Imitation stone for outer curtain wall and production method

An exterior curtain wall and imitation stone technology, which is applied in the field of building decoration materials, can solve the problems of slow processing speed, affect the progress of the project, and high labor costs, and achieve the effects of increasing installation efficiency, saving labor costs, and fully utilizing resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

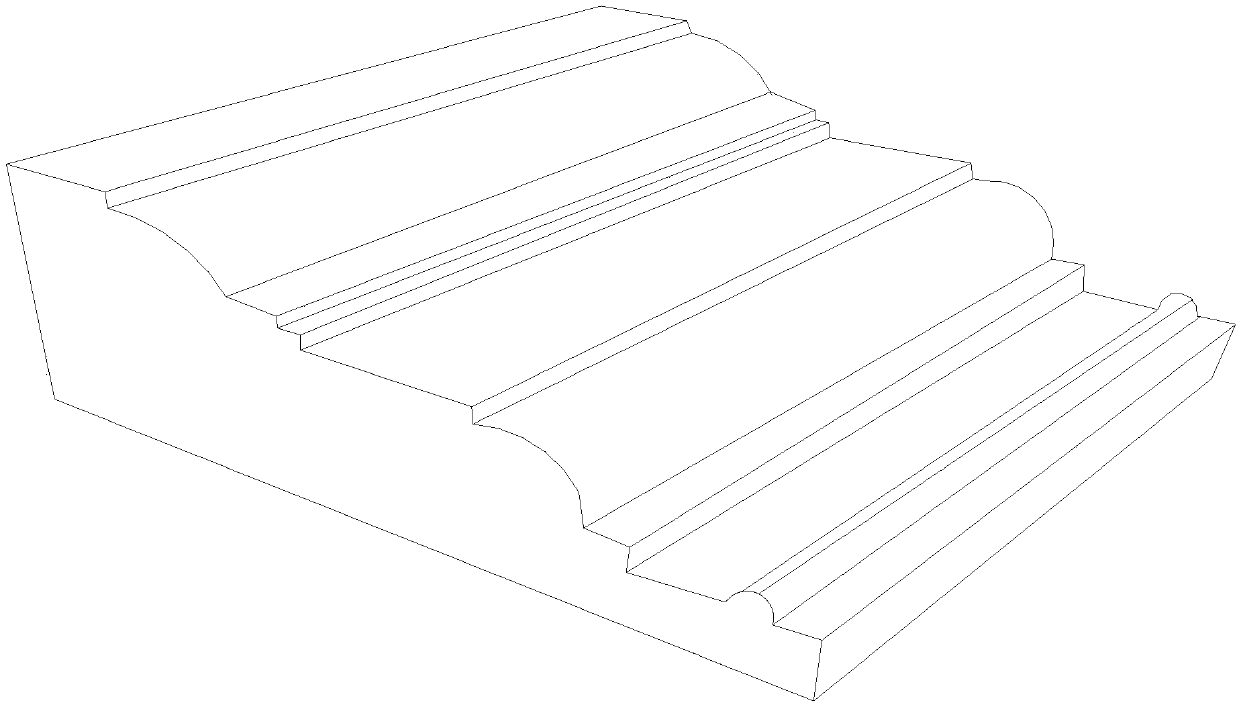

Image

Examples

Embodiment

[0031] The imitation stone of the outer curtain wall mentioned in the present invention mainly includes cement, quartz sand, quartz powder, fiber and fine material, and the cement is Portland cement, and its main components are tricalcium silicate, dicalcium silicate and tricalcium aluminate. , Tetracalcium ferric aluminate, the fine material is the stone powder precipitated in the production, the fiber composition is ,,,,,,, and the composition is the total mass of cement 18%~25%, quartz sand 17%~ 22%, quartz powder 17%~24%, fiber 16%~22%, fine material 16%~21%. It is the best ratio made by the company's experimental staff after many experiments and comparisons, and it has certain enhancements compared with the original stone imitation indicators.

[0032] It is further explained that the ratio of the main components of the imitation stone of the outer curtain wall is that the mass ratio of cement: quartz sand: quartz powder: fiber: fine material is 1:1:1:1:1. The cement use...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com