Phosphorous slag aerated concrete and preparation method thereof

A technology of air-entrained concrete and phosphorus slag, which is used in ceramic products, climate sustainability, other household appliances, etc., to achieve novel processing technology, reduce CO2 emissions, and reduce consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

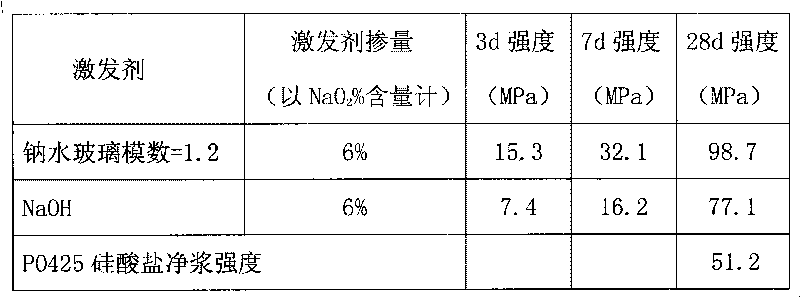

Examples

Embodiment 1

[0047] A kind of phosphorus slag aerated concrete and preparation method thereof, comprises the following steps:

[0048] a. Preparation of water glass with a modulus of 1.2: Weigh 211.4 g of commercially available water glass with a modulus of 3.16, add 48.0 g of flake NaOH, and stir with a glass rod until NaOH is completely dissolved. ready for use;

[0049] B, weighing: get mixed into cementitious material by the proportion of phosphorus slag 80% (weight percent example, the same after), fly ash 20%; Water glass modulus 1.2; Alkali content 6% (being the consumption of water glass Press Na 2 O weight is calculated as 6% of the weight of the gelled material); 0.1% of the air-entraining agent aluminum powder (that is, the consumption of the aluminum powder is 0.1% of the weight of the gelled material), and the ratio of water to the gelled material is 0.3. The total amount of powder prepared in this embodiment is 1000g, and the specific data is taken by weighing as follows: ...

Embodiment 2

[0057] A kind of phosphorus slag aerated concrete and preparation method thereof, comprises the following steps:

[0058] a. Preparation of water glass with a modulus of 1.0: Weigh 205.5 g of commercially available water glass with a modulus of 3.16, add 61.7 g of flake NaOH, and stir with a glass rod until NaOH is completely dissolved. ready for use;

[0059] B, weighing: phosphorus slag 90% (weight percent example, the same afterward), fly ash 10% ratio is taken and mixed into cementitious material; Water glass modulus 1.0; Alkali content 7% (being the consumption of water glass according to Na 2 O weight is calculated as 7% of the gelled material weight); Aluminum powder 0.1% (the consumption that is aluminum powder is 0.1% of the gelled material weight); Water and the ratio 0.28 of the gelled material. The total amount of powder prepared in this example is 1000g, and the specific data is taken by weighing as follows:

[0060] 900g of phosphorus slag; 100g of fly ash; 1....

Embodiment 3

[0067] A kind of phosphorus slag aerated concrete and preparation method thereof, comprises the following steps:

[0068] a. Preparation of water glass with a modulus of 1.2: Weigh 246.6g of commercially available water glass with a modulus of 3.16, add 56.0g of flake NaOH, and stir with a glass rod until NaOH is completely dissolved. ready for use;

[0069] B, weighing: phosphorus slag 80% (weight percent example, the same afterward), fly ash 20% ratio is taken and mixed into cementitious material; Water glass modulus 1.2; Alkali content 7% (being the consumption of water glass according to Na 2 O weight is calculated as 7% of the gelled material weight); Aluminum powder 0.1% (the consumption that is aluminum powder is 1% of the gelled material weight), the ratio 0.28 of water and the gelled material. The total amount of powder prepared in this example is 1000g, and the specific data is taken by weighing as follows:

[0070] Phosphorus slag 800g; fly ash 200g; elemental si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com