Heat treatment method for regulating and controlling static and dynamic load mechanical properties and anisotropy of SLM titanium alloy

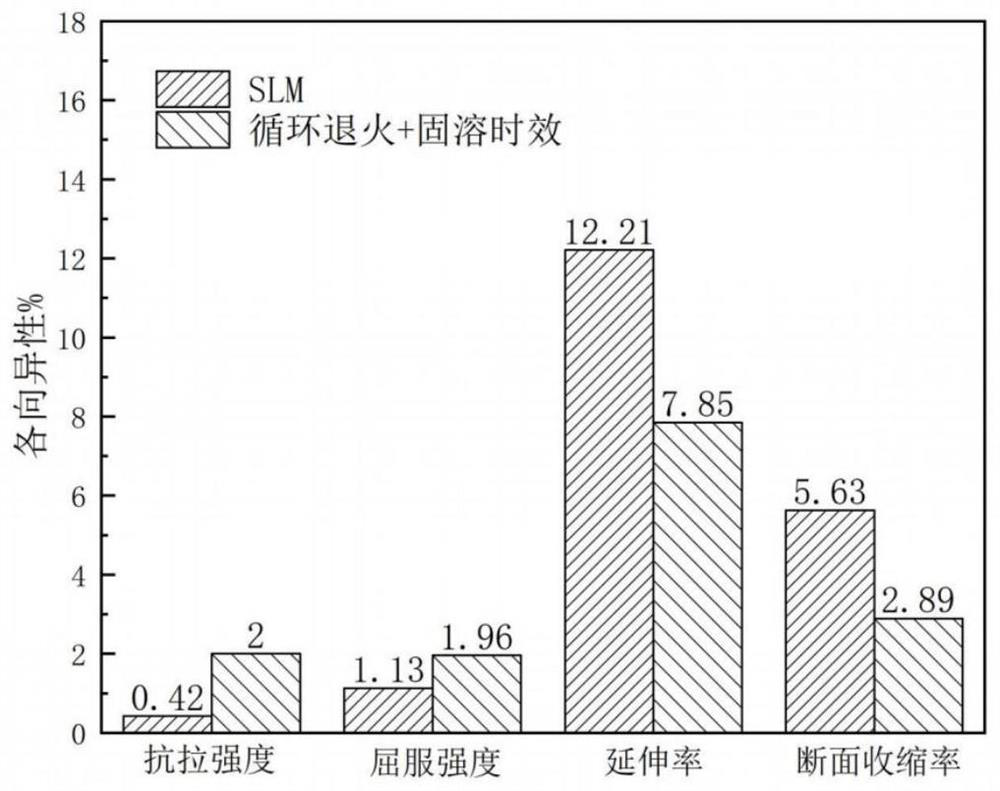

A heat treatment method and anisotropic technology, applied in the direction of additive processing, etc., can solve the problems of large anisotropy difference in mechanical properties of parts, poor plastic-toughness matching, low plastic and toughness, etc., so as to improve the mechanical properties of static and dynamic loads. , the effect of reducing anisotropy and stable mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to fully understand the technical content of the present invention, the technical solution provided by the present invention will be further introduced and illustrated below in conjunction with the specific implementation process and the accompanying drawings.

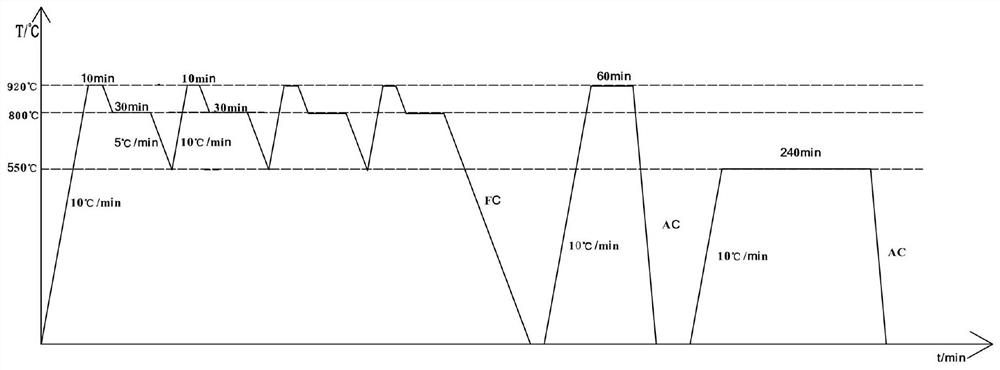

[0023] figure 1 It is a heat treatment process flow chart of the present invention, wherein the horizontal line represents the heat preservation process, the number above the horizontal line represents the heat preservation time, the oblique line represents the heating or cooling process, and the number next to it represents the heating or cooling rate.

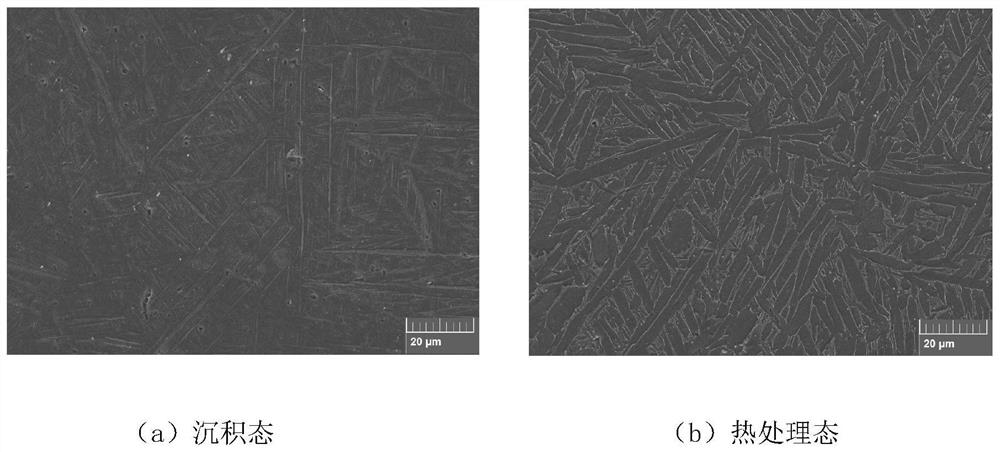

[0024] figure 2 (a) is the microstructure diagram of SLM Ti-6Al-4V deposited state, which is composed of lath α phase and needle α phase; figure 2 (b) is the microstructure of SLM Ti-6Al-4V after heat treatment. It can be seen that the coarse β columnar grains disappear, and the structure is a dual-state structure composed of equiaxed α phase, lath ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com