Double-rectangular tube buckled assembled buckling-restrained bracing member

A kind of anti-buckling bracing, prefabricated technology, applied in building components, anti-vibration and other directions, can solve the problems of poor durability, single variety, and high requirements for production accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

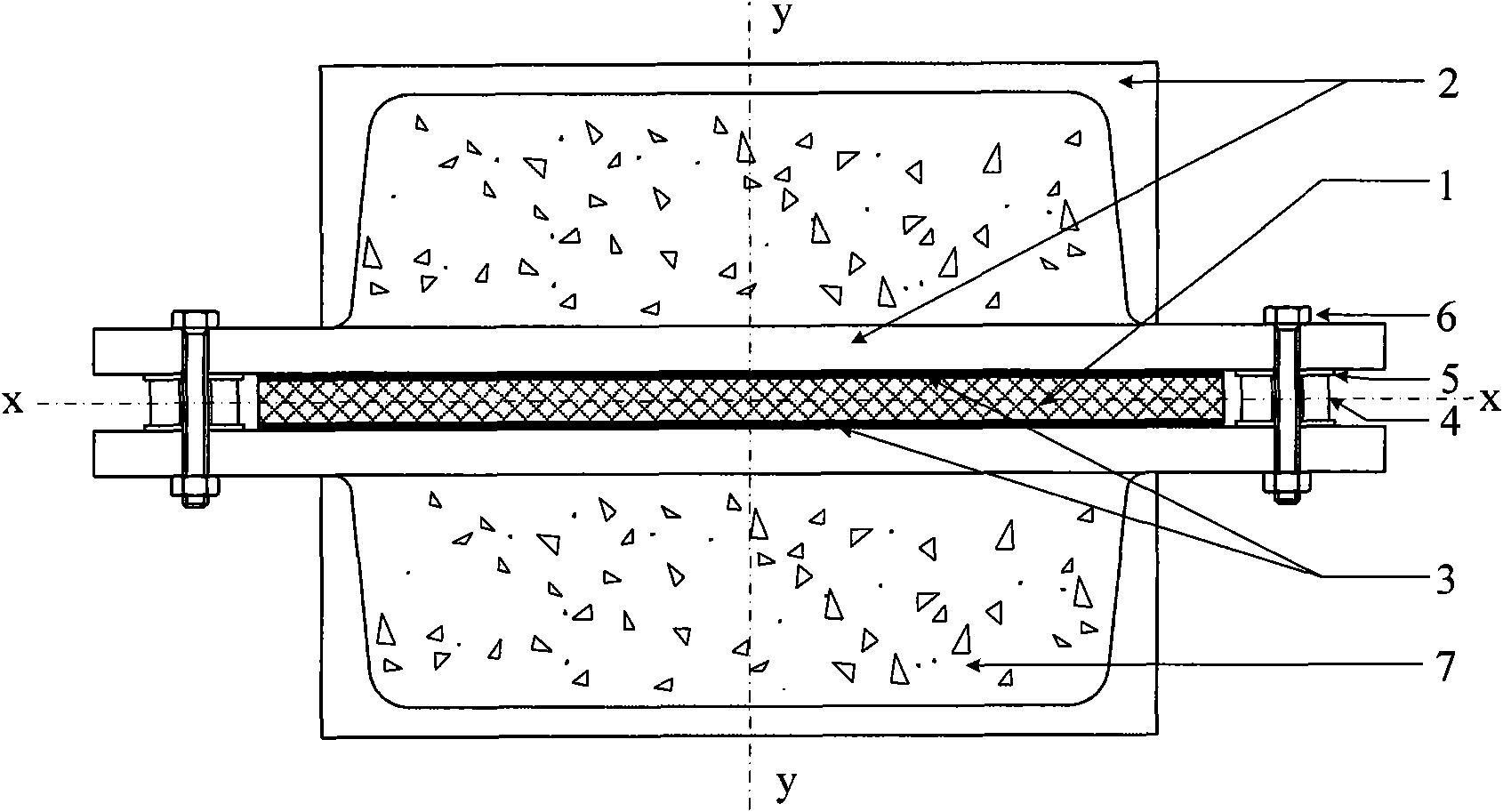

[0022] Attached below Figure 1~6 , detailing the implementation of this patent.

[0023] like figure 1 As shown, a double-rectangular tube buckle-mounted anti-buckling support member includes the following components:

[0024] 1——Inline core component;

[0025] 2—constrained square steel pipe;

[0026] 3 - hard rubber;

[0027] 4——steel backing plate;

[0028] 5——Rubber gasket;

[0029] 6 - high-strength bolts;

[0030] 7 - concrete;

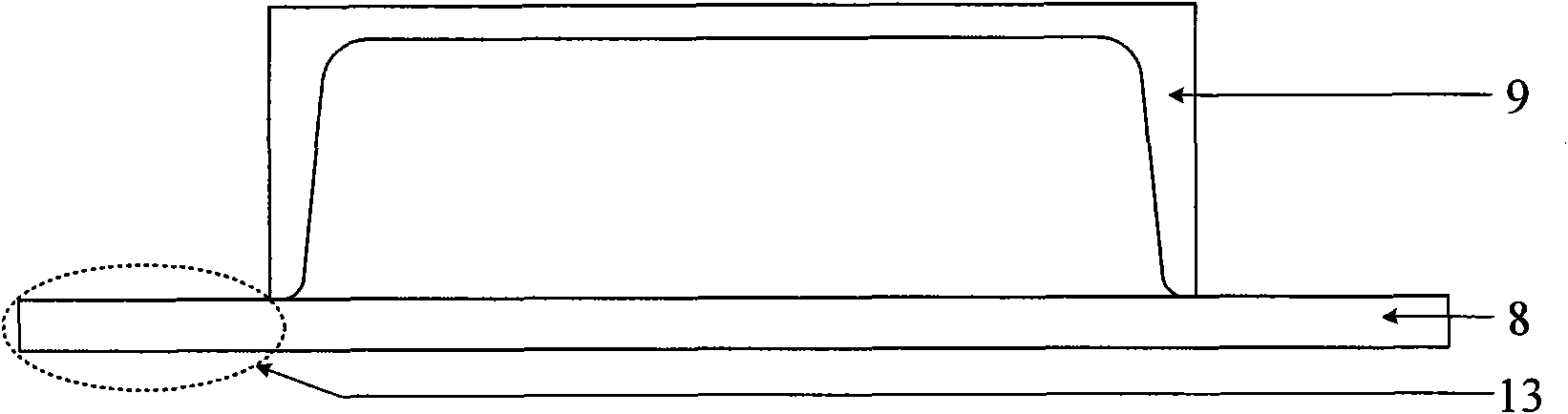

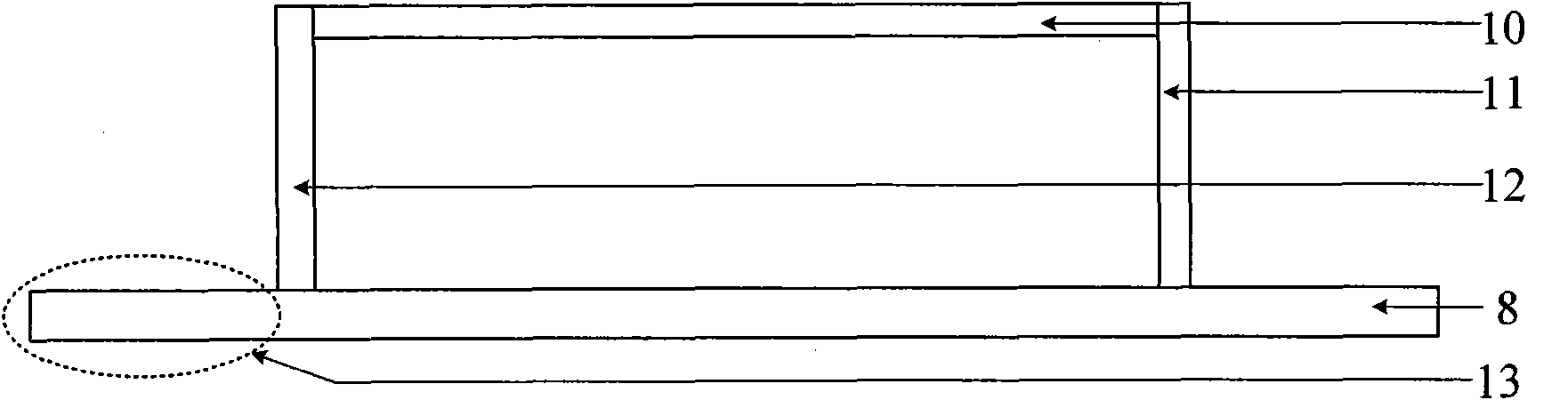

[0031] like figure 1 , 5 , shown in 6, described inline core member (1) adopts the flat steel plate of low strength and high ductility; As Image 6 As shown, hard rubber (3) is pasted on the surface of the area where the inline core member (1) is wrapped by the restraint member (2);

[0032] like figure 1 , 5 , shown in 6, described restriction square steel pipe (2) totally two, its size is all the same, and its length is less than the length of inline core member (1); As figure 2 As shown, the restraining member (2) is composed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com