Eccentric support frame system easy to repair

A technology of eccentric support and frame system, which is applied to building components, building structure, earthquake resistance, etc., can solve the problems of long time, complicated construction, and large residual deformation of the web, and achieves easy control of processing accuracy and energy consumption effect. Better and lower construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

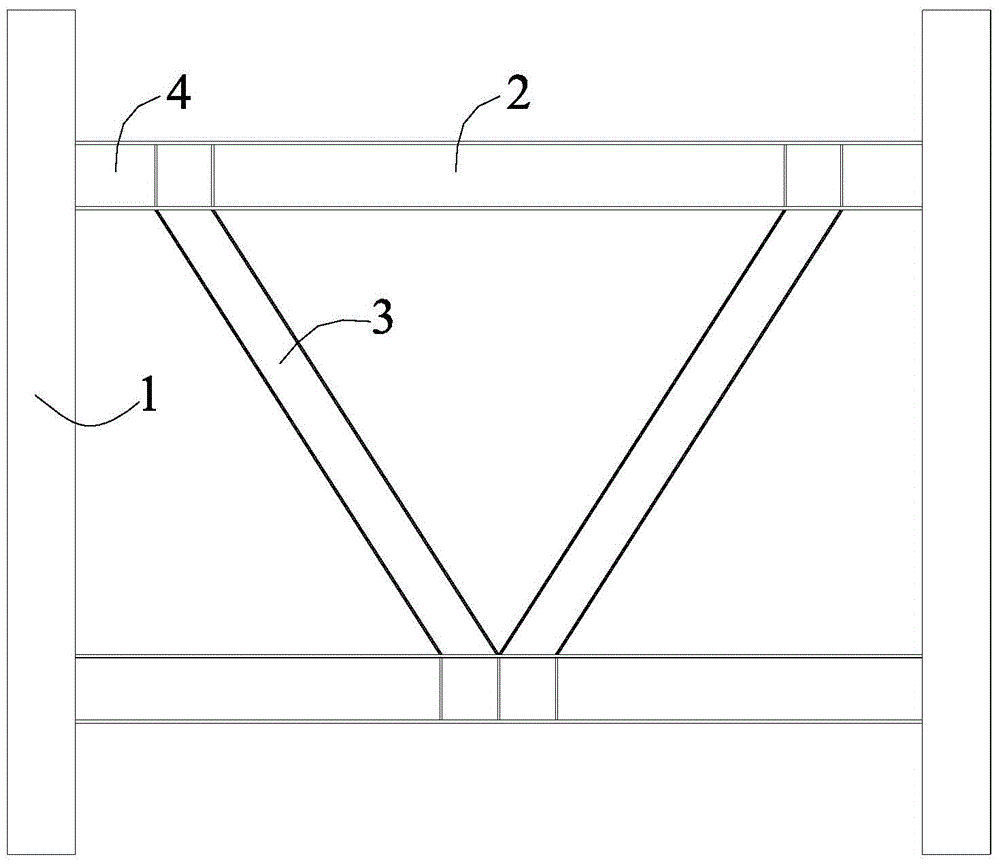

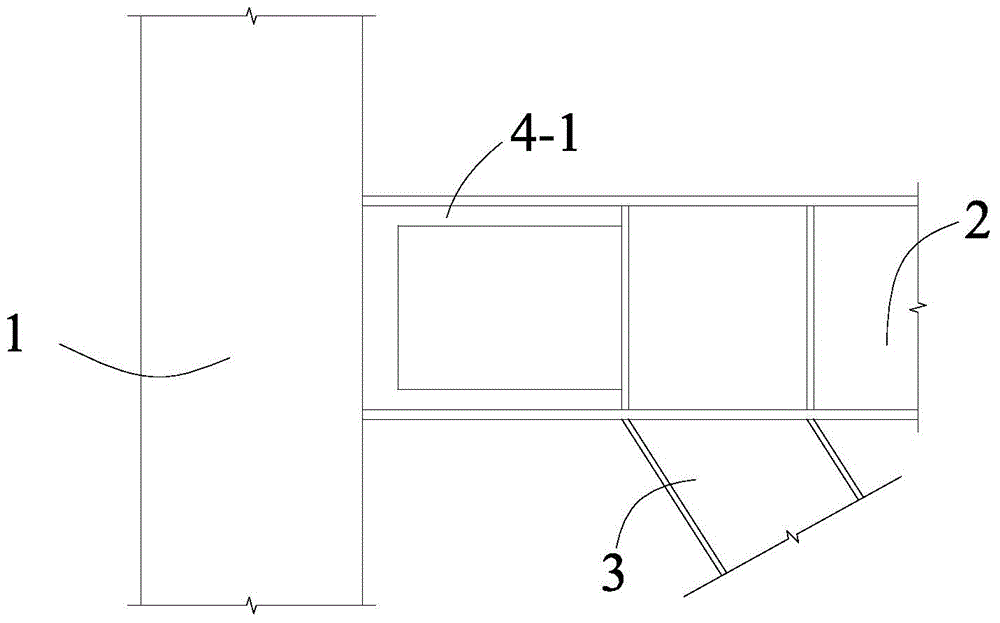

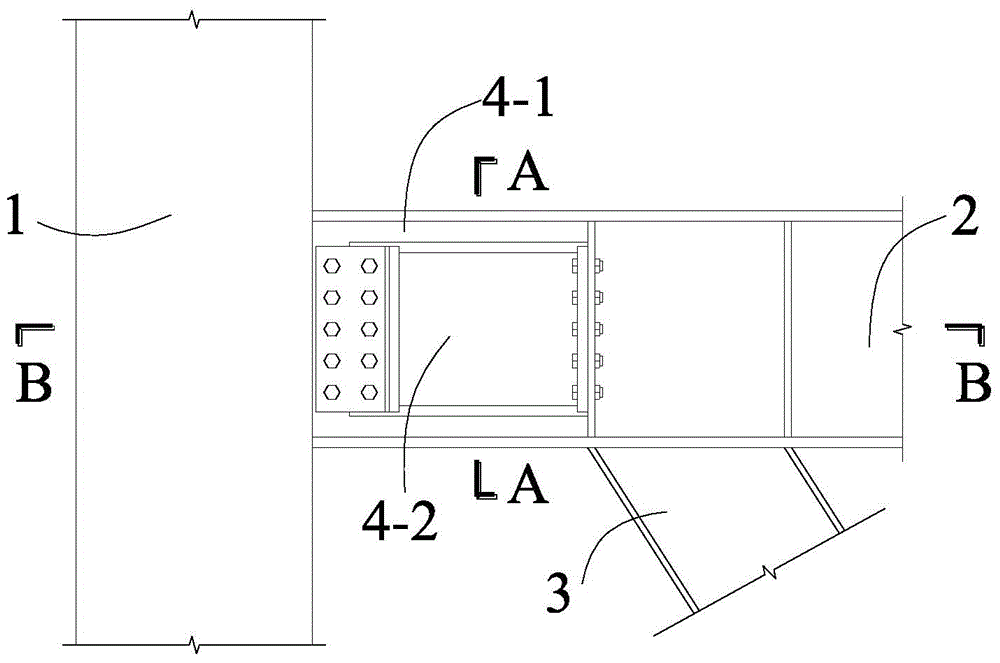

[0033] Such as Figure 2-7 As shown, an easily repairable eccentric support frame system includes frame column 1, frame non-energy-dissipating beam section 2, support 3 and frame energy-dissipating beam section 4; the frame energy-dissipating beam section 4 is located at the intersection point of support 3 and beam Between the beam and the column, it consists of two parts: the beam elastic part 4-1 and the energy dissipation part 4-2; the beam elastic part 4-1 is obtained by removing part of the web from the conventional energy dissipation beam section, and the energy dissipation part 4 -2 can be placed in the corresponding vacant position, and the two ends along the length direction of the energy-dissipating beam section are fixed to the web of the beam elastic part 4-1; the beam elastic part 4-1 is made of high-yield steel, The energy dissipation plate 4-2-2 in the energy dissipation component 4-2 is made of low-yield steel; one end of the energy dissipation component 4-2 al...

Embodiment 2

[0035] Such as Figure 8 Shown: this embodiment is the same as the rest of embodiment 1, the difference is that the connection plate 4-2-1 is directly connected with the energy dissipation plate 4-2-2.

Embodiment 3

[0037] Such as Figure 9 Shown: This embodiment is the same as the rest of Embodiment 1, except that the energy dissipation plate 4-2-2 has regular polygonal holes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com