Axle case for turning drive vehicle axle

A technology for driving axles and axle housings, applied in the directions of axles, wheels, vehicle components, etc., can solve the problems of poor ability to withstand overturning moments, inflexible design and manufacture of deformation, and low impact bearing capacity, etc. , The appearance is simple and beautiful, and the cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

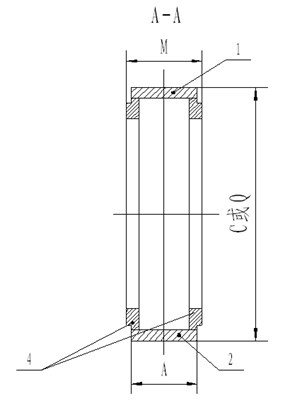

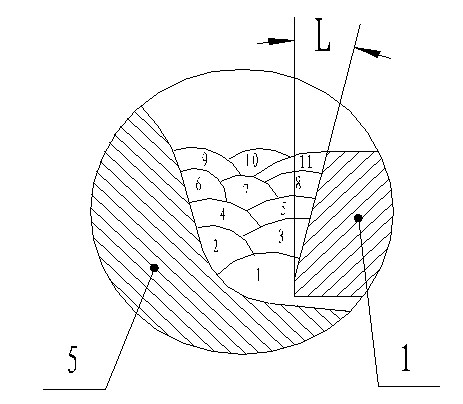

[0037] like figure 1 As shown, a steering drive axle housing A includes an upper cover plate 1, a lower cover plate 2, four side plates 3, two steel rings 4, and two steering forks 5. The materials of the upper cover plate 1, the cover plate 2, the side plate 3 and the steel ring 4 are all steel plates. The middle part of the upper cover plate 1 and the lower cover plate 2 is a U-shaped structure facing opposite, the bottom is arc-shaped, and the two sides of the arc are transition slopes. Two steel rings 4 are welded in the middle of the arc, and the steel rings 4 have the effect of reinforcing ribs, which can strengthen the strength of the shell and improve the torsional rigidity. The outer diameter of the steel ring 4 fits with the arcs of the side plate 3 , the upper cover plate 1 and the lower cover plate 2 respectively. The side plate 3 is adapted to the shape of the upper cover plate 1, the lower cover plate 2 and the steel ring 4, the two ends of the side plate 3 are...

Embodiment 2

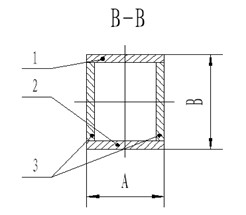

[0040] like figure 2 As shown, a steering drive axle housing B includes an upper cover plate 1, a lower cover plate 2, four side plates 3, two steel rings 4, and two steering forks 5. The materials of the upper cover plate 1, the cover plate 2, the side plate 3 and the steel ring 4 are all steel plates. The middle part of the upper cover plate 1 and the lower cover plate 2 is a U-shaped structure facing opposite, the bottom is flat, and the inclined surfaces on both sides of the bottom are in arc transition with the bottom plane and the straight line sections at both ends of the cover plate. Two steel rings 4 are welded in the middle of the U shape, and the steel rings 4 have the effect of reinforcing ribs, which can strengthen the strength of the shell and improve the torsional rigidity. The outer diameter of the steel ring 4 is attached to the arc of the side plate 3, the upper cover plate 1 and the lower cover plate 2 respectively. The side plate 3 is adapted to the shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com