Dual-core visual inspection buckling restraint support

A technology of buckling restraint and restraint plate, which is applied to building components, earthquake resistance, building types, etc., can solve the problems of reducing the overall stiffness of restraining components, destroying the main body of the structure, increasing the difficulty and cost of post-earthquake repair, and improving low-cycle fatigue performance. , The effect of improving low cycle fatigue performance and reducing surface strain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

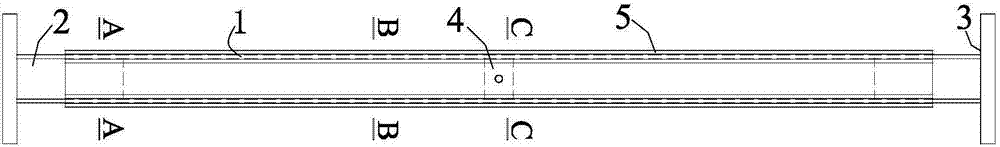

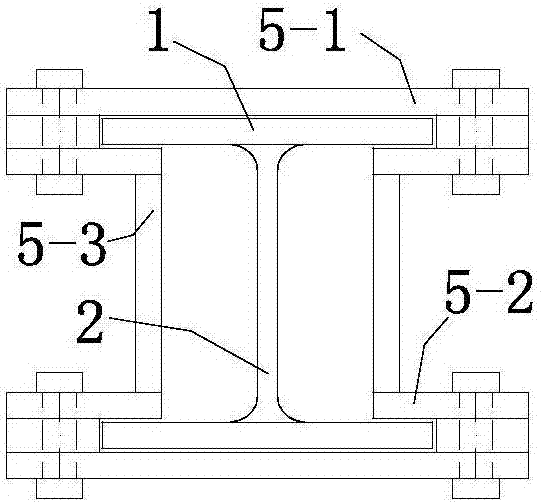

[0036] Such as Figure 1~7 Shown: a dual-core visual inspection buckling restraint support, including two energy-dissipating inner core plates 1, two sets of end stiffening plates 2, two end connecting plates 3, a connecting positioning plate 4 and a peripheral restraining component 5; Two energy-dissipating inner core plates 1 are placed in parallel along the thickness direction; the end stiffening plate 2 is a rectangular plate, and the two opposite sides of the end stiffening plate 2 are vertically fixed to the inner side of the parallel energy-dissipating inner core plate 1 as a cross section For the web, the other side of the end stiffening plate 2 is in the same plane as the end edge of the energy dissipating inner core plate 1; the end connecting plate 3 is connected to the end edges of the two energy dissipating inner core plates 1 and the end stiffening plate 2 One side is fixed; the connecting positioning plate 4 is also a rectangular plate, and the two opposite sides...

Embodiment 2

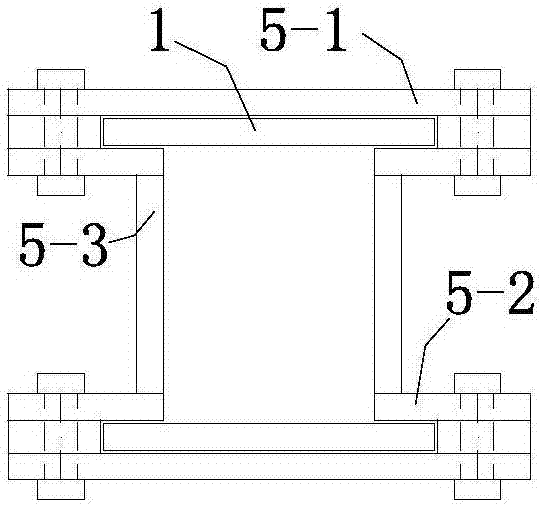

[0038] Such as Figure 8 Shown: this embodiment is the same as the rest of the embodiment 1, the difference is that the constraining plate 5-1 is a channel steel, and the inner side of the web is constrained close to the energy dissipating inner core plate 1, and two partial constraining plates 5-2 It forms a groove weld with the connecting plate 5-3.

Embodiment 3

[0040] Such as Picture 9 Shown: this embodiment is the same as the rest of the embodiment 1, the difference is that the energy-consuming inner core plate 1 is narrow in the middle and wide on both sides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com