All-steel-assembled buckling restrained brace with lateral side capable of being inspected

A buckling-constrained and assembled technology, applied in protective buildings/shelters, building components, earthquake-proof, etc., can solve the inconvenient core deformation or damage state, the inability to easily replace the inner core, and the quality of the weld at the end of the stiffener Defects and other problems, to achieve the effect of easy performance evaluation, easy control of processing accuracy, and good economic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solutions of the present invention will be further introduced below in conjunction with the accompanying drawings and embodiments.

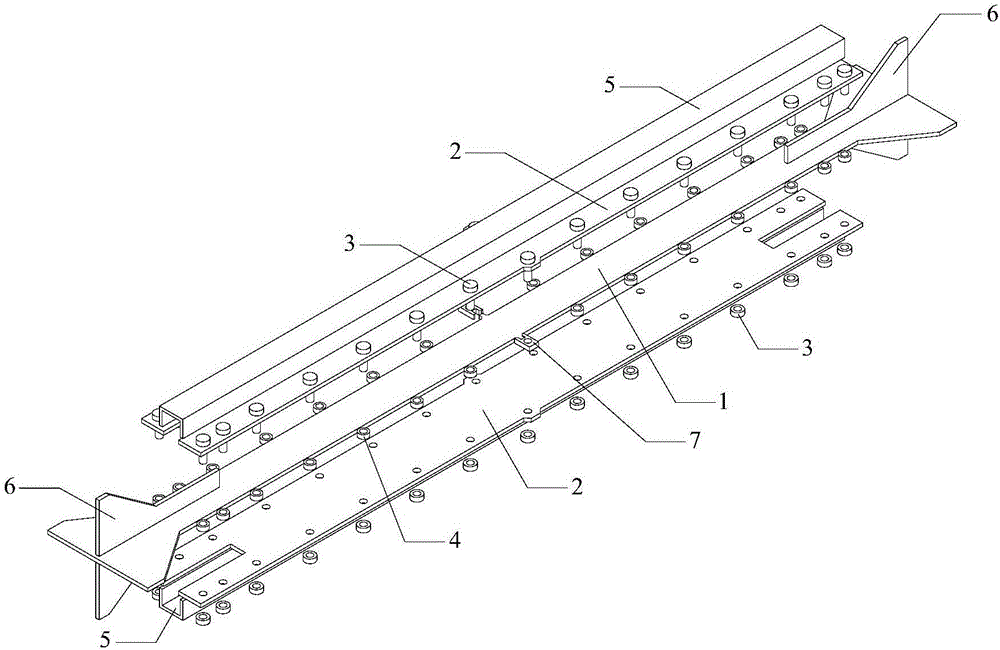

[0046] Such as figure 1As shown, the present invention provides an all-steel assembled buckling restraint brace that can be inspected from the side, which is composed of the following components, including the inner core 1, end stiffeners 6, restraint panels 2, high-strength bolts 3, washers 4, and limit grooves 7. Stiffener end weld 8 and stiffener 5.

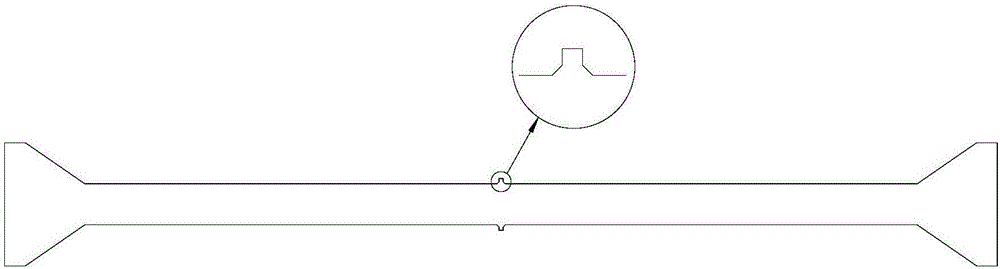

[0047] The inner core is a steel plate with a straight cross section. In order to prevent the restraining member from sliding in the axial direction, a protrusion is provided in the middle of the inner core. In order to avoid damage to the unconstrained section at the end of the inner core, the end of the inner core is enlarged, and the entire inner core is cut and processed at one time.

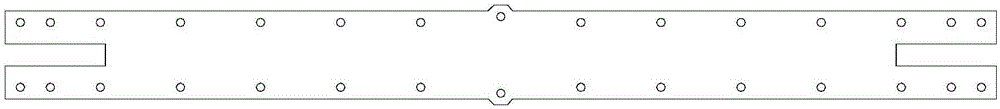

[0048] The constraining panel contains two rows of bolt holes distributed longitudinal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com