Numerical control main axle unit

A CNC spindle and spindle technology, which is applied to metal processing mechanical parts, driving devices, metal processing equipment, etc., can solve the problems of difficult control of spindle machining accuracy and difficult disassembly of the spindle, so as to achieve easier control of machining accuracy, improve accuracy, and smoothness. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

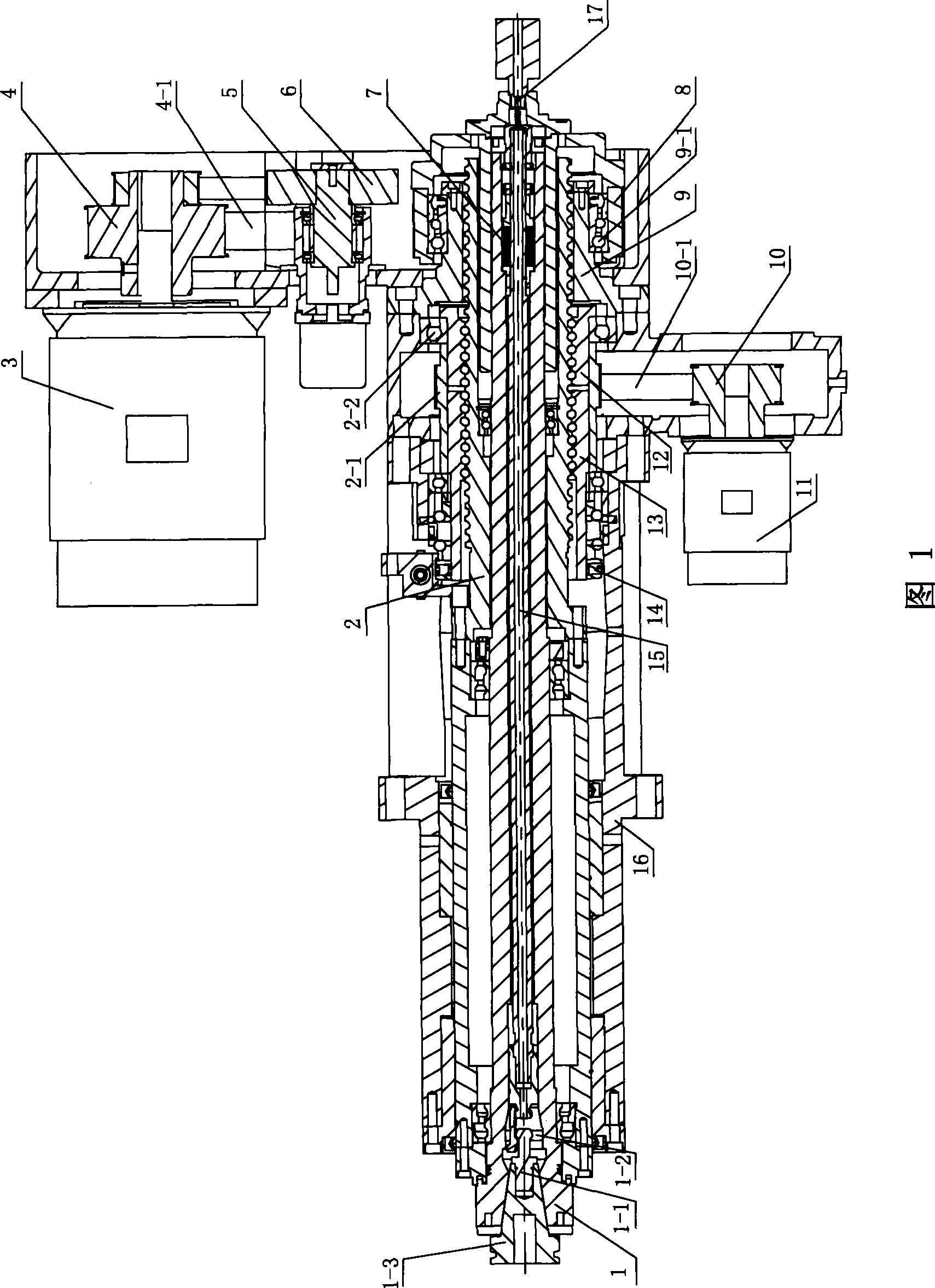

[0021] With reference to Fig. 1, a kind of numerical control spindle unit of the present invention comprises:

[0022] A main shaft 1 for carrying machining tools, the main shaft 1 has an inner cavity through its two ends;

[0023] A hollow tie rod 15 is installed in the inner cavity of the main shaft 1, and its front end is connected with a pulling claw 1-2, and the pulling claw 1-2 is detachably connected with a tension screw 1-1, and the tension screw 1- 1 detachably connect a machining tool 1-3, the machining tool 1-3 can be a tool for cutting, drilling, boring, reaming, tapping and other functions; the pull claw 1-2 and the tension screw 1-1 The connection mode between them is clamping connection, and the connection mode between the tensioning screw 1-1 and the machining tool 1-3 is threaded connection;

[0024] A main shaft feed driving device for driving the axial sliding of the main shaft 1 includes a first servo motor 11 connected to the numerical control center of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com