Multifunctional testing device used for lining structure

A test device and multi-functional technology, which is applied in the direction of measuring device, using stable tension/pressure test material strength, instrument, etc., to achieve the effect of broad application prospect, simple and convenient operation, and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

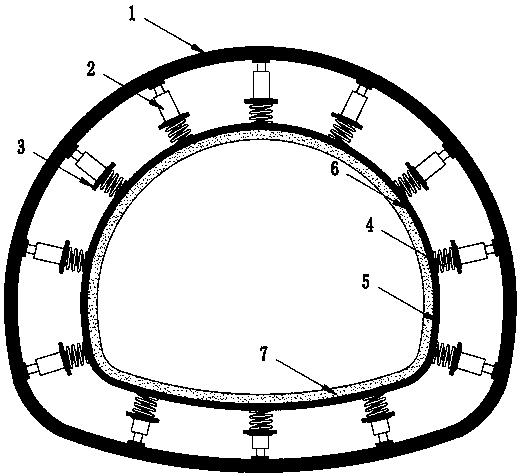

[0025] figure 1 Among them, the loading module is arranged in the reaction force device (1).

[0026] The reaction force device (1) is formed by bending and welding steel plates. The reaction force device is used to bear the reaction force transmitted from the loading of lining or other test structures.

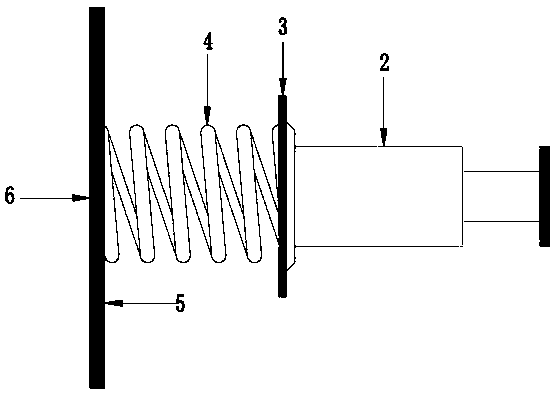

[0027] The loading module consists of a jack (2), a force transmission steel plate (3), a formation spring (4), a steel backing plate (5) and a rubber backing (6). One end of the jack (2) is fixed on the reaction force device by bolts, and the other end is connected with the force transmission steel plate (3) by bolts, the other end of the force transmission steel plate (3) is welded with the formation spring (4), and the other end of the formation spring is welded with a steel pad Plate (5), under the steel backing plate (5), paste a rubber cushion with the same size as the steel backing plate.

[0028] Such as figure 1 As shown, the test lining is horseshoe-shaped, with...

Embodiment 2

[0030] figure 1 Among them, the loading module is arranged in the reaction force device (1).

[0031] The reaction force device (1) is formed by bending and welding steel plates. The reaction force device is used to bear the reaction force transmitted from the loading of lining or other test structures.

[0032] The loading module consists of a jack (2), a force transmission steel plate (3), a formation spring (4), a steel backing plate (5) and a rubber backing (6). One end of the jack (2) is fixed on the reaction force device by bolts, and the other end is connected with the force transmission steel plate (3) by bolts, the other end of the force transmission steel plate (3) is welded with the formation spring (4), and the other end of the formation spring is welded with a steel pad Plate (5), under the steel backing plate (5), paste a rubber cushion with the same size as the steel backing plate.

[0033] Such as figure 1 As shown, the test lining is horseshoe-shaped, with...

Embodiment 3

[0035] figure 1 Among them, the loading module is arranged in the reaction force device (1).

[0036] The reaction force device (1) is formed by bending and welding steel plates. The reaction force device is used to bear the reaction force transmitted from the loading of lining or other test structures.

[0037] The loading module consists of a jack (2), a force transmission steel plate (3), a formation spring (4), a steel backing plate (5) and a rubber backing (6). One end of the jack (2) is fixed on the reaction force device by bolts, and the other end is connected with the force transmission steel plate (3) by bolts, the other end of the force transmission steel plate (3) is welded with the formation spring (4), and the other end of the formation spring is welded with a steel pad Plate (5), under the steel backing plate (5), paste a rubber cushion with the same size as the steel backing plate.

[0038] Such as figure 1 As shown, the test lining is horseshoe-shaped, with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com