High-toughness zinc alloy material and preparation method thereof

A zinc alloy, strong and tough technology, applied in the field of strong and tough zinc alloy materials and their preparation, can solve the problems of enhanced toughness and complicated preparation process, and achieve the effects of improved strength and toughness, simple preparation process, and high strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

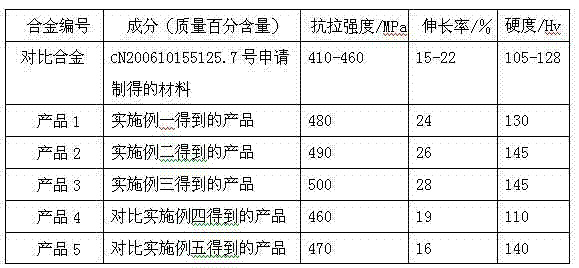

Embodiment 1

[0026] Preparation of cobalt-plated copper wire and chrome-plated iron wire:

[0027] The copper wire is pure copper, and its diameter is 1mm.

[0028] The weight percentage of the chemical composition of the iron wire: C is 0.05%, Si is 0.2%, Mn is 0.25%, P<0.02%, S<0.025%, and the rest is Fe; the diameter of the iron wire is 1mm.

[0029] The overall lengths of the copper wire and the iron wire are equivalent, and the two metal wires account for 10% of the volume of the material.

[0030] Take the copper wire and carry out cobalt-plating treatment on its surface according to the conventional method to prepare cobalt-plated copper wire; the thickness of the cobalt-plated layer is 50 microns.

[0031] The surface of the iron wire was chrome-plated according to a conventional method to prepare a chrome-plated iron wire; the thickness of the chrome-plated layer was 100 microns.

[0032] According to the conventional method of cleaning ball production, each of the above-mention...

Embodiment 2

[0036] Zinc alloy matrix composition by weight percentage: Al is 46%, Sr is 0.5%, Si is 3%, Cu is 4%, Pb is 3%, Fe is 1.2%, Gd is 1%, Mn is 6%, Ho is 0.03%, and the rest is Zn for compounding.

[0037] The copper wire is pure copper with a diameter of 2mm.

[0038] The weight percentage of the chemical composition of the iron wire: C is 0.09%, Si is 0.3%, Mn is 0.35%, P<0.02%, S<0.025%, and the rest is Fe; the diameter of the iron wire is 2mm.

[0039] The overall lengths of the two copper wires and iron wires are equivalent, and the two metal wires account for 35% of the volume of the material.

[0040] Take the copper wire and carry out cobalt-plating treatment on its surface according to the conventional method to prepare cobalt-plated copper wire, and the thickness of the cobalt-plated layer is 150 microns. The surface of the iron wire was chrome-plated according to a conventional method to prepare a chrome-plated iron wire; the thickness of the chrome-plated layer was 2...

Embodiment 3

[0043] Zinc alloy matrix composition by weight percentage: Al is 41%, Sr is 0.4%, Si is 2%, Cu is 3%, Pb is 2%, Fe is 0.9%, Gd is 0.7%, Mn is 5%, Ho is 0.02%, and the rest is Zn for compounding.

[0044] The copper wire is pure copper with a diameter of 1.5mm.

[0045] The weight percentage of the chemical composition of the iron wire: C is 0.07%, Si is 0.25%, Mn is 0.3%, P<0.02%, S<0.025%, and the rest is Fe; the diameter of the iron wire is 1.5mm.

[0046] The overall lengths of the copper wire and the iron wire are equivalent, and the volume percentage of the two metal wires is 25% of the material.

[0047] Take the copper wire and carry out cobalt-plating treatment on its surface according to the conventional method to prepare cobalt-plated copper wire, and the thickness of the cobalt-plated layer is 80 microns. The surface of the iron wire was chrome-plated according to a conventional method to prepare a chrome-plated iron wire; the thickness of the chrome-plated layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com