Clamping positioning device for finish machining aero-engine turbine blade

A technology for aero-engine and turbine blades, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., to achieve the effects of controlling blade processing accuracy, improving positioning accuracy, and not easy to loosen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

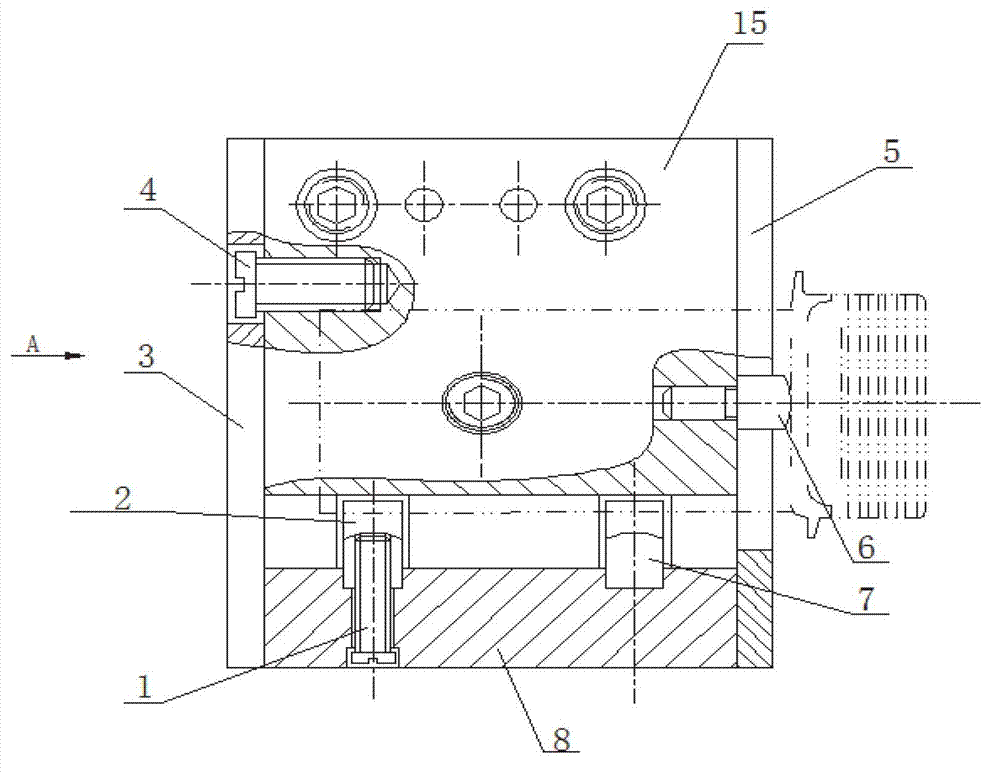

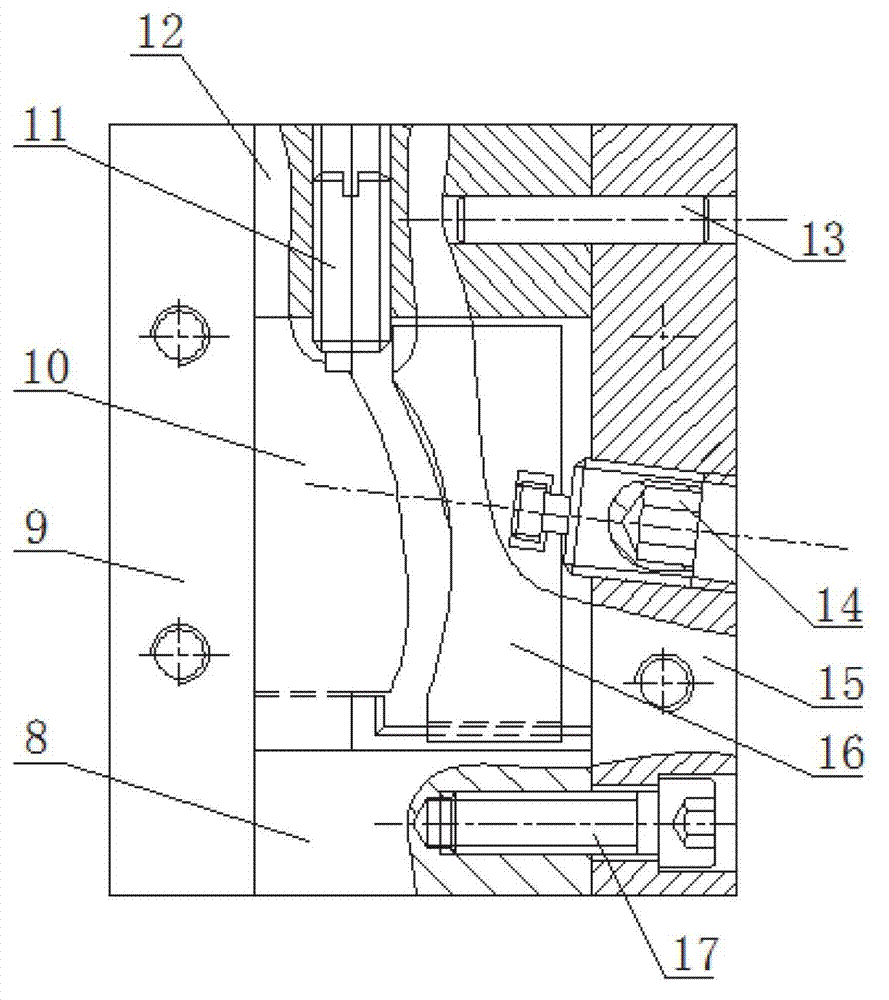

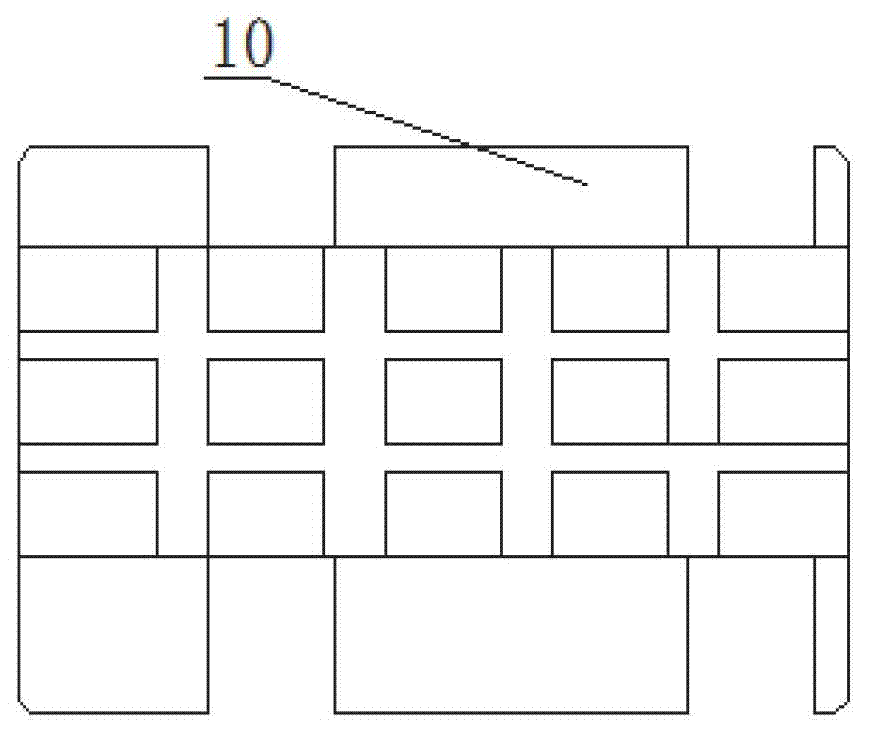

[0024] The clamping and positioning device used for finishing the tenon of the turbine blade of the aero-engine in this embodiment has a structure as attached Figures 1 to 4 As shown, the composition includes a frame composed of front cover plate 15, rear cover plate 9, left cover plate 3, right cover plate 5, upper cover plate 12 and lower cover plate 8 through connecting screws 17 and connecting positioning pins 13, etc. The right cover plate 5 is designed with an opening for placing the blade body into the frame and a positioning pin 6 for axially positioning the blade. The axial positioning of the blade is realized by pressing the end of the positioning pin against the edge plate surface between the blade body and the tenon. . The back positioning and pressing block 16 that matches the profile of the back of the airfoil in the frame can be adjusted on the front cover 15 in the pressing direction through the adjusting pressing screw 14 arranged on the front cover, and is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com