Patents

Literature

31results about How to "Quite strong" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

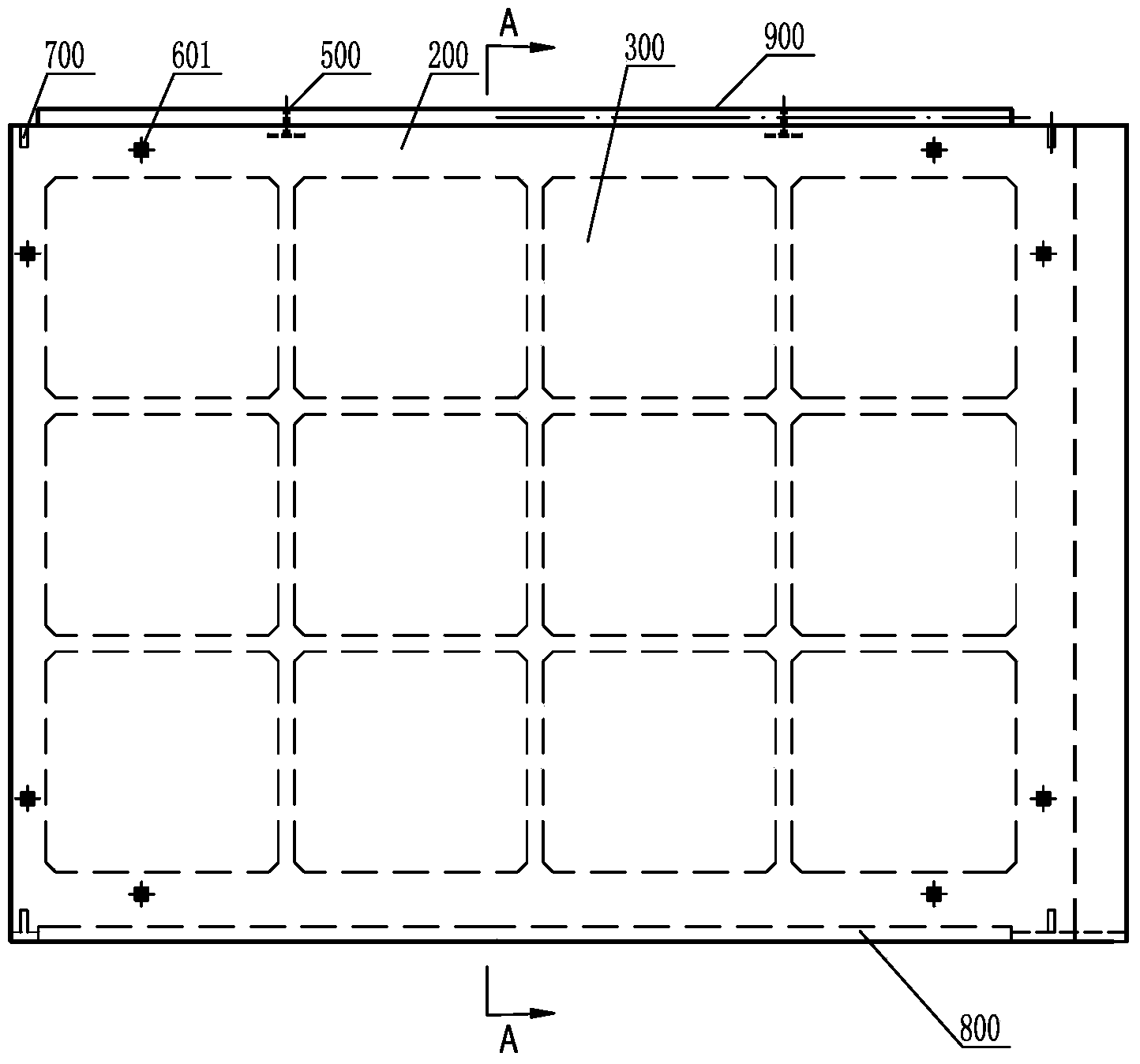

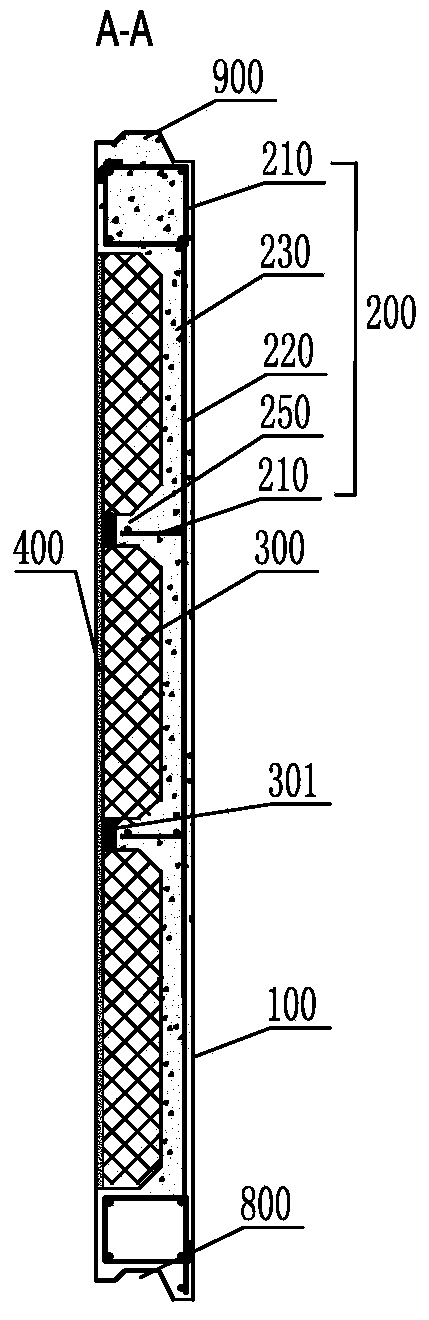

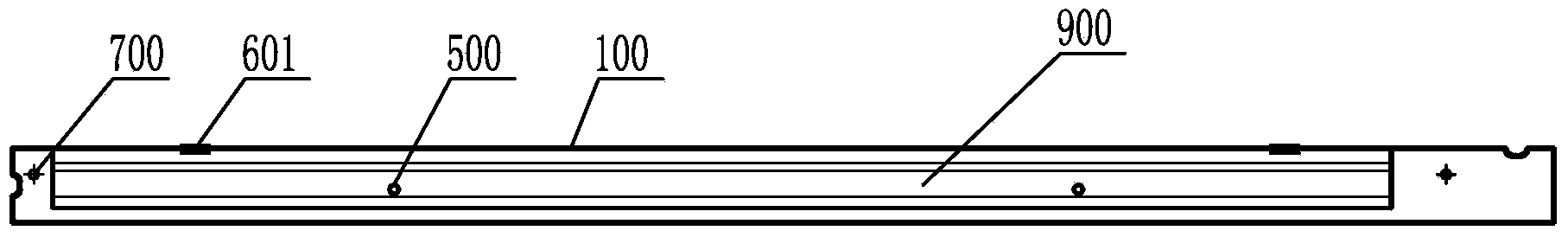

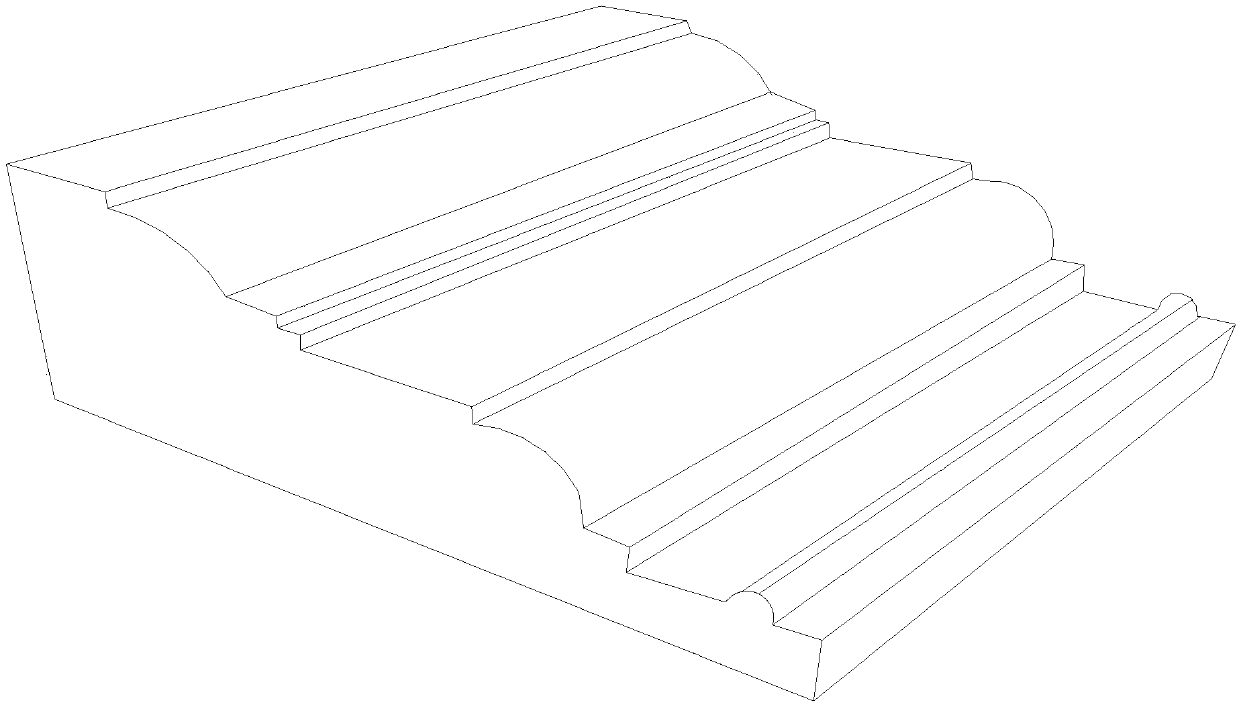

Integrally prefabricated multifunctional composite external wall panel and industrial building external wall

The invention discloses an integrally prefabricated multifunctional composite external wall panel and an industrial building external wall. The external wall panel comprises an outer decoration layer, a reinforcing bar fine aggregate concrete structural layer, a light-weight heat insulation layer and an indoor decoration layer which are fixedly connected from the outside to the inside, wherein the reinforcing bar fine aggregate concrete structural layer is filled into the light-weight heat insulation layer for forming plate ribs; heat insulation pads are arranged on the end surfaces of the plate ribs; first connecting elements are arranged on the periphery of the external wall panel; the top and the bottom of the external wall panel are respectively provided with positioning mechanisms; the top of the external wall panel is provided with hanging rings; and pre-buried accessories are arranged in the external wall panel. The external wall is formed by the external wall panels through vertical and horizontal distribution, surrounding and shielding, the periphery of each external wall panel is provided with a connecting mechanism connected with a main body stress component; the back part of the connecting mechanism is pre-buried in the reinforcing bar fine aggregate concrete structural layer of the external wall panel; and the adjacent external wall panels are sealed and connected through telescopic sealing elements. The integrally prefabricated multifunctional composite external wall panel and the industrial building external wall have the advantages that the industrial production can be realized; the weight is light; the transportation and the construction are convenient; the heat insulation performance and the sound isolation performance are good; the intensity and the weatherability are good; the internal and external decoration construction is not needed; and the installation is convenient.

Owner:黄涛 +1

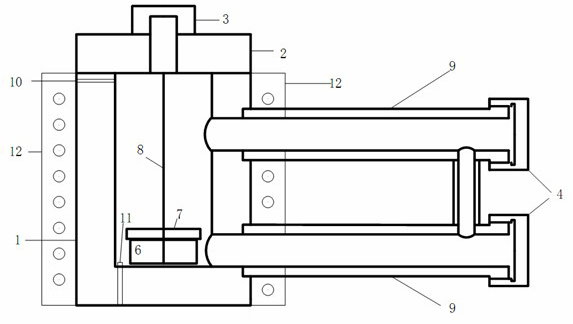

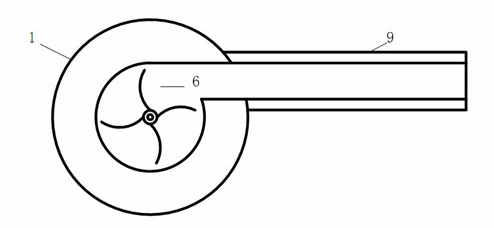

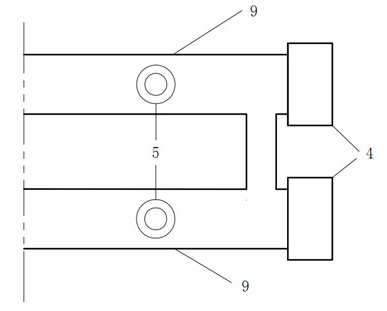

High-temperature and high-pressure flowing device for evaluating corrosion resistance performance of materials

InactiveCN102680384AReal-time observation of flow corrosionReal-time observation of phase stateWeather/light/corrosion resistanceData acquisitionWorking temperature

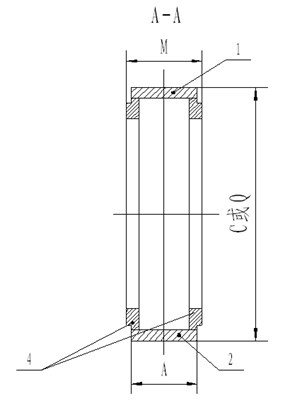

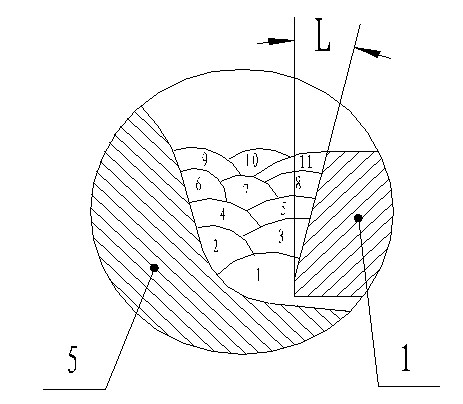

The invention relates to a high-temperature and high-pressure flowing device for evaluating corrosion resistance performance of materials. The high-temperature and high-pressure flowing device comprises a high-temperature and high-pressure autoclave body, a high-temperature and high-pressure autoclave cover, a branch pipe, a branch pipe sealing device, a visual window, a blade, a flow-limiting plate, a stirring rod, a pressure sensor, a temperature sensor, a time relay, and a data collection and control system; the device is manufactured by adopting solidly forging corrosion-resistant alloy steel, achieves maximum working gas sealing pressure of 70MPa and highest working temperature of 200 DEG C, and has the advantages of acid corrosion, alkaline corrosion, chlorine gas and the like corrosion resistance as well as obvious corrosion resistance. A magnetic coupling is arranged, and the revolving speed is digitally controlled by a computer and displayed and recorded in real time, thus realizing circulating flowing of the corrosive medium.. The visual windows are arranged on the two branch pipes of the corrosion device and have equal sealing property, strength, corrosion resistance, temperature resistance, thermal fatigue service life to the high-temperature and high-pressure autoclave body, thus being capable of observing the flowing corrosion conditions of the materials and phase states of the corrosion medium in real time under different temperature and pressure conditions.

Owner:SOUTHWEST PETROLEUM UNIV

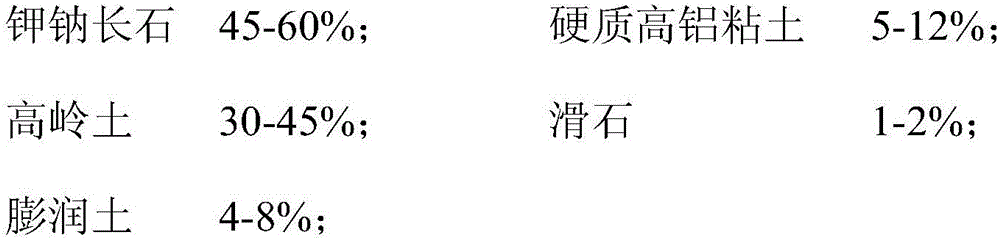

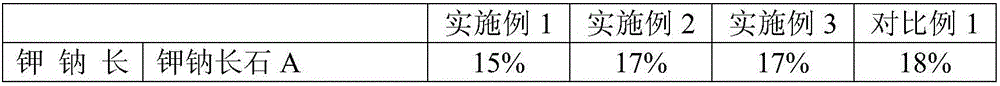

Porcelain plate blank powder and preparation technology thereof

InactiveCN105948702AConvenient sourceAvoid the disadvantages of not being suitable for dry grinding equipmentClaywaresSodium BentoniteWastewater

The invention discloses porcelain plate blank powder. The porcelain plate blank powder is prepared from components in percentage by weight as follows: 45%-60% of potassium-sodium feldspar, 5%-12% of hard high-alumina clay, 30%-45% of kaolin, 1%-2% of talc and 4%-8% of bentonite, and the weight percentage sum of the components is 100%. The porcelain plate blank powder adopts simple composition and can be applied to a dry process for preparation of a porcelain plate blank with the thickness of 2 cm, and the prepared porcelain plate blank has high strength and low water absorption. The invention further discloses a preparation technology of the porcelain plate blank powder. The preparation technology is simple, the energy consumption is low and small amount of wastewater and waste gas is produced.

Owner:FOSHAN VIEWGRES

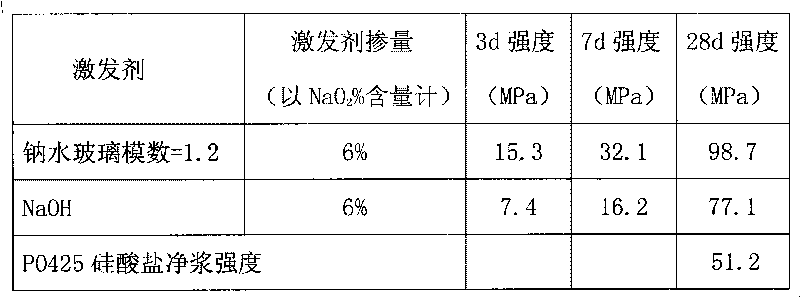

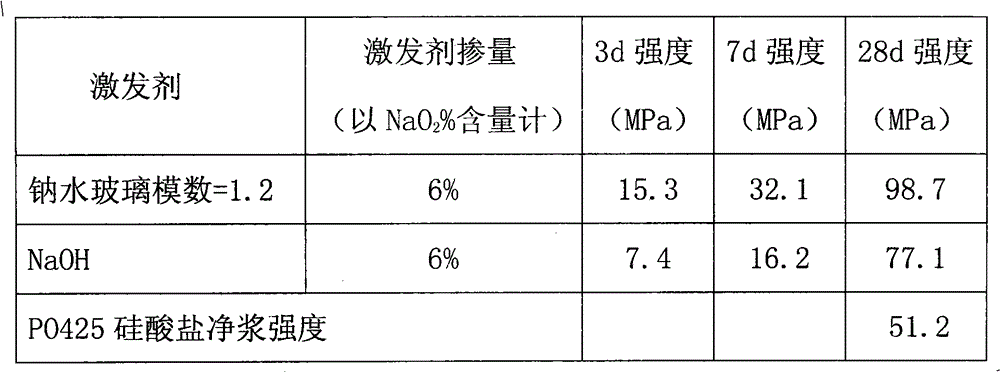

Phosphorous slag aerated concrete and preparation method thereof

ActiveCN101708981AEmission reductionLow costSolid waste managementClinker productionSlagThermal insulation

The invention discloses a phosphorous slag aerated concrete. The concrete is characterized by consisting of a binding material, an exciting agent, an air entraining agent and water which are mixed, wherein the binding material consists of 60 to 100 weight percent of phosphorous slag and 0 to 40 weight percent of pulverized fuel ash; the exciting agent is water glass with modulus of 1.0 to 1.6; the water glass accounts for 5 to 8 weight percent of the binding material based on the weight of Na2O; the air entraining agent is aluminum powder or simple substance silicon; the using amount of the aluminum powder is 0.1 to 0.2 weight percent of the binding material; the using amount of the simple substance silicon is 0.05 to 0.1 weight percent of the binding material; and the weight ratio of theusing amount of the water to the using amount of the binding material is 0.28 to 0.32. The phosphorous slag aerated concrete product is prepared by taking the industrial waste slag such as the phosphorous slag and the like as the binding material and mixing the phosphorous slag, the exciting agent, the air entraining agent and the water. The phosphorous slag aerated concrete has the advantages that: the preparation process is simple without vapor-pressure process, so that the equipment investment can be greatly reduced; and the product is a sealed porous structure and has the characteristics of light weight, high strength, low thermal conductivity, good thermal insulation property and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

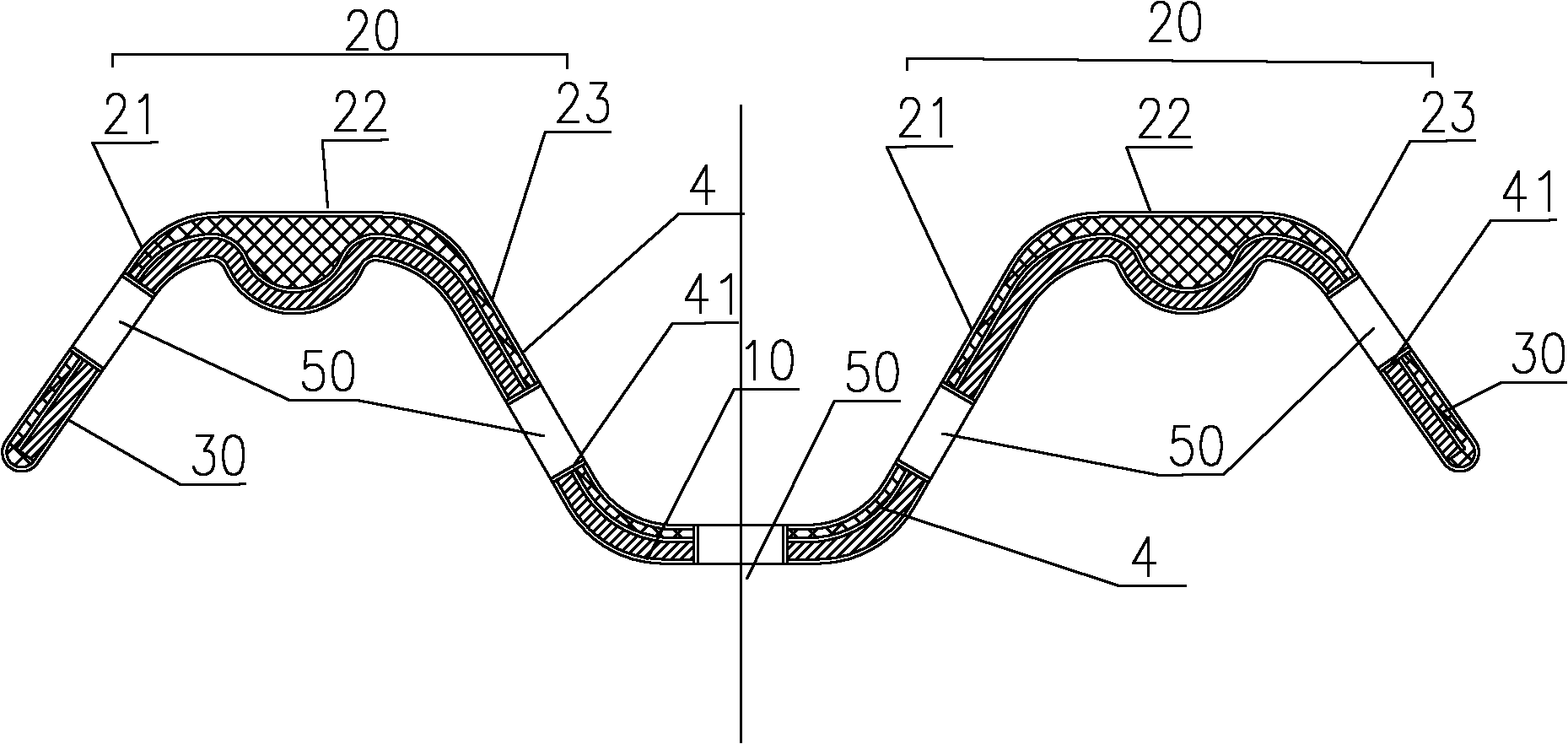

Corrugated guardrail plate

InactiveCN102535334AImprove impact resistanceImprove buffering effectFencingBridge structural detailsManufacturing technologyHigh probability

The invention discloses a corrugated guardrail plate comprising a baseplate fixedly connected with an obstruction block or a standing column, wherein corrugated plates respectively extend out of two sides of the baseplate; the baseplate is integrated with the corrugated plates; the corrugated plates protrude to the same side of the plate face of the baseplate and exceed the plate face of the baseplate; a smooth transition is adopted between the baseplate and each corrugated plate; both the baseplate and the corrugated plates extend in the length direction of the guardrail plate and are thermoplastic composite plates; and each thermoplastic composite plate comprises a reinforcing frame wrapped in a thermoplastic material layer. Aiming to overcome the defects of high probability of corrosion, high rigidity and poor collision energy absorption of a steel guardrail plate, small elastic modulus, large size and high cost of an all-plastic guardrail plate, and complex manufacturing technology and worse collision energy absorption of a plastic-steel guardrail plate, the invention provides the corrugated guardrail plate, which has the advantages of corrosion resistance and appropriately matched rigidity and flexibility and can reduce harm to a vehicle and personnel to the greatest extent.

Owner:HUNAN JINHONG TECH CO LTD

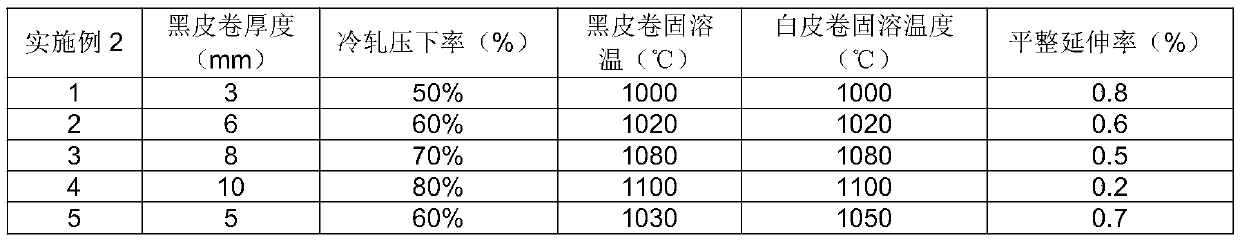

Stainless cold-rolling strip steel and manufacturing method thereof

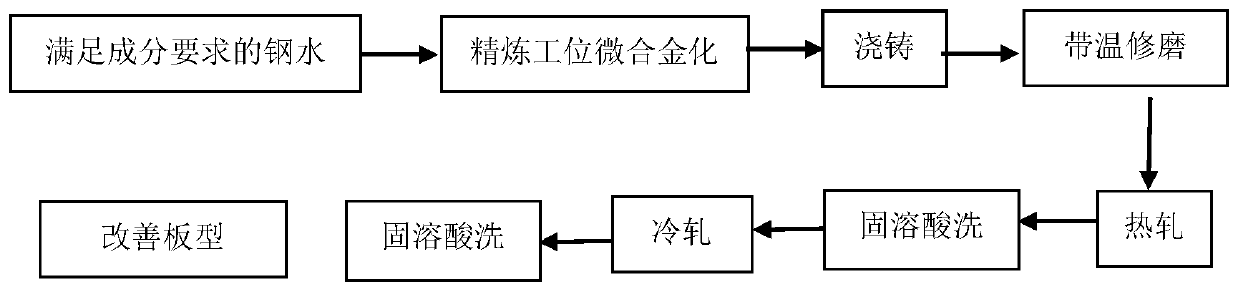

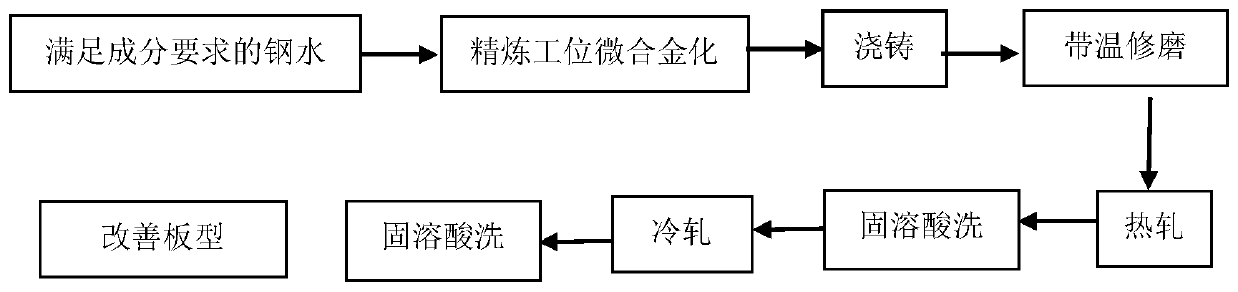

ActiveCN101724784AHigh strengthReduce manufacturing costRoll force/gap control deviceTemperature control deviceRoom temperatureAcid washing

The invention relates to a stainless cold-rolling strip steel containing the following components in percentage by weight: not more than 0.02 wt% of C, 0.3 to 0.80 wt% of Si, 0.2 to 0.80 wt% of Mn, not more than 0.040 wt% of P, not more than 0.15 wt% of S, 16.5 to 19.5 wt% of Cr, not more than 0.02 wt% of N, 0.2 to 0.6 wt% of Nb, 0.005 to 0.08 wt% of Al and the balance of Fe and inevitable impurities. The manufacturing method of the stainless cold-rolling strip steel comprises the following steps of: continuously casting the components into a plate blank after smelting, wherein the electromagnetic stirring is adopted in the continuous casting process so that the isometric crystal ratio of the section of the plate blank reaches above 40%; hot rolling: the plate blank is heated to 950 to 1200 DEG C, rolled into strip steel for multiple times and then coiled into a steel roll, wherein the final rolling temperature is 750 to 900 DEG C, the coiling temperature is 350 to 700 DEG C, and then the steel roll is air-cooled into the room temperature; cold rolling: the hot-rolled steel roll is firstly acid-washed, wherein the annealing temperature is 800 to 1000 DEG C, and the annealing time is 0.5 to 5.0 min; rolling for multiple times by cold rolling, wherein the overall reduction is 60% to 75%; and finally annealing the cold-rolled strip steel by acid washing, wherein the annealing temperature is 800 to 1,050 DEG C, and the annealing time is 0.5 to 3 min; and cooling the steel roll below 550 DEG C so that the high-strength strip steel is obtained.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

Oil shale ash and fly ash co-doped mineral aggregate concrete and preparation method thereof

InactiveCN113264735ALow early strengthReduced compressive strengthSolid waste managementCement productionMining engineeringWater reducer

The invention discloses an oil shale ash and fly ash co-doped mineral aggregate concrete and a preparation method thereof, and belongs to the technical field of concrete. The oil shale ash and fly ash co-doped mineral aggregate concrete is prepared from the following raw materials in parts by mass: 130 to 150 parts of cement, 50 to 70 parts of oil shale ash, 90 to 110 parts of fly ash, 700 to 750 parts of quartz sand, 1100 to 1200 parts of gravel, 5 to 8 parts of alkali activator, 4 to 6 parts of water reducing agent and 150 to 170 parts of water. By improving the formula of the concrete, all the raw materials in the formula can generate a synergistic effect, so that when the oil shale ash and the fly ash replace a part of cement to prepare the concrete, the strength of the concrete is kept equivalent to that of unreplaced concrete, and the use amount of the cement is greatly saved; meanwhile, the utilization rate of the oil shale ash and the coal ash is increased.

Owner:BEIHUA UNIV

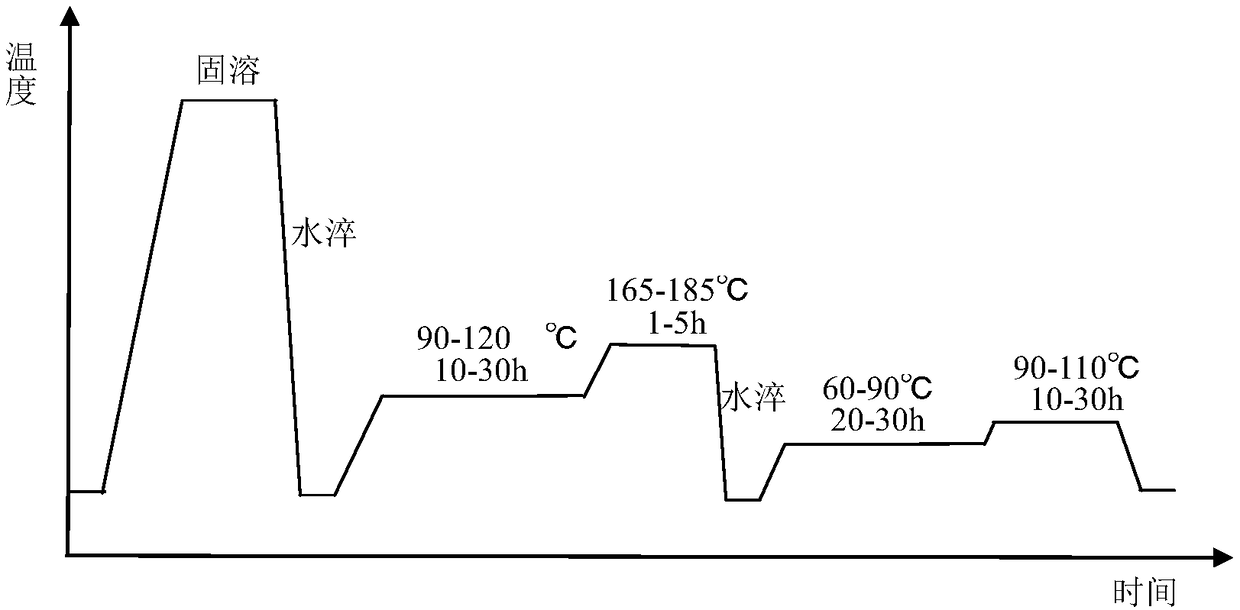

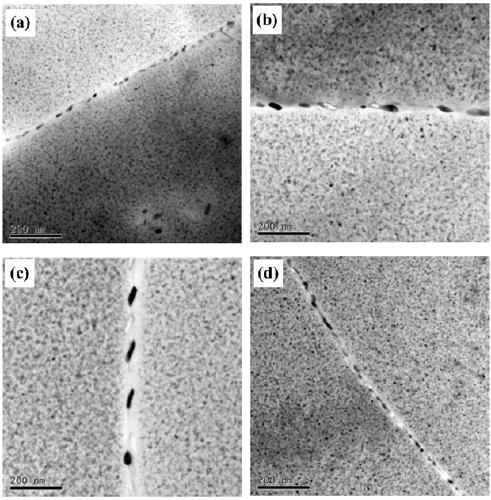

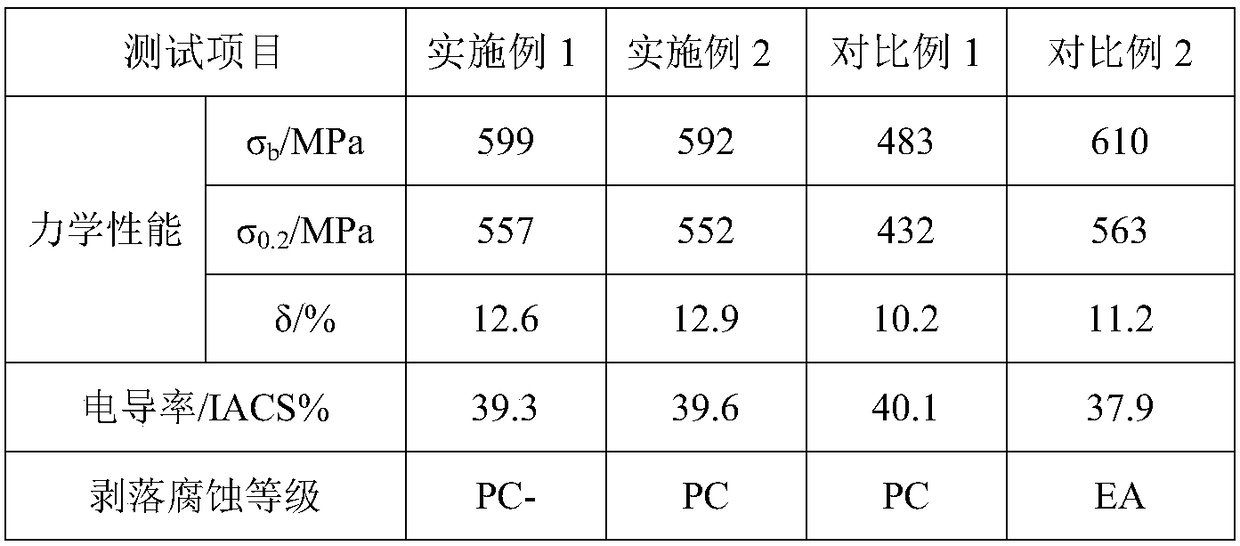

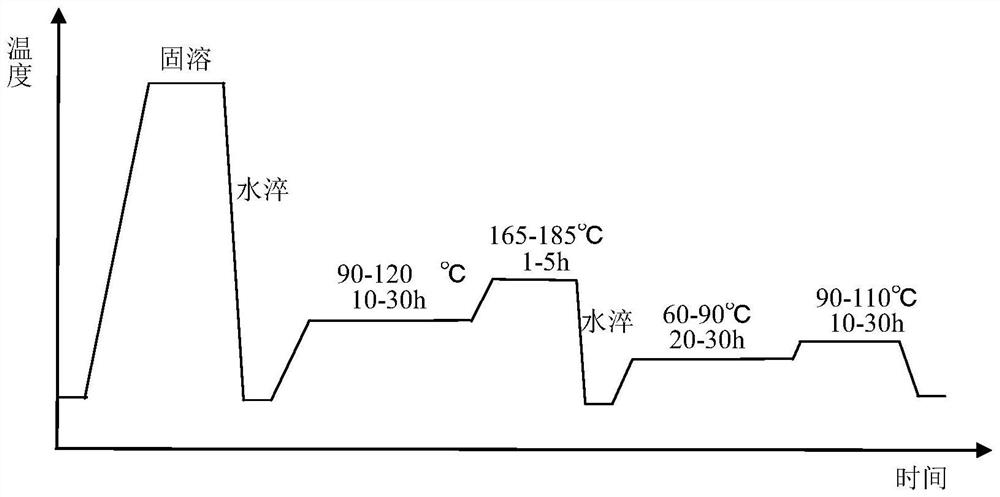

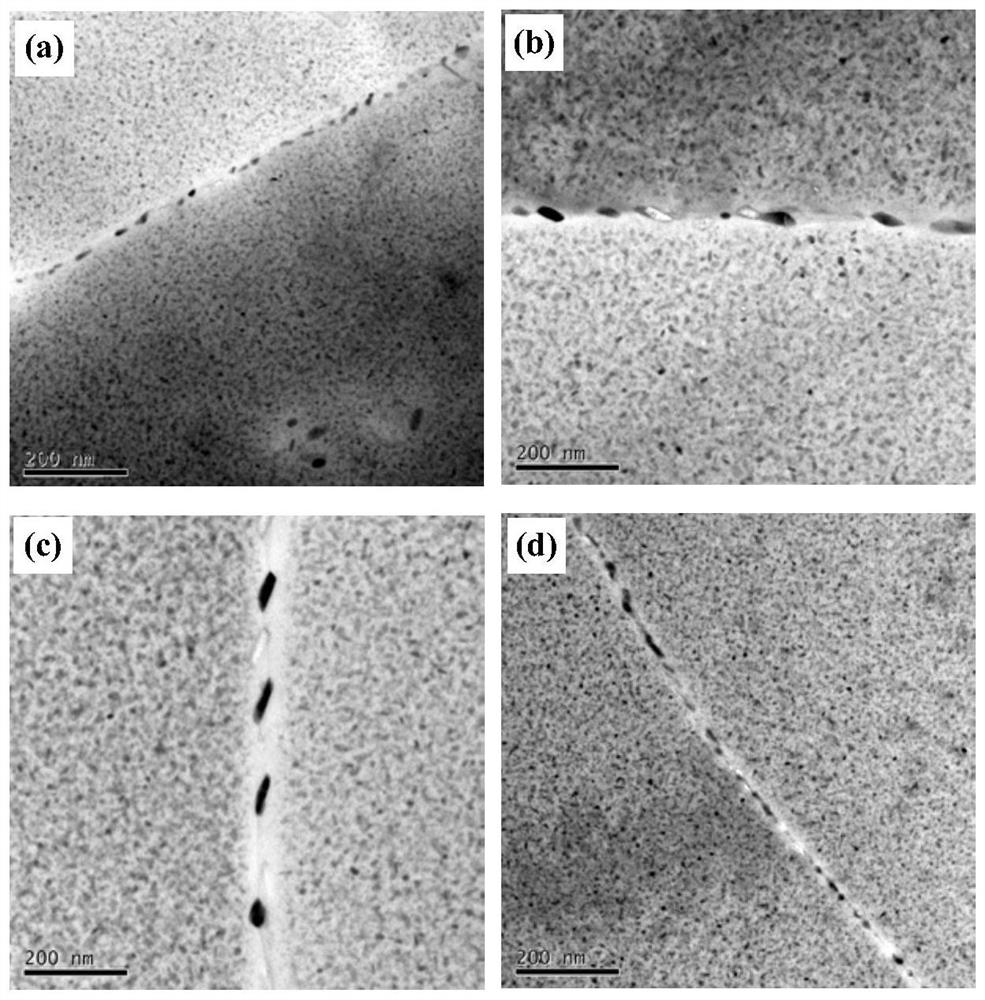

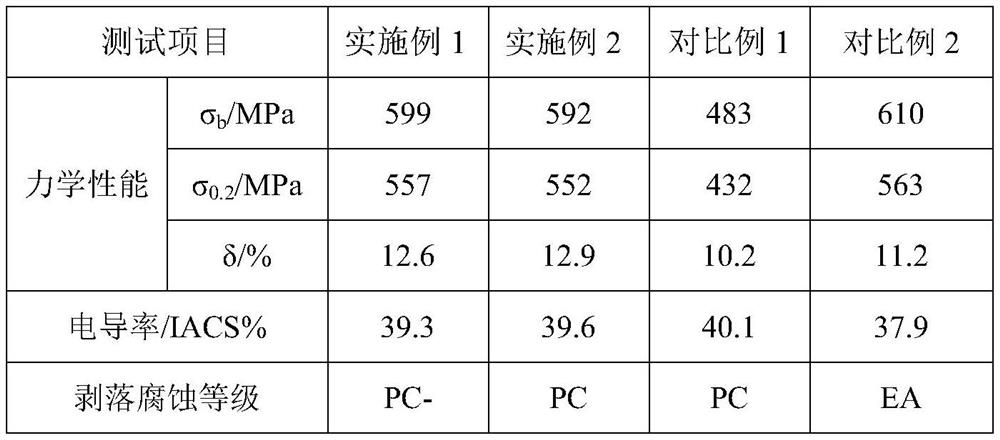

Aging heat treatment method for 7-series aluminum alloy

The invention discloses an aging heat treatment method for a 7-series aluminum alloy, and belongs to the field of non-ferrous metal materials and heat treatment thereof. The aging heat treatment method is used for the 7-series aluminum alloy after solid solution treatment, and comprises the following steps that (1) first-stage aging is performed, specifically, a 7-series aluminum alloy workpiece is placed in a heating furnace of 90-120 DEG C for heat preservation for 10-30h; (2) second-stage aging is performed, specifically, the temperature is raised to a second-stage predetermined aging temperature of 165 DEG C-185 DEG C along with the furnace, and after the heat preservation is performed for 1-5h, the 7-series aluminum alloy workpiece is subjected to water cooling to the room temperature; (3) third-stage aging is performed, specifically, the 7-series aluminum alloy workpiece is then placed at a third-stage predetermined aging temperature of 60-90 DEG C for heat preservation for 20-30h; and (4) fourth-stage aging is performed, specifically, the temperature is raised to a fourth-stage predetermined aging temperature of 90-110 DEG C along with the furnace, and after the heat preservation is performed for 10-30h, the 7-series aluminum alloy workpiece is subjected to air cooling to the room temperature. In the second-stage high-temperature aging process, a method of lowering the temperature than the RRA temperature and increasing the heat preservation time is adopted, and the problem of uneven structure and performance caused by the temperature gradient due to rapid heating and cooling of large components is solved.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH +1

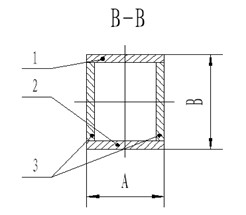

Axle case for turning drive vehicle axle

InactiveCN102514448ASimple and beautiful appearanceCompact structureAxle unitsAutomotive engineeringGas protection

The invention relates to an axle case for a turning drive vehicle axle. The axle case comprises an axle case body and a turning fork which are connected in a manner of gas metal arc welding (GMAW) and is characterized in that: the axle case body is formed by welding an upper cover plate, a lower cover plate, lateral plates and steel rings; the central parts of the upper cover plate and the lower cover plate have U-shaped structures in opposite orientations; the bottoms of the U-shaped structures are in the shapes of an arc shape and a plane shape; the middle parts of the U-shaped structures are welded with two steel rings; the outer diameters of the steel rings are firmly combined with the lateral plates, the upper cover plate and the lower cover plate respectively; the lateral plates are adaptive to the shapes of the upper cover plate, the lower cover plate and the steel rings; lateral surfaces at both ends of each lateral plate are mutually vertical to the upper cover plate and the lower cover plate; and the cross section of the axle case body is rectangular. The axle case has the advantages of simple and artistic whole appearance, high strength, high rigidity, high toughness, high impact resistance and light weight.

Owner:泸州开士乐工程技术有限责任公司

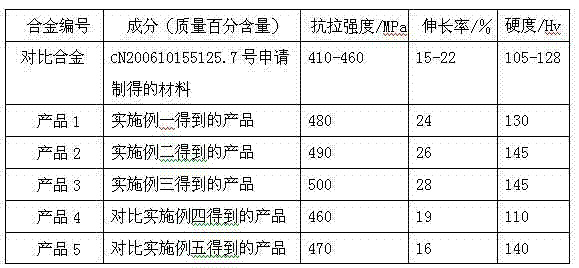

High-strength stainless steel and manufacturing method thereof

The invention discloses high-strength stainless steel. The high-strength stainless steel comprises the following components in percentage by mass (mass%): 0.04-0.09 mass% of C, 1.5-2.5 mass% of Si, Mnless than 1.0 mass%, 13.0-15.0 mass% of Cr, 6.0-7.0 mass% of Ni, N less than 0.010 mass%, 0.6-1.0 mass% of Mo, 0.6-1.0 mass% of Cu, 0.3-0.8 mass% of Ti, B less than 0.03 mass%, V less than 0.3 mass%,P less than and equal to 0.030 mass%, S less than and equal to 0.005 mass%, and the balance of Fe and inevitable impurity elements, wherein Cr+Mo+0.5Ti=Creq, Ni+30*(C+N)+0.5Mn+0.25Cu=Nieq, and Creq / Nieq is not more than 1.8 and not less than 1.4. The high-strength stainless steel obtains a full austenite structure in the hot working process through reasonable component design; a structure after the solid solution treatment is an austenite and martensite dual-phase structure; and a high-temperature ferrite is separated out preferentially during solidification, so that the generation of weldinghot cracks is effectively reduced, and meanwhile, the strength of welding lines is guaranteed to be equivalent to that of a base metal after welding.

Owner:浙江吉森金属科技有限公司

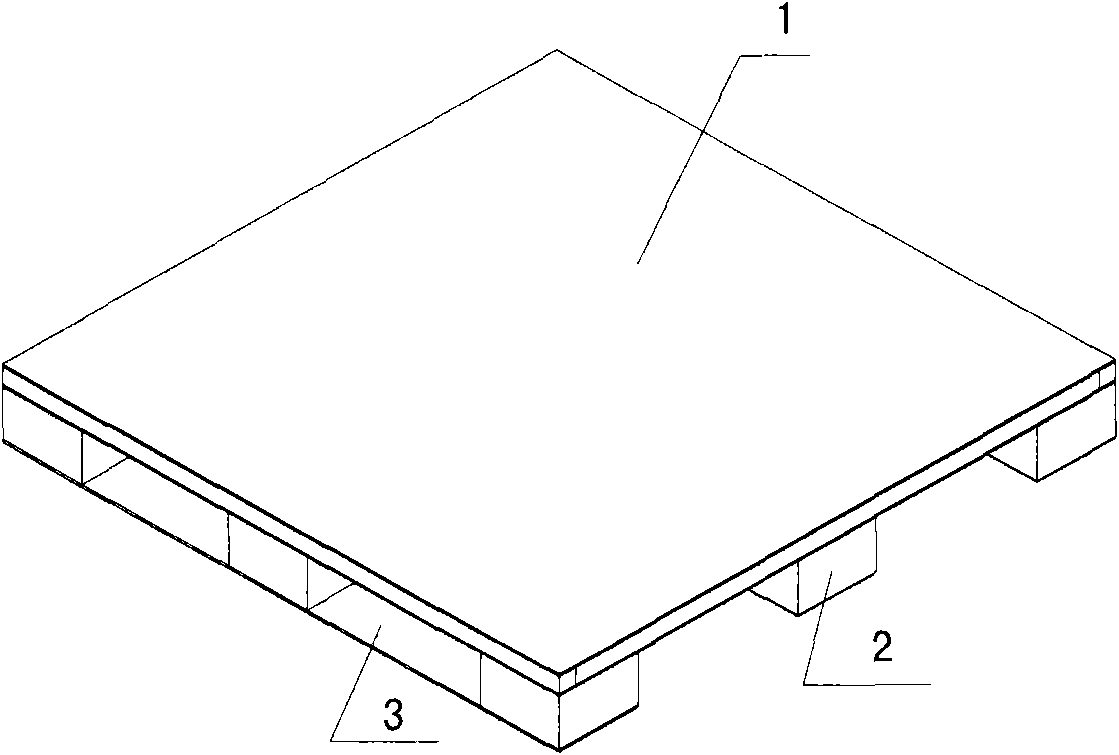

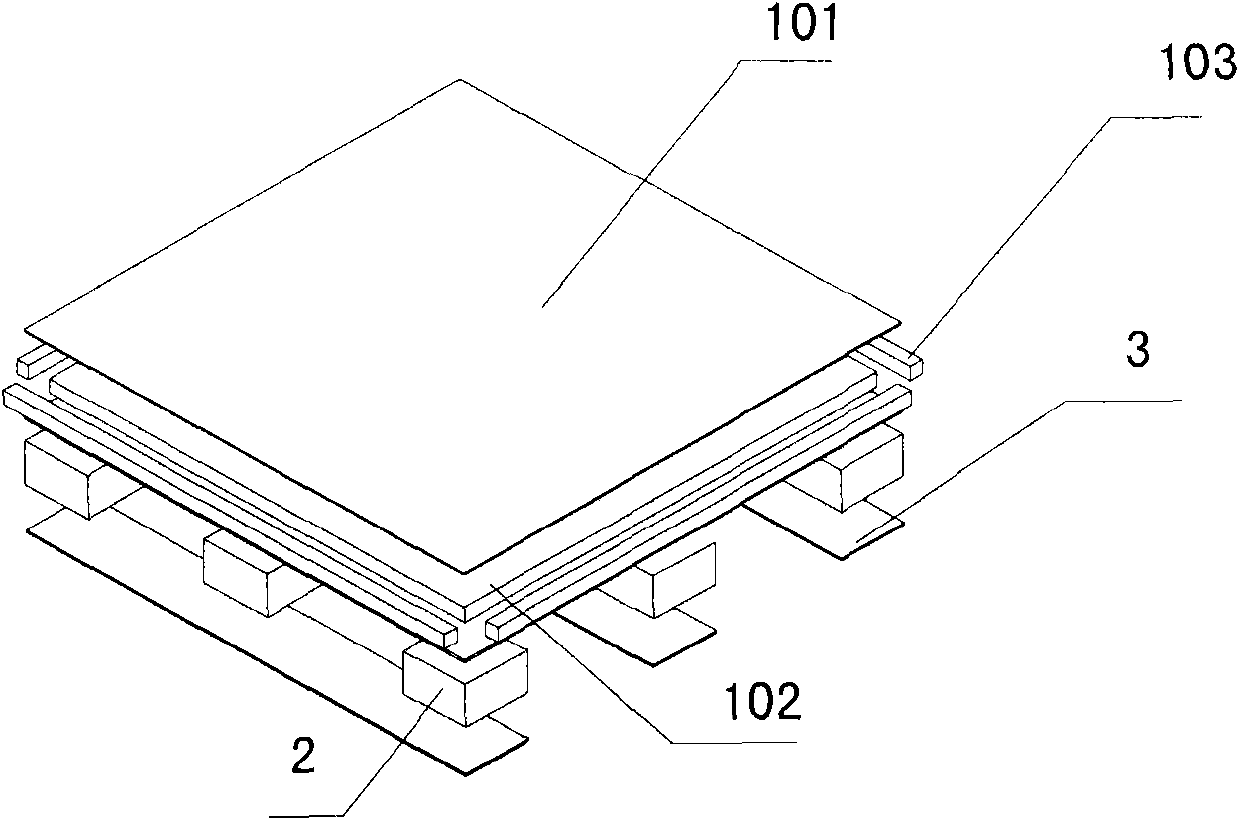

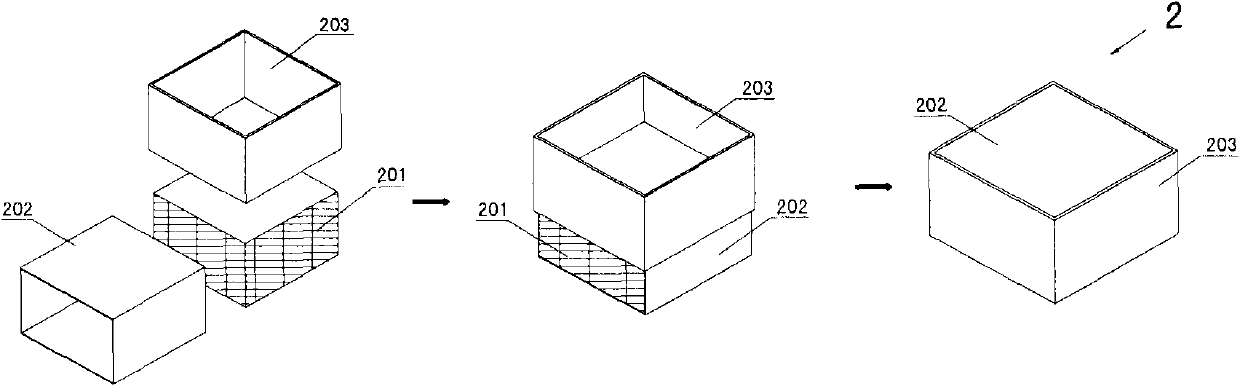

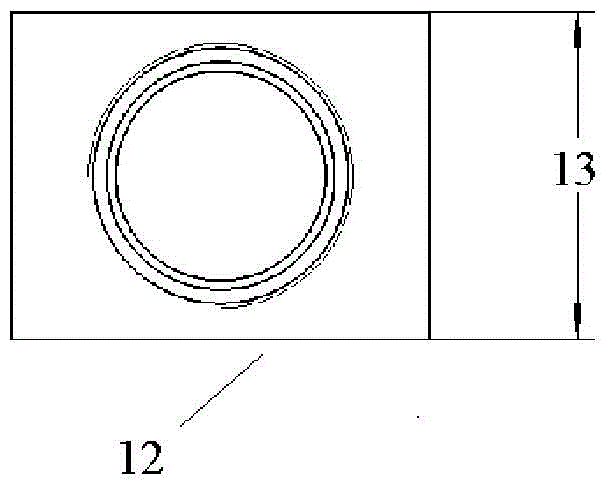

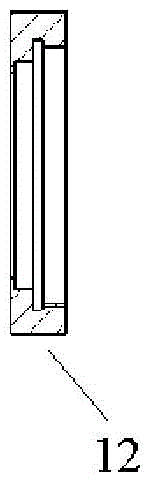

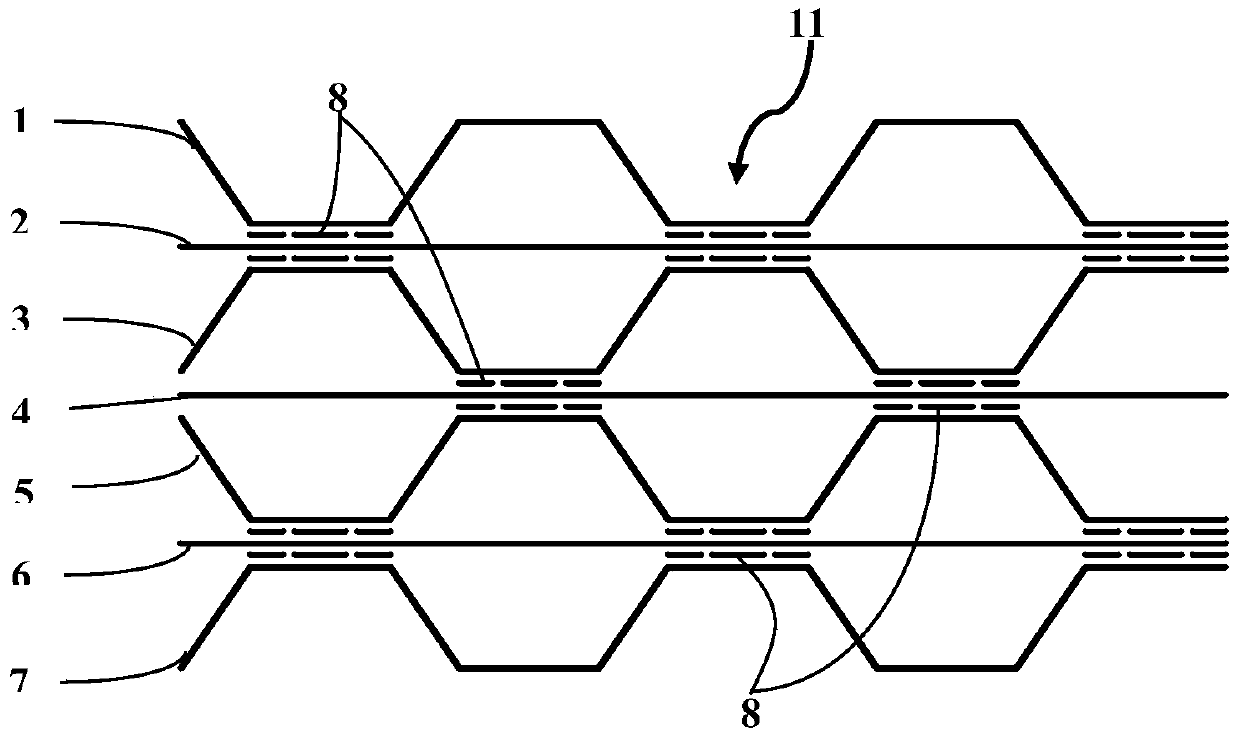

Honeycomb paperboard all-paper tray and manufacturing method thereof

InactiveCN102085939AWith strengthQuite strongPaper/cardboard articlesRigid containersEnvironmental resistanceCardboard

The invention discloses a honeycomb paperboard all-paper tray and a manufacturing method thereof. The honeycomb paperboard all-paper tray comprises a top board, bottom piers and a bottom belt, wherein the top board comprises a honeycomb paperboard base material, paper cardboards compounded on upper and lower surfaces of the honeycomb paperboard base material, and paper square tubes which are compounded at the periphery of the honeycomb paperboard base material; each bottom pier comprises a honeycomb paperboard filled block, an inner sleeve of the paper square tube and an outer sleeve of the paper square tube; the inner sleeve of the paper square tube is sleeved outside the honeycomb paperboard filled block; and the outer sleeve of the paper square tube is sleeved outside the honeycomb paperboard filled block and the inner sleeve of the paper square tube along a direction vertical to the direction of sleeving the inner sleeve of the paper square tube. The manufacturing method comprises the following steps of: manufacturing the top board; manufacturing the bottom piers; manufacturing the bottom belt; and adhering various bottom piers on the same bottom belt at intervals to form a bottom pier assembly, and parallelly adhering one end of each of the various bottom piers which is not adhered with the bottom belt to the lower surface of the top board. The honeycomb paperboard all-paper tray meets the requirement on environment friendliness, and has the advantages of low cost and high compressive strength and bending resistance.

Owner:青岛众和恒业蜂窝纸板制品有限公司

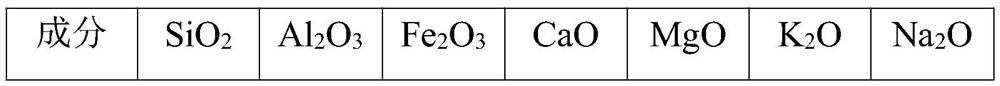

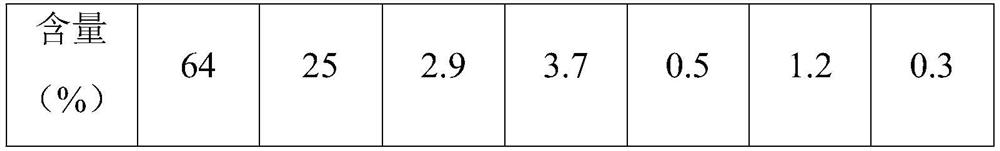

Diatomite asphalt mixture modification agent and modified asphalt mixture

InactiveCN105907115AImprove high temperature stabilityImprove wear resistanceBuilding insulationsFailure strainUltrasonic vibration

The invention discloses a diatomite asphalt mixture modification agent and a modified asphalt mixture. The diatomite asphalt mixture modification agent is prepared from activated diatomite and polyethylene wax, wherein the mass percent of the polyethylene wax is 2%-22%; the activated diatomite is diatomite obtained by carrying out an activation step on diatomite raw ores; the activation step comprises the following steps of crushing the diatomite raw ores, scrubbing, grading and carrying out ultrasonic vibration; the fineness of the activated diatomite is 325-800 meshes. Compared with an asphalt mixture modified by SBS (Styrene Butadiene Styrene), the dynamic stability DS of the asphalt mixture modified by the modification agent is increased by at least 30%, the water stability (residue stability) is increased by at least 3% and the low-temperature anti-cracking performance (low-temperature failure strain) is improved by at least 1%.

Owner:SICHUAN HONGHUI TECH

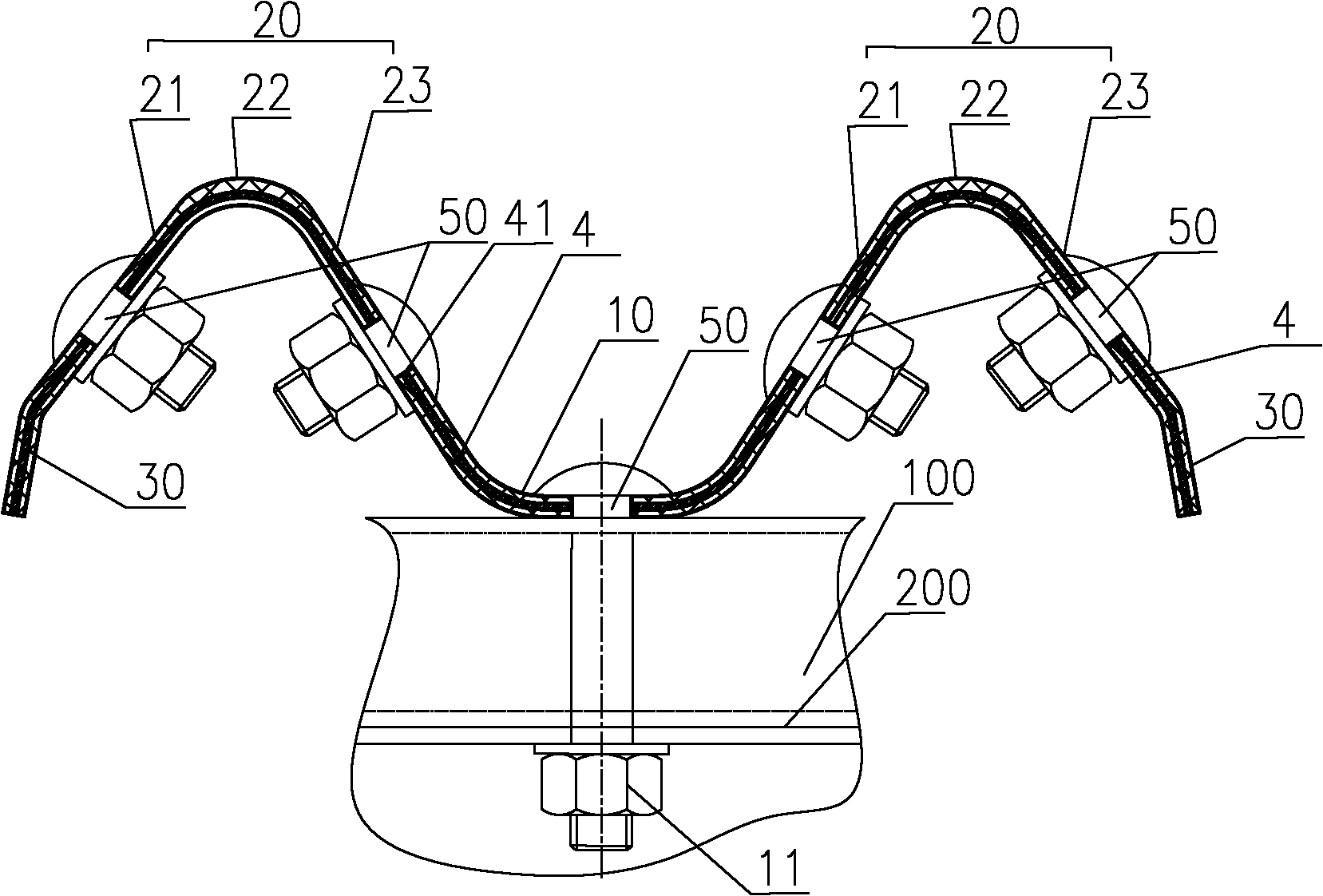

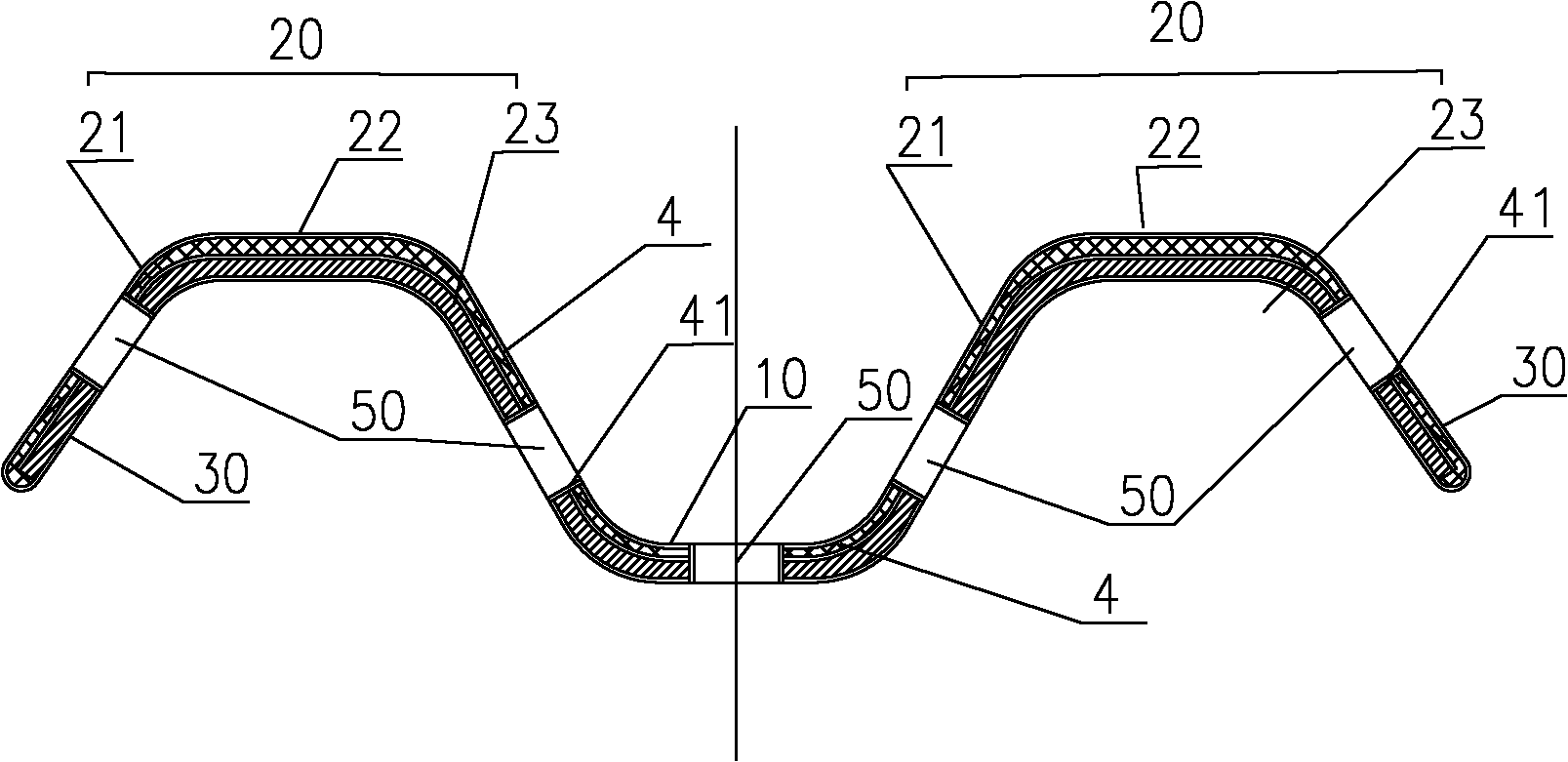

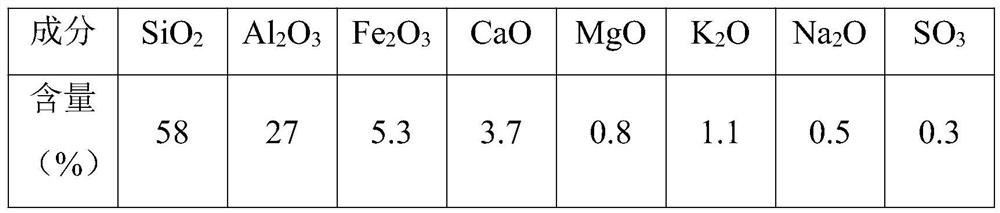

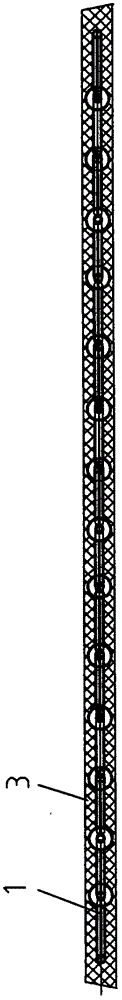

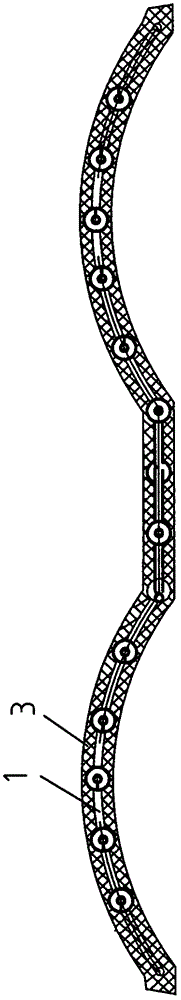

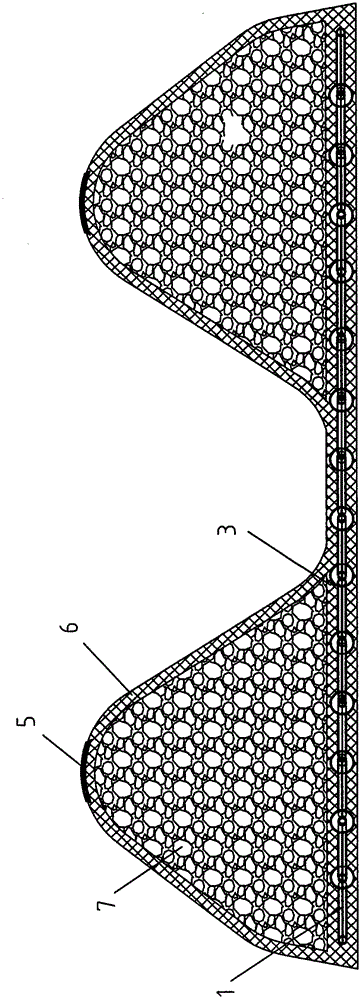

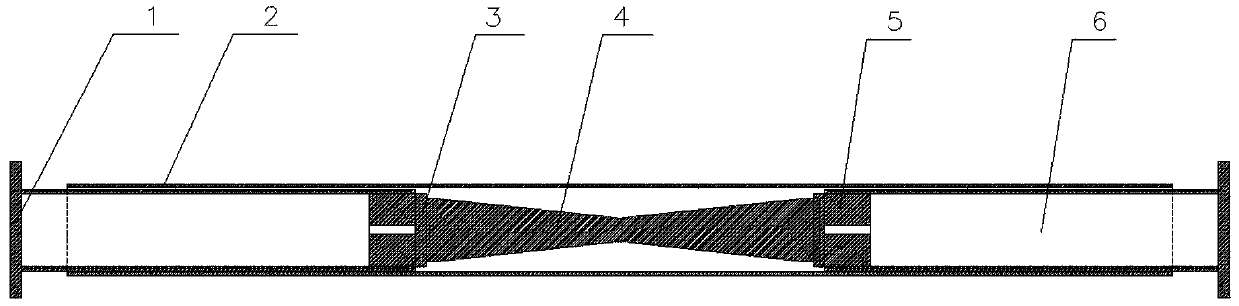

Energy-absorbing flexible guard board

InactiveCN105350474AQuite strongShorten speedRoadway safety arrangementsPlastic materialsEngineering

The invention discloses an energy-absorbing flexible guard board. Especially, a plurality of wireropes (1) are intertwined to form a latticed wirerope net (2), the wirerope net (2) is wrapped by a compact plastic material to form a composite board (3), at least more than three steel wires are twisted to form one wirerope (1), and any two adjacent wireropes (1) are intertwined at an interval to form knots (4) of the latticed wirerope net (2). The energy-absorbing flexible guard board is suitable for impact protection of various static objects and moving objects, and is especially suitable for serving as a highway protection plate, and has especially-dramatic effect, and can serve as an upgrade product of the highway protection plate.

Owner:王筱文

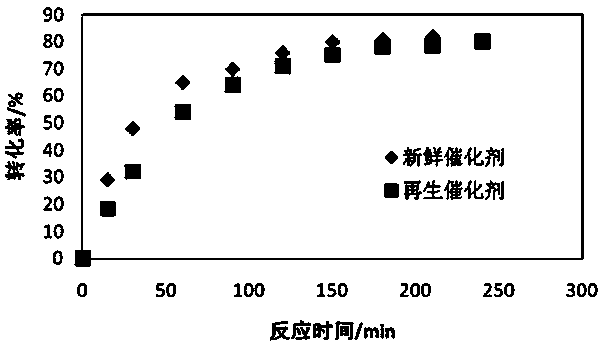

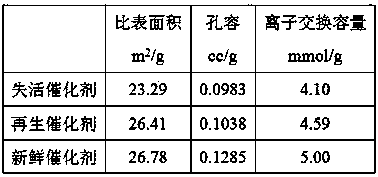

Method for regenerating catalysts for olefin esterification reaction and hydration reaction

InactiveCN104001554ASimple recycling processSimple and fast operationOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst regeneration/reactivationHydration reactionPtru catalyst

The invention provides a method for regenerating catalysts for an olefin esterification reaction and a hydration reaction. Polymer adsorbed at the active center positions of the surfaces of the catalysts is leached and washed through organic solvents, the organic solvents for leaching is washed through distilled water, and the adsorbed water is removed through drying. The obtained regenerated catalysts can replace new catalysts to be supplemented to the olefin esterification reaction and the hydration reaction, and the indexes, including the activity, the particle size, the strength and the like, of the regenerated catalysts and the new catalysts are all the same.

Owner:FUZHOU UNIV

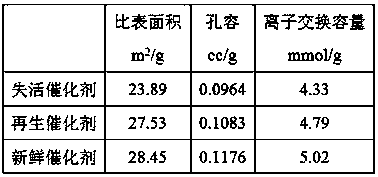

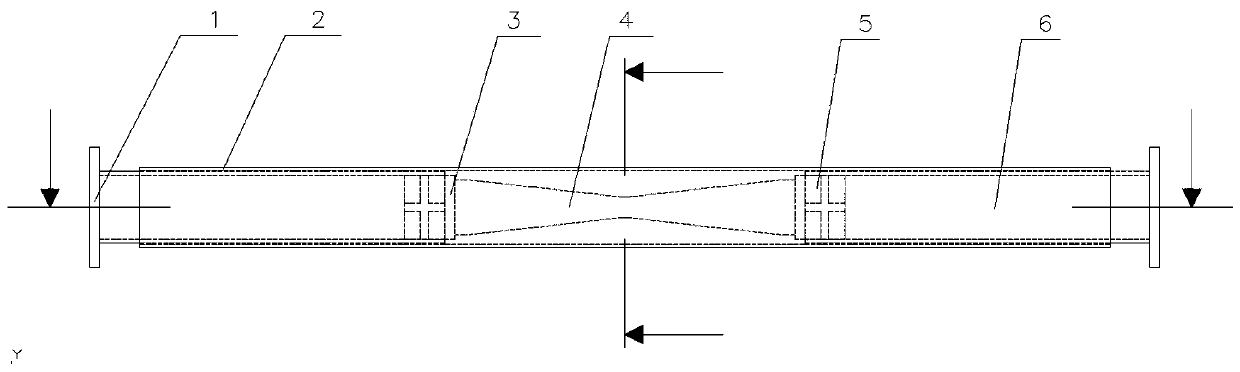

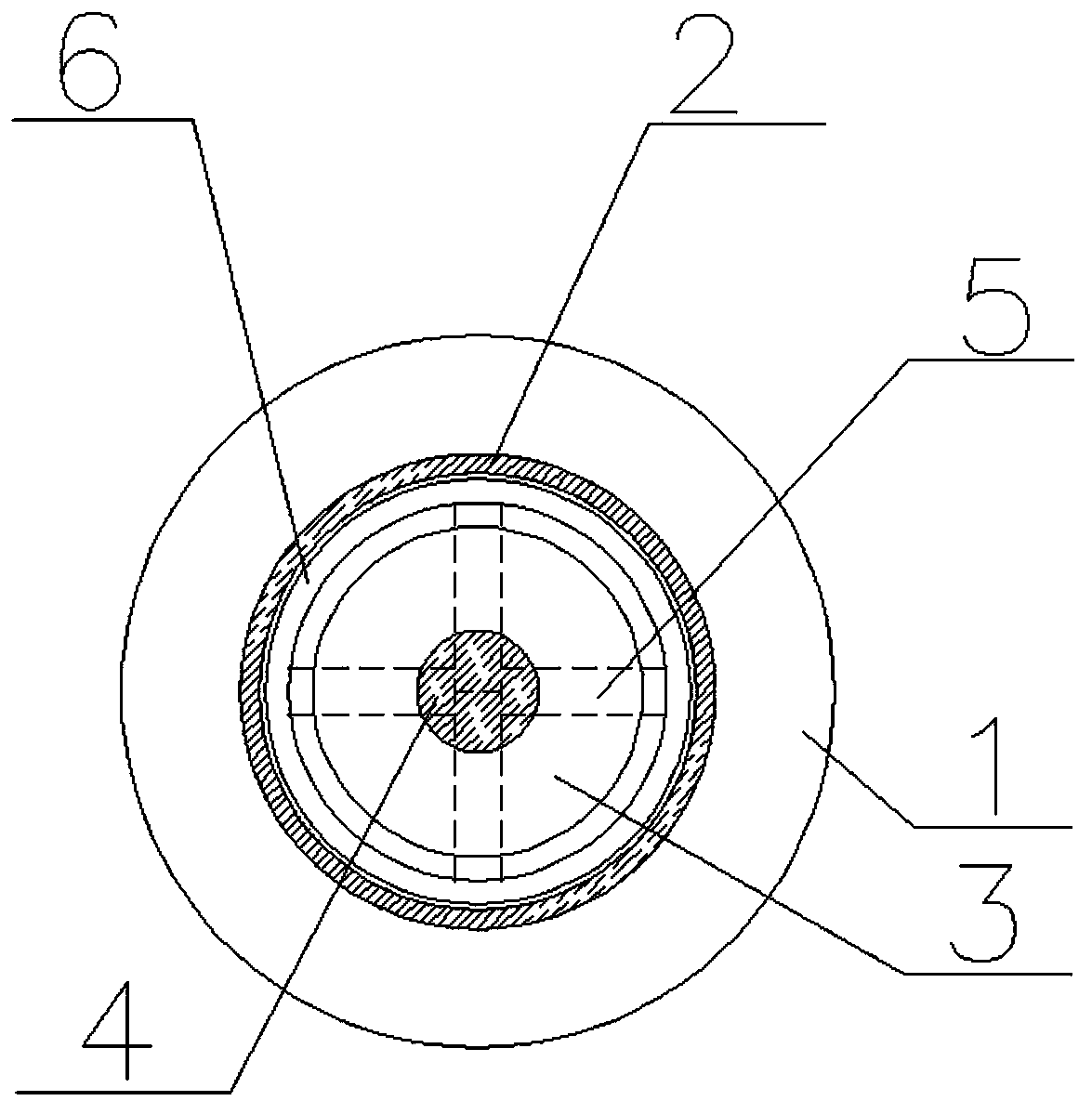

Novel assembled buckling-restrained brace

PendingCN111519784AQuite strongNo squeezeProtective buildings/sheltersShock proofingFriction weldingShock resistance

The invention discloses a novel assembled buckling-restrained brace. The novel assembled buckling-restrained brace comprises an outer connecting plate and an anti-instability steel pipe, the outer connecting plate is fixedly connected with a force transmission round pipe, the force transmission round pipe is nested in the anti-instability steel pipe, the end, away from the outer connecting plate,of the force transmission round pipe is connected with a round connecting end plate in a welded mode, and the other end of the round connecting end plate is connected with a dumbbell-shaped energy consumption cone steel bar in a friction welded mode, cross stiffening ribs are embedded in the ends, away from the connecting plates, of the force transmission round pipes, the circle centers of the force transmission outer connecting plates, the circle centers of the anti-instability steel pipes, the circle connecting end plates, the circle centers of the dumbbell-shaped energy dissipation cone steel bars, the circle centers of the cross stiffening ribs and the circle centers of the force transmission round pipes are located on the same axis, gaps of 2 mm are formed in the force transmission round pipes and the anti-instability steel pipes, and the cross stiffening rib is connected with the circular connecting end plate in a welding manner and is not fixedly connected with the force transfer circular pipe. The structure is convenient to machine, easy to install, environmentally friendly, capable of improving production efficiency, stable in structural form and capable of remarkably enhancing energy consumption capacity and improving shock resistance and shock absorption capacity of the structure.

Owner:山东天元建设机械有限公司 +1

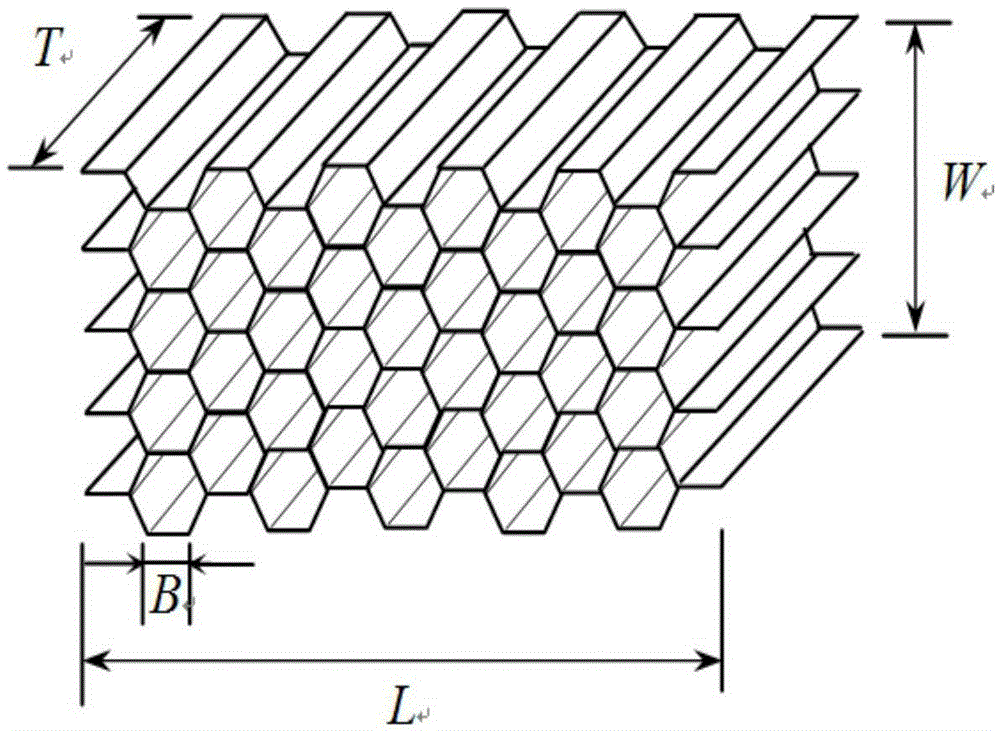

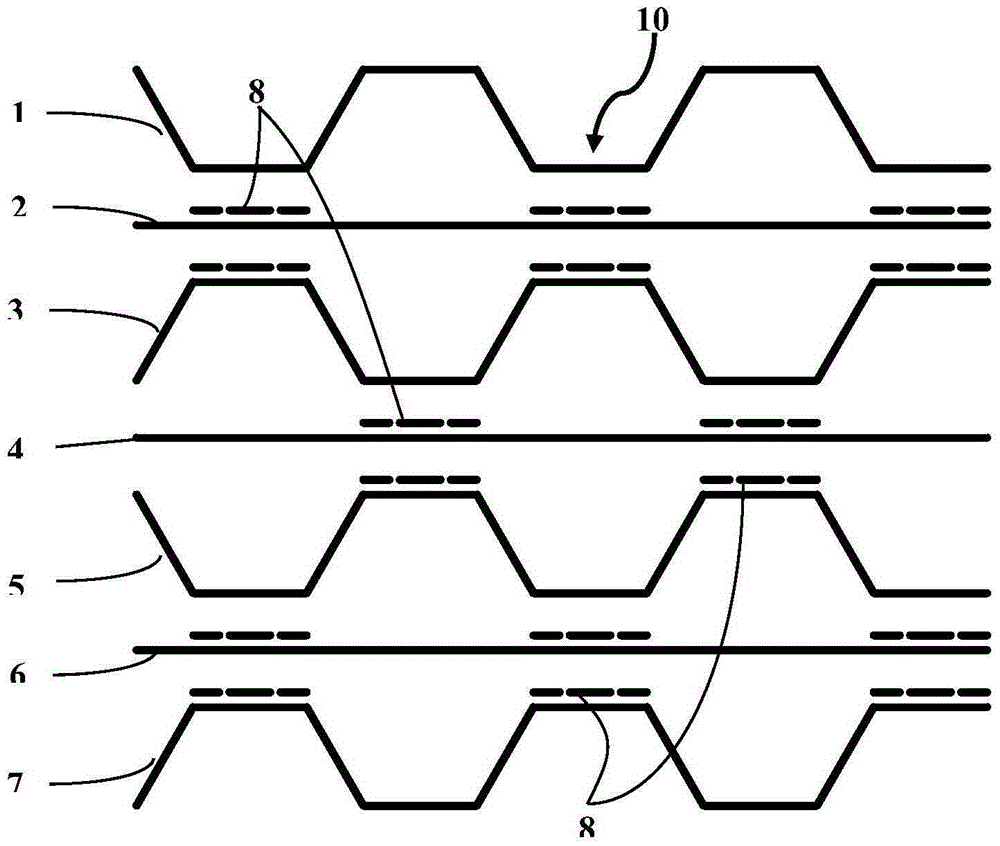

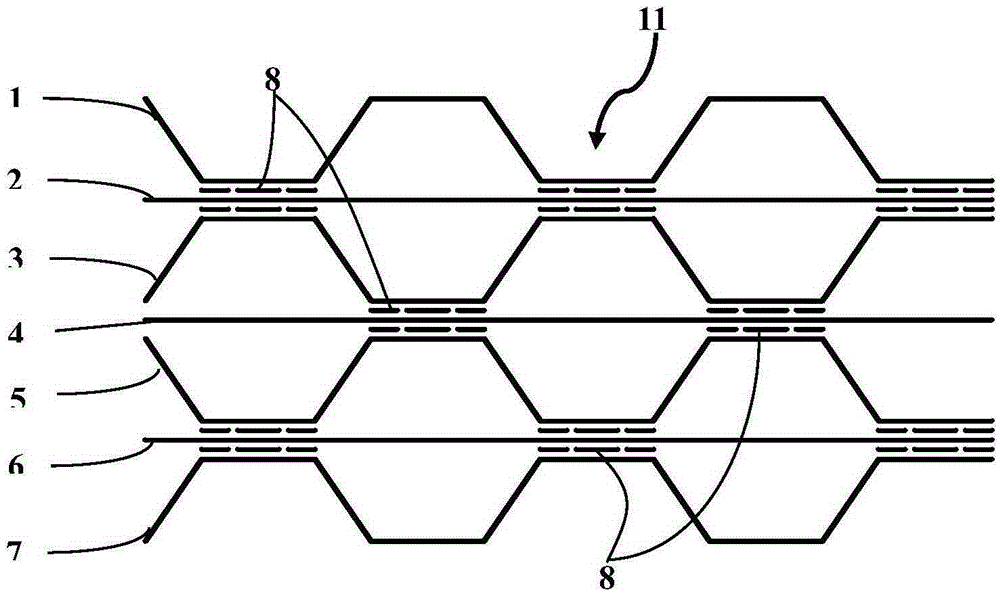

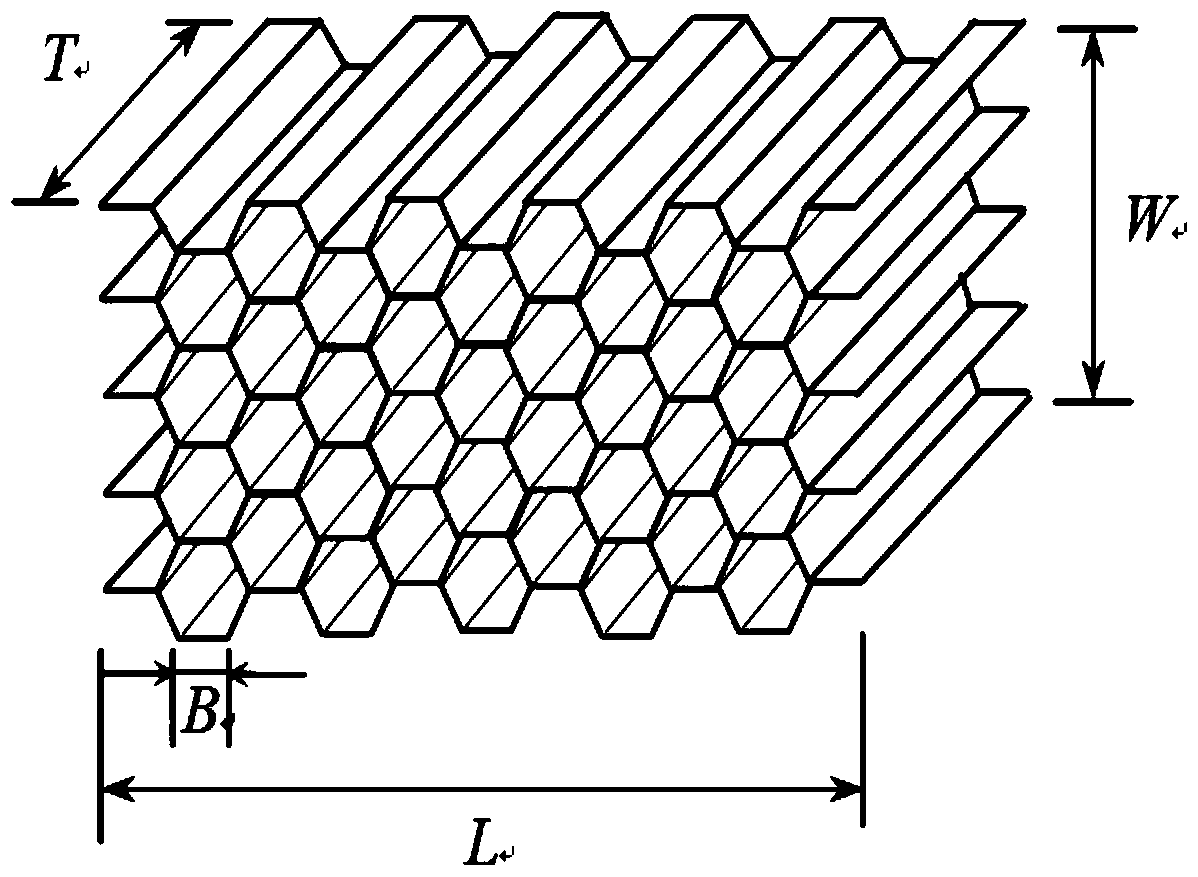

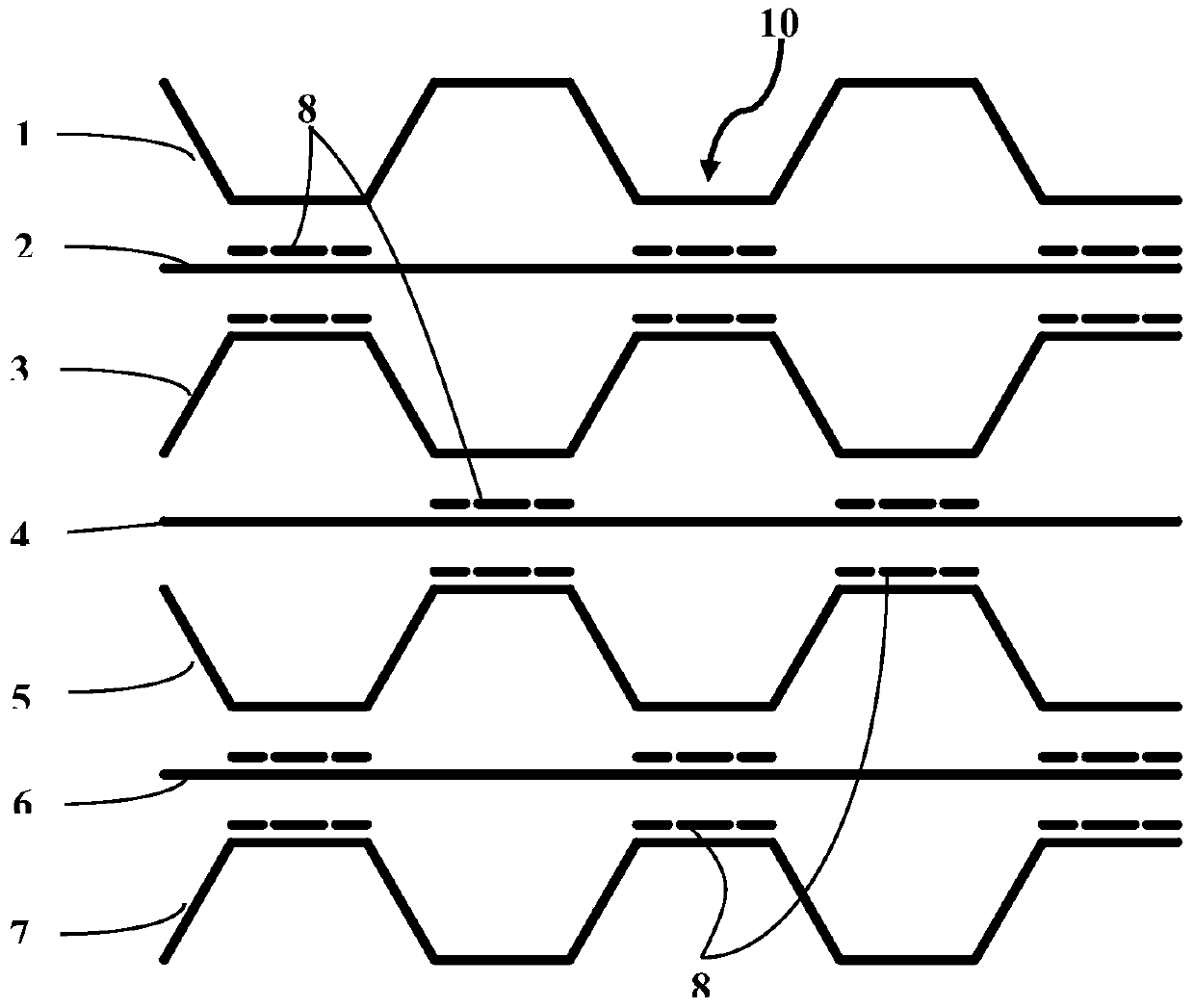

Thin slab layer for formation of enhanced honeycomb structure and preparation method of honeycomb structure

ActiveCN105291491AQuite strongImprove production efficiencyLamination ancillary operationsSynthetic resin layered productsAramidesCell wall

The invention provides a thin slab layer for formation of an enhanced honeycomb structure and a preparation method of the honeycomb structure. The thin slab layer for formation of the enhanced honeycomb structure and the preparation method of the honeycomb structure have the following beneficial effects: the problem that an enhanced honeycomb structure can only be manufactured by a forming method but cannot be manufactured by a tension method in the prior art is solved; a thin slab material at cell gluing positions in the forming-mode manufacturing is replaced with a strengthening layer of three cell wall width, and the position of binder line is changed between the thin slab material and the strengthening layer so as to realize tension-mode manufacturing; and materials which are not easy to form, such as aromatic polyamide paper, can be used to make the enhanced honeycomb structure, so as to expand the material application range and reduce manufacturing cost. Strength of the honeycomb structure obtained by the preparation method is similar to strength of a honeycomb structure prepared by a conventional forming method. The preparation method has high manufacturing efficiency.

Owner:北京金轮沃德科技有限公司

Imitation stone for outer curtain wall and production method

The invention relates to a decorative building material, in particular to an imitation stone for an outer curtain wall, and also provides a production method of the imitation stone for the outer curtain wall. Aiming at solving the problems of an existing outer curtain wall that line equidensity of granite and marble is high, weight is heavy, mounting is complex, chromatic aberration is obvious andprocessing speed is slow, a ratio that the imitation stone comprises 18-25% of cement, 17-22% of quartz sand, 17-24% of quartz powder, 16-22% of fibers and 16-21% of fine stuff is adopted, so that the imitation stone for the outer curtain wall is reduced by about 30% in density compared with existing natural stones such as the marble, and price is reduced by about 40%; and meanwhile, the processing speed is high, energy is saved, labor cost is also greatly saved, strength is equivalent, and the fiber ingredient is added, so that a thin plate made from the product of the invention hardly cracks, mounting benefit and speed are improved by about 30% during mounting, construction period is greatly shortened, and the labor cost is saved.

Owner:浙江创璞节能材料有限公司

Phosphorous slag aerated concrete and preparation method thereof

ActiveCN101708981BEmission reductionLow costSolid waste managementClinker productionSlagThermal insulation

The invention discloses a phosphorous slag aerated concrete. The concrete is characterized by consisting of a binding material, an exciting agent, an air entraining agent and water which are mixed, wherein the binding material consists of 60 to 100 weight percent of phosphorous slag and 0 to 40 weight percent of pulverized fuel ash; the exciting agent is water glass with modulus of 1.0 to 1.6; the water glass accounts for 5 to 8 weight percent of the binding material based on the weight of Na2O; the air entraining agent is aluminum powder or simple substance silicon; the using amount of the aluminum powder is 0.1 to 0.2 weight percent of the binding material; the using amount of the simple substance silicon is 0.05 to 0.1 weight percent of the binding material; and the weight ratio of theusing amount of the water to the using amount of the binding material is 0.28 to 0.32. The phosphorous slag aerated concrete product is prepared by taking the industrial waste slag such as the phosphorous slag and the like as the binding material and mixing the phosphorous slag, the exciting agent, the air entraining agent and the water. The phosphorous slag aerated concrete has the advantages that: the preparation process is simple without vapor-pressure process, so that the equipment investment can be greatly reduced; and the product is a sealed porous structure and has the characteristics of light weight, high strength, low thermal conductivity, good thermal insulation property and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Stainless cold-rolling strip steel and manufacturing method thereof

ActiveCN101724784BHigh strengthReduce manufacturing costRoll force/gap control deviceTemperature control deviceStrip steelMaterials science

The invention relates to a stainless cold-rolling strip steel containing the following components in percentage by weight: not more than 0.02 wt% of C, 0.3 to 0.80 wt% of Si, 0.2 to 0.80 wt% of Mn, not more than 0.040 wt% of P, not more than 0.15 wt% of S, 16.5 to 19.5 wt% of Cr, not more than 0.02 wt% of N, 0.2 to 0.6 wt% of Nb, 0.005 to 0.08 wt% of Al and the balance of Fe and inevitable impurities. The manufacturing method of the stainless cold-rolling strip steel comprises the following steps of: continuously casting the components into a plate blank after smelting, wherein the electromagnetic stirring is adopted in the continuous casting process so that the isometric crystal ratio of the section of the plate blank reaches above 40%; hot rolling: the plate blank is heated to 950 to 1200 DEG C, rolled into strip steel for multiple times and then coiled into a steel roll, wherein the final rolling temperature is 750 to 900 DEG C, the coiling temperature is 350 to 700 DEG C, and then the steel roll is air-cooled into the room temperature; cold rolling: the hot-rolled steel roll is firstly acid-washed, wherein the annealing temperature is 800 to 1000 DEG C, and the annealing time is 0.5 to 5.0 min; rolling for multiple times by cold rolling, wherein the overall reduction is 60% to 75%; and finally annealing the cold-rolled strip steel by acid washing, wherein the annealing temperature is 800 to 1,050 DEG C, and the annealing time is 0.5 to 3 min; and cooling the steel roll below 550 DEG C so that the high-strength strip steel is obtained.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

Method for preparing boracic low-alloy high-speed steel rolls

InactiveCN101623751BReduce heat treatment energy consumptionShort cycleFurnace typesHeat treatment furnacesRoom temperatureAlloy

The invention relates to a method for preparing boracic low-alloy high-speed steel rolls, which is characterized by comprising the following steps: firstly carrying out metal mold casting of the roll, wherein a roll body is made of boracic low-alloy high-speed steel, and a roll core is made of ductile cast iron; putting the roll into a heating furnace at the temperature of lower than 200 DEG C after rough machining, preserving heat for 1-3 hours, then heating to the temperature of 520-580 DEG C at the temperature rising speed of 15-25 DEG C per hour, and air cooling after heat preservation; and then, putting the roll into the heating furnace at the temperature of lower than 300 DEG C again, preserving heat for 1-2 hours, then heating to the temperature of 480-510 DEG C at the temperature rising speed of 28-40 DEG C per hour, cooling the furnace to the temperature of lower than 180 DEG C after heat preservation, and air cooling to the room temperature. The method not only has low energy consumption and a short heating processing period, but also has good use effect when being used for the heating processing of the boracic low-alloy high-speed steel roll.

Owner:BEIJING UNIV OF TECH

High-toughness zinc alloy material and preparation method thereof

The invention discloses a high-toughness zinc alloy material and a preparation method thereof. The alloy material takes zinc alloy as a substrate, and metal wire balls formed by copper wires and iron wires are distributed in the substrate, wherein the diameters of the copper wires and the iron wires are 1-2mm, the diameters of the metal wire balls are 10-15cm, the total lengths of the copper wires and the iron wires in the material are equal, and the copper wires and the iron wires account for 10-35% of the material in volume percent. The high-toughness zinc alloy material provided by the invention has stronger toughness, low production cost and a simple preparation process.

Owner:东莞市爱联实业有限公司

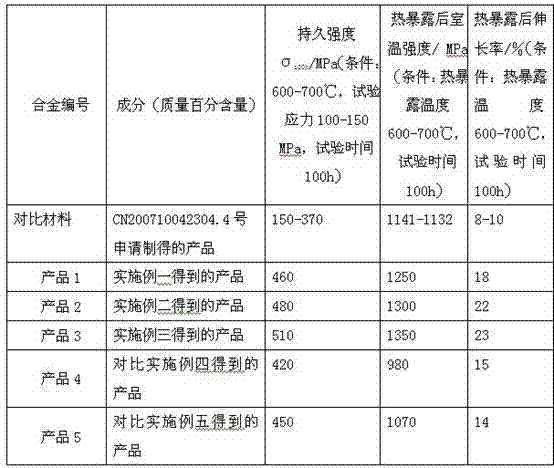

Heat-resistant titanium alloy material and preparation method thereof

Owner:金湖中博物联网科技有限公司

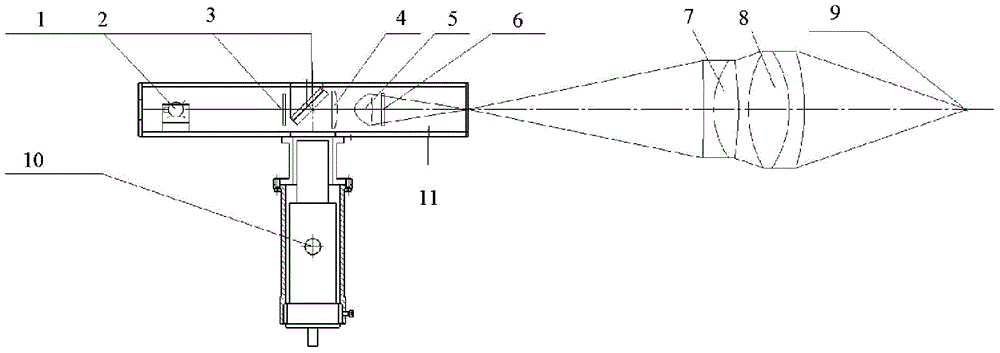

Calibration lamp system for astronomical observation spectrometer

The invention provides a calibration lamp system for an astroobservation spectrometer. The system is characterized in that the structure of the system is as follows: a color temperature filter, a semi-transparent semi-reflection mirror, a first group of lenses, a piece of frosted glass, and a second group of lenses are successively arranged at an optical axis of a white-light lamp source. A thorium-argon hollow cathode lamp is arranged at a vertical optical axis of the semi-transparent semi-reflection mirror. A distance between the filament of the white-light lamp and the semi-transparent semi-reflection mirror is equal to a distance between the filament of the thorium-argon hollow cathode lamp and the semi-transparent semi-reflection mirror. The first group of lenses are coupled with the second group of lenses by a focal point. According to the calibration lamp system provided by the invention, two kinds of light sources are coupled to one output point perfectly; and the system is essential to the astroobservation spectrometer. When the system is in use, the light source switching becomes convenient; the light source is uniform; and the intensities of the two groups of light are equal. A box body is used as an adjusting guide rail, thereby substantially simplifying the structure. The adjusting time and the manufacturing cost are saved.

Owner:NANJING INST OF ASTRONOMICAL OPTICS & TECH NAT ASTRONOMICAL OBSE

Sheet layer for forming reinforced honeycomb structure and method for preparing honeycomb structure

ActiveCN105291491BQuite strongImprove production efficiencyLamination ancillary operationsSynthetic resin layered productsAramidesUltimate tensile strength

The invention provides a thin slab layer for formation of an enhanced honeycomb structure and a preparation method of the honeycomb structure. The thin slab layer for formation of the enhanced honeycomb structure and the preparation method of the honeycomb structure have the following beneficial effects: the problem that an enhanced honeycomb structure can only be manufactured by a forming method but cannot be manufactured by a tension method in the prior art is solved; a thin slab material at cell gluing positions in the forming-mode manufacturing is replaced with a strengthening layer of three cell wall width, and the position of binder line is changed between the thin slab material and the strengthening layer so as to realize tension-mode manufacturing; and materials which are not easy to form, such as aromatic polyamide paper, can be used to make the enhanced honeycomb structure, so as to expand the material application range and reduce manufacturing cost. Strength of the honeycomb structure obtained by the preparation method is similar to strength of a honeycomb structure prepared by a conventional forming method. The preparation method has high manufacturing efficiency.

Owner:北京金轮沃德科技有限公司

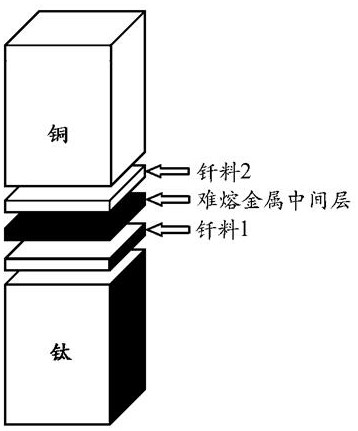

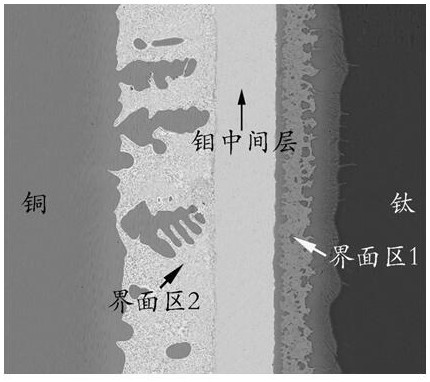

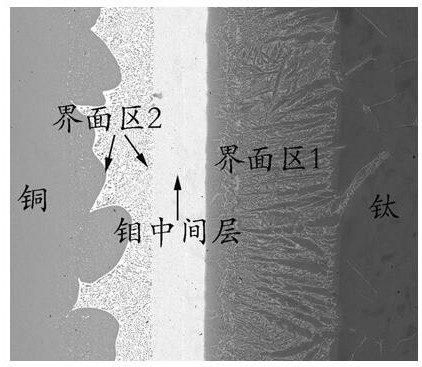

A connection structure and brazing method for welding titanium and copper by using multi-intermediate brazing filler metal

ActiveCN112605551BAvoid miscibilityElimination of brittle interfacial reaction productsSoldering apparatusWelding/soldering/cutting articlesTitaniumCopper

The invention discloses a connection structure for welding titanium and copper by using multi-intermediate layer brazing material, which comprises a titanium base material and a copper base material. The structure of the intermediate layer includes a brazing filler metal 1 and a brazing filler metal 2. A refractory metal intermediate layer is arranged between the brazing filler metal 1 and the brazing filler metal 2, and the refractory metal intermediate layer does not melt within the brazing temperature range; the brazing filler metal 1 is located in the titanium base metal. Between the interlayer of the refractory metal and melting at the brazing temperature to realize the diffusion brazing connection; the brazing filler metal 2 is located between the interlayer of the refractory metal and the copper base material, and melts at the brazing temperature to realize the active brazing connection The brazing method comprises the following steps: pre-treatment of the surfaces to be welded of titanium base material and copper base material; pre-treatment of multi-intermediate layer materials; assembly of brazed components; brazing in furnace; solving joints in conventional titanium-copper welding The problem of generating a large amount of brittle intermetallic compounds at the interface leads to a titanium-copper joint without brittle interface reaction products.

Owner:CHONGQING UNIV OF TECH

A medium-strength and high-ductility titanium alloy

ActiveCN105925843BQuite strongGood high temperature oxidation resistanceRoom temperatureLiquid hydrogen

The invention provides medium-strength high-plasticity titanium alloy. The medium-strength high-plasticity titanium alloy is prepared from, by mass, 11%-26% of Nb, 4%-11% of Mo+W, 0.08%-0.19% of O and the balance Ti and inevitable impurities, wherein Mo>=3%, and 0%<=W<=4%. After the titanium alloy is subjected to heat treatment, the room temperature tensile strength of the alloy is 600-800 MPa, the room temperature ductility is not smaller than 20%, the cold and heat machinability is excellent, and the titanium alloy has high plasticity under the normal temperature condition and the liquid hydrogen temperature condition and can meet the requirement for rivets and ultralow-temperature structural parts in the application fields such as the aviation field and the aerospace field.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

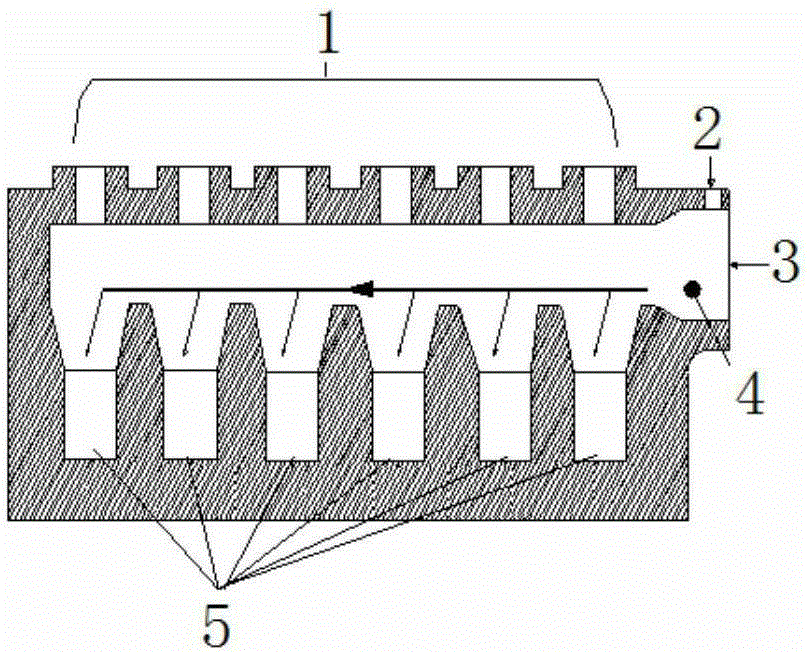

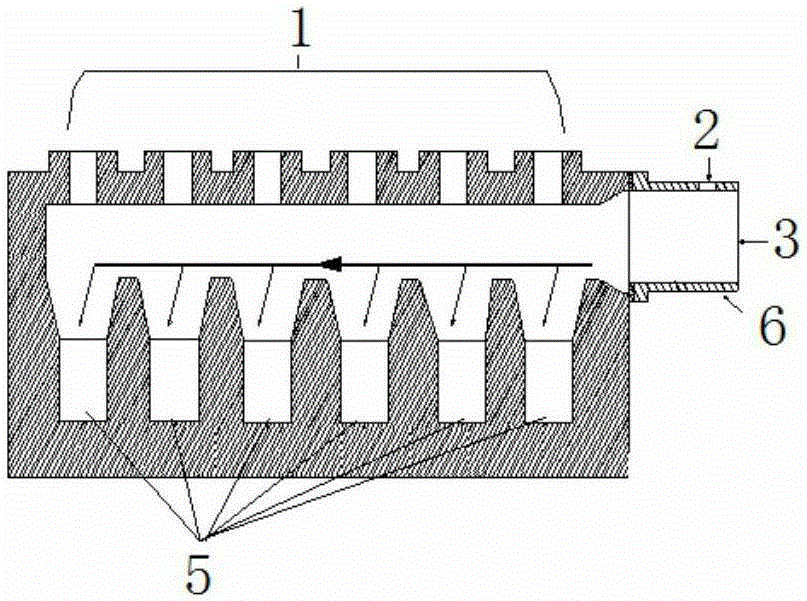

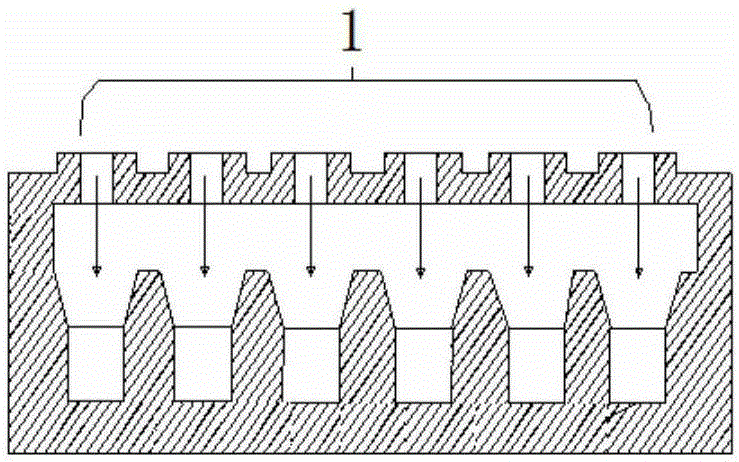

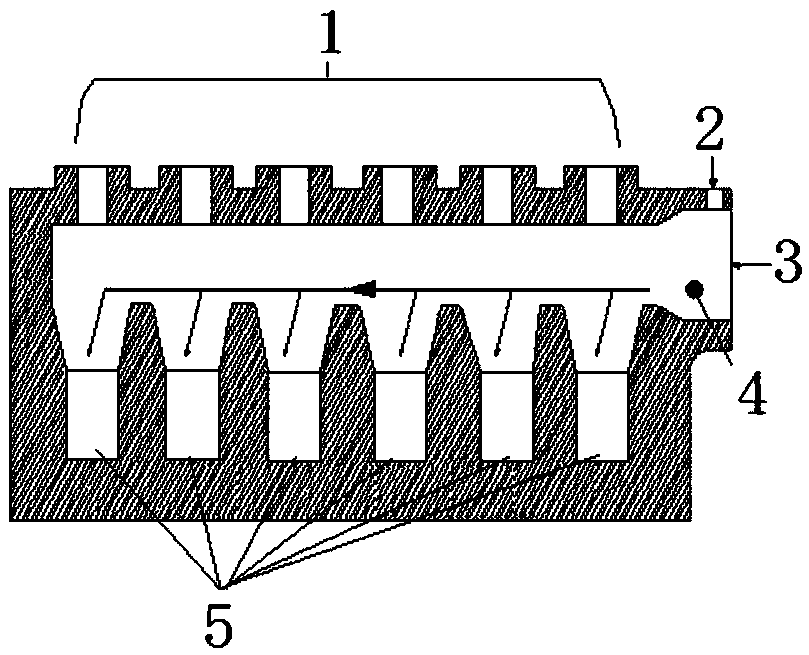

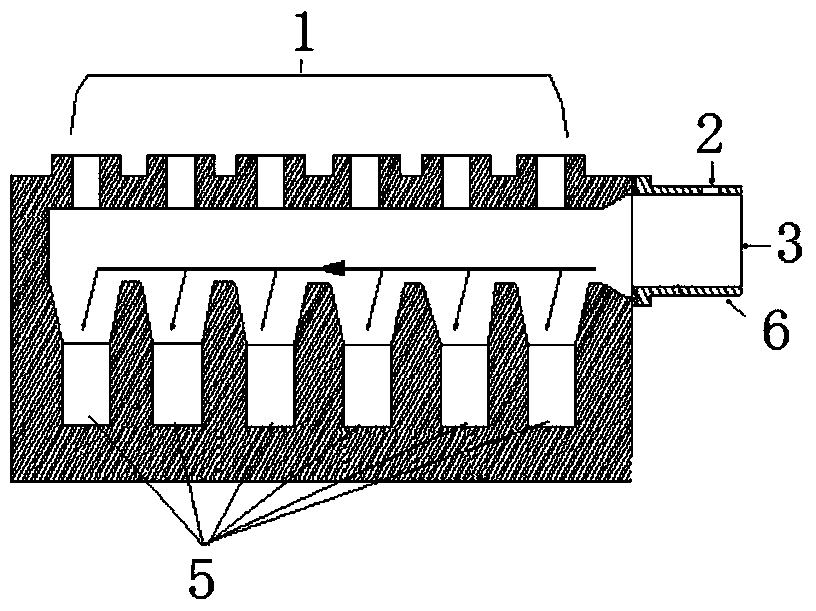

Gas engine cylinder cover

ActiveCN105201677AReduce in quantityReduce installation processInternal combustion piston enginesFuel supply apparatusCombustion chamberCombustor

The invention discloses a gas engine cylinder cover comprising a gas cylinder cover in which a gas inlet manifold and a gas mixing chamber are arranged; the gas cylinder cover is in an integrated structure with the gas inlet manifold and the gas mixing chamber; the gas inlet manifold is provided with a gas nozzle hole; an air inlet is corresponding to one end of the gas inlet manifold; the gas cylinder cover is integrated with the gas inlet manifold and the gas mixing chamber to form one part, so that the number of parts of an engine is reduced, installation processes are reduced, the whole quality is improved, and the structure is compact; the gas inlet manifold is integrated onto the gas cylinder cover, so that the strength of the gas inlet manifold is the same with that of the gas cylinder cover, the structural strength of the gas inlet manifold is extremely improved, the gas inlet manifold can bear the explosion mixture shock same to that on a combustor, and the reliability of the gas inlet manifold is enhanced.

Owner:Y & C ENGINE

Aging heat treatment method for 7 series aluminum alloy

The invention discloses an aging heat treatment method for a 7-series aluminum alloy, and belongs to the field of non-ferrous metal materials and heat treatment thereof. The aging heat treatment method is used for the 7-series aluminum alloy after solid solution treatment, and comprises the following steps that (1) first-stage aging is performed, specifically, a 7-series aluminum alloy workpiece is placed in a heating furnace of 90-120 DEG C for heat preservation for 10-30h; (2) second-stage aging is performed, specifically, the temperature is raised to a second-stage predetermined aging temperature of 165 DEG C-185 DEG C along with the furnace, and after the heat preservation is performed for 1-5h, the 7-series aluminum alloy workpiece is subjected to water cooling to the room temperature; (3) third-stage aging is performed, specifically, the 7-series aluminum alloy workpiece is then placed at a third-stage predetermined aging temperature of 60-90 DEG C for heat preservation for 20-30h; and (4) fourth-stage aging is performed, specifically, the temperature is raised to a fourth-stage predetermined aging temperature of 90-110 DEG C along with the furnace, and after the heat preservation is performed for 10-30h, the 7-series aluminum alloy workpiece is subjected to air cooling to the room temperature. In the second-stage high-temperature aging process, a method of lowering the temperature than the RRA temperature and increasing the heat preservation time is adopted, and the problem of uneven structure and performance caused by the temperature gradient due to rapid heating and cooling of large components is solved.

Owner:BEIJING NAT INNOVATION INST OF LIGHTWEIGHT LTD +1

A gas engine cylinder head

ActiveCN105201677BReduce in quantityReduce installation processInternal combustion piston enginesFuel supply apparatusCombustorCombustion chamber

The invention discloses a gas engine cylinder cover comprising a gas cylinder cover in which a gas inlet manifold and a gas mixing chamber are arranged; the gas cylinder cover is in an integrated structure with the gas inlet manifold and the gas mixing chamber; the gas inlet manifold is provided with a gas nozzle hole; an air inlet is corresponding to one end of the gas inlet manifold; the gas cylinder cover is integrated with the gas inlet manifold and the gas mixing chamber to form one part, so that the number of parts of an engine is reduced, installation processes are reduced, the whole quality is improved, and the structure is compact; the gas inlet manifold is integrated onto the gas cylinder cover, so that the strength of the gas inlet manifold is the same with that of the gas cylinder cover, the structural strength of the gas inlet manifold is extremely improved, the gas inlet manifold can bear the explosion mixture shock same to that on a combustor, and the reliability of the gas inlet manifold is enhanced.

Owner:Y & C ENGINE

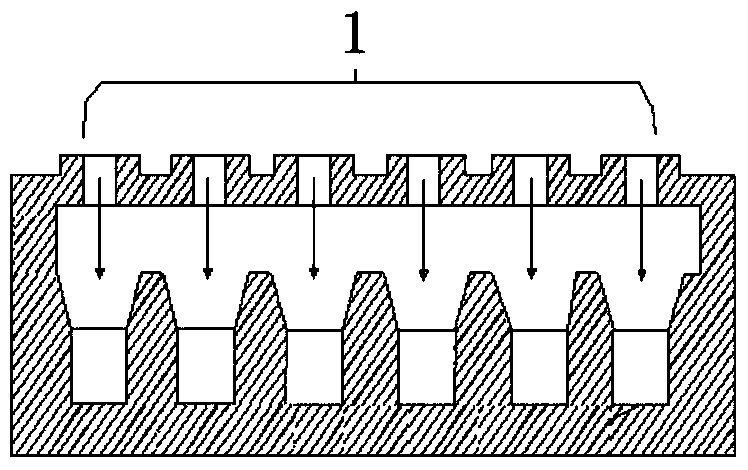

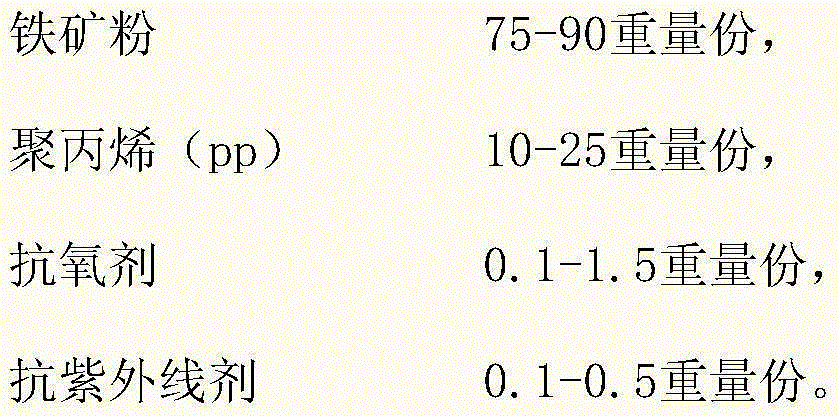

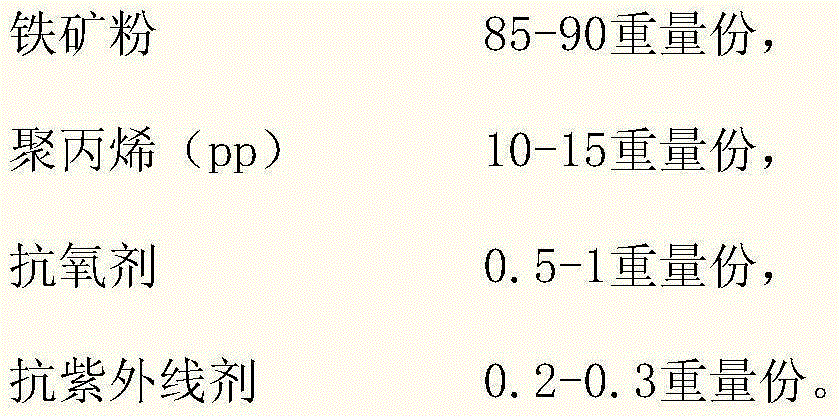

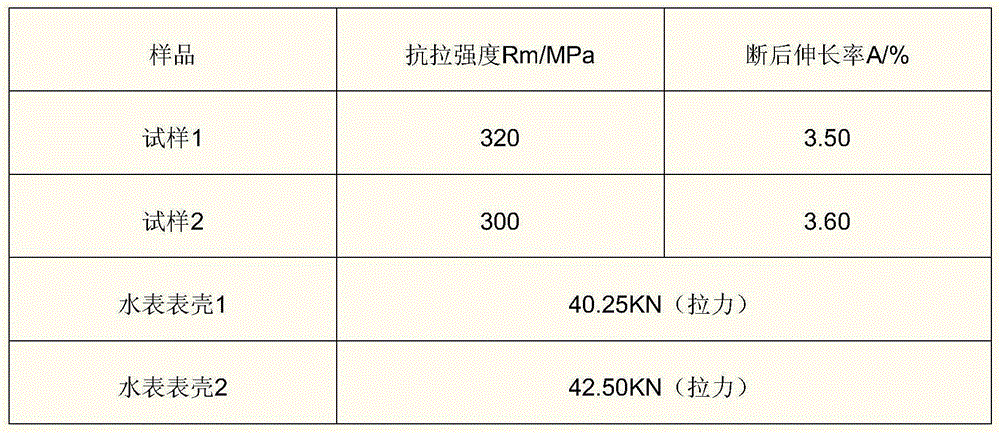

Water meter casing material and preparation method thereof

Owner:宁波金泉智能水表有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com