Modularized bamboo-shaped buckling restrained brace

A buckling-constrained, modularized technology, applied to building components, earthquake resistance, etc., can solve problems such as increased deformation of circular mandrels, reduced production efficiency, buckling of core components, etc., to reduce overall torsional deformation and improve low-cycle fatigue performance , the effect of reducing surface strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

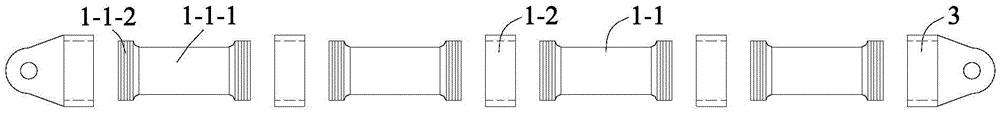

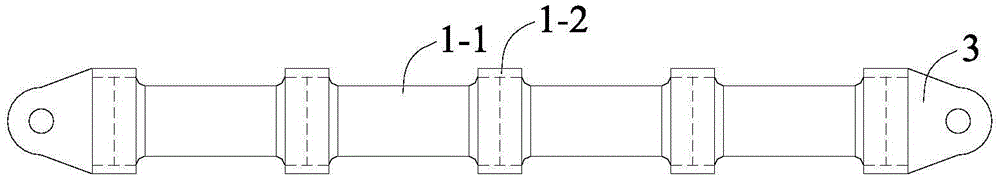

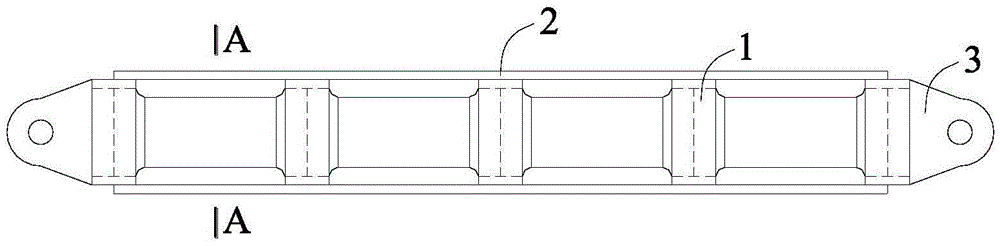

[0041] Such as Figure 1~4 Shown: a modular bamboo-shaped buckling-constrained support, including a core component 1, an outer constraint component 2 and a structural connection component 3, the core component 1 consists of four circular energy-dissipating sections 1-1 and three elastic sleeves 1-2 composition, the cross-sectional area of the end connection section 1-1-2 of the circular energy dissipation section 1-1 is larger than the cross-sectional area of the middle section 1-1-1, and is often set as the cross section of the connection section 1-1-2 The area is 1.6 times that of the middle section 1-1-1, the surface of the connecting section 1-1-2 has external threads, the inner surface of the elastic sleeve 1-2 has internal threads, and the connecting section of the circular energy dissipation section 1-1 1-1-2 The core component 1 is formed through the elastic sleeve 1-2 screw connection, the inner surface of the outer constraint component 2 is in close contact with ...

Embodiment 2

[0044] Such as Figure 5 Shown: this embodiment is the same as the rest of embodiment 1, the difference is that the inner surface of the elastic sleeve 1-2 is circular, the outer surface is hexagonal deformation, the elastic sleeve 1-2 is connected with the outer constraint member 2 tangent to the inner surface.

Embodiment 3

[0046] Such as Image 6 As shown: this embodiment is the same as the rest of embodiment 2, except that the outer constraining component 2 is a six-deformation sleeve, the inner surface of which is in close contact with the outer surface of the elastic sleeve 1-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com