Horizontal precise polishing machine tool workpiece main shaft and tool system centering method

A workpiece spindle and tool technology, which is applied in the field of centering between workpiece spindle and tool system of horizontal precision grinding and polishing machine tools, can solve the problems of complex and expensive positioning, achieve high measurement accuracy, low cost, and little influence on machine tool layout Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Include the following steps:

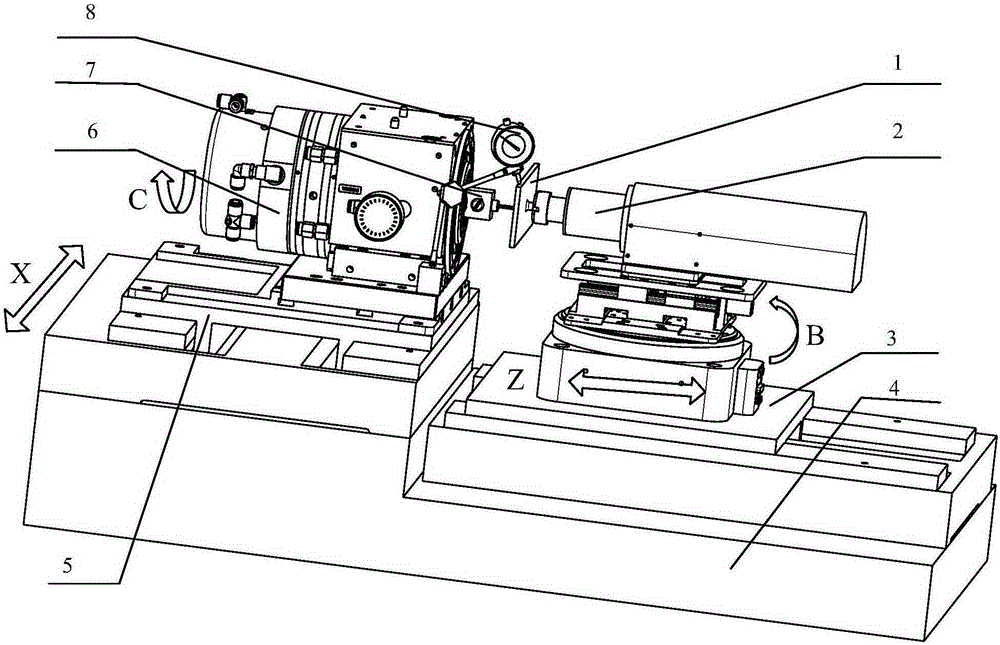

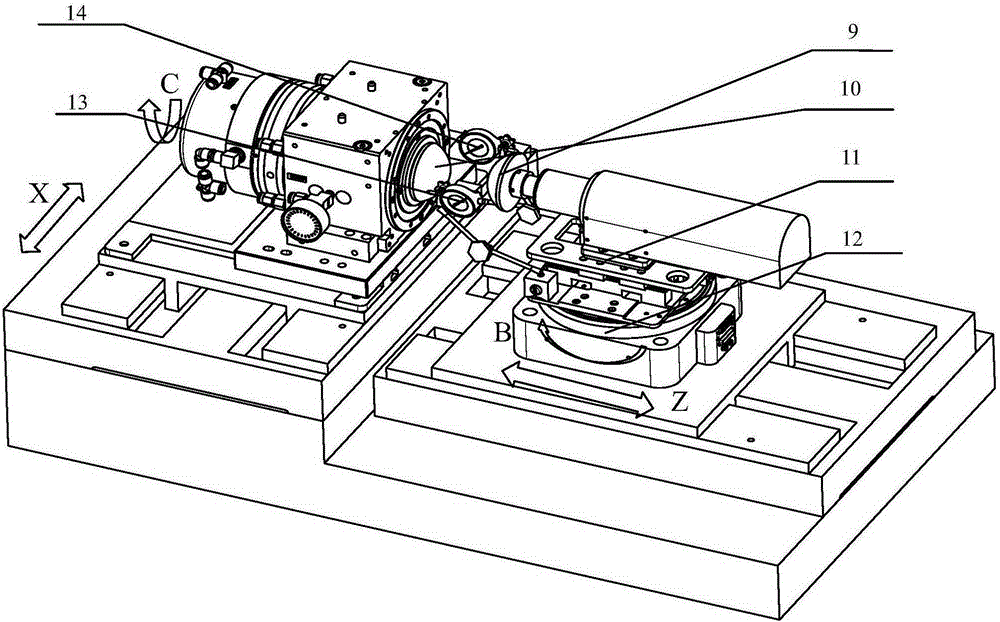

[0054] Step 1. Establish the coordinate system X-Z-B-C of the machine tool, wherein the X axis is parallel to the movement direction of the machine tool workpiece spindle, the Z axis is parallel to the movement direction of the machine tool system 2, the B axis is the rotation axis of the machine tool turntable 12, and the C axis is the rotation axis of the machine tool workpiece spindle ;

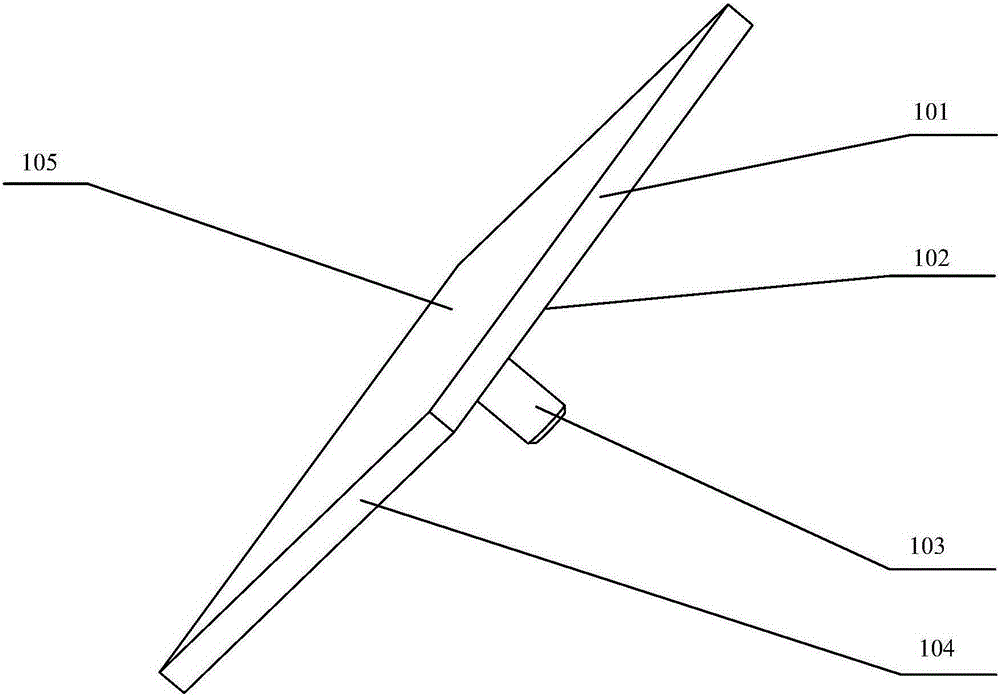

[0055] Step 2. After each axis of the machine tool returns to the reference point, adjust the turntable so that the tool system axis 207 is parallel to the Z axis, install the calibration plate 1 on the tool system 2, and use the dial indicator I8 to assist in detection so that the plane 101 on the calibration plate is parallel to the X axis parallel:

[0056] Step 3: Pass the center punch 701 through the magnetic base 702, relative to the rotation axis of the workpiece spindle, and eccentrically adsorb it on the end surface 601 of the workpiece spind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com