Direct-injection type fan-shaped nozzle applied to cavity structure of afterburner

A technology of afterburner and fan-shaped nozzle, applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problems of fuel accumulation and dripping at the outlet, poor fuel atomization effect, etc., to improve combustion performance and reduce processing difficulty , The effect of improving the performance of the circumferential flame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the purpose and effect of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings. It should be pointed out that the specific implementations described here are only used to explain the present invention, not to limit the present invention.

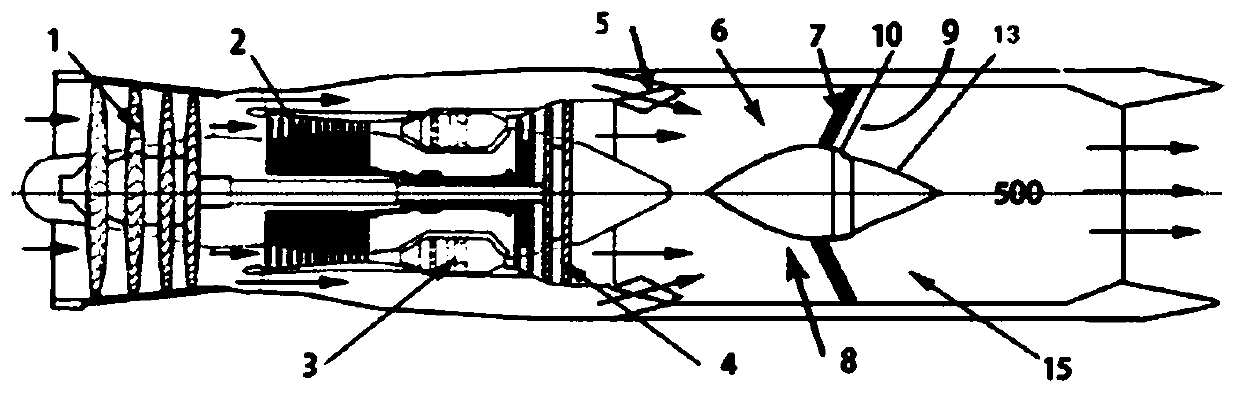

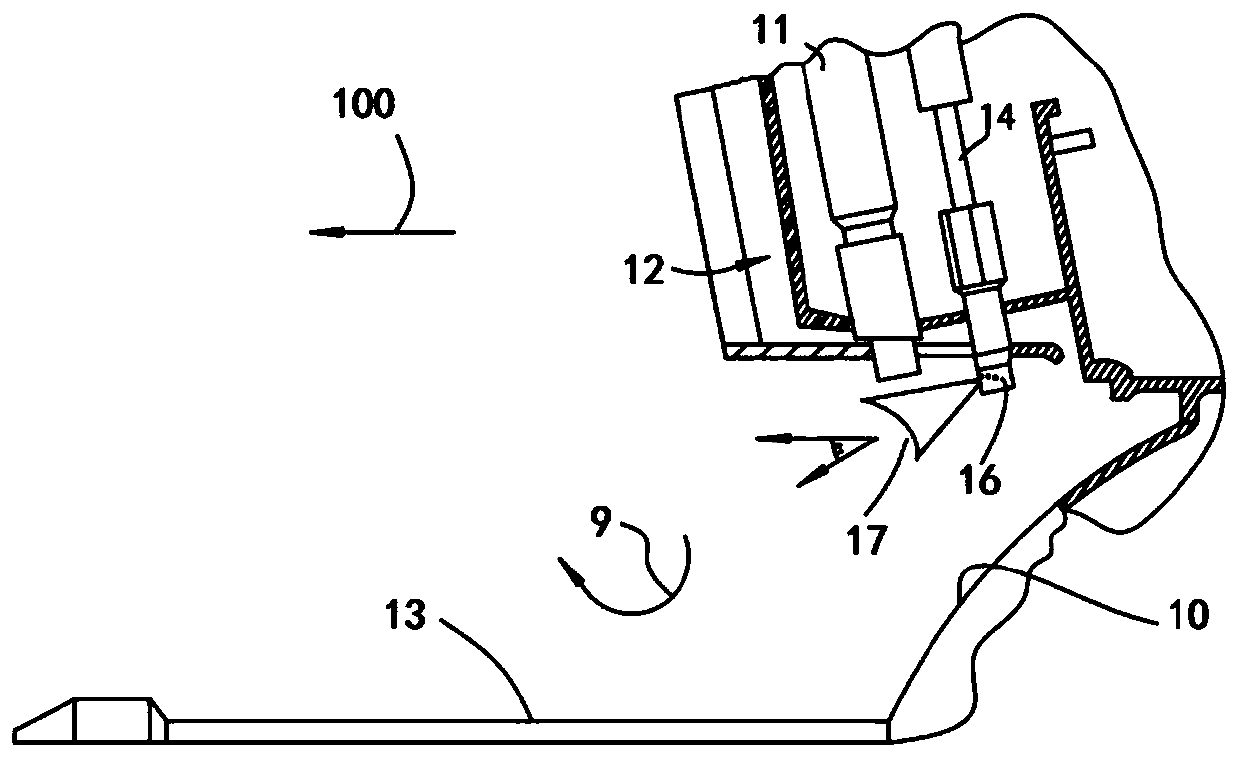

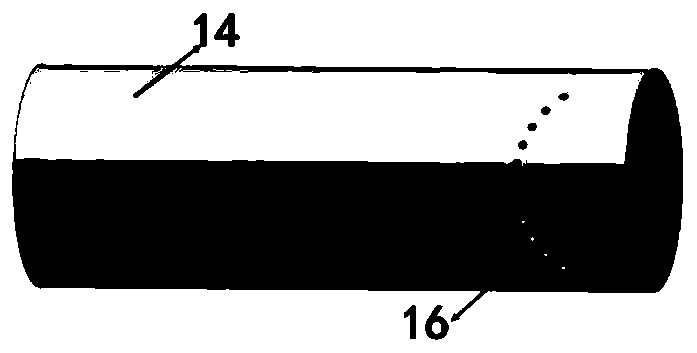

[0030] Such as figure 1 Shown is a structural diagram of a turbofan aero-engine that adopts a direct-injection fan nozzle and a concave cavity structure afterburner of the present invention. A fan 1 and a compressor 2 are sequentially arranged along the direction of air flow 100, that is, the central axis 500 of the gas turbine, and the air flows into the combustion chamber 3 after passing through the compressor; A blender 5 is arranged between the side walls of the afterburner chamber 15 , and a diffuser section 6 is formed between the blender 5 and the support plate 7 .

[0031] The structure after the turbine 4 belongs to the af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com