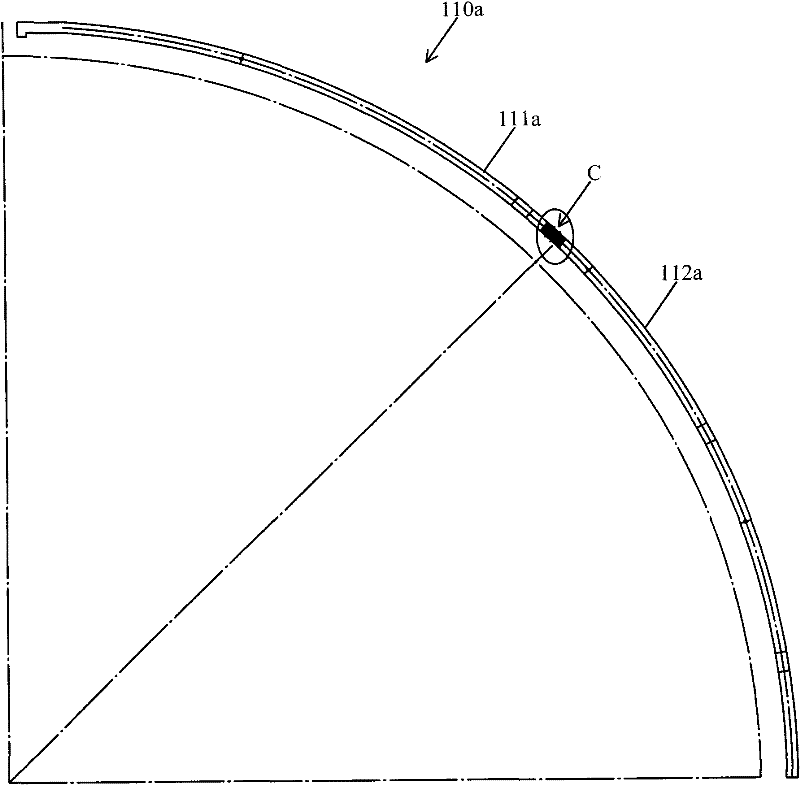

InactiveCN102192779AAvoiding the problem of placing in an anechoic chamberEasy to transportSubsonic/sonic/ultrasonic wave measurementSpherical shapedEngineering

The invention discloses an acoustic power measuring frame which comprises multiple arc bracket guide rails. The arc bracket guide rails are connected at one end and are entirely in a partial-spherical shape, wherein each bracket guide rail comprises multiple arc connection sections in movable connection. The bracket guide rail of the acoustic power measuring frame is formed by connecting multiple arc connection sections in a movable mode; and thus, in the transportation process, each connection section of the bracket guide rail can be removed, the space taken by the whole is reduced, and the transportation is convenient. Moreover, in the manufacturing process of the acoustic power measuring frame, the processing can be performed by section, the size of the required plate is relatively small, the processing precision is easier to control, the plate waste is greatly reduced, and the manufacturing cost is lowered.

Owner:上海声望声学科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com