A kind of 225mpa level weather resistance low yield point damper steel plate and steel strip preparation method

A low yield point and damper technology, applied in the field of metallurgy, can solve problems such as poor weather resistance and poor weather resistance, and achieve the effects of stable process mechanical properties, low smelting costs, and excellent atmospheric corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A. Hot metal pretreatment desulfurization: blast furnace hot metal (chemical composition C 4.0wt%, Si 0.20wt%, Mn 0.25wt%, P0.130wt%, S 0.025wt%, the rest is Fe and unavoidable impurities) transport To the KR method molten iron pretreatment device for desulfurization treatment, the insertion depth of the stirring head is controlled at 2400mm, according to 10.0 kg / t 钢 Add a conventional CaO-based desulfurizer for desulfurization treatment, and control the stirring time to 5 minutes; after the stirring, carry out the slag removal operation to ensure that the molten iron surface in the ladle is exposed ≥ 4 / 5, and remove the desulfurization slag; the molten iron composition after pretreatment The control is: C 4.0wt%, Si 0.20wt%, Mn 0.25wt%, P 0.130wt%, S 0.010wt%, the rest is Fe and unavoidable impurities.

[0032] B. Converter smelting of molten iron: 960kg / t in step A 钢 Pretreated desulfurized hot metal (chemical composition C 4.0wt%, Si0.20wt%, Mn 0.25wt%, P 0.130wt%, ...

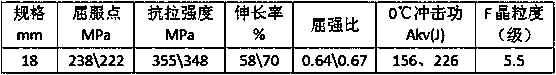

Embodiment 2

[0046] A. Hot metal pretreatment desulfurization: blast furnace hot metal (chemical composition C 4.1wt%, Si 0.30wt%, Mn 0.32wt%, P0.145wt%, S 0.030wt%, the rest is Fe and unavoidable impurities) transport To the KR method molten iron pretreatment device for desulfurization treatment, the insertion depth of the stirring head is controlled at 2300mm, according to 9.0 kg / t 钢 Add a conventional CaO-based desulfurizer for desulfurization treatment, and control the stirring time to 5 minutes; after the stirring, carry out the slag removal operation to ensure that the molten iron surface in the ladle is exposed ≥ 4 / 5, and remove the desulfurization slag; the molten iron composition after pretreatment The control is: C 4.1wt%, Si 0.30wt%, Mn 0.32wt%, P 0.145wt%, S0.016wt%, the rest is Fe and unavoidable impurities.

[0047] B. Converter smelting of molten iron: 960kg / t in step A 钢 Pretreated desulfurized hot metal (C 4.1wt%, Si 0.30wt%, Mn0.32wt%, P 0.145wt%, S0.016wt%, the rest is ...

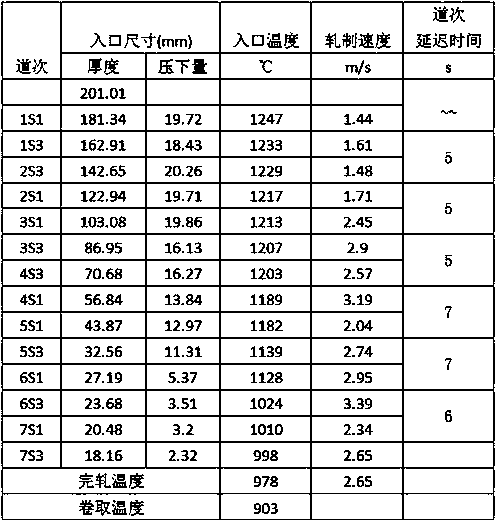

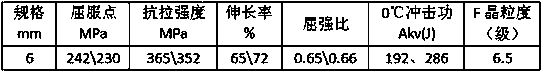

Embodiment 3

[0061] A. Hot metal pretreatment desulfurization: blast furnace hot metal (chemical composition C 4.2wt%, Si 0.40wt%, Mn 0.40wt%, P0.160wt%, S 0.040wt%, the rest is Fe and unavoidable impurities) transport To the KR method molten iron pretreatment device for desulfurization treatment, the insertion depth of the stirring head is controlled at 2200mm, according to 8.0 kg / t 钢 Add a conventional CaO-based desulfurizer for desulfurization treatment, and control the stirring time to 5 minutes; after the stirring, carry out the slag removal operation to ensure that the molten iron surface in the ladle is exposed ≥ 4 / 5, and remove the desulfurization slag; the molten iron composition after pretreatment The control is: C 4.2wt%, Si 0.40wt%, Mn 0.40wt%, P 0.160wt%, S0.020wt%, the rest is Fe and unavoidable impurities.

[0062] B. Converter smelting of molten iron: 960kg / t in step A 钢 Pretreated desulfurized hot metal (C 4.2wt%, Si 0.40wt%, Mn0.40wt%, P 0.160wt%, S 0.020wt%, the rest is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com