Acoustic power measuring frame

A technology for measuring racks and sound power, applied to measuring devices, measuring ultrasonic/sonic waves/infrasonic waves, instruments, etc., can solve problems such as installation and transportation of sound power measuring racks, and reduce manufacturing costs of sound power measuring racks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

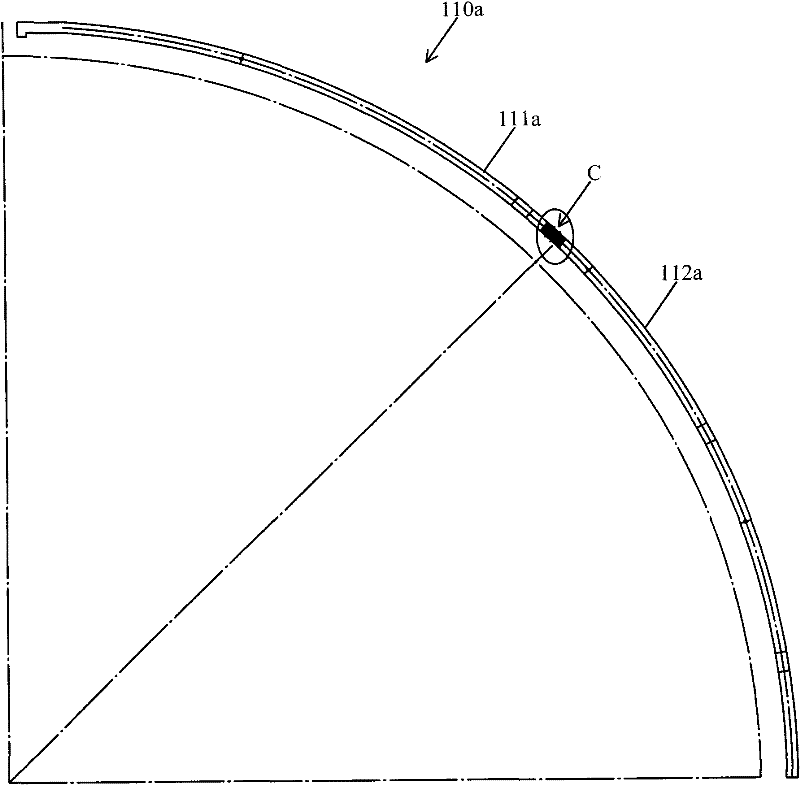

[0026] Please refer to Figure 3 to Figure 6 ,in image 3 It is a structural schematic diagram of the support guide rail of the sound power measurement stand provided by Embodiment 1 of the present invention; Figure 4 and Figure 5 respectively image 3 An enlarged schematic diagram of the connecting ends of the two connecting segments, wherein (a) is a cross-sectional view, and (b) is a view in the direction of A-A; Figure 6 An enlarged schematic illustration of the assembly of the connected ends of two connected segments together.

[0027] As shown in the figure, the bracket rail 110a includes a first connecting section 111a and a second connecting section 112a. Wherein the connection end C1 of the first connection section 111a has a slot C11 (such as Figure 4 ), the connecting end C2 of the second connecting section 112a is an insert structure (such as Figure 5 ) to insert into slot C11. In addition, there are corresponding positioning holes C3 and C4 on the sock...

Embodiment 2

[0033] Please refer to Figure 7 , which is a structural schematic diagram of the support guide rail of the sound power measurement stand provided in Embodiment 2 of the present invention. It can be seen from the figure that it is different from Embodiment 1 in that the two adjacent connecting sections are pivoted, that is, the two adjacent connecting sections can be folded.

[0034] Specifically, as shown in the figure, the two connecting sections 111b and 112b of the bracket guide rail 110b are pivotally connected to each other, so that the connecting section 112b can rotate around the connecting point D toward the connecting section 111b. In this way, when the sound power measurement stand is not in use, the stand rails can be folded for storage or transportation to save space.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com