Buckling-resistant supporting element bound by four square pipes

An anti-buckling bracing, square and rectangular tube technology, applied in building components, anti-vibration and other directions, can solve problems such as increased production costs, difficulty in ensuring the accuracy requirements of core and peripheral reservations, and production and construction effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

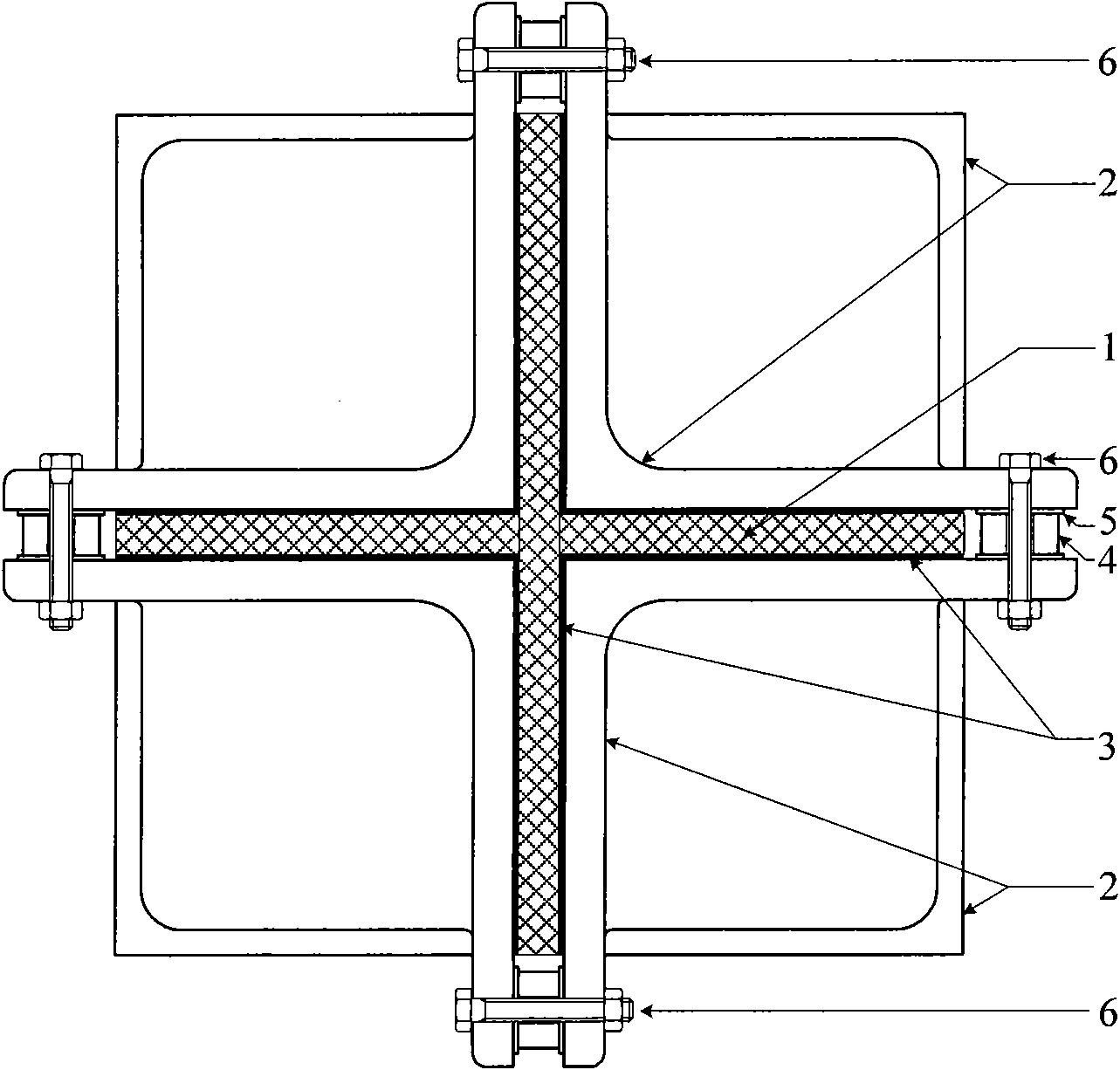

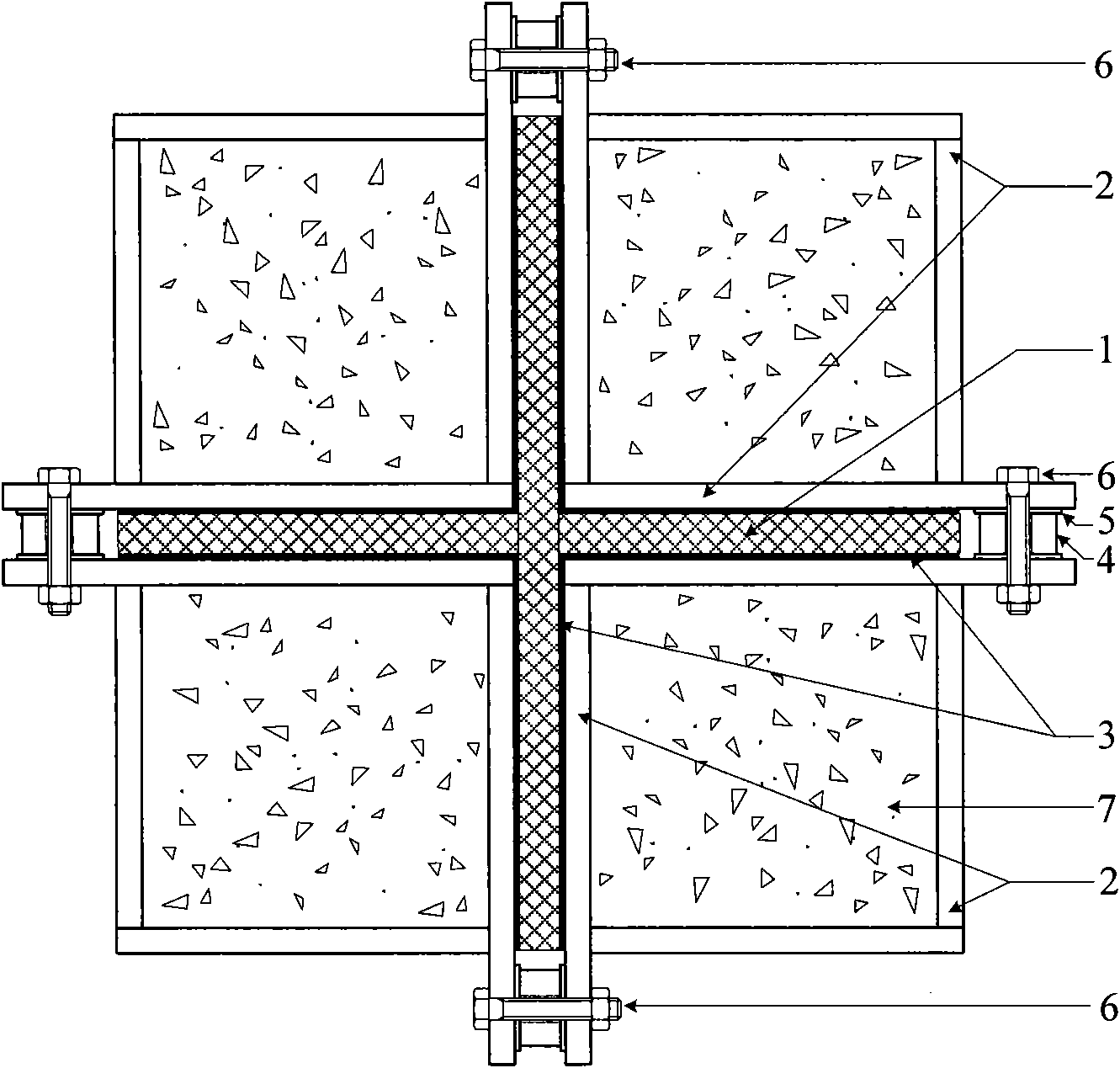

[0020] Attached below Figure 1-8 , detailing the specific implementation of this patent.

[0021] Such as Figure 1~2 As shown, a buckling-resistant support member consisting of four square tubes bundled includes the following components:

[0022] 1——cruciform inner core member;

[0023] 2——rectangular tube, four;

[0024] 3 - hard rubber;

[0025] 4——steel backing plate;

[0026] 5——Rubber gasket;

[0027] 6 - high-strength bolts;

[0028] 7 - concrete;

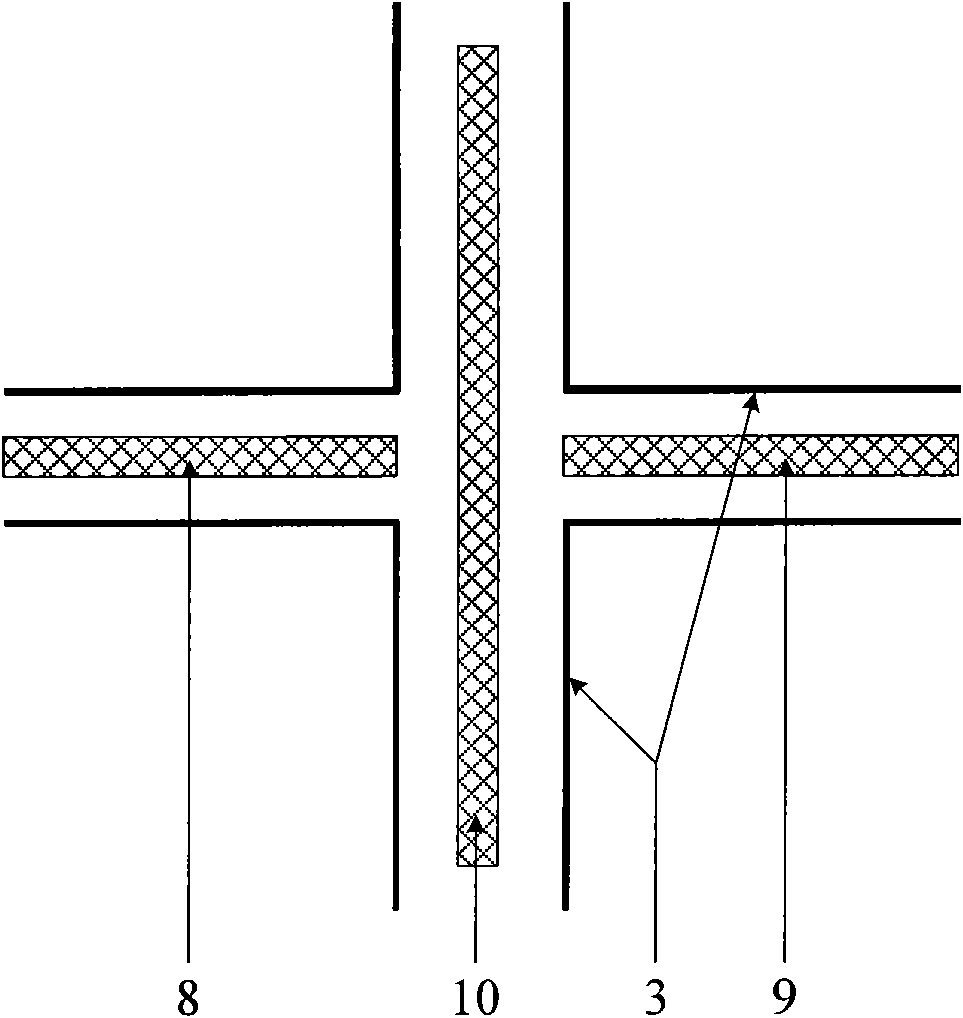

[0029] Such as image 3 As shown, the cross-shaped core member (1) is composed of two narrower flat steel plates (8), (9) and one wider flat steel plate (10) by welding; as image 3 , 8 As shown, hard rubber (3) is pasted on the surface of the area wrapped by four square rectangular tubes of the cross-shaped core member (1);

[0030] There are four square tubes (2) in total, all of the same size, and their length is less than the length of the cross-shaped core member (1); as Figure 4 As shown, the square tube ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com